service SKODA FABIA 2000 1.G / 6Y User Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2000, Model line: FABIA, Model: SKODA FABIA 2000 1.G / 6YPages: 86, PDF Size: 3.58 MB

Page 14 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 4 02

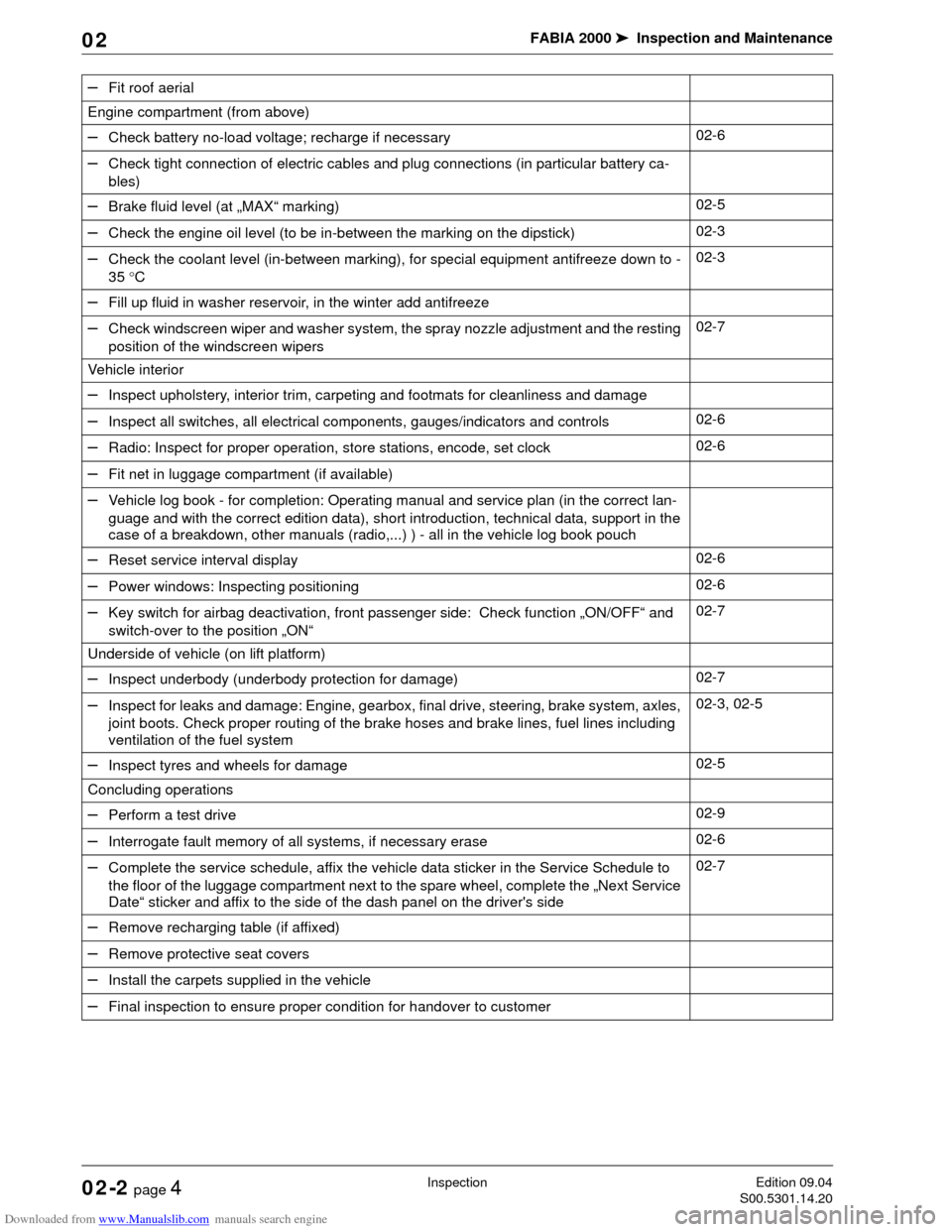

–Fit roof aerial

Engine compartment (from above)

–Check battery no-load voltage; recharge if necessary02-6

–Check tight connection of electric cables and plug connections (in particular battery ca-

bles)

–Brake fluid level (at „MAX“ marking)02-5

–Check the engine oil level (to be in-between the marking on the dipstick)02-3

–Check the coolant level (in-between marking), for special equipment antifreeze down to -

35 °C02-3

–Fill up fluid in washer reservoir, in the winter add antifreeze

–Check windscreen wiper and washer system, the spray nozzle adjustment and the resting

position of the windscreen wipers02-7

Vehicle interior

–Inspect upholstery, interior trim, carpeting and footmats for cleanliness and damage

–Inspect all switches, all electrical components, gauges/indicators and controls02-6

–Radio: Inspect for proper operation, store stations, encode, set clock02-6

–Fit net in luggage compartment (if available)

–Vehicle log book - for completion: Operating manual and service plan (in the correct lan-

guage and with the correct edition data), short introduction, technical data, support in the

case of a breakdown, other manuals (radio,...) ) - all in the vehicle log book pouch

–Reset service interval display02-6

–Power windows: Inspecting positioning02-6

–Key switch for airbag deactivation, front passenger side: Check function „ON/OFF“ and

switch-over to the position „ON“02-7

Underside of vehicle (on lift platform)

