Brake SKODA FABIA 2000 1.G / 6Y User Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2000, Model line: FABIA, Model: SKODA FABIA 2000 1.G / 6YPages: 86, PDF Size: 3.58 MB

Page 18 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 8 02

Every 240 000 km (QG0)

Includes: Inspection every 120 000 km and additional operations stated in the table below

Inspection Service (QG1, QG2)

♦Vehicles with WIV (QG1) must be filled with oils which conform to the VW standard 503 00 (petrol engines) VW

506 00 (SDI, TDI diesel engines) or VW 506 01 (TDI PD diesel engines), possibility of damage when using other

oils.

♦Vehicles with WIV which have been filled with oils which do not conform to the VW standard 503 00 or VW 506 00

or VW 506 01, must be coded in the WIV with a fixed oil change limitation (QG2) ⇒Chapter 02-6. Work involvedChapter

–Replace tensioning pulley (PD diesel engine as of 08.03)02-3

♦Every 2 years - in addition change brake fluid

♦Every 4 years - replace contents set for tyre repair

♦Every 90 000 km - replace the guide pulley and the tensioning pulley (PD diesel engine up to 07.03)

♦Every 120 000 km - replace the timing belt and the guide pulley (038 109 244 H) (diesel engines as of 05.01 to

04.02 except the PD engine)

♦Every 120 000 km - Replace the timing belt (PD Diesel engine as of 08.03)

♦Every 150 000 km - replace the timing belt (diesel engines as of 05.02 and with the guide pulleyr 038 109 244

M) - except on the TDI PD engine

♦Every 240 000 km - Replace the tensioning pulley (PD Diesel engine as of 08.03)

♦Exhaust-emission analysis (EEA). Expiry date - see EEA tag on the vehicle identification plate (only valid for

some countries)

♦At each inspection - check the 'use by date' of the first aid kit

♦Recommendation: Replace windscreen wiper blades every 2 years

Note

Work involvedChapter

–Interrogate fault memory of all systems, if necessary erase02-6

–Visual inspection: Engine and components in the engine compartment for leaks and dam-

age02-3

–Change the engine oil, replace the oil filter02-3

–Conduct a visual inspection of the airbag units for external damage02-7

–Reset service interval display02-6

–Inspecting brake system for leaks and damage02-5

–Check the thickness of the brake pads on all wheels02-5

–Check gearbox, final drive, drive shafts and joint boots for leaks and damage

–Axle joints: Inspect boots for leaks and damage

–Track rod ends: Inspect play and correct attachment of boots

Page 19 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 9 02

–Check the tyre inflation pressure (including spare wheel), correct if necessary02-5

–Inspect tyre wear (including spare wheel)02-5

–Inspect tyre tread depth (including spare wheel) and record (FL..., FR..., RR..., RL...,

SP...)02-5

–Inspect exhaust system for leaks, damage and attachment

–Brake fluid volume: Check level, if necessary top up02-5

–Battery: test02-6

–Check the anti-freeze in the cooling system and record ...... °C, check for leaks, top up

coolant if necessary02-3

–Flap lock for the engine bonnet: grease

–Inspect operation of all switches, all electrical components, gauges/indicators and con-

trols for proper operation02-6

–Windscreen wiper and washer system: Inspect condition of wiper blades, wiper operation,

washer system: if necessary top up fluid02-7

–Inspect plenum chamber for dirt, clean if necessary02-7

–Inspect operation of tilting roof and grease the runners02-7

–Headlights: Inspect, if necessary adjust02-6

–Gear oil: Inspect level and top up if necessary (manual gearbox)02-4

–Draining the fuel filter (diesel engine)

–Inspect trailer coupling (with removable arm - manufacturer Profsvar)02-7

–Check underbody protection and body paintwork for damage02-7

–Dust and odour filter element for the passenger compartment: replace02-7

–Air filter: Clean the housing, replace the insert every 4 years or 60.000 km.02-3

–Replace the fuel filter (diesel engine with fuel operation, which does not comply with DIN

EN 590-standard)

–Ribbed V-belt: Inspect condition and for vehicles without tensioning pulley also the ten-

sion - every 60.000 km02-3

–Replace the fuel filter (diesel engine) - every 60.000 km

–Spark plugs: replace - every 60.000 km.02-3

–Automatic gearbox: Check the ATF level, and top up if necessary, every 60.000 km

–Check the timing belt for the camshaft on a 4-cylinder petrol engine at 90.000 km and

then every 30.000 km after that

–Replace the emergency battery for the alarm system - every five years02-6

After each inspection

–Complete the „Next Service“ sticker and affix sticker to the side of the dash panel (on the

driver's side)

–Perform road test including inspection of proper operation of footbrakes and handbrake,

gearshift and steering, final inspection02-9

–„Mirror tag“ - complete and attach to interior mirror

–Hand customer the completed and signed form Work involvedChapter

Page 20 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 10 02

Oil change (QG1, QG2)

Work involvedChapter

–Change engine oil

–Replace engine oil filter02-3

–Disc brake pads: Inspect thickness02-5

–Reset service interval display02-6

–Drain away water from the fuel filter (diesel engine with fuel operation, which does not

comply with DIN EN 590-standard)

After each oil change

–Enter the next service date on the „Next Service“ sticker and affix sticker to the side of

the dash panel on the driver's side, that is according to the indicator or the kilometer

schedule (also the date for changing the brake fluid)

