boot SKODA FABIA 2000 1.G / 6Y User Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2000, Model line: FABIA, Model: SKODA FABIA 2000 1.G / 6YPages: 86, PDF Size: 3.58 MB

Page 48 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

ChassisEdition 02.04

S00.5301.13.2002-5 page 2 02

ways replace the brake linings on both sides (repair

measure).

Avoid soiling from brake fluid or grease flowing out.

Inspecting brake system for leaks and

damage

–Inspect master brake cylinder, brake servo unit (for

ABS: hydraulic unit), brake pressure regulator, brake

calipers for leaks and damage.

–Inspect brake hoses for twisting.

–Ensure that the brake hoses do not touch any parts of

the vehicle when the steering is turned to full left or full

right lock.

–Inspect the brake hoses for porous and brittle points.

Inspect the brake hoses and brake lines for chafing

points.

–Inspect the brake connections and attachments to en-

sure they are correctly fitted, free of leaks and corro-

sion.

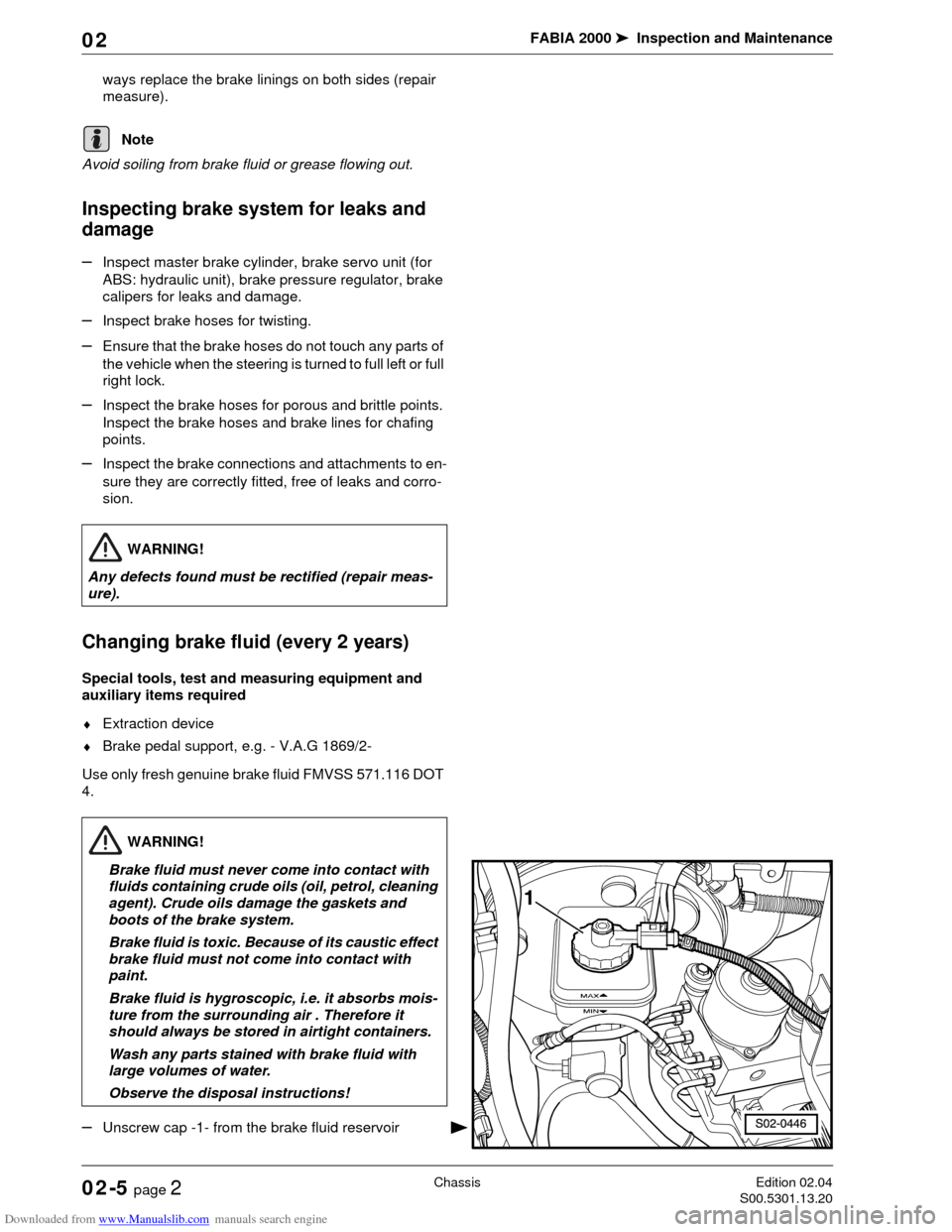

Changing brake fluid (every 2 years)

Special tools, test and measuring equipment and

auxiliary items required

♦Extraction device

♦Brake pedal support, e.g. - V.A.G 1869/2-

Use only fresh genuine brake fluid FMVSS 571.116 DOT

4.

–Unscrew cap -1- from the brake fluid reservoir

Note

WARNING!

Any defects found must be rectified (repair meas-

ure).

WARNING!

Brake fluid must never come into contact with

fluids containing crude oils (oil, petrol, cleaning

agent). Crude oils damage the gaskets and

boots of the brake system.

Brake fluid is toxic. Because of its caustic effect

brake fluid must not come into contact with

paint.

Brake fluid is hygroscopic, i.e. it absorbs mois-

ture from the surrounding air . Therefore it

should always be stored in airtight containers.

Wash any parts stained with brake fluid with

large volumes of water.

Observe the disposal instructions!

Page 51 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

ChassisEdition 02.04

S00.5301.13.2002-5 page 5 02

Track rod ends: Inspect play, correct at-

tachment and joint boots

–Raise vehicle (wheel clear of the ground) and inspect

play by moving the track rods and wheels. Clearance:

There must not be any play present.

–Inspect attachment.

–Inspect seals for damage and correct installation.

Inspecting tyres (including spare wheel)

Only tyres of the same type may be fitted to the vehicle.

Tyres of the same brand and tread pattern must always

be fitted to wheels on the same axle!

Delivery Inspection:

–Inspect the tyre tread and side wall for damage, if nec-

essary remove any foreign bodies from the tyres, such

as nails or glass splinters.

Inspection Service:

–Inspect the tyre tread and side wall for damage, if nec-

essary remove any foreign bodies from the tyres, such

as nails or glass splinters.

–Inspect tyres for scrubbing, tread worn down on one

side, porous side walls, cuts and punctures. Any de-

fects found must be advised to the customer and the

customer's attention must be drawn to any necessary

repair measures!

Inspecting tyre wear

–The wear pattern on the front tyres makes it possible

to assess whether it is necessary to inspect the wheel

toe and camber:

♦The formation of ridges on the tyre tread is an indica-

tion of wheel toe errors.

♦Tread worn on one side is usually attributable to cam-

ber errors.

–If such signs of wear are found, determine the cause

by checking the chassis alignment (repair measure).

Note

WARNING!

Tyres that are more than 6 years old must only be

used in case of emergency and while driving very

carefully.