–Inspect underbody (underbody protection for damage)02-7

–Inspect for leaks and damage: Engine, gearbox, final drive, steering, brake system, axles,

joint boots. Check proper routing of the brake hoses and brake lines, fuel lines including

ventilation of the fuel system02-3, 02-5

–Inspect tyres and wheels for damage02-5

Concluding operations

–Perform a test drive02-9

–Interrogate fault memory of all systems, if necessary erase02-6

–Complete the service schedule, affix the vehicle data sticker in the Service Schedule to

the floor of the luggage compartment next to the spare wheel, complete the „Next Service

Date“ sticker and affix to the side of the dash panel on the driver's side02-7

–Remove recharging table (if affixed)

–Remove protective seat covers

–Install the carpets supplied in the vehicle

–Final inspection to ensure proper condition for handover to customer

Page 15 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 5 02

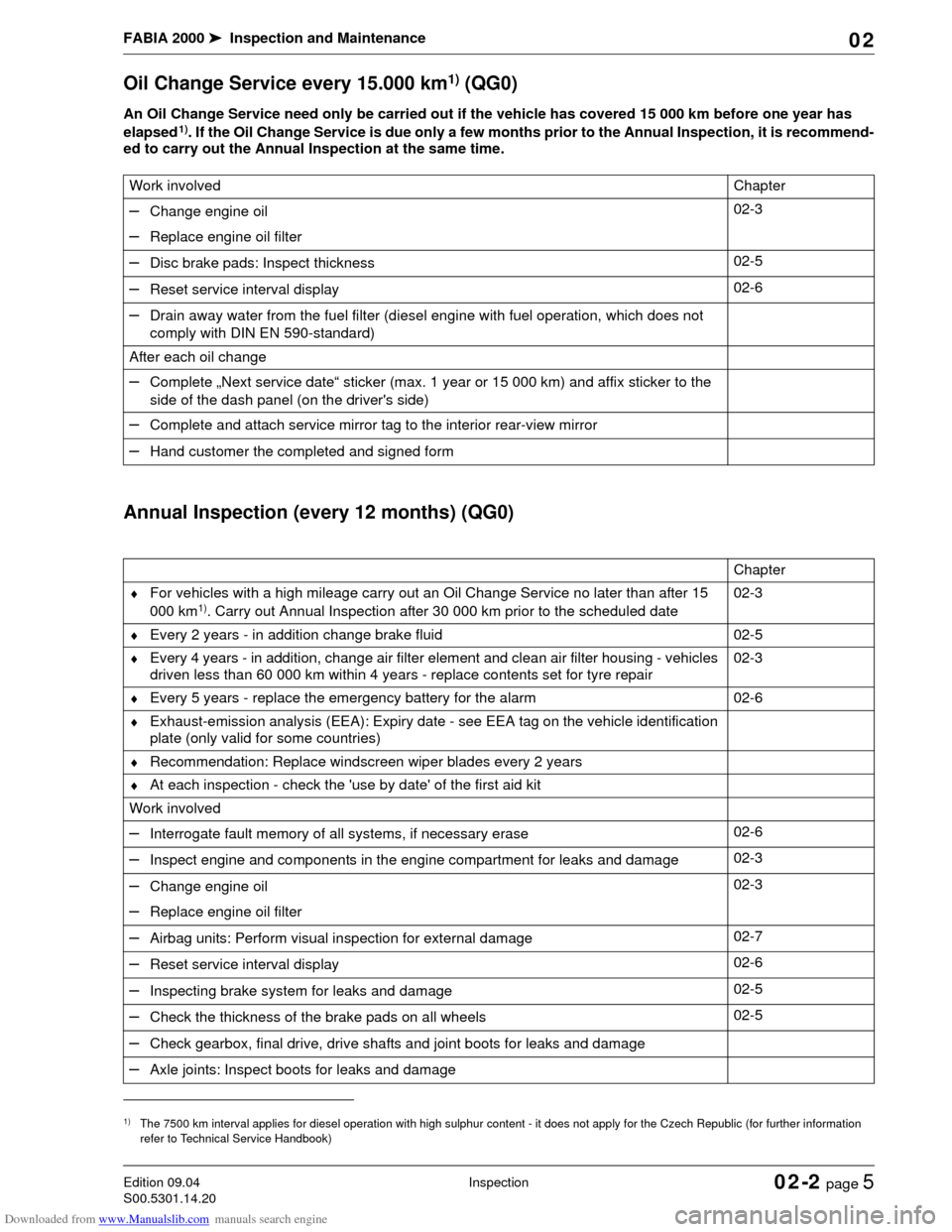

Oil Change Service every 15.000 km1) (QG0)

An Oil Change Service need only be carried out if the vehicle has covered 15 000 km before one year has

elapsed1). If the Oil Change Service is due only a few months prior to the Annual Inspection, it is recommend-

ed to carry out the Annual Inspection at the same time.