–Complete and attach service mirror tag to the interior rear-view mirror

–Hand customer the completed and signed form

Page 47 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

ChassisEdition 02.04

S00.5301.13.2002-5 page 1 02

02-5 Chassis

Inspecting thickness of front and rear

brake pads/linings

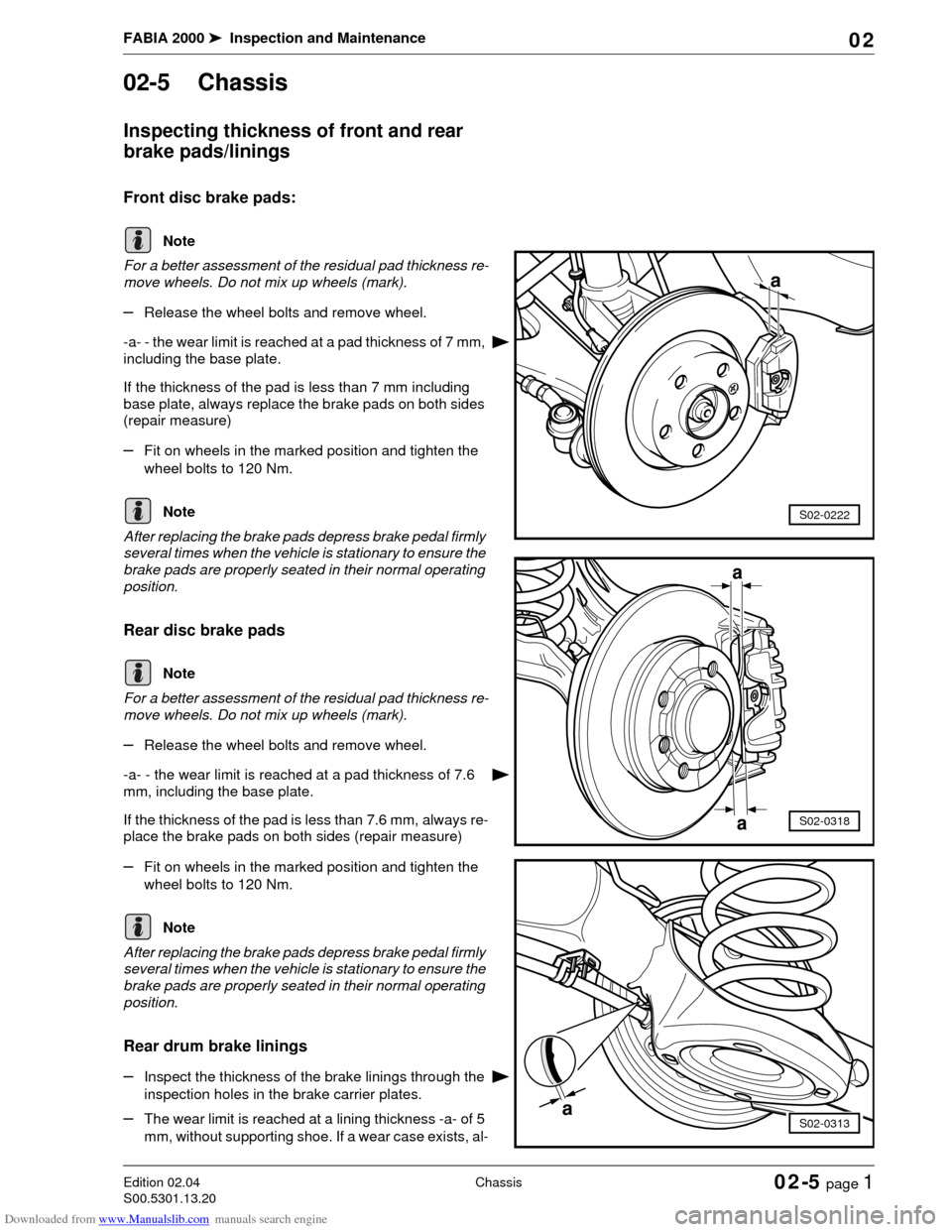

Front disc brake pads:

For a better assessment of the residual pad thickness re-

move wheels. Do not mix up wheels (mark).

–Release the wheel bolts and remove wheel.

-a- - the wear limit is reached at a pad thickness of 7 mm,

including the base plate.

If the thickness of the pad is less than 7 mm including

base plate, always replace the brake pads on both sides

(repair measure)

–Fit on wheels in the marked position and tighten the

wheel bolts to 120 Nm.

After replacing the brake pads depress brake pedal firmly

several times when the vehicle is stationary to ensure the

brake pads are properly seated in their normal operating

position.

Rear disc brake pads

For a better assessment of the residual pad thickness re-

move wheels. Do not mix up wheels (mark).

–Release the wheel bolts and remove wheel.

-a- - the wear limit is reached at a pad thickness of 7.6

mm, including the base plate.

If the thickness of the pad is less than 7.6 mm, always re-

place the brake pads on both sides (repair measure)

–Fit on wheels in the marked position and tighten the

wheel bolts to 120 Nm.

After replacing the brake pads depress brake pedal firmly

several times when the vehicle is stationary to ensure the

brake pads are properly seated in their normal operating

position.

Rear drum brake linings

–Inspect the thickness of the brake linings through the

inspection holes in the brake carrier plates.

–The wear limit is reached at a lining thickness -a- of 5

mm, without supporting shoe. If a wear case exists, al-

Note

a

S02-0222Note

Note

S02-0318

a

a

Note

S02-0313a

Page 48 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

ChassisEdition 02.04

S00.5301.13.2002-5 page 2 02

ways replace the brake linings on both sides (repair

measure).

Avoid soiling from brake fluid or grease flowing out.

