Exhaust SKODA FABIA 2000 1.G / 6Y Workshop Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2000, Model line: FABIA, Model: SKODA FABIA 2000 1.G / 6YPages: 86, PDF Size: 3.58 MB

Page 3 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

List of SupplementsEdition 09.04

S00.5301.14.20

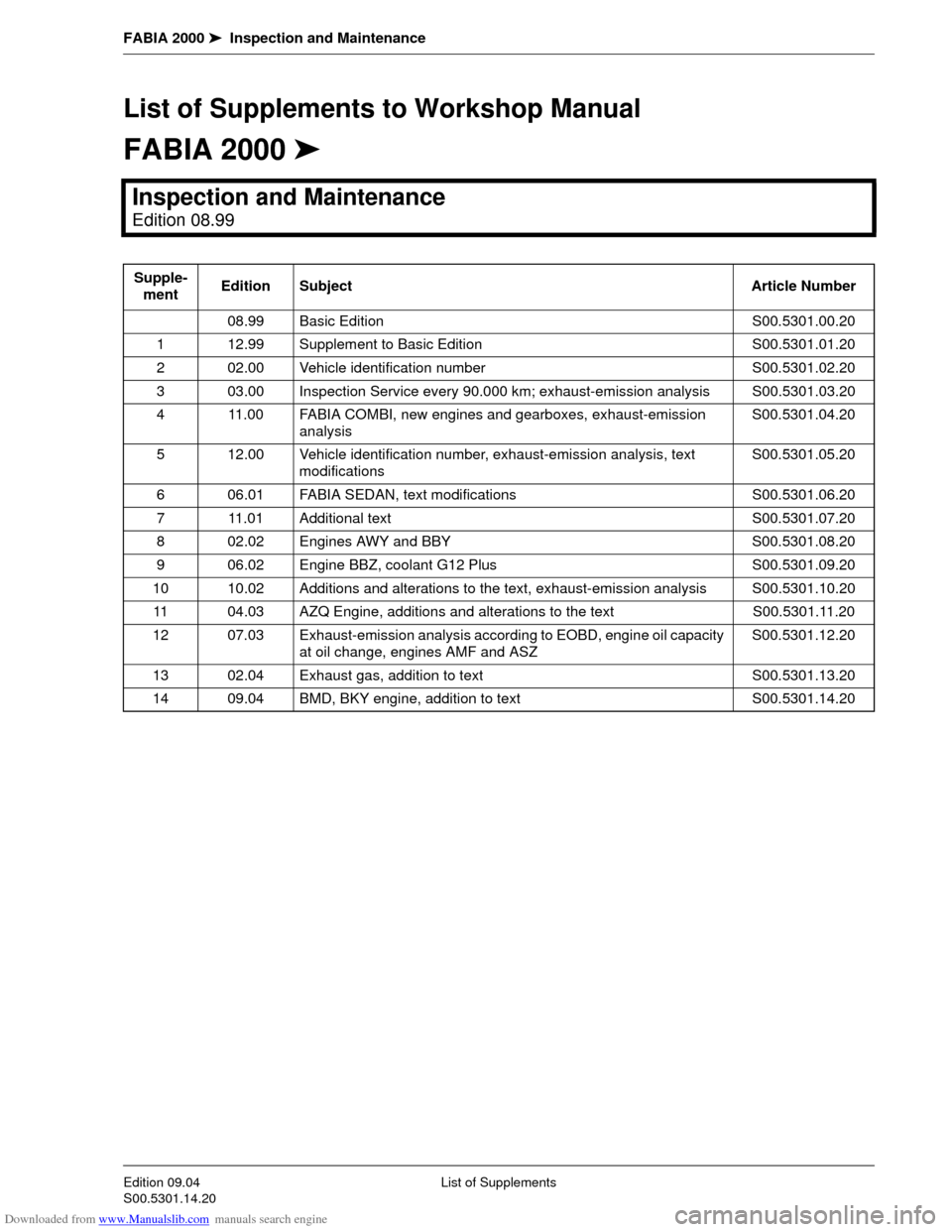

List of Supplements to Workshop Manual

FABIA 2000➤

Inspection and Maintenance

Edition 08.99

Supple-

mentEdition Subject Article Number

08.99 Basic Edition S00.5301.00.20

1 12.99 Supplement to Basic Edition S00.5301.01.20

2 02.00 Vehicle identification number S00.5301.02.20

3 03.00 Inspection Service every 90.000 km; exhaust-emission analysis S00.5301.03.20

4 11.00 FABIA COMBI, new engines and gearboxes, exhaust-emission

analysisS00.5301.04.20

5 12.00 Vehicle identification number, exhaust-emission analysis, text

modificationsS00.5301.05.20

6 06.01 FABIA SEDAN, text modifications S00.5301.06.20

7 11.01 Additional text S00.5301.07.20

8 02.02 Engines AWY and BBY S00.5301.08.20

9 06.02 Engine BBZ, coolant G12 Plus S00.5301.09.20

10 10.02 Additions and alterations to the text, exhaust-emission analysis S00.5301.10.20

11 04.03 AZQ Engine, additions and alterations to the text S00.5301.11.20

12 07.03 Exhaust-emission analysis according to EOBD, engine oil capacity

at oil change, engines AMF and ASZS00.5301.12.20

13 02.04 Exhaust gas, addition to text S00.5301.13.20

14 09.04 BMD, BKY engine, addition to text S00.5301.14.20

Page 6 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Table of ContentsEdition 09.04

