air condition SKODA FABIA 2000 1.G / 6Y Workshop Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2000, Model line: FABIA, Model: SKODA FABIA 2000 1.G / 6YPages: 86, PDF Size: 3.58 MB

Page 5 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Table of ContentsEdition 09.04

S00.5301.14.20I Table of Contents

02 – Inspection and Maintenance

General points..........................................................................................

- Vehicle identification data ............................................................................

- Storage of ŠKODA new vehicles ....................................................................

- Vehicle handover from stock ........................................................................

- Additional customer information regarding inspection and maintenance .....................

Inspection................................................................................................

- Pre-Delivery Inspection -PDI- (Export) .............................................................

- Pre-sales Inspection - (the Czech Republic) ......................................................

- Delivery Inspection (Export) .........................................................................

- Oil Change Service every 15.000 km

1) (QG0) ....................................................

- Annual Inspection (every 12 months) (QG0) ......................................................

- Every 30 000 km (QG0) ..............................................................................

- Every 60 000 km (QG0) ..............................................................................

- Every 90 000 km (QG0) ..............................................................................

- Every 120 000 km (QG0) .............................................................................

- Every 150.000 km (QG0) .............................................................................

- Every 240 000 km (QG0) .............................................................................

- Inspection Service (QG1, QG2) .....................................................................

- Oil change (QG1, QG2)..............................................................................

Engines...................................................................................................

- Engine overview .......................................................................................

- Engine fitted ............................................................................................

- Visual inspection: Engine for leaks and damage .................................................

- Replace engine oil filter ...............................................................................

- Replacing timing belt and tensioning pulley for camshaft drive (1.9 TDI engines) ..........

- Replacing timing belt and tensioning pulley for camshaft drive (1.4 TDI engines) ..........

- Inspecting timing belt for camshaft drive for wear and running (petrol engine) ..............

- Replacing toothed belt and guide pulley for camshaft drive (1.9 SDI engines) ..............

- Inspecting engine oil level ............................................................................

- Change engine oil .....................................................................................

- Inspecting antifreeze protection, replenishing coolant additive if necessary .................

- Inspecting coolant level (volume) ...................................................................

- Ribbed V-belt: Inspect condition....................................................................

- Routing of V-ribbed belt ..............................................................................

- Replace spark plugs ..................................................................................

- Replace air filter element .............................................................................

- Replacing the fuel filter (diesel engine) ............................................................

- Draining the fuel filter (diesel engine) ..............................................................

Gearbox...................................................................................................

- Gearbox/Final drive: Check the oil level and top it if necessary ................................

- Inspecting ATF level, if necessary topping up ....................................................

Chassis...................................................................................................

- Inspecting thickness of front and rear brake pads/linings .......................................

- Inspecting brake system for leaks and damage ..................................................