Inspecting brake system for leaks and

damage

–Inspect master brake cylinder, brake servo unit (for

ABS: hydraulic unit), brake pressure regulator, brake

calipers for leaks and damage.

–Inspect brake hoses for twisting.

–Ensure that the brake hoses do not touch any parts of

the vehicle when the steering is turned to full left or full

right lock.

–Inspect the brake hoses for porous and brittle points.

Inspect the brake hoses and brake lines for chafing

points.

–Inspect the brake connections and attachments to en-

sure they are correctly fitted, free of leaks and corro-

sion.

Changing brake fluid (every 2 years)

Special tools, test and measuring equipment and

auxiliary items required

♦Extraction device

♦Brake pedal support, e.g. - V.A.G 1869/2-

Use only fresh genuine brake fluid FMVSS 571.116 DOT

4.

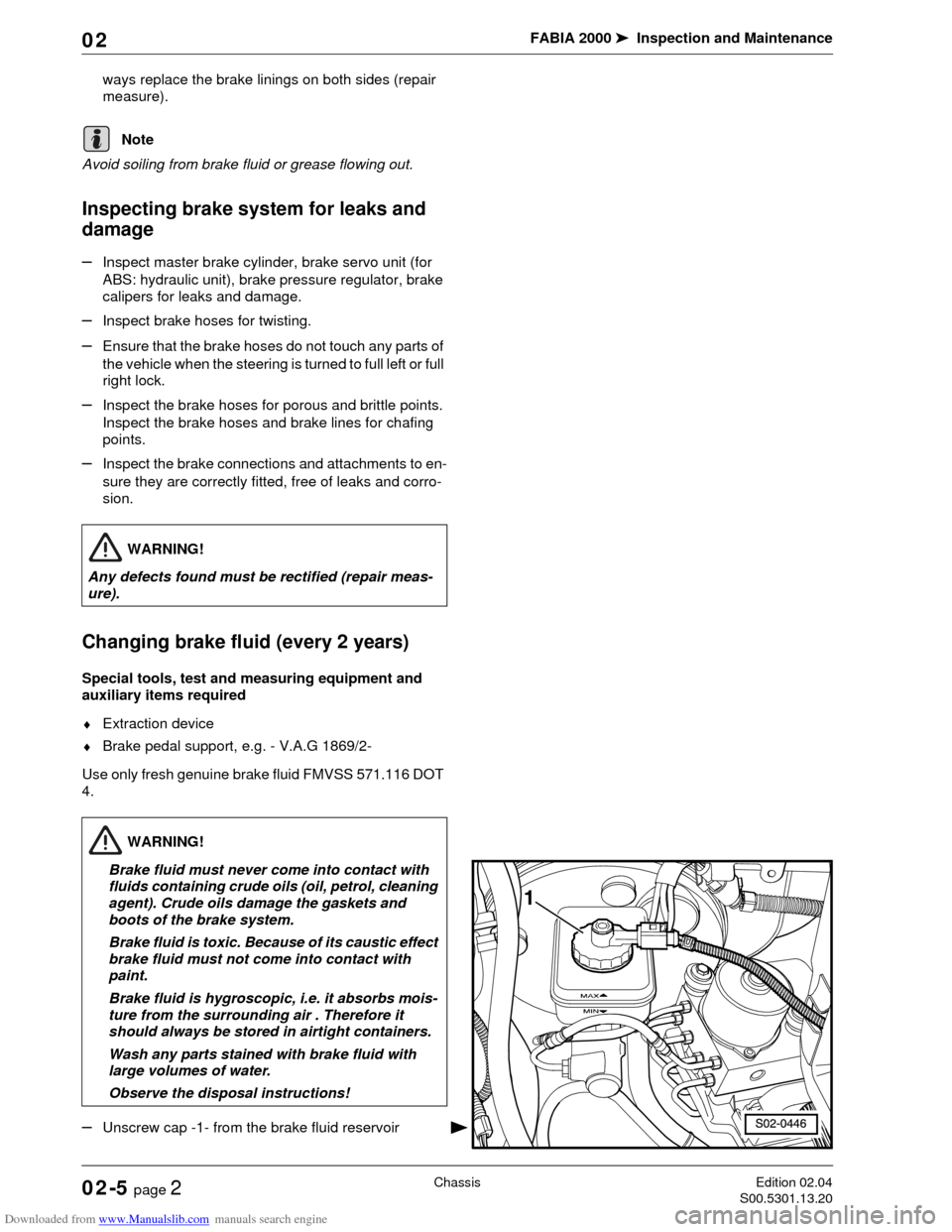

–Unscrew cap -1- from the brake fluid reservoir

Note

WARNING!

Any defects found must be rectified (repair meas-

ure).

WARNING!

Brake fluid must never come into contact with

fluids containing crude oils (oil, petrol, cleaning

agent). Crude oils damage the gaskets and

boots of the brake system.

Brake fluid is toxic. Because of its caustic effect

brake fluid must not come into contact with

paint.

Brake fluid is hygroscopic, i.e. it absorbs mois-

ture from the surrounding air . Therefore it

should always be stored in airtight containers.

Wash any parts stained with brake fluid with

large volumes of water.

Observe the disposal instructions!