S00.5301.14.20II

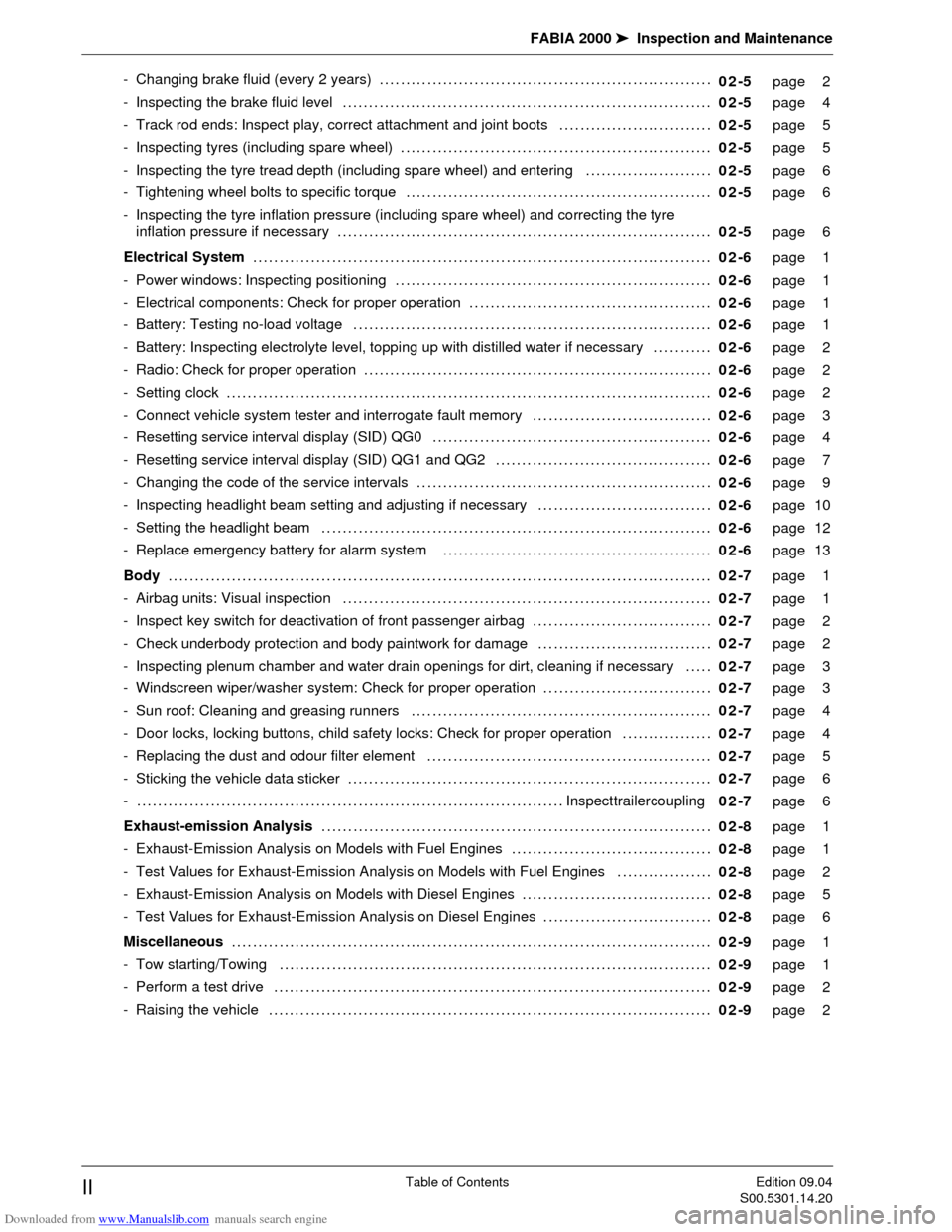

- Changing brake fluid (every 2 years)...............................................................

- Inspecting the brake fluid level ......................................................................

- Track rod ends: Inspect play, correct attachment and joint boots .............................

- Inspecting tyres (including spare wheel) ...........................................................

- Inspecting the tyre tread depth (including spare wheel) and entering ........................

- Tightening wheel bolts to specific torque ..........................................................

- Inspecting the tyre inflation pressure (including spare wheel) and correcting the tyre

inflation pressure if necessary .......................................................................

Electrical System.......................................................................................

- Power windows: Inspecting positioning ............................................................

- Electrical components: Check for proper operation ..............................................

- Battery: Testing no-load voltage ....................................................................

- Battery: Inspecting electrolyte level, topping up with distilled water if necessary ...........

- Radio: Check for proper operation..................................................................

- Setting clock ............................................................................................

- Connect vehicle system tester and interrogate fault memory..................................

- Resetting service interval display (SID) QG0 .....................................................

- Resetting service interval display (SID) QG1 and QG2 .........................................

- Changing the code of the service intervals ........................................................

- Inspecting headlight beam setting and adjusting if necessary .................................

- Setting the headlight beam ..........................................................................

- Replace emergency battery for alarm system ...................................................

Body.......................................................................................................

- Airbag units: Visual inspection ......................................................................

- Inspect key switch for deactivation of front passenger airbag ..................................

- Check underbody protection and body paintwork for damage .................................

- Inspecting plenum chamber and water drain openings for dirt, cleaning if necessary .....

- Windscreen wiper/washer system: Check for proper operation ................................

- Sun roof: Cleaning and greasing runners .........................................................

- Door locks, locking buttons, child safety locks: Check for proper operation .................

- Replacing the dust and odour filter element ......................................................

- Sticking the vehicle data sticker .....................................................................

- ................................................................................. Inspect trailer coupling

Exhaust-emission Analysis..........................................................................

- Exhaust-Emission Analysis on Models with Fuel Engines ......................................

- Test Values for Exhaust-Emission Analysis on Models with Fuel Engines..................

- Exhaust-Emission Analysis on Models with Diesel Engines ....................................

- Test Values for Exhaust-Emission Analysis on Diesel Engines................................

Miscellaneous...........................................................................................

- Tow starting/Towing ..................................................................................

- Perform a test drive ...................................................................................

- Raising the vehicle ....................................................................................02-5page 2