02-1page 1

02-1page 1

02-1page 3

02-1page 3

02-1page 3

02-2page 1

02-2page 1

02-2page 2

02-2page 3

02-2page 5

02-2page 5

02-2page 6

02-2page 7

02-2page 7

02-2page 7

02-2page 7

02-2page 8

02-2page 8

02-2page 10

02-3page 1

02-3page 1

02-3page 4

02-3page 6

02-3page 7

02-3page 7

02-3page 7

02-3page 7

02-3page 8

02-3page 8

02-3page 8

02-3page 10

02-3page 12

02-3page 14

02-3page 14

02-3page 17

02-3page 18

02-3page 18

02-3page 19

02-4page 1

02-4page 1

02-4page 2

02-5page 1

02-5page 1

02-5page 2

Page 9 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

General pointsEdition 09.04

S00.5301.14.2002-1 page 3 02

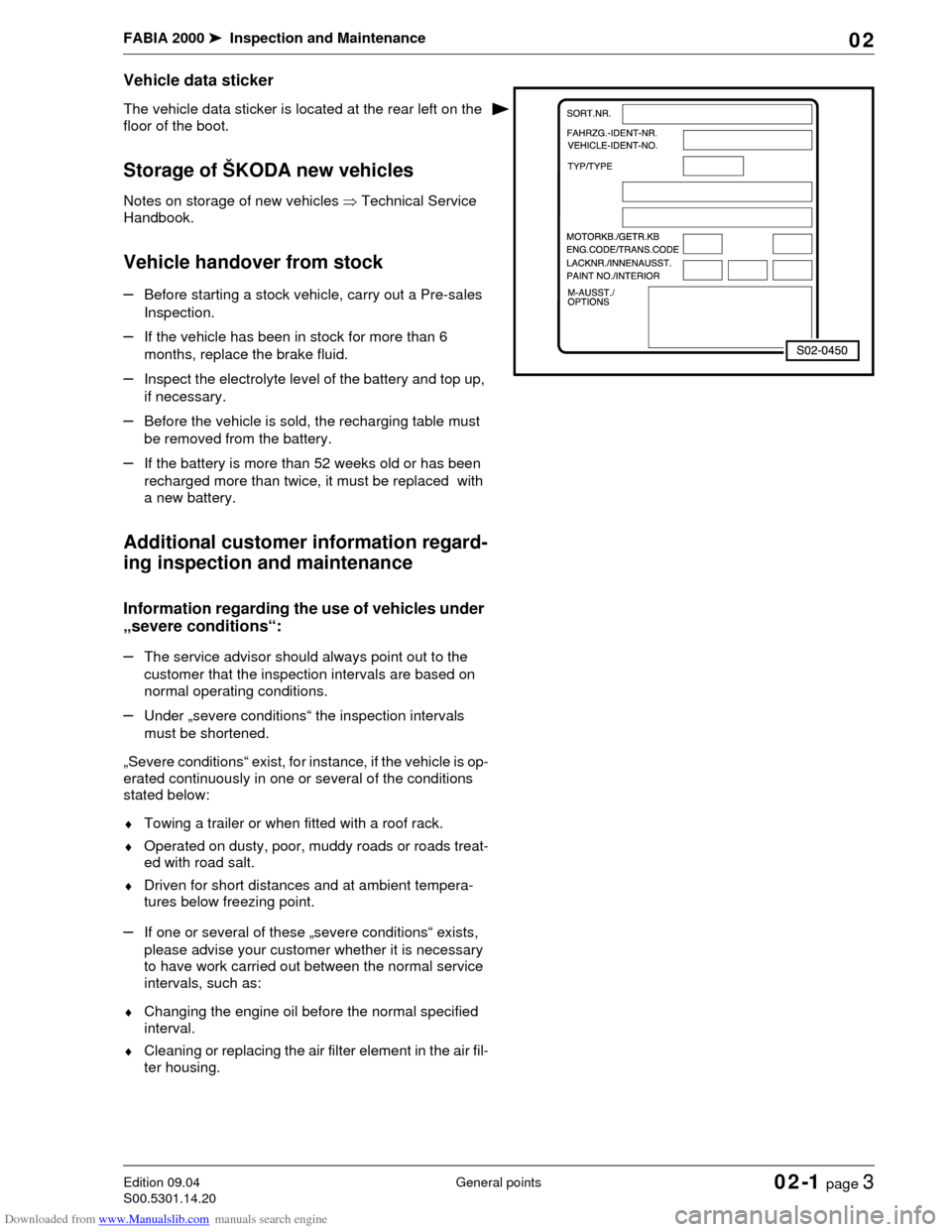

Vehicle data sticker

The vehicle data sticker is located at the rear left on the

floor of the boot.

Storage of ŠKODA new vehicles

Notes on storage of new vehicles ⇒Technical Service

Handbook.

Vehicle handover from stock

–Before starting a stock vehicle, carry out a Pre-sales

Inspection.

–If the vehicle has been in stock for more than 6

months, replace the brake fluid.

–Inspect the electrolyte level of the battery and top up,

if necessary.

–Before the vehicle is sold, the recharging table must

be removed from the battery.

–If the battery is more than 52 weeks old or has been

recharged more than twice, it must be replaced with

a new battery.

Additional customer information regard-

ing inspection and maintenance

Information regarding the use of vehicles under

„severe conditions“:

–The service advisor should always point out to the

customer that the inspection intervals are based on

normal operating conditions.

–Under „severe conditions“ the inspection intervals

must be shortened.

„Severe conditions“ exist, for instance, if the vehicle is op-

erated continuously in one or several of the conditions

stated below:

♦Towing a trailer or when fitted with a roof rack.

♦Operated on dusty, poor, muddy roads or roads treat-

ed with road salt.

♦Driven for short distances and at ambient tempera-

tures below freezing point.

–If one or several of these „severe conditions“ exists,

please advise your customer whether it is necessary

to have work carried out between the normal service

intervals, such as:

♦Changing the engine oil before the normal specified

interval.

♦Cleaning or replacing the air filter element in the air fil-

ter housing.