Annual Inspection (every 12 months) (QG0)

1)The 7500 km interval applies for diesel operation with high sulphur content - it does not apply for the Czech Republic (for further information

refer to Technical Service Handbook)

Work involvedChapter

–Change engine oil

–Replace engine oil filter02-3

–Disc brake pads: Inspect thickness02-5

–Reset service interval display02-6

–Drain away water from the fuel filter (diesel engine with fuel operation, which does not

comply with DIN EN 590-standard)

After each oil change

–Complete „Next service date“ sticker (max. 1 year or 15 000 km) and affix sticker to the

side of the dash panel (on the driver's side)

–Complete and attach service mirror tag to the interior rear-view mirror

–Hand customer the completed and signed form

Chapter

♦For vehicles with a high mileage carry out an Oil Change Service no later than after 15

000 km1). Carry out Annual Inspection after 30 000 km prior to the scheduled date02-3

♦Every 2 years - in addition change brake fluid 02-5

♦Every 4 years - in addition, change air filter element and clean air filter housing - vehicles

driven less than 60 000 km within 4 years - replace contents set for tyre repair 02-3

♦Every 5 years - replace the emergency battery for the alarm 02-6

♦Exhaust-emission analysis (EEA): Expiry date - see EEA tag on the vehicle identification

plate (only valid for some countries)

♦Recommendation: Replace windscreen wiper blades every 2 years

♦At each inspection - check the 'use by date' of the first aid kit

Work involved

–Interrogate fault memory of all systems, if necessary erase02-6

–Inspect engine and components in the engine compartment for leaks and damage02-3

–Change engine oil

–Replace engine oil filter02-3

–Airbag units: Perform visual inspection for external damage02-7

–Reset service interval display02-6

–Inspecting brake system for leaks and damage02-5

–Check the thickness of the brake pads on all wheels02-5

–Check gearbox, final drive, drive shafts and joint boots for leaks and damage

–Axle joints: Inspect boots for leaks and damage

Page 16 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 6 02

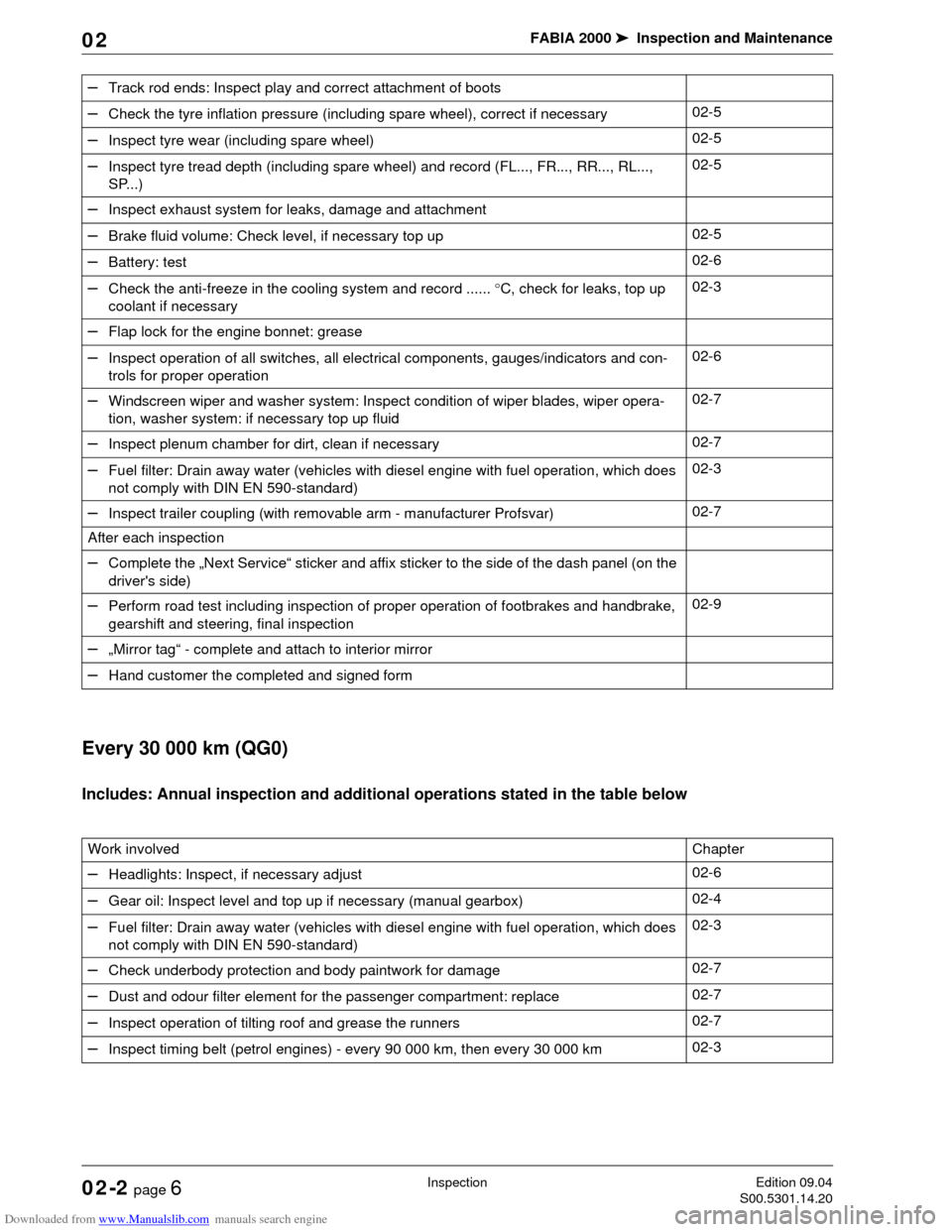

Every 30 000 km (QG0)