02-5page 4

02-5page 5

02-5page 5

02-5page 6

02-5page 6

02-5page 6

02-6page 1

02-6page 1

02-6page 1

02-6page 1

02-6page 2

02-6page 2

02-6page 2

02-6page 3

02-6page 4

02-6page 7

02-6page 9

02-6page 10

02-6page 12

02-6page 13

02-7page 1

02-7page 1

02-7page 2

02-7page 2

02-7page 3

02-7page 3

02-7page 4

02-7page 4

02-7page 5

02-7page 6

02-7page 6

02-8page 1

02-8page 1

02-8page 2

02-8page 5

02-8page 6

02-9page 1

02-9page 1

02-9page 2

02-9page 2

Page 15 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 5 02

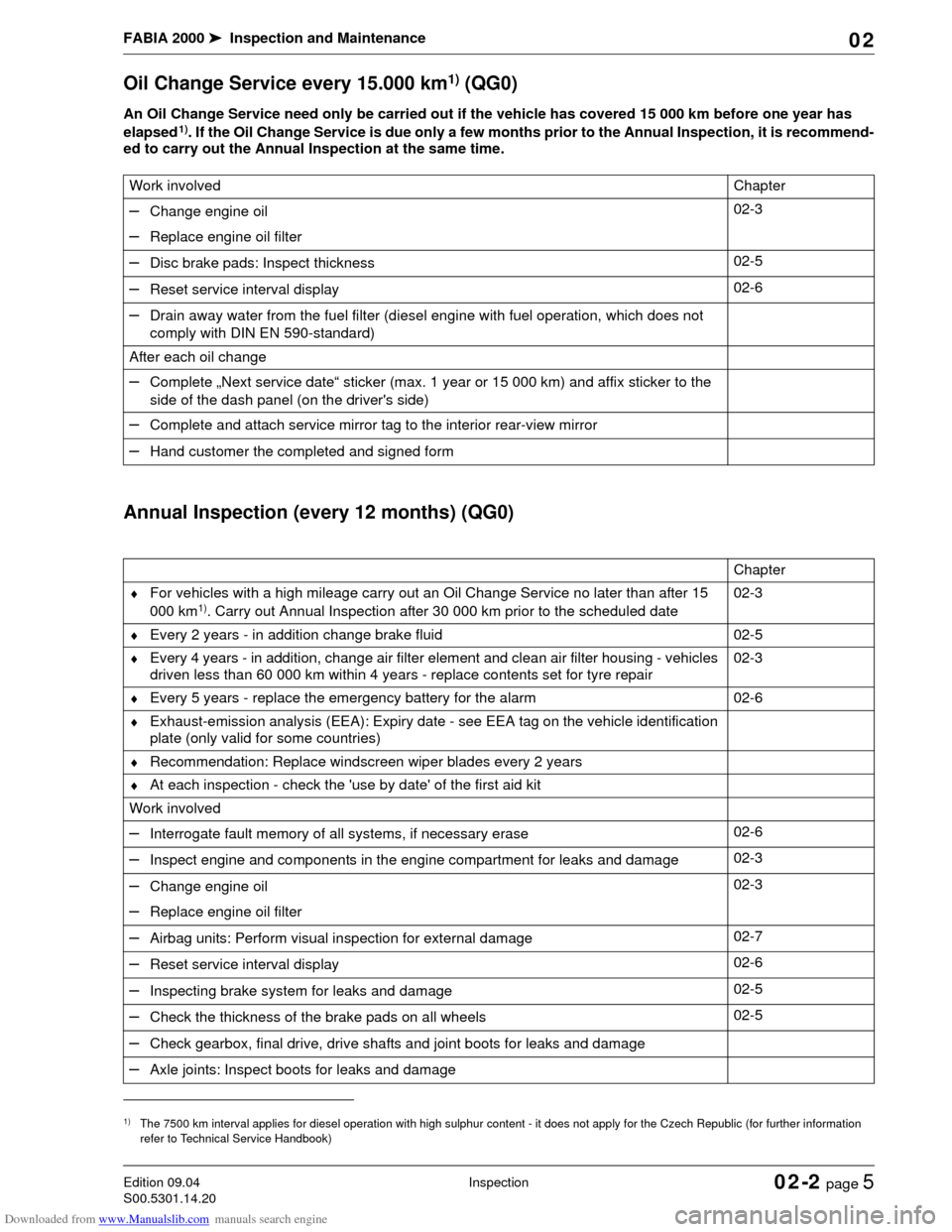

Oil Change Service every 15.000 km1) (QG0)

An Oil Change Service need only be carried out if the vehicle has covered 15 000 km before one year has

elapsed1). If the Oil Change Service is due only a few months prior to the Annual Inspection, it is recommend-

ed to carry out the Annual Inspection at the same time.

Annual Inspection (every 12 months) (QG0)

1)The 7500 km interval applies for diesel operation with high sulphur content - it does not apply for the Czech Republic (for further information

refer to Technical Service Handbook)

Work involvedChapter

–Change engine oil

–Replace engine oil filter02-3

–Disc brake pads: Inspect thickness02-5

–Reset service interval display02-6

–Drain away water from the fuel filter (diesel engine with fuel operation, which does not

comply with DIN EN 590-standard)

After each oil change

–Complete „Next service date“ sticker (max. 1 year or 15 000 km) and affix sticker to the

side of the dash panel (on the driver's side)

–Complete and attach service mirror tag to the interior rear-view mirror

–Hand customer the completed and signed form

Chapter

♦For vehicles with a high mileage carry out an Oil Change Service no later than after 15

000 km1). Carry out Annual Inspection after 30 000 km prior to the scheduled date02-3

♦Every 2 years - in addition change brake fluid 02-5

♦Every 4 years - in addition, change air filter element and clean air filter housing - vehicles

driven less than 60 000 km within 4 years - replace contents set for tyre repair 02-3

♦Every 5 years - replace the emergency battery for the alarm 02-6

♦Exhaust-emission analysis (EEA): Expiry date - see EEA tag on the vehicle identification

plate (only valid for some countries)

♦Recommendation: Replace windscreen wiper blades every 2 years

♦At each inspection - check the 'use by date' of the first aid kit

Work involved

–Interrogate fault memory of all systems, if necessary erase02-6

–Inspect engine and components in the engine compartment for leaks and damage02-3

–Change engine oil

–Replace engine oil filter02-3

–Airbag units: Perform visual inspection for external damage02-7

–Reset service interval display02-6

–Inspecting brake system for leaks and damage02-5

–Check the thickness of the brake pads on all wheels02-5

–Check gearbox, final drive, drive shafts and joint boots for leaks and damage

–Axle joints: Inspect boots for leaks and damage

Page 16 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 6 02

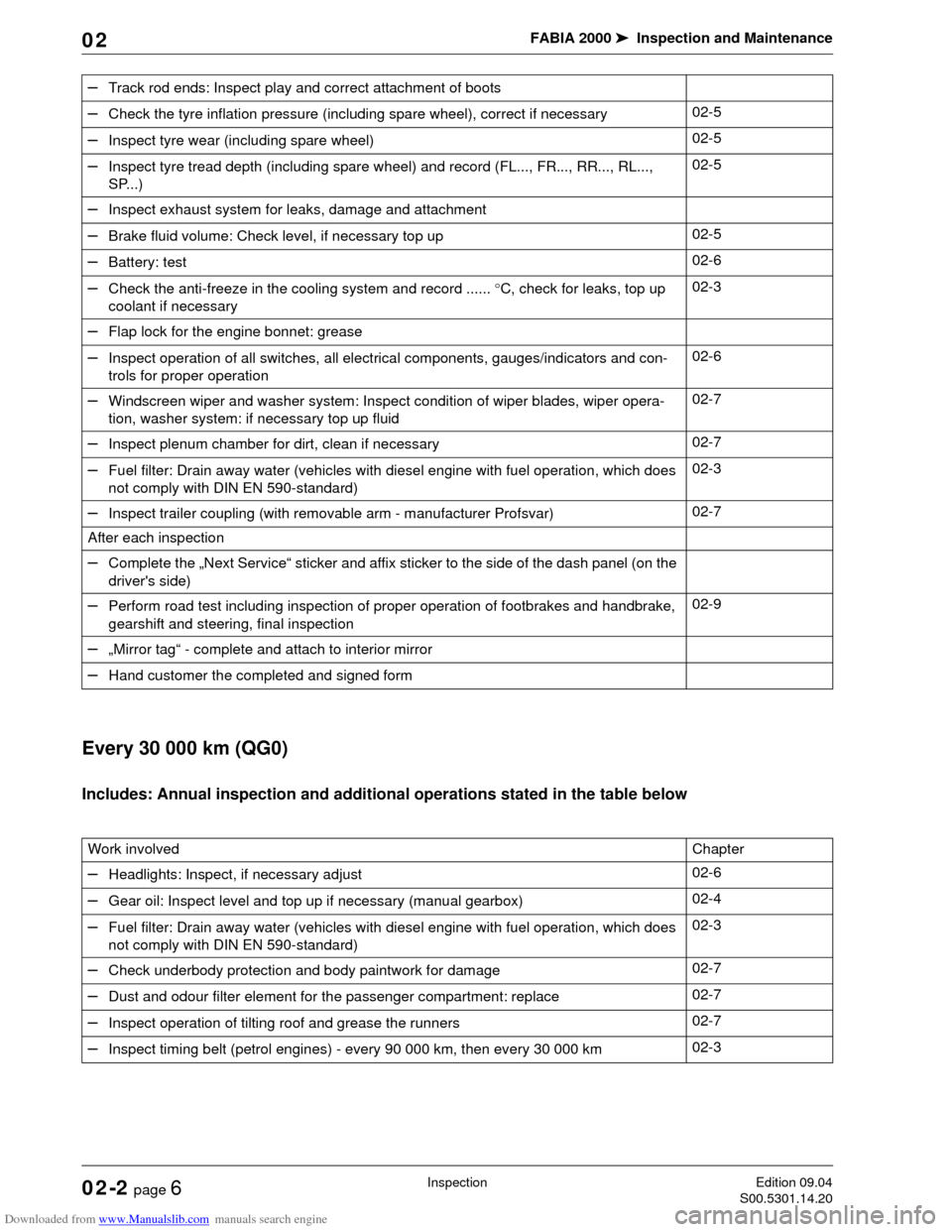

Every 30 000 km (QG0)