Page 49 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

ChassisEdition 02.04

S00.5301.13.2002-5 page 3 02

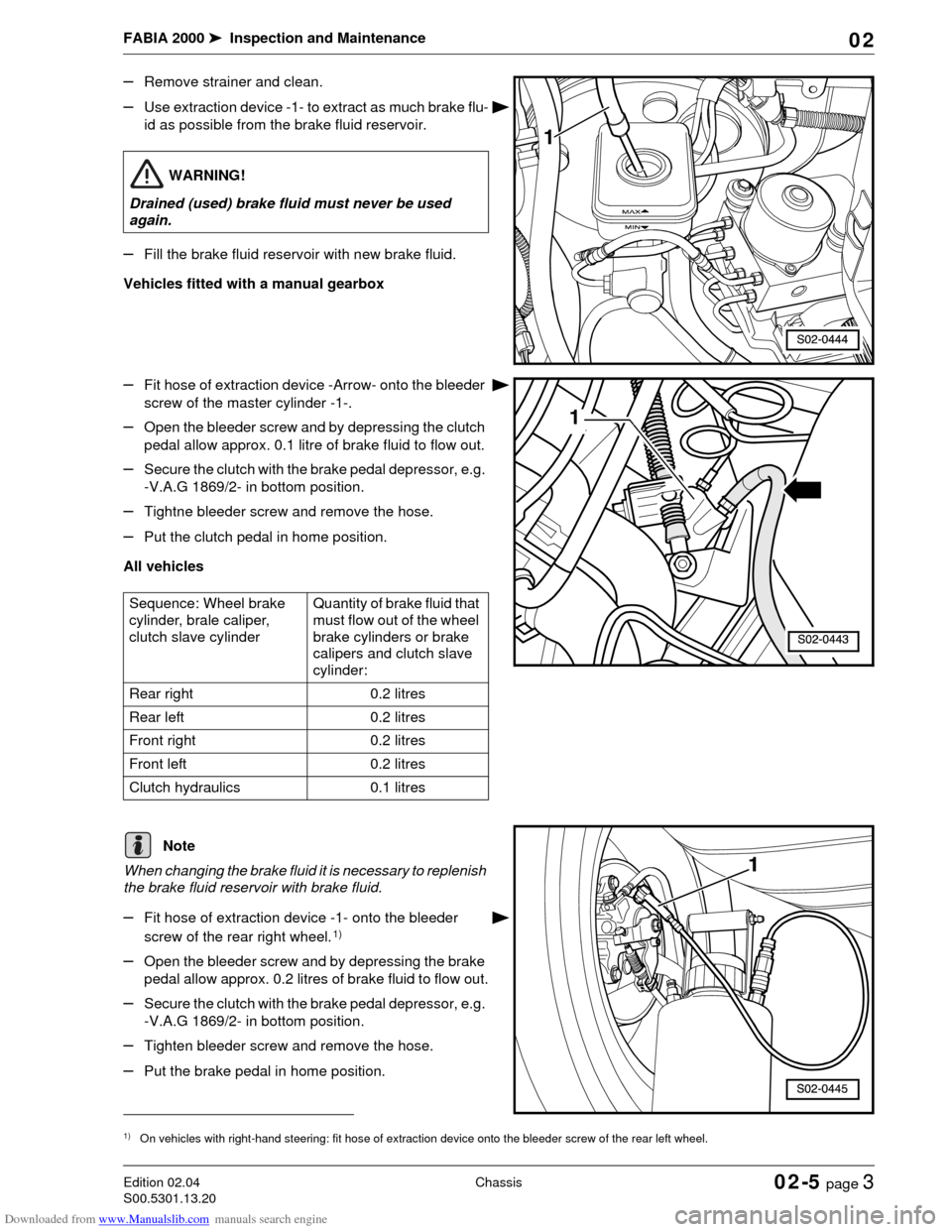

–Remove strainer and clean.

–Use extraction device -1- to extract as much brake flu-

id as possible from the brake fluid reservoir.

–Fill the brake fluid reservoir with new brake fluid.

Vehicles fitted with a manual gearbox

–Fit hose of extraction device -Arrow- onto the bleeder

screw of the master cylinder -1-.

–Open the bleeder screw and by depressing the clutch

pedal allow approx. 0.1 litre of brake fluid to flow out.

–Secure the clutch with the brake pedal depressor, e.g.

-V.A.G 1869/2- in bottom position.

–Tightne bleeder screw and remove the hose.

–Put the clutch pedal in home position.

All vehicles

When changing the brake fluid it is necessary to replenish

the brake fluid reservoir with brake fluid.