Page 13 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 3 02

Delivery Inspection (Export)

–Proper operation of seat belts, seat belt height adjuster, power windows and sun roof

–Inspect upholstery, interior trim, carpeting and footmats for cleanliness and damage

–Inspect all switches, all electrical components, gauges/indicators and controls02-6

–Radio: Inspect for proper operation, store stations, set clock, encode02-6

–Reset service interval display02-6

–Power windows: Inspecting positioning02-6

–Key switch for airbag deactivation, front passenger side: Check function „ON/OFF“ and

switch-over to the position „ON“02-7

–Fit net in luggage compartment (if available)

–Check the car tool kit, spare wheel and accessories, that they have all been supplied and

are properly secured

–Install the carpets supplied in the vehicle

–Perform a test drive

Underside of vehicle (on lift platform)

–Inspect underbody (underbody protection for damage)02-7

–Inspect for leaks and damage: Engine, gearbox, final drive, steering, brake system, axles,

joint boots. Check proper routing of the brake hoses and brake lines, fuel lines including

ventilation of the fuel system02-3, 02-5

–Inspect tyres and wheels for damage02-5

Concluding operations

–Interrogate fault memory of all systems, if necessary erase02-6

–Remove protective seat covers

–Remove recharging table (if affixed)

–Complete the service schedule, affix the vehicle data sticker in the Service Schedule to

the floor of the luggage compartment next to the spare wheel„Next Service Date“ sticker

and affix to the side of the dash panel on the driver's side, hand the card „Škoda Assist-

ance“ to the customer02-7

–Final inspection to ensure proper condition for handover to the customer

Inspections and operations to be completed Chapter

Vehicle (exterior)

–Plastic and rubber parts: Inspect for cleanliness and damage

–Inspect bodywork and paintwork for damage02-7

–Check operation of the tailgate lock and the fuel filler cap, door contact switch, operation

of the door handles, door locks and safety buttons, central locking from outside as well as

inside, child safety locks, ability to close all locks on the vehicle using all keys (including

the spare key)02-7

–Check operation of the anti-theft alarm system

–Tighten the wheel bolts to specified torque (steel and light alloy wheels 120 Nm), fit wheel

caps02-5

–Check the tyre inflation pressure (including spare wheel), if necessary correct the tyre in-

flation pressure, fit valve caps02-5

–Vehicles in stock for more than 6 months: Change brake fluid02-5

Page 14 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 4 02

–Fit roof aerial

Engine compartment (from above)

–Check battery no-load voltage; recharge if necessary02-6

–Check tight connection of electric cables and plug connections (in particular battery ca-

bles)

–Brake fluid level (at „MAX“ marking)02-5

–Check the engine oil level (to be in-between the marking on the dipstick)02-3

–Check the coolant level (in-between marking), for special equipment antifreeze down to -

35 °C02-3

–Fill up fluid in washer reservoir, in the winter add antifreeze

–Check windscreen wiper and washer system, the spray nozzle adjustment and the resting

position of the windscreen wipers02-7

Vehicle interior

–Inspect upholstery, interior trim, carpeting and footmats for cleanliness and damage

–Inspect all switches, all electrical components, gauges/indicators and controls02-6

–Radio: Inspect for proper operation, store stations, encode, set clock02-6

–Fit net in luggage compartment (if available)

–Vehicle log book - for completion: Operating manual and service plan (in the correct lan-

guage and with the correct edition data), short introduction, technical data, support in the

case of a breakdown, other manuals (radio,...) ) - all in the vehicle log book pouch

–Reset service interval display02-6

–Power windows: Inspecting positioning02-6

–Key switch for airbag deactivation, front passenger side: Check function „ON/OFF“ and

switch-over to the position „ON“02-7

Underside of vehicle (on lift platform)

–Inspect underbody (underbody protection for damage)02-7

–Inspect for leaks and damage: Engine, gearbox, final drive, steering, brake system, axles,

joint boots. Check proper routing of the brake hoses and brake lines, fuel lines including

ventilation of the fuel system02-3, 02-5

–Inspect tyres and wheels for damage02-5

Concluding operations

–Perform a test drive02-9

–Interrogate fault memory of all systems, if necessary erase02-6

–Complete the service schedule, affix the vehicle data sticker in the Service Schedule to

the floor of the luggage compartment next to the spare wheel, complete the „Next Service

Date“ sticker and affix to the side of the dash panel on the driver's side02-7

–Remove recharging table (if affixed)

–Remove protective seat covers

–Install the carpets supplied in the vehicle

–Final inspection to ensure proper condition for handover to customer

Page 17 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 7 02

Every 60 000 km (QG0)

Includes: Inspection every 30 000 km and additional operations stated in the table below

Every 90 000 km (QG0)

Includes: Inspection every 30 000 km and additional operations stated in the table below

Every 120 000 km (QG0)

Includes: Inspection every 60 000 km and additional operations stated in the table below

Every 150.000 km (QG0)

Includes: Inspection every 60 000 km and additional operations stated in the table below

Work involvedChapter

–Air filter: Clean housing, replace filter element02-3

–Fuel filter: replace (vehicles with diesel engine)02-3

–Ribbed V-belt: Inspect condition and for vehicles without tensioning pulley also the ten-

sion02-3

–Spark plugs: replace02-3

–Automatic gearbox: Inspect ATF1) level, if necessary top up

1)Automatic transmission fluid for the automatic gearbox

02-4

Work involvedChapter

–Timing belt for camshaft drive: replace (ASY diesel engines up to 04.2001)02-3

–Timing belt and tensioning pulley for camshaft drive: replace (PD diesel engine up to