Includes: Annual inspection and additional operations stated in the table below

–Track rod ends: Inspect play and correct attachment of boots

–Check the tyre inflation pressure (including spare wheel), correct if necessary02-5

–Inspect tyre wear (including spare wheel)02-5

–Inspect tyre tread depth (including spare wheel) and record (FL..., FR..., RR..., RL...,

SP...)02-5

–Inspect exhaust system for leaks, damage and attachment

–Brake fluid volume: Check level, if necessary top up02-5

–Battery: test02-6

–Check the anti-freeze in the cooling system and record ...... °C, check for leaks, top up

coolant if necessary02-3

–Flap lock for the engine bonnet: grease

–Inspect operation of all switches, all electrical components, gauges/indicators and con-

trols for proper operation02-6

–Windscreen wiper and washer system: Inspect condition of wiper blades, wiper opera-

tion, washer system: if necessary top up fluid02-7

–Inspect plenum chamber for dirt, clean if necessary02-7

–Fuel filter: Drain away water (vehicles with diesel engine with fuel operation, which does

not comply with DIN EN 590-standard)02-3

–Inspect trailer coupling (with removable arm - manufacturer Profsvar)02-7

After each inspection

–Complete the „Next Service“ sticker and affix sticker to the side of the dash panel (on the

driver's side)

–Perform road test including inspection of proper operation of footbrakes and handbrake,

gearshift and steering, final inspection02-9

–„Mirror tag“ - complete and attach to interior mirror

–Hand customer the completed and signed form

Work involvedChapter

–Headlights: Inspect, if necessary adjust02-6

–Gear oil: Inspect level and top up if necessary (manual gearbox)02-4

–Fuel filter: Drain away water (vehicles with diesel engine with fuel operation, which does

not comply with DIN EN 590-standard)02-3

–Check underbody protection and body paintwork for damage02-7

–Dust and odour filter element for the passenger compartment: replace02-7

–Inspect operation of tilting roof and grease the runners02-7

–Inspect timing belt (petrol engines) - every 90 000 km, then every 30 000 km02-3

Page 17 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 7 02

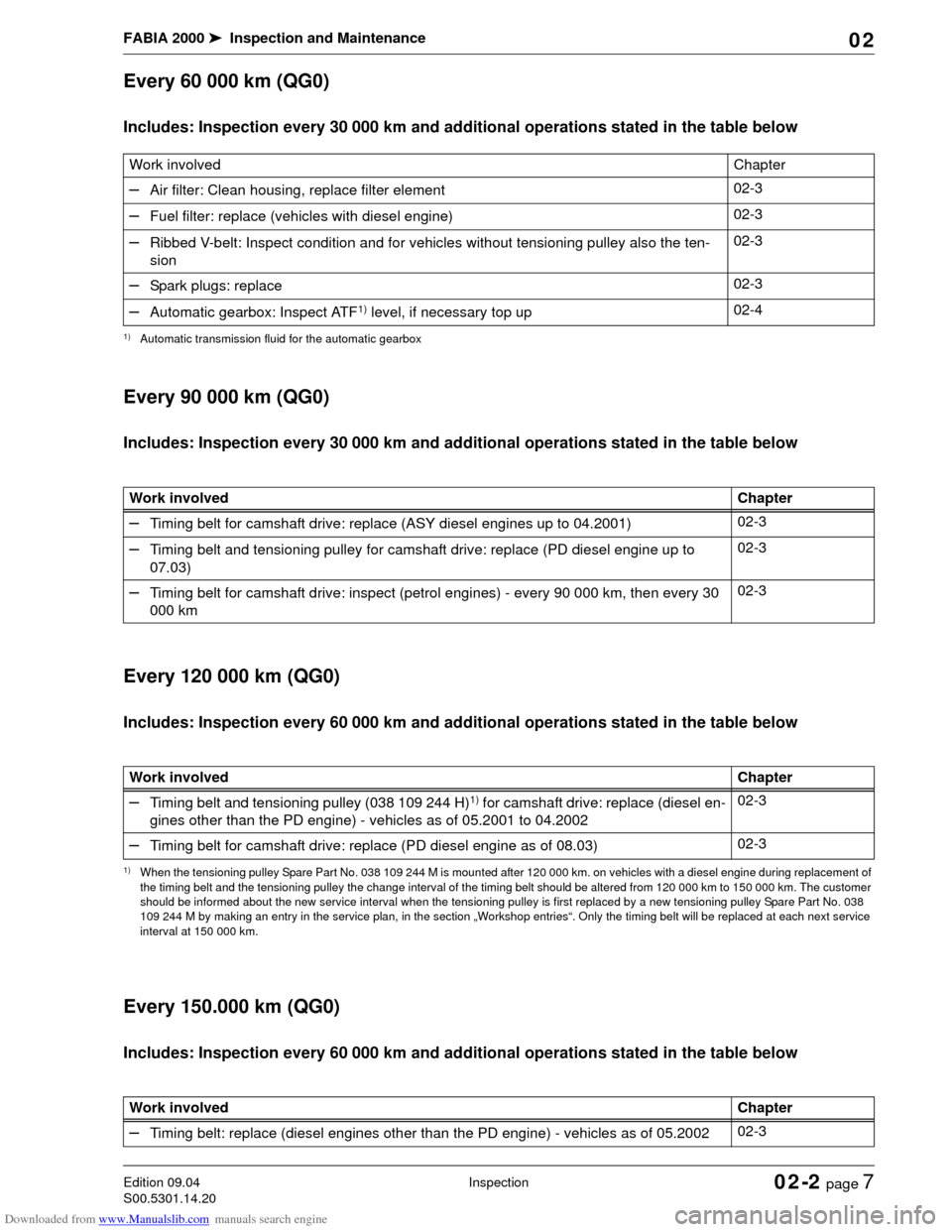

Every 60 000 km (QG0)