Includes: Annual inspection and additional operations stated in the table below

–Track rod ends: Inspect play and correct attachment of boots

–Check the tyre inflation pressure (including spare wheel), correct if necessary02-5

–Inspect tyre wear (including spare wheel)02-5

–Inspect tyre tread depth (including spare wheel) and record (FL..., FR..., RR..., RL...,

SP...)02-5

–Inspect exhaust system for leaks, damage and attachment

–Brake fluid volume: Check level, if necessary top up02-5

–Battery: test02-6

–Check the anti-freeze in the cooling system and record ...... °C, check for leaks, top up

coolant if necessary02-3

–Flap lock for the engine bonnet: grease

–Inspect operation of all switches, all electrical components, gauges/indicators and con-

trols for proper operation02-6

–Windscreen wiper and washer system: Inspect condition of wiper blades, wiper opera-

tion, washer system: if necessary top up fluid02-7

–Inspect plenum chamber for dirt, clean if necessary02-7

–Fuel filter: Drain away water (vehicles with diesel engine with fuel operation, which does

not comply with DIN EN 590-standard)02-3

–Inspect trailer coupling (with removable arm - manufacturer Profsvar)02-7

After each inspection

–Complete the „Next Service“ sticker and affix sticker to the side of the dash panel (on the

driver's side)

–Perform road test including inspection of proper operation of footbrakes and handbrake,

gearshift and steering, final inspection02-9

–„Mirror tag“ - complete and attach to interior mirror

–Hand customer the completed and signed form

Work involvedChapter

–Headlights: Inspect, if necessary adjust02-6

–Gear oil: Inspect level and top up if necessary (manual gearbox)02-4

–Fuel filter: Drain away water (vehicles with diesel engine with fuel operation, which does

not comply with DIN EN 590-standard)02-3

–Check underbody protection and body paintwork for damage02-7

–Dust and odour filter element for the passenger compartment: replace02-7

–Inspect operation of tilting roof and grease the runners02-7

–Inspect timing belt (petrol engines) - every 90 000 km, then every 30 000 km02-3

Page 18 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 8 02

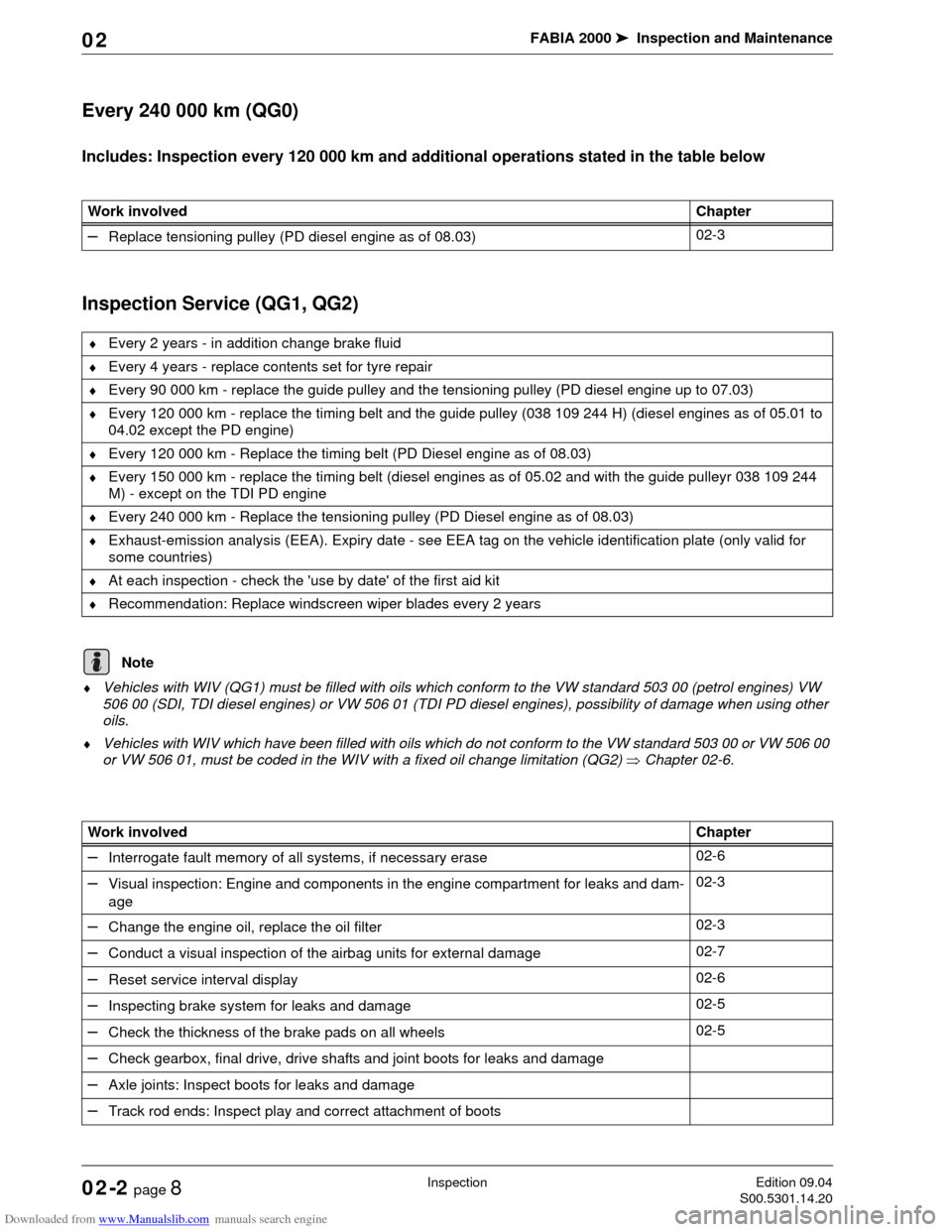

Every 240 000 km (QG0)

Includes: Inspection every 120 000 km and additional operations stated in the table below

Inspection Service (QG1, QG2)

♦Vehicles with WIV (QG1) must be filled with oils which conform to the VW standard 503 00 (petrol engines) VW

506 00 (SDI, TDI diesel engines) or VW 506 01 (TDI PD diesel engines), possibility of damage when using other

oils.