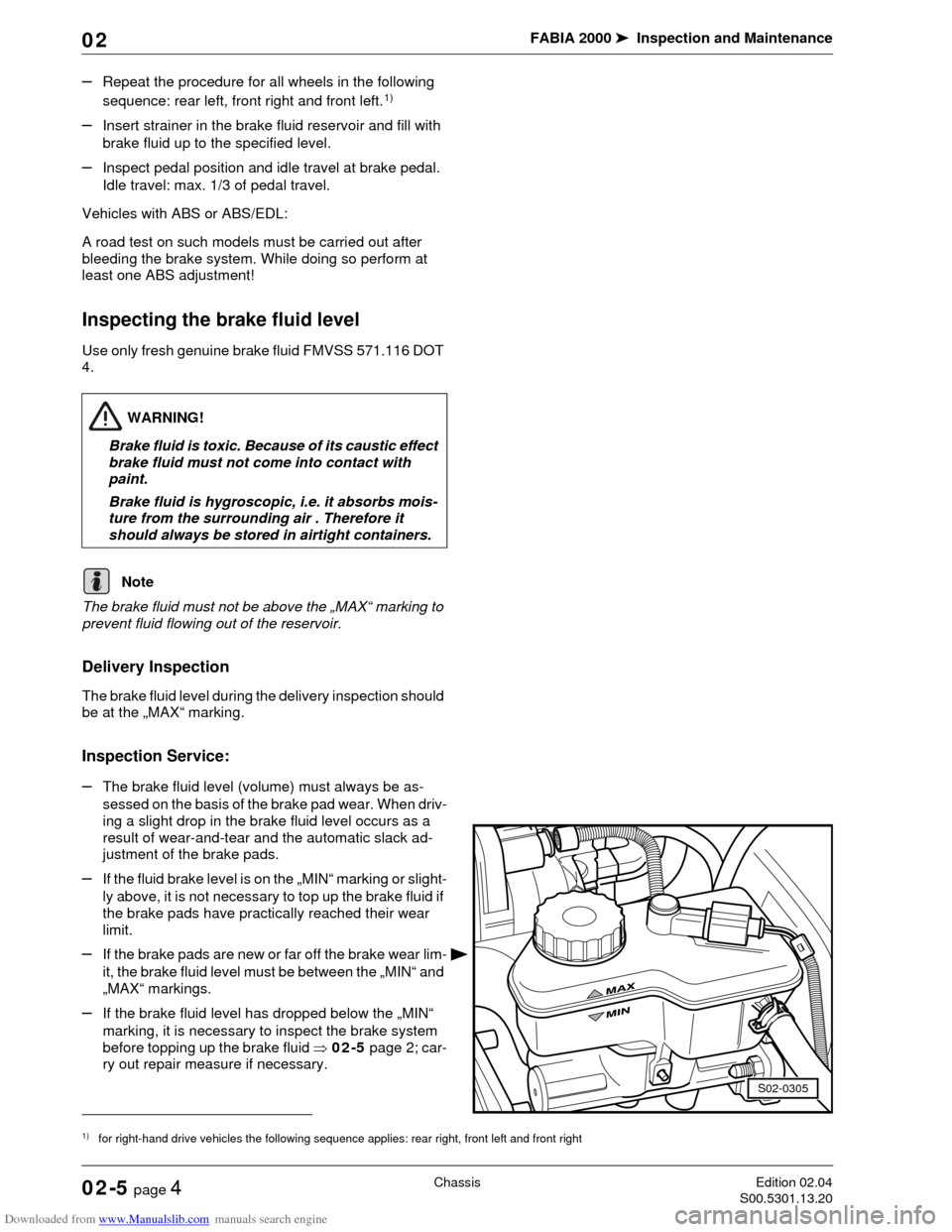

–Fit hose of extraction device -1- onto the bleeder

screw of the rear right wheel.

1)

–Open the bleeder screw and by depressing the brake

pedal allow approx. 0.2 litres of brake fluid to flow out.

–Secure the clutch with the brake pedal depressor, e.g.

-V.A.G 1869/2- in bottom position.

–Tighten bleeder screw and remove the hose.

–Put the brake pedal in home position.

WARNING!

Drained (used) brake fluid must never be used

again.

Sequence: Wheel brake

cylinder, brale caliper,

clutch slave cylinderQuantity of brake fluid that

must flow out of the wheel

brake cylinders or brake

calipers and clutch slave

cylinder:

Rear right 0.2 litres

Rear left 0.2 litres

Front right 0.2 litres

Front left 0.2 litres

Clutch hydraulics 0.1 litres

1)On vehicles with right-hand steering: fit hose of extraction device onto the bleeder screw of the rear left wheel.

Note

Page 50 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

ChassisEdition 02.04

S00.5301.13.2002-5 page 4 02

–Repeat the procedure for all wheels in the following

sequence: rear left, front right and front left.

1)

–Insert strainer in the brake fluid reservoir and fill with

brake fluid up to the specified level.

–Inspect pedal position and idle travel at brake pedal.

Idle travel: max. 1/3 of pedal travel.

Vehicles with ABS or ABS/EDL:

A road test on such models must be carried out after

bleeding the brake system. While doing so perform at

least one ABS adjustment!