Includes: Inspection every 30 000 km and additional operations stated in the table below

Every 90 000 km (QG0)

Includes: Inspection every 30 000 km and additional operations stated in the table below

Every 120 000 km (QG0)

Includes: Inspection every 60 000 km and additional operations stated in the table below

Every 150.000 km (QG0)

Includes: Inspection every 60 000 km and additional operations stated in the table below

Work involvedChapter

–Air filter: Clean housing, replace filter element02-3

–Fuel filter: replace (vehicles with diesel engine)02-3

–Ribbed V-belt: Inspect condition and for vehicles without tensioning pulley also the ten-

sion02-3

–Spark plugs: replace02-3

–Automatic gearbox: Inspect ATF1) level, if necessary top up

1)Automatic transmission fluid for the automatic gearbox

02-4

Work involvedChapter

–Timing belt for camshaft drive: replace (ASY diesel engines up to 04.2001)02-3

–Timing belt and tensioning pulley for camshaft drive: replace (PD diesel engine up to

07.03)02-3

–Timing belt for camshaft drive: inspect (petrol engines) - every 90 000 km, then every 30

000 km02-3

Work involvedChapter

–Timing belt and tensioning pulley (038 109 244 H)1) for camshaft drive: replace (diesel en-

gines other than the PD engine) - vehicles as of 05.2001 to 04.2002

1)When the tensioning pulley Spare Part No. 038 109 244 M is mounted after 120 000 km. on vehicles with a diesel engine during replacement of

the timing belt and the tensioning pulley the change interval of the timing belt should be altered from 120 000 km to 150 000 km. The customer

should be informed about the new service interval when the tensioning pulley is first replaced by a new tensioning pulley Spare Part No. 038

109 244 M by making an entry in the service plan, in the section „Workshop entries“. Only the timing belt will be replaced at each next service

interval at 150 000 km.

02-3

–Timing belt for camshaft drive: replace (PD diesel engine as of 08.03)02-3

Work involvedChapter

–Timing belt: replace (diesel engines other than the PD engine) - vehicles as of 05.200202-3

Page 18 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 8 02

Every 240 000 km (QG0)

Includes: Inspection every 120 000 km and additional operations stated in the table below

Inspection Service (QG1, QG2)

♦Vehicles with WIV (QG1) must be filled with oils which conform to the VW standard 503 00 (petrol engines) VW

506 00 (SDI, TDI diesel engines) or VW 506 01 (TDI PD diesel engines), possibility of damage when using other

oils.

♦Vehicles with WIV which have been filled with oils which do not conform to the VW standard 503 00 or VW 506 00

or VW 506 01, must be coded in the WIV with a fixed oil change limitation (QG2) ⇒Chapter 02-6. Work involvedChapter

–Replace tensioning pulley (PD diesel engine as of 08.03)02-3

♦Every 2 years - in addition change brake fluid

♦Every 4 years - replace contents set for tyre repair

♦Every 90 000 km - replace the guide pulley and the tensioning pulley (PD diesel engine up to 07.03)

♦Every 120 000 km - replace the timing belt and the guide pulley (038 109 244 H) (diesel engines as of 05.01 to

04.02 except the PD engine)

♦Every 120 000 km - Replace the timing belt (PD Diesel engine as of 08.03)

♦Every 150 000 km - replace the timing belt (diesel engines as of 05.02 and with the guide pulleyr 038 109 244

M) - except on the TDI PD engine

♦Every 240 000 km - Replace the tensioning pulley (PD Diesel engine as of 08.03)

♦Exhaust-emission analysis (EEA). Expiry date - see EEA tag on the vehicle identification plate (only valid for

some countries)

♦At each inspection - check the 'use by date' of the first aid kit

♦Recommendation: Replace windscreen wiper blades every 2 years

Note

Work involvedChapter

–Interrogate fault memory of all systems, if necessary erase02-6

–Visual inspection: Engine and components in the engine compartment for leaks and dam-

age02-3

–Change the engine oil, replace the oil filter02-3

–Conduct a visual inspection of the airbag units for external damage02-7

–Reset service interval display02-6

–Inspecting brake system for leaks and damage02-5

–Check the thickness of the brake pads on all wheels02-5

–Check gearbox, final drive, drive shafts and joint boots for leaks and damage

–Axle joints: Inspect boots for leaks and damage

–Track rod ends: Inspect play and correct attachment of boots

Page 19 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 9 02

–Check the tyre inflation pressure (including spare wheel), correct if necessary02-5