♦Vehicles with WIV which have been filled with oils which do not conform to the VW standard 503 00 or VW 506 00

or VW 506 01, must be coded in the WIV with a fixed oil change limitation (QG2) ⇒Chapter 02-6. Work involvedChapter

–Replace tensioning pulley (PD diesel engine as of 08.03)02-3

♦Every 2 years - in addition change brake fluid

♦Every 4 years - replace contents set for tyre repair

♦Every 90 000 km - replace the guide pulley and the tensioning pulley (PD diesel engine up to 07.03)

♦Every 120 000 km - replace the timing belt and the guide pulley (038 109 244 H) (diesel engines as of 05.01 to

04.02 except the PD engine)

♦Every 120 000 km - Replace the timing belt (PD Diesel engine as of 08.03)

♦Every 150 000 km - replace the timing belt (diesel engines as of 05.02 and with the guide pulleyr 038 109 244

M) - except on the TDI PD engine

♦Every 240 000 km - Replace the tensioning pulley (PD Diesel engine as of 08.03)

♦Exhaust-emission analysis (EEA). Expiry date - see EEA tag on the vehicle identification plate (only valid for

some countries)

♦At each inspection - check the 'use by date' of the first aid kit

♦Recommendation: Replace windscreen wiper blades every 2 years

Note

Work involvedChapter

–Interrogate fault memory of all systems, if necessary erase02-6

–Visual inspection: Engine and components in the engine compartment for leaks and dam-

age02-3

–Change the engine oil, replace the oil filter02-3

–Conduct a visual inspection of the airbag units for external damage02-7

–Reset service interval display02-6

–Inspecting brake system for leaks and damage02-5

–Check the thickness of the brake pads on all wheels02-5

–Check gearbox, final drive, drive shafts and joint boots for leaks and damage

–Axle joints: Inspect boots for leaks and damage

–Track rod ends: Inspect play and correct attachment of boots

Page 19 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 9 02

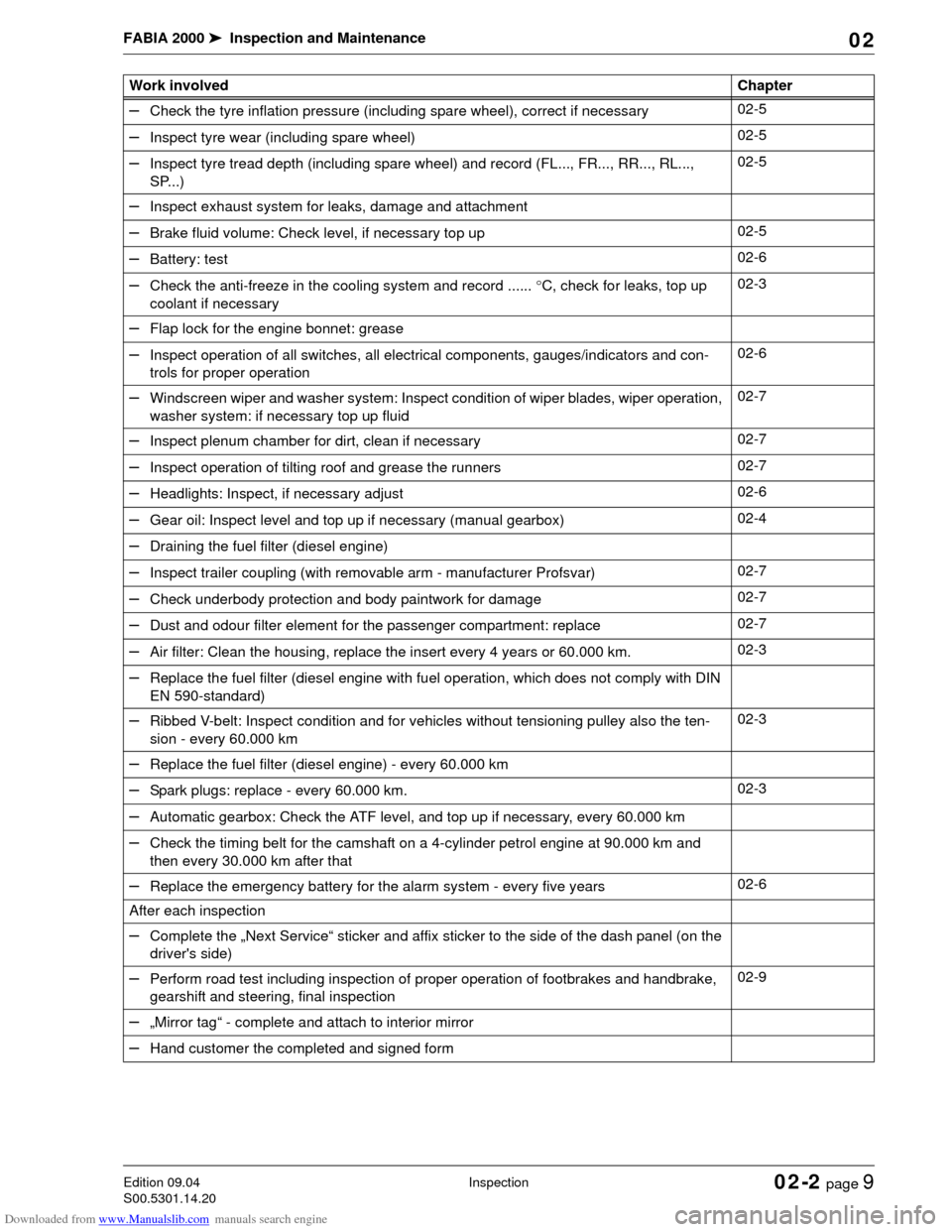

–Check the tyre inflation pressure (including spare wheel), correct if necessary02-5

–Inspect tyre wear (including spare wheel)02-5

–Inspect tyre tread depth (including spare wheel) and record (FL..., FR..., RR..., RL...,

SP...)02-5

–Inspect exhaust system for leaks, damage and attachment

–Brake fluid volume: Check level, if necessary top up02-5

–Battery: test02-6

–Check the anti-freeze in the cooling system and record ...... °C, check for leaks, top up

coolant if necessary02-3

–Flap lock for the engine bonnet: grease

–Inspect operation of all switches, all electrical components, gauges/indicators and con-

trols for proper operation02-6

–Windscreen wiper and washer system: Inspect condition of wiper blades, wiper operation,

washer system: if necessary top up fluid02-7

–Inspect plenum chamber for dirt, clean if necessary02-7

–Inspect operation of tilting roof and grease the runners02-7

–Headlights: Inspect, if necessary adjust02-6

–Gear oil: Inspect level and top up if necessary (manual gearbox)02-4

–Draining the fuel filter (diesel engine)

–Inspect trailer coupling (with removable arm - manufacturer Profsvar)02-7

–Check underbody protection and body paintwork for damage02-7

–Dust and odour filter element for the passenger compartment: replace02-7

–Air filter: Clean the housing, replace the insert every 4 years or 60.000 km.02-3

–Replace the fuel filter (diesel engine with fuel operation, which does not comply with DIN

EN 590-standard)

–Ribbed V-belt: Inspect condition and for vehicles without tensioning pulley also the ten-

sion - every 60.000 km02-3

–Replace the fuel filter (diesel engine) - every 60.000 km

–Spark plugs: replace - every 60.000 km.02-3

–Automatic gearbox: Check the ATF level, and top up if necessary, every 60.000 km

–Check the timing belt for the camshaft on a 4-cylinder petrol engine at 90.000 km and

then every 30.000 km after that

–Replace the emergency battery for the alarm system - every five years02-6

After each inspection

–Complete the „Next Service“ sticker and affix sticker to the side of the dash panel (on the

driver's side)