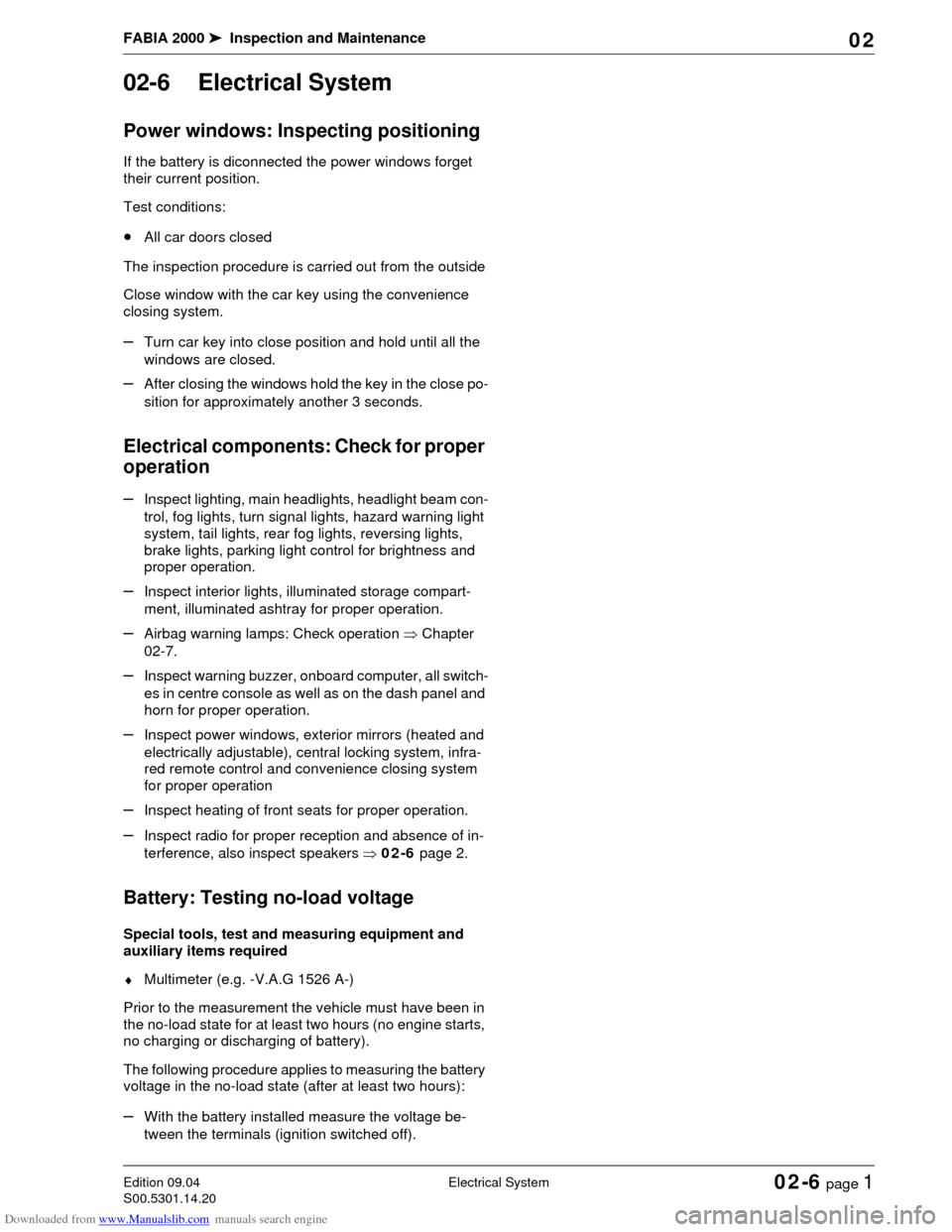

Inspecting the brake fluid level

Use only fresh genuine brake fluid FMVSS 571.116 DOT

4.

The brake fluid must not be above the „MAX“ marking to

prevent fluid flowing out of the reservoir.

Delivery Inspection

The brake fluid level during the delivery inspection should

be at the „MAX“ marking.

Inspection Service:

–The brake fluid level (volume) must always be as-

sessed on the basis of the brake pad wear. When driv-

ing a slight drop in the brake fluid level occurs as a

result of wear-and-tear and the automatic slack ad-

justment of the brake pads.

–If the fluid brake level is on the „MIN“ marking or slight-

ly above, it is not necessary to top up the brake fluid if

the brake pads have practically reached their wear

limit.

–If the brake pads are new or far off the brake wear lim-

it, the brake fluid level must be between the „MIN“ and

„MAX“ markings.

–If the brake fluid level has dropped below the „MIN“

marking, it is necessary to inspect the brake system

before topping up the brake fluid ⇒02-5 page 2; car-

ry out repair measure if necessary.

1)for right-hand drive vehicles the following sequence applies: rear right, front left and front right

WARNING!

Brake fluid is toxic. Because of its caustic effect

brake fluid must not come into contact with

paint.

Brake fluid is hygroscopic, i.e. it absorbs mois-

ture from the surrounding air . Therefore it

should always be stored in airtight containers.

Note

S02-0305

Page 55 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Electrical SystemEdition 09.04

S00.5301.14.2002-6 page 1 02

02-6 Electrical System

Power windows: Inspecting positioning

If the battery is diconnected the power windows forget

their current position.

Test conditions:

•All car doors closed

The inspection procedure is carried out from the outside

Close window with the car key using the convenience

closing system.

–Turn car key into close position and hold until all the

windows are closed.

–After closing the windows hold the key in the close po-

sition for approximately another 3 seconds.

Electrical components: Check for proper

operation

–Inspect lighting, main headlights, headlight beam con-

trol, fog lights, turn signal lights, hazard warning light

system, tail lights, rear fog lights, reversing lights,

brake lights, parking light control for brightness and

proper operation.

–Inspect interior lights, illuminated storage compart-

ment, illuminated ashtray for proper operation.

–Airbag warning lamps: Check operation ⇒Chapter

02-7.

–Inspect warning buzzer, onboard computer, all switch-

es in centre console as well as on the dash panel and

horn for proper operation.

–Inspect power windows, exterior mirrors (heated and

electrically adjustable), central locking system, infra-

red remote control and convenience closing system

for proper operation

–Inspect heating of front seats for proper operation.

–Inspect radio for proper reception and absence of in-

terference, also inspect speakers ⇒02-6 page 2.

Battery: Testing no-load voltage

Special tools, test and measuring equipment and

auxiliary items required

♦Multimeter (e.g. -V.A.G 1526 A-)

Prior to the measurement the vehicle must have been in

the no-load state for at least two hours (no engine starts,

no charging or discharging of battery).

The following procedure applies to measuring the battery

voltage in the no-load state (after at least two hours):

–With the battery installed measure the voltage be-

tween the terminals (ignition switched off).

Page 57 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Electrical SystemEdition 09.04

S00.5301.14.2002-6 page 3 02

holding the knob in the left or right position respective-

ly.