–Inspect tyre wear (including spare wheel)02-5

–Inspect tyre tread depth (including spare wheel) and record (FL..., FR..., RR..., RL...,

SP...)02-5

–Inspect exhaust system for leaks, damage and attachment

–Brake fluid volume: Check level, if necessary top up02-5

–Battery: test02-6

–Check the anti-freeze in the cooling system and record ...... °C, check for leaks, top up

coolant if necessary02-3

–Flap lock for the engine bonnet: grease

–Inspect operation of all switches, all electrical components, gauges/indicators and con-

trols for proper operation02-6

–Windscreen wiper and washer system: Inspect condition of wiper blades, wiper operation,

washer system: if necessary top up fluid02-7

–Inspect plenum chamber for dirt, clean if necessary02-7

–Inspect operation of tilting roof and grease the runners02-7

–Headlights: Inspect, if necessary adjust02-6

–Gear oil: Inspect level and top up if necessary (manual gearbox)02-4

–Draining the fuel filter (diesel engine)

–Inspect trailer coupling (with removable arm - manufacturer Profsvar)02-7

–Check underbody protection and body paintwork for damage02-7

–Dust and odour filter element for the passenger compartment: replace02-7

–Air filter: Clean the housing, replace the insert every 4 years or 60.000 km.02-3

–Replace the fuel filter (diesel engine with fuel operation, which does not comply with DIN

EN 590-standard)

–Ribbed V-belt: Inspect condition and for vehicles without tensioning pulley also the ten-

sion - every 60.000 km02-3

–Replace the fuel filter (diesel engine) - every 60.000 km

–Spark plugs: replace - every 60.000 km.02-3

–Automatic gearbox: Check the ATF level, and top up if necessary, every 60.000 km

–Check the timing belt for the camshaft on a 4-cylinder petrol engine at 90.000 km and

then every 30.000 km after that

–Replace the emergency battery for the alarm system - every five years02-6

After each inspection

–Complete the „Next Service“ sticker and affix sticker to the side of the dash panel (on the

driver's side)

–Perform road test including inspection of proper operation of footbrakes and handbrake,

gearshift and steering, final inspection02-9

–„Mirror tag“ - complete and attach to interior mirror

–Hand customer the completed and signed form Work involvedChapter

Page 20 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 10 02

Oil change (QG1, QG2)

Work involvedChapter

–Change engine oil

–Replace engine oil filter02-3

–Disc brake pads: Inspect thickness02-5

–Reset service interval display02-6

–Drain away water from the fuel filter (diesel engine with fuel operation, which does not

comply with DIN EN 590-standard)

After each oil change

–Enter the next service date on the „Next Service“ sticker and affix sticker to the side of

the dash panel on the driver's side, that is according to the indicator or the kilometer

schedule (also the date for changing the brake fluid)

–Complete and attach service mirror tag to the interior rear-view mirror

–Hand customer the completed and signed form

Page 32 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 12 02

–Perform a test drive and again check the coolant anti-

freeze protection.