–Perform road test including inspection of proper operation of footbrakes and handbrake,

gearshift and steering, final inspection02-9

–„Mirror tag“ - complete and attach to interior mirror

–Hand customer the completed and signed form Work involvedChapter

Page 21 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 1 02

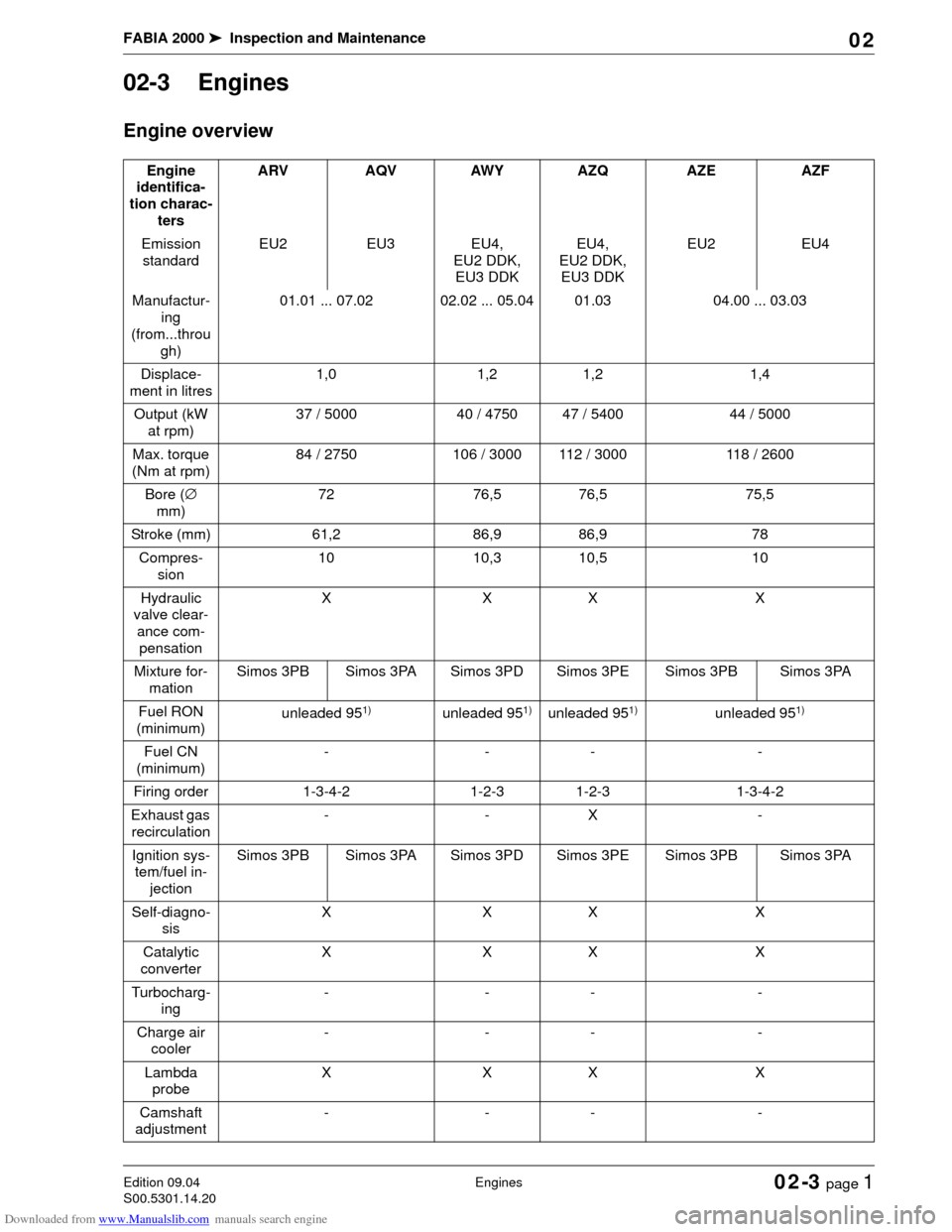

02-3 Engines

Engine overview

Engine

identifica-

tion charac-

tersARV AQV AWY AZQ AZE AZF

Emission

standardEU2 EU3 EU4,

EU2 DDK,

EU3 DDKEU4,

EU2 DDK,

EU3 DDKEU2 EU4

Manufactur-

ing

(from...throu

gh)01.01 ... 07.02 02.02 ... 05.04 01.03 04.00 ... 03.03

Displace-

ment in litres1,0 1,2 1,2 1,4

Output (kW

at rpm)37 / 5000 40 / 4750 47 / 5400 44 / 5000

Max. torque

(Nm at rpm)84 / 2750 106 / 3000 112 / 3000 118 / 2600

Bore (∅

mm)72 76,5 76,5 75,5

Stroke (mm) 61,2 86,9 86,9 78

Compres-

sion10 10,3 10,5 10

Hydraulic

valve clear-

ance com-

pensationXXX X

Mixture for-

mationSimos 3PB Simos 3PA Simos 3PD Simos 3PE Simos 3PB Simos 3PA

Fuel RON

(minimum)unleaded 95

1)unleaded 951)unleaded 951)unleaded 951)