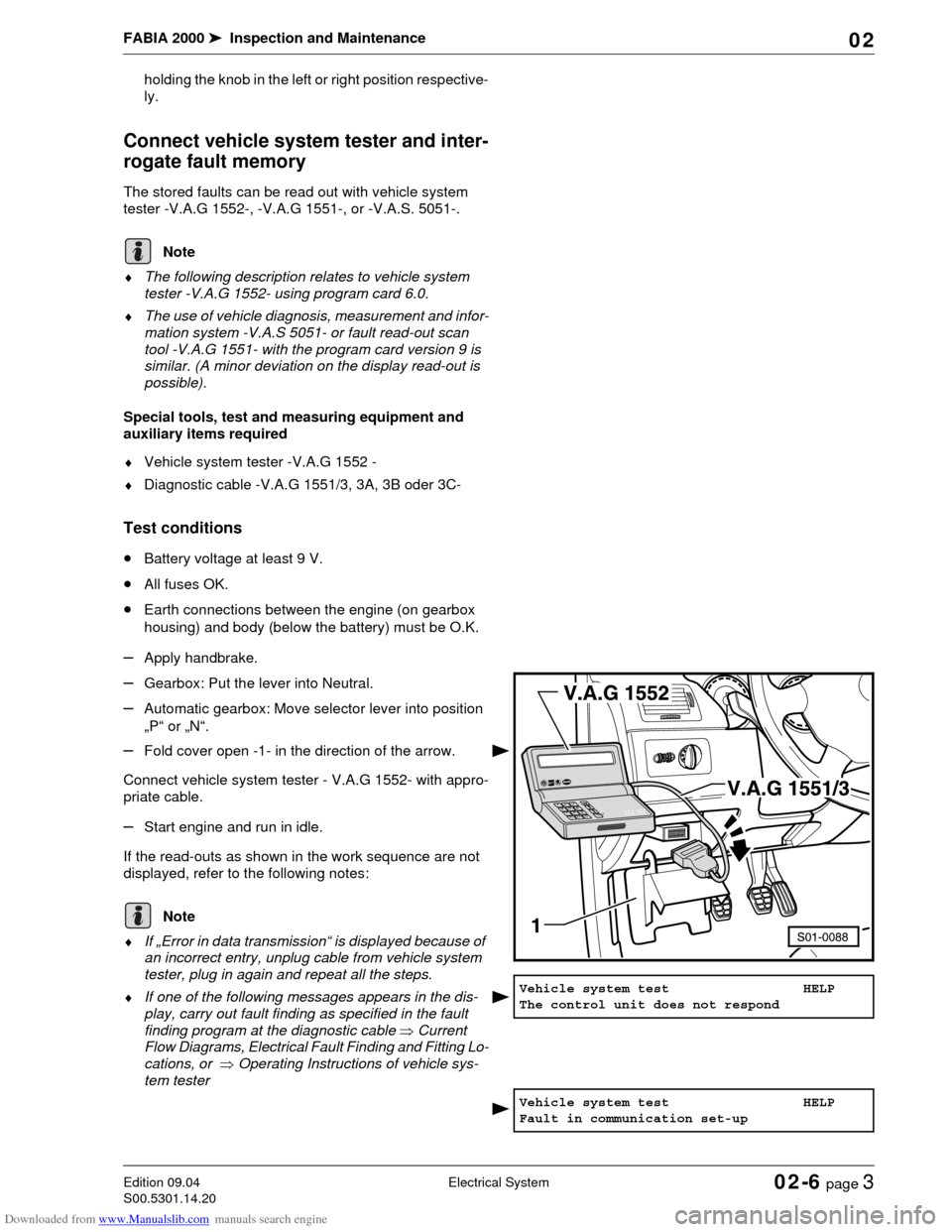

Connect vehicle system tester and inter-

rogate fault memory

The stored faults can be read out with vehicle system

tester -V.A.G 1552-, -V.A.G 1551-, or -V.A.S. 5051-.

♦The following description relates to vehicle system

tester -V.A.G 1552- using program card 6.0.

♦The use of vehicle diagnosis, measurement and infor-

mation system -V.A.S 5051- or fault read-out scan

tool -V.A.G 1551- with the program card version 9 is

similar. (A minor deviation on the display read-out is

possible).

Special tools, test and measuring equipment and

auxiliary items required

♦Vehicle system tester -V.A.G 1552 -

♦Diagnostic cable -V.A.G 1551/3, 3A, 3B oder 3C-

Test conditions

•Battery voltage at least 9 V.

•All fuses OK.

•Earth connections between the engine (on gearbox

housing) and body (below the battery) must be O.K.

–Apply handbrake.

–Gearbox: Put the lever into Neutral.

–Automatic gearbox: Move selector lever into position

„P“ or „N“.

–Fold cover open -1- in the direction of the arrow.

Connect vehicle system tester - V.A.G 1552- with appro-

priate cable.

–Start engine and run in idle.

If the read-outs as shown in the work sequence are not

displayed, refer to the following notes:

♦If „Error in data transmission“ is displayed because of

an incorrect entry, unplug cable from vehicle system

tester, plug in again and repeat all the steps.

♦If one of the following messages appears in the dis-

play, carry out fault finding as specified in the fault

finding program at the diagnostic cable ⇒Current

Flow Diagrams, Electrical Fault Finding and Fitting Lo-

cations, or ⇒Operating Instructions of vehicle sys-

tem tester

Note

1552V.A.