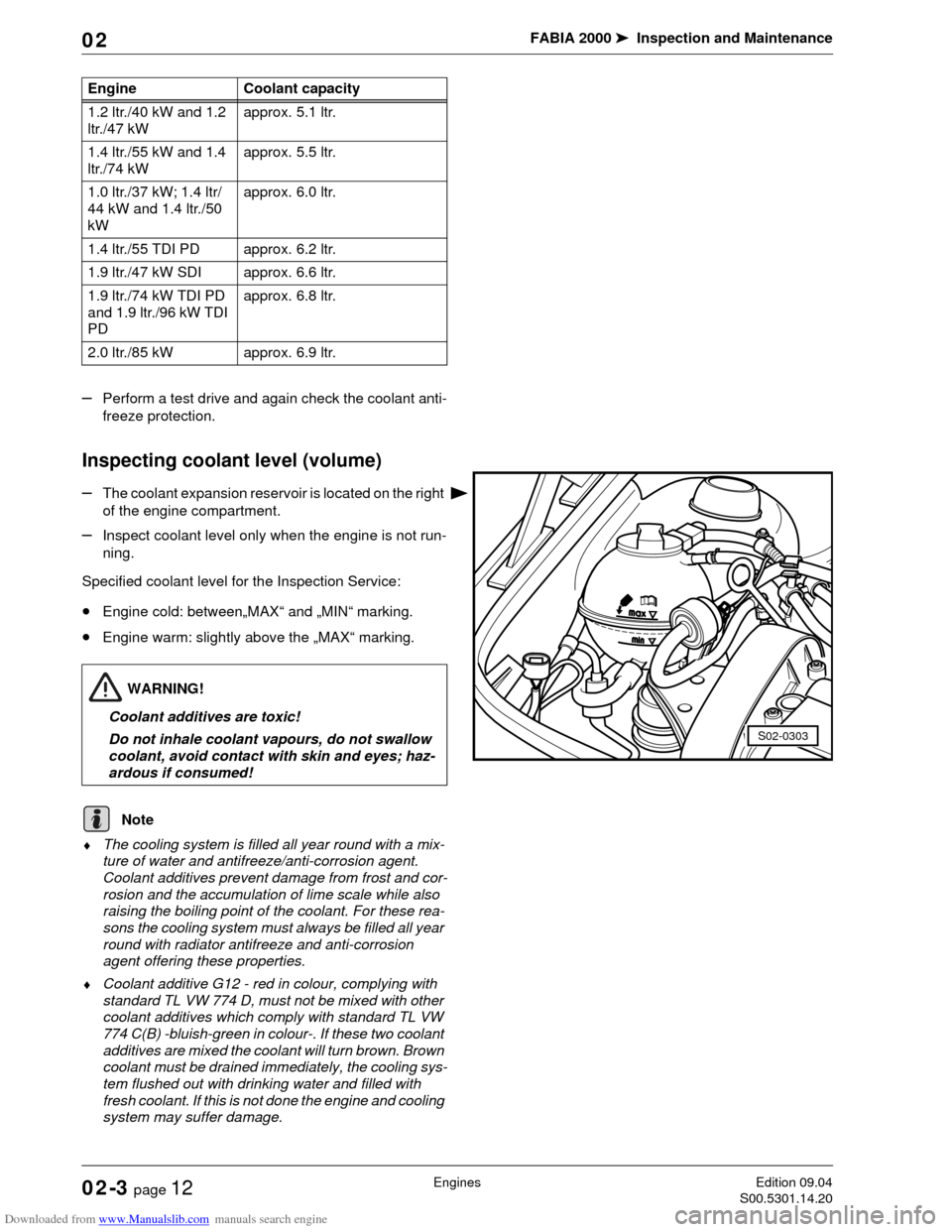

Inspecting coolant level (volume)

–The coolant expansion reservoir is located on the right

of the engine compartment.

–Inspect coolant level only when the engine is not run-

ning.

Specified coolant level for the Inspection Service:

•Engine cold: between„MAX“ and „MIN“ marking.

•Engine warm: slightly above the „MAX“ marking.

♦The cooling system is filled all year round with a mix-

ture of water and antifreeze/anti-corrosion agent.

Coolant additives prevent damage from frost and cor-

rosion and the accumulation of lime scale while also

raising the boiling point of the coolant. For these rea-

sons the cooling system must always be filled all year

round with radiator antifreeze and anti-corrosion

agent offering these properties.

♦Coolant additive G12 - red in colour, complying with

standard TL VW 774 D, must not be mixed with other

coolant additives which comply with standard TL VW

774 C(B) -bluish-green in colour-. If these two coolant

additives are mixed the coolant will turn brown. Brown

coolant must be drained immediately, the cooling sys-

tem flushed out with drinking water and filled with

fresh coolant. If this is not done the engine and cooling

system may suffer damage. Engine Coolant capacity

1.2 ltr./40 kW and 1.2

ltr./47 kWapprox. 5.1 ltr.

1.4 ltr./55 kW and 1.4

ltr./74 kWapprox. 5.5 ltr.

1.0 ltr./37 kW; 1.4 ltr/

44 kW and 1.4 ltr./50

kWapprox. 6.0 ltr.

1.4 ltr./55 TDI PD approx. 6.2 ltr.

1.9 ltr./47 kW SDI approx. 6.6 ltr.

1.9 ltr./74 kW TDI PD

and 1.9 ltr./96 kW TDI

PDapprox. 6.8 ltr.

2.0 ltr./85 kW approx. 6.9 ltr.

S02-0303

WARNING!

Coolant additives are toxic!

Do not inhale coolant vapours, do not swallow

coolant, avoid contact with skin and eyes; haz-

ardous if consumed!

Note

Page 50 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

ChassisEdition 02.04

S00.5301.13.2002-5 page 4 02

–Repeat the procedure for all wheels in the following

sequence: rear left, front right and front left.

1)

–Insert strainer in the brake fluid reservoir and fill with

brake fluid up to the specified level.

–Inspect pedal position and idle travel at brake pedal.

Idle travel: max. 1/3 of pedal travel.

Vehicles with ABS or ABS/EDL:

A road test on such models must be carried out after

bleeding the brake system. While doing so perform at

least one ABS adjustment!