Fuel CN

(minimum)--- -

Firing order 1-3-4-2 1-2-3 1-2-3 1-3-4-2

Exhaust gas

recirculation--X -

Ignition sys-

tem/fuel in-

jectionSimos 3PB Simos 3PA Simos 3PD Simos 3PE Simos 3PB Simos 3PA

Self-diagno-

sisXXX X

Catalytic

converterXXX X

Turbocharg-

ing--- -

Charge air

cooler--- -

Lambda

probeXXX X

Camshaft

adjustment--- -

Page 22 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 2 02

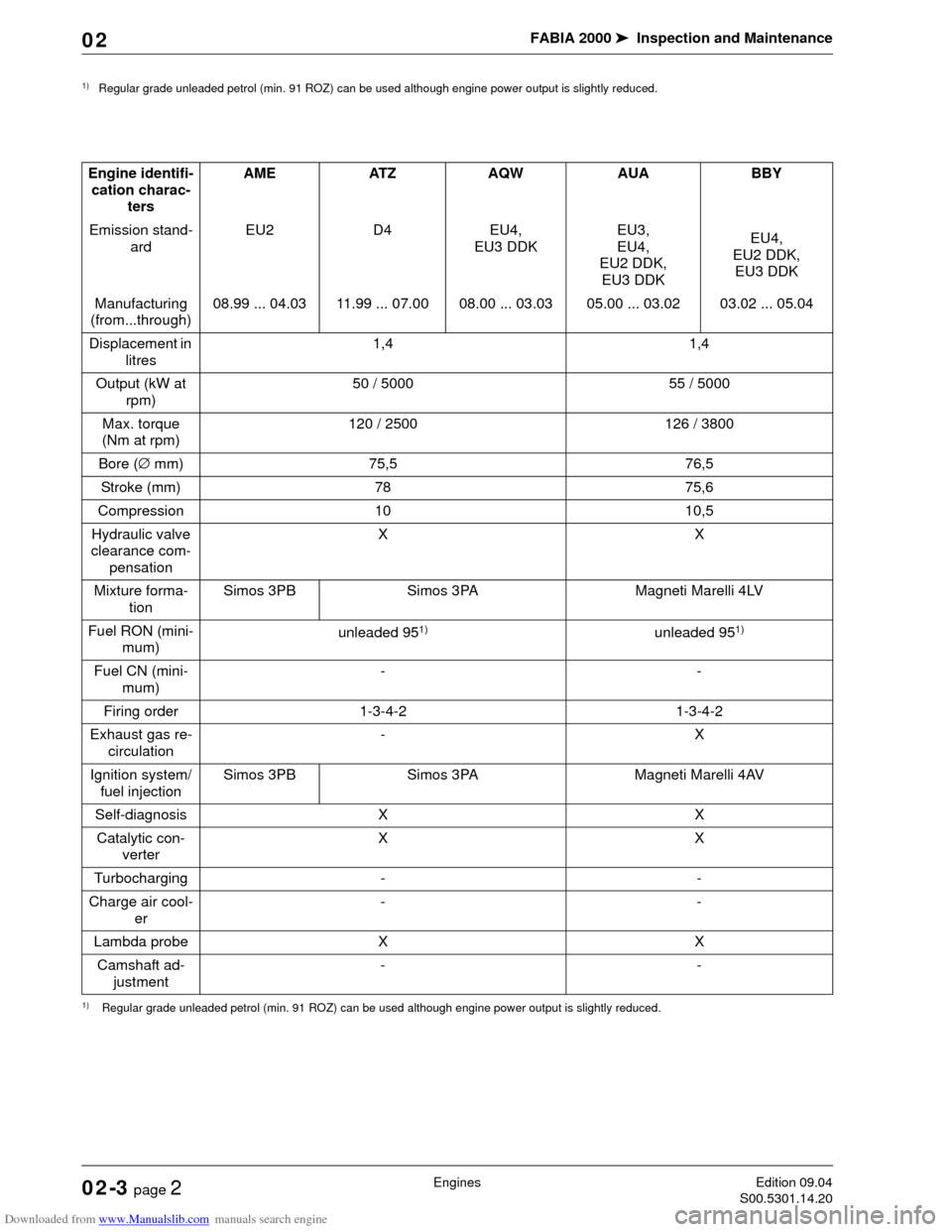

1)Regular grade unleaded petrol (min. 91 ROZ) can be used although engine power output is slightly reduced.

Engine identifi-

cation charac-

tersAME ATZ AQW AUA BBY

Emission stand-

ardEU2 D4 EU4,

EU3 DDKEU3,

EU4,

EU2 DDK,

EU3 DDKEU4,

EU2 DDK,

EU3 DDK

Manufacturing

(from...through)08.99 ... 04.03 11.99 ... 07.00 08.00 ... 03.03 05.00 ... 03.02 03.02 ... 05.04

Displacement in

litres1,4 1,4

Output (kW at

rpm)50 / 5000 55 / 5000

Max. torque

(Nm at rpm)120 / 2500 126 / 3800

Bore (∅ mm) 75,5 76,5

Stroke (mm) 78 75,6

Compression 10 10,5

Hydraulic valve

clearance com-

pensationXX

Mixture forma-

tionSimos 3PB Simos 3PA Magneti Marelli 4LV

Fuel RON (mini-

mum)unleaded 95

1)

1) Regular grade unleaded petrol (min. 91 ROZ) can be used although engine power output is slightly reduced.

unleaded 951)

Fuel CN (mini-

mum)--

Firing order 1-3-4-2 1-3-4-2

Exhaust gas re-

circulation-X

Ignition system/

fuel injectionSimos 3PB Simos 3PA Magneti Marelli 4AV

Self-diagnosis X X

Catalytic con-

verterXX

Turbocharging - -

Charge air cool-

er--

Lambda probe X X

Camshaft ad-

justment--

Page 23 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 3 02

Engine identification

charactersAMF AUB BBZ ASY

Emission standard EU3 EU4

EU2 DDK,

EU3 DDKEU4,

EU2 DDK,

EU3 DDKEU3

Manufacturing

(from...through)05.03 08.99 ... 05.02 05.02 08.99

Displacement in litres 1,4 1,4 1,9

Output (kW at rpm) 55 / 4000 74 / 6000 47 / 4000

Max. torque (Nm at rpm) 195 / 2200 126 / 4400 125 / 1600 - 2800

Bore (∅ mm) 79,5 76,5 79,5

Stroke (mm) 95,5 75,6 95,5

Compression 19,5 10,5 19,5

Hydraulic valve clearance

compensationXXX

Mixture formation Bosch PDE - injec-

torsMagneti Marelli 4LV Bosch VP

Fuel RON (minimum) -

unleaded 98

1)

1)Regular grade unleaded petrol (min. 95 ROZ) can be used although engine power output is slightly reduced.