G

.H

E

LPQ O C9 8 76 5 43 2 1

Note

Vehicle system test HELP

The control unit does not respond

Vehicle system test HELP

Fault in communication set-up

Page 63 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Electrical SystemEdition 09.04

S00.5301.14.2002-6 page 9 02

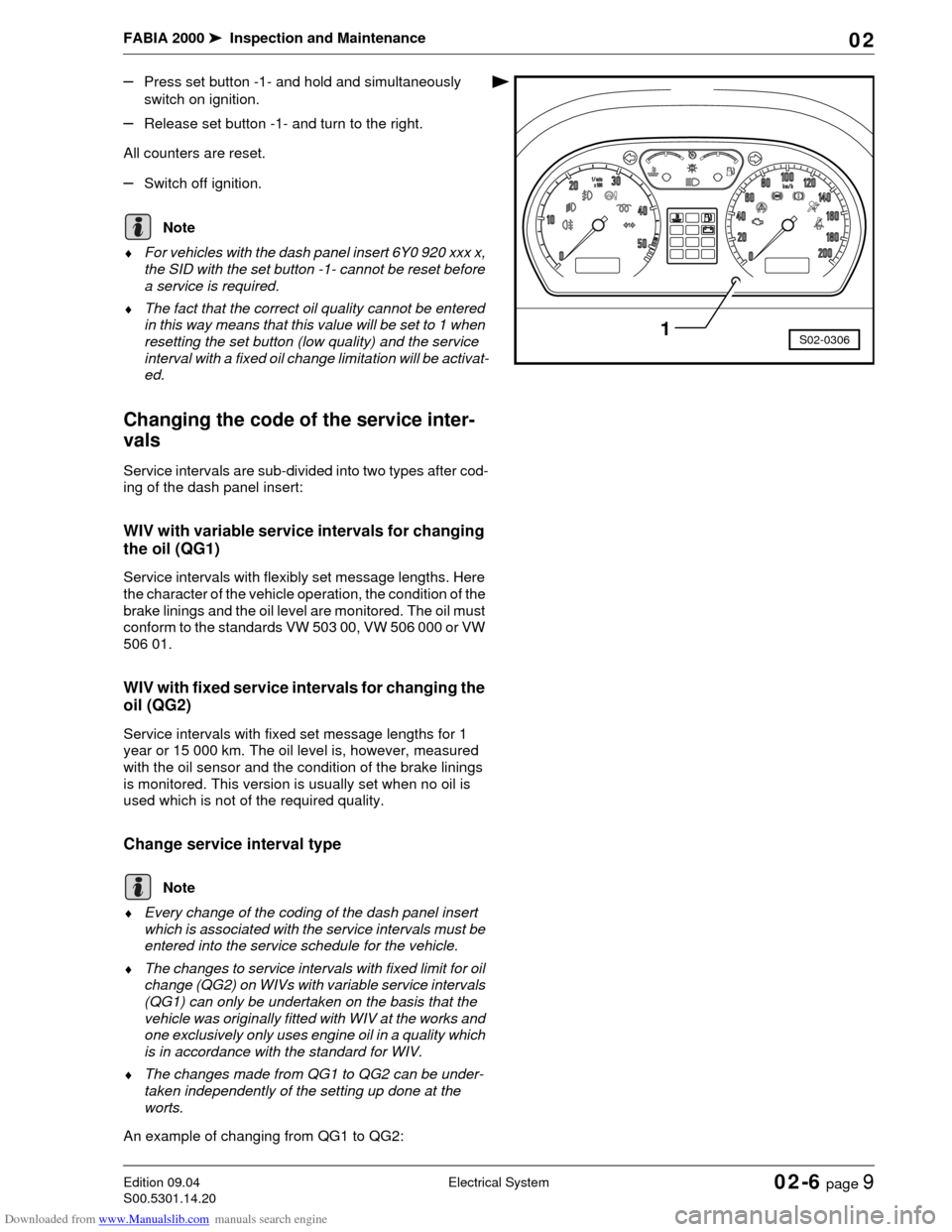

–Press set button -1- and hold and simultaneously

switch on ignition.

–Release set button -1- and turn to the right.

All counters are reset.

–Switch off ignition.

♦For vehicles with the dash panel insert 6Y0 920 xxx x,

the SID with the set button -1- cannot be reset before

a service is required.

♦The fact that the correct oil quality cannot be entered

in this way means that this value will be set to 1 when

resetting the set button (low quality) and the service

interval with a fixed oil change limitation will be activat-

ed.

Changing the code of the service inter-

vals

Service intervals are sub-divided into two types after cod-

ing of the dash panel insert:

WIV with variable service intervals for changing

the oil (QG1)

Service intervals with flexibly set message lengths. Here

the character of the vehicle operation, the condition of the

brake linings and the oil level are monitored. The oil must

conform to the standards VW 503 00, VW 506 000 or VW

506 01.

WIV with fixed service intervals for changing the

oil (QG2)

Service intervals with fixed set message lengths for 1

year or 15 000 km. The oil level is, however, measured

with the oil sensor and the condition of the brake linings

is monitored. This version is usually set when no oil is

used which is not of the required quality.

Change service interval type

♦Every change of the coding of the dash panel insert

which is associated with the service intervals must be

entered into the service schedule for the vehicle.

♦The changes to service intervals with fixed limit for oil

change (QG2) on WIVs with variable service intervals

(QG1) can only be undertaken on the basis that the

vehicle was originally fitted with WIV at the works and

one exclusively only uses engine oil in a quality which

is in accordance with the standard for WIV.

♦The changes made from QG1 to QG2 can be under-

taken independently of the setting up done at the

worts.

An example of changing from QG1 to QG2:

S02-03061

Note

Note