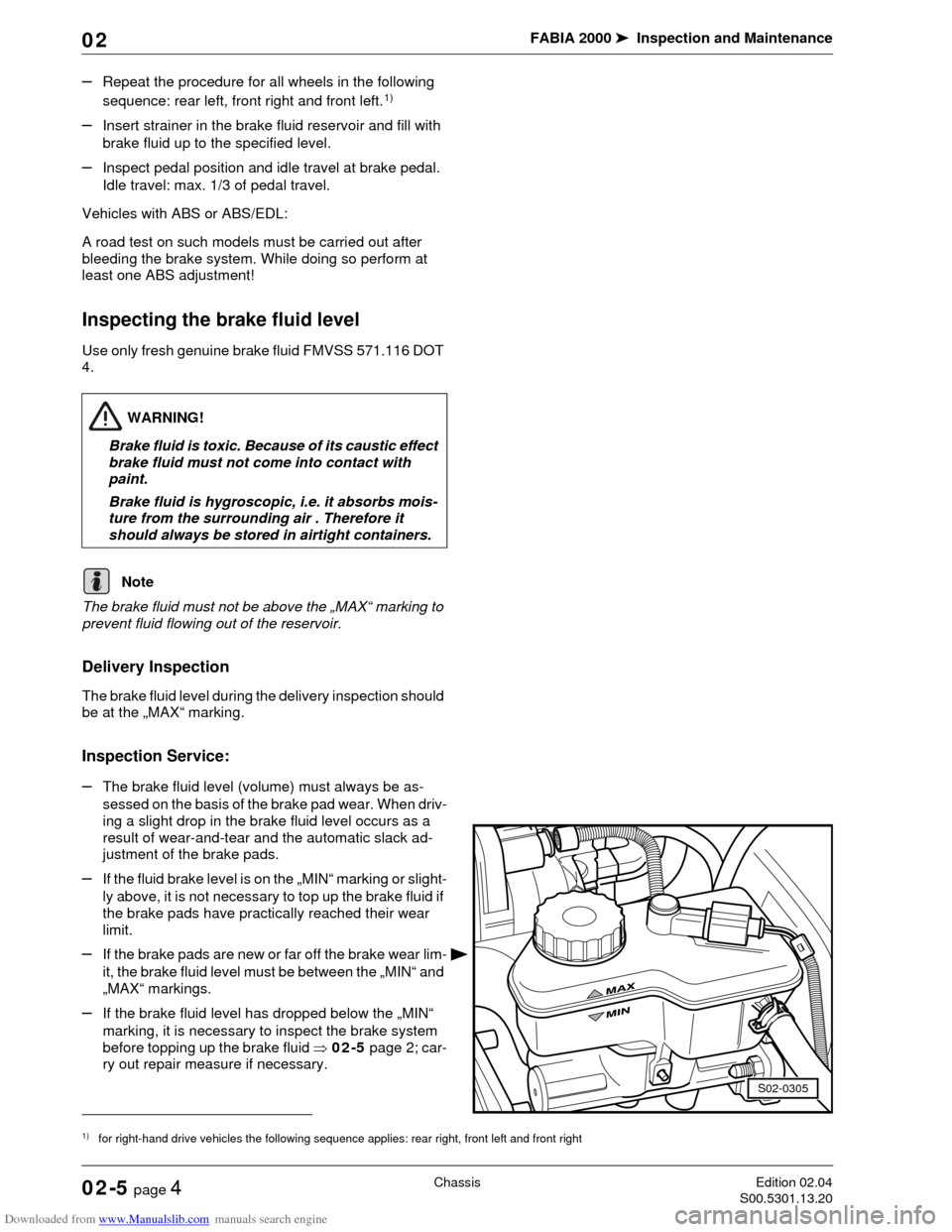

Inspecting the brake fluid level

Use only fresh genuine brake fluid FMVSS 571.116 DOT

4.

The brake fluid must not be above the „MAX“ marking to

prevent fluid flowing out of the reservoir.

Delivery Inspection

The brake fluid level during the delivery inspection should

be at the „MAX“ marking.

Inspection Service:

–The brake fluid level (volume) must always be as-

sessed on the basis of the brake pad wear. When driv-

ing a slight drop in the brake fluid level occurs as a

result of wear-and-tear and the automatic slack ad-

justment of the brake pads.

–If the fluid brake level is on the „MIN“ marking or slight-

ly above, it is not necessary to top up the brake fluid if

the brake pads have practically reached their wear

limit.

–If the brake pads are new or far off the brake wear lim-

it, the brake fluid level must be between the „MIN“ and

„MAX“ markings.

–If the brake fluid level has dropped below the „MIN“

marking, it is necessary to inspect the brake system

before topping up the brake fluid ⇒02-5 page 2; car-

ry out repair measure if necessary.

1)for right-hand drive vehicles the following sequence applies: rear right, front left and front right

WARNING!

Brake fluid is toxic. Because of its caustic effect

brake fluid must not come into contact with

paint.

Brake fluid is hygroscopic, i.e. it absorbs mois-

ture from the surrounding air . Therefore it

should always be stored in airtight containers.

Note

S02-0305

Page 51 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

ChassisEdition 02.04

S00.5301.13.2002-5 page 5 02

Track rod ends: Inspect play, correct at-

tachment and joint boots

–Raise vehicle (wheel clear of the ground) and inspect

play by moving the track rods and wheels. Clearance:

There must not be any play present.

–Inspect attachment.

–Inspect seals for damage and correct installation.

Inspecting tyres (including spare wheel)

Only tyres of the same type may be fitted to the vehicle.

Tyres of the same brand and tread pattern must always

be fitted to wheels on the same axle!

Delivery Inspection:

–Inspect the tyre tread and side wall for damage, if nec-

essary remove any foreign bodies from the tyres, such

as nails or glass splinters.

Inspection Service:

–Inspect the tyre tread and side wall for damage, if nec-

essary remove any foreign bodies from the tyres, such

as nails or glass splinters.

–Inspect tyres for scrubbing, tread worn down on one

side, porous side walls, cuts and punctures. Any de-

fects found must be advised to the customer and the

customer's attention must be drawn to any necessary

repair measures!

Inspecting tyre wear

–The wear pattern on the front tyres makes it possible

to assess whether it is necessary to inspect the wheel

toe and camber:

♦The formation of ridges on the tyre tread is an indica-

tion of wheel toe errors.

♦Tread worn on one side is usually attributable to cam-

ber errors.

–If such signs of wear are found, determine the cause

by checking the chassis alignment (repair measure).

Note

WARNING!

Tyres that are more than 6 years old must only be

used in case of emergency and while driving very

carefully.