-

Fuel CN (minimum) 49 - 49

Firing order 1-2-3 1-3-4-2 1-3-4-2

Exhaust gas recirculation X X X

Ignition system/fuel injec-

tionBosch PDE - injec-

torsMagneti Marelli 4AV Bosch VP

Self-diagnosis X X X

Catalytic converter X X X

Turbocharging X - -

Charge air cooler X - -

Lambda probe - X -

Camshaft adjustment - - -

Engine identification char-

actersATD ASZ AZL BMD BKY

Emission standard EU3 EU3 EU4,

EU2 DDK,

EU3 DDKEU4,

EU2 DDKEU4,

EU2 DDK

Manufacturing (from...through) 02.00 06.03 08.00 05.04 05.04

Displacement in litres 1,9 1,9 2,0 1,2 1,4

Output (kW at rpm) 74 / 4000 96 / 4000 85 / 5400 40 / 4750 55 / 5000

Max. torque (Nm at rpm) 240 / 1800 -

2800310 / 1900 170 / 2400 108 / 3000 126 / 3800

Bore (∅ mm) 79,5 79,5 82,5 76,5 76,5

Stroke (mm) 95,5 95,5 92,8 86,9 75,6

Page 24 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 4 02

Engine fitted

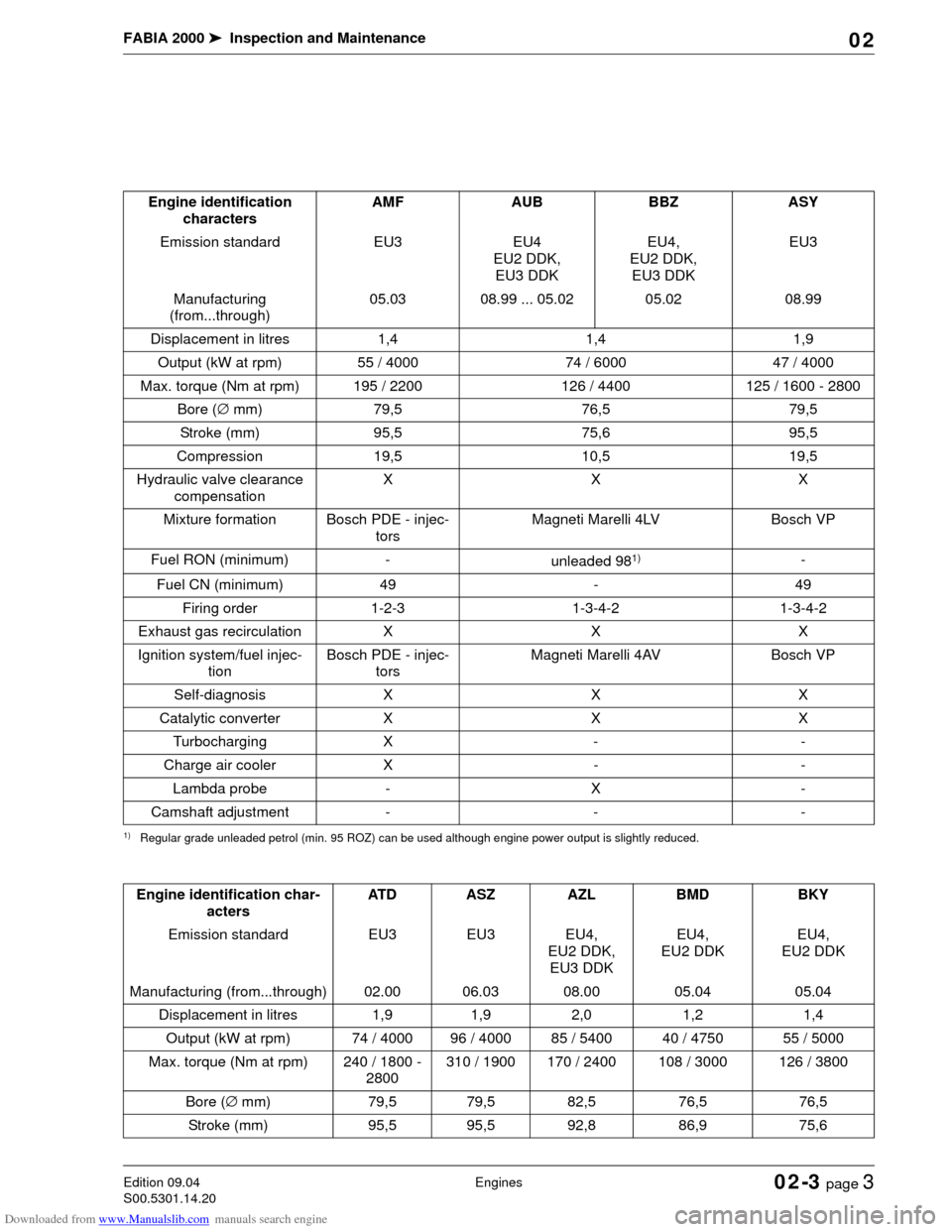

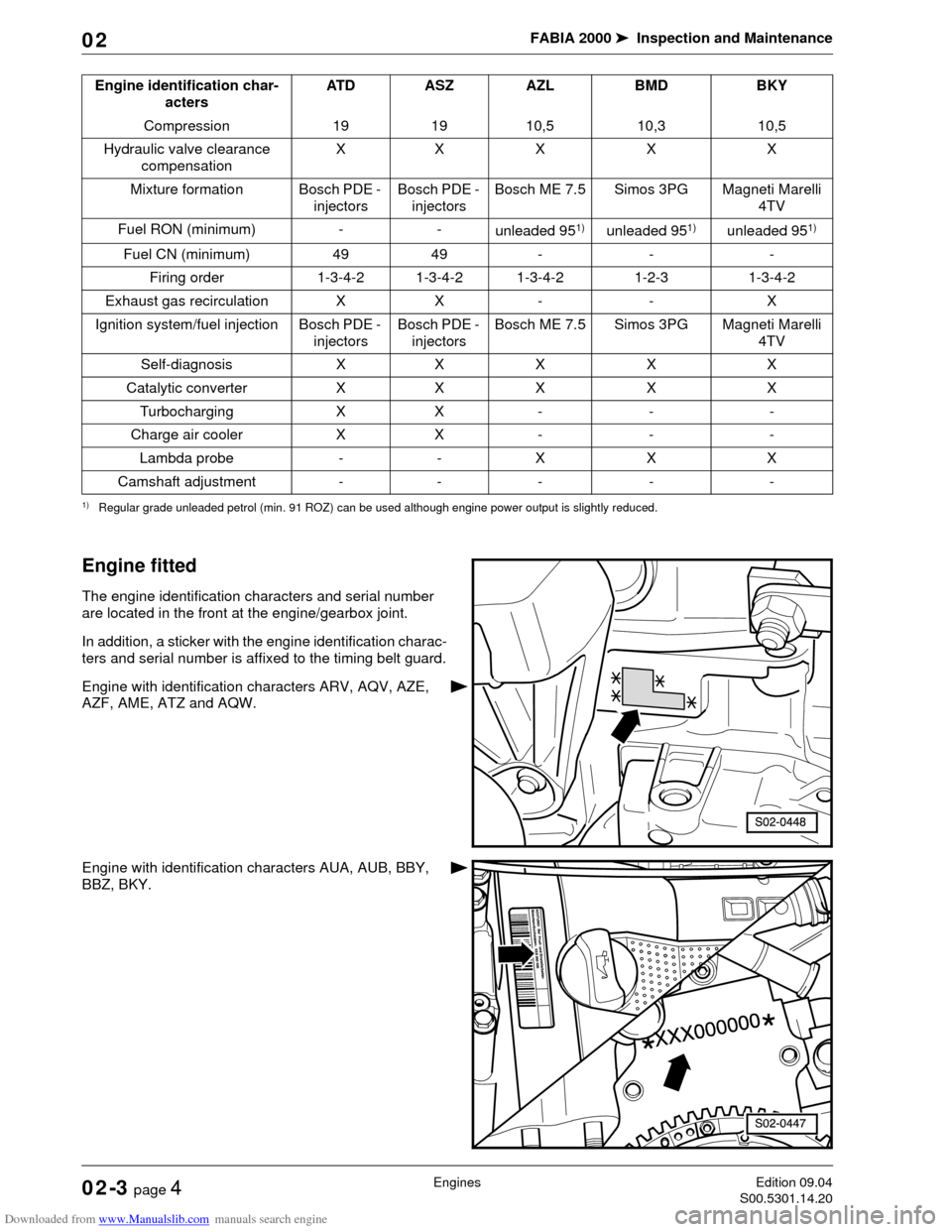

The engine identification characters and serial number

are located in the front at the engine/gearbox joint.

In addition, a sticker with the engine identification charac-

ters and serial number is affixed to the timing belt guard.

Engine with identification characters ARV, AQV, AZE,

AZF, AME, ATZ and AQW.

Engine with identification characters AUA, AUB, BBY,

BBZ, BKY.Compression 19 19 10,5 10,3 10,5

Hydraulic valve clearance

compensationXX X X X

Mixture formation Bosch PDE -

injectorsBosch PDE -

injectorsBosch ME 7.5 Simos 3PG Magneti Marelli

4TV

Fuel RON (minimum) - -

unleaded 95

1)unleaded 951)unleaded 951)

Fuel CN (minimum) 49 49 - - -

Firing order 1-3-4-2 1-3-4-2 1-3-4-2 1-2-3 1-3-4-2

Exhaust gas recirculation X X - - X

Ignition system/fuel injection Bosch PDE -

injectorsBosch PDE -

injectorsBosch ME 7.5 Simos 3PG Magneti Marelli

4TV

Self-diagnosis X X X X X

Catalytic converter X X X X X

Turbocharging X X - - -

Charge air cooler X X - - -

Lambda probe - - X X X

Camshaft adjustment - - - - -

1)Regular grade unleaded petrol (min. 91 ROZ) can be used although engine power output is slightly reduced.

Engine identification char-

actersAT D A S Z A Z L B M D B K Y