07.03)02-3

–Timing belt for camshaft drive: inspect (petrol engines) - every 90 000 km, then every 30

000 km02-3

Work involvedChapter

–Timing belt and tensioning pulley (038 109 244 H)1) for camshaft drive: replace (diesel en-

gines other than the PD engine) - vehicles as of 05.2001 to 04.2002

1)When the tensioning pulley Spare Part No. 038 109 244 M is mounted after 120 000 km. on vehicles with a diesel engine during replacement of

the timing belt and the tensioning pulley the change interval of the timing belt should be altered from 120 000 km to 150 000 km. The customer

should be informed about the new service interval when the tensioning pulley is first replaced by a new tensioning pulley Spare Part No. 038

109 244 M by making an entry in the service plan, in the section „Workshop entries“. Only the timing belt will be replaced at each next service

interval at 150 000 km.

02-3

–Timing belt for camshaft drive: replace (PD diesel engine as of 08.03)02-3

Work involvedChapter

–Timing belt: replace (diesel engines other than the PD engine) - vehicles as of 05.200202-3

Page 19 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 9 02

–Check the tyre inflation pressure (including spare wheel), correct if necessary02-5

–Inspect tyre wear (including spare wheel)02-5

–Inspect tyre tread depth (including spare wheel) and record (FL..., FR..., RR..., RL...,

SP...)02-5

–Inspect exhaust system for leaks, damage and attachment

–Brake fluid volume: Check level, if necessary top up02-5

–Battery: test02-6

–Check the anti-freeze in the cooling system and record ...... °C, check for leaks, top up

coolant if necessary02-3

–Flap lock for the engine bonnet: grease

–Inspect operation of all switches, all electrical components, gauges/indicators and con-

trols for proper operation02-6

–Windscreen wiper and washer system: Inspect condition of wiper blades, wiper operation,

washer system: if necessary top up fluid02-7

–Inspect plenum chamber for dirt, clean if necessary02-7

–Inspect operation of tilting roof and grease the runners02-7

–Headlights: Inspect, if necessary adjust02-6

–Gear oil: Inspect level and top up if necessary (manual gearbox)02-4

–Draining the fuel filter (diesel engine)

–Inspect trailer coupling (with removable arm - manufacturer Profsvar)02-7

–Check underbody protection and body paintwork for damage02-7

–Dust and odour filter element for the passenger compartment: replace02-7

–Air filter: Clean the housing, replace the insert every 4 years or 60.000 km.02-3

–Replace the fuel filter (diesel engine with fuel operation, which does not comply with DIN

EN 590-standard)

–Ribbed V-belt: Inspect condition and for vehicles without tensioning pulley also the ten-

sion - every 60.000 km02-3

–Replace the fuel filter (diesel engine) - every 60.000 km

–Spark plugs: replace - every 60.000 km.02-3

–Automatic gearbox: Check the ATF level, and top up if necessary, every 60.000 km

–Check the timing belt for the camshaft on a 4-cylinder petrol engine at 90.000 km and

then every 30.000 km after that

–Replace the emergency battery for the alarm system - every five years02-6

After each inspection

–Complete the „Next Service“ sticker and affix sticker to the side of the dash panel (on the

driver's side)

–Perform road test including inspection of proper operation of footbrakes and handbrake,

gearshift and steering, final inspection02-9

–„Mirror tag“ - complete and attach to interior mirror

–Hand customer the completed and signed form Work involvedChapter

Page 34 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 14 02

The listed G12 PLUS coolant additives may be inter-

mixed.

Ribbed V-belt: Inspect condition

Special tools, test and measuring equipment and

auxiliary items required

♦Wrench socket

Perform the following procedure:

–Raise vehicle.

–Remove bottom engine compartment cover at right.

–Use a socket wrench to crank the engine at the belt

pulley -2-.

–Check ribbed V-belt for:

♦Splits in the carcass (initial splits, splits in core, splits

across carcass).

♦Separation of layers (top layer, cords).

♦Sections of carcass broken out.

♦Fraying of cords.

♦Wear to sides (abrasion of material, frayed sides,

hardening of sides, glazed and hardened surfaces).

♦Traces of oil and grease.

♦Correct tension (vehicles without tensioning pulley).

♦It is essential to replace the V-ribbed belt if defects are

found. This will help prevent any operational prob-

lems. Replacing the ribbed V-belt is a repair measure.

♦Engines fitted with an AC compressor are equipped

with a double ribbed V-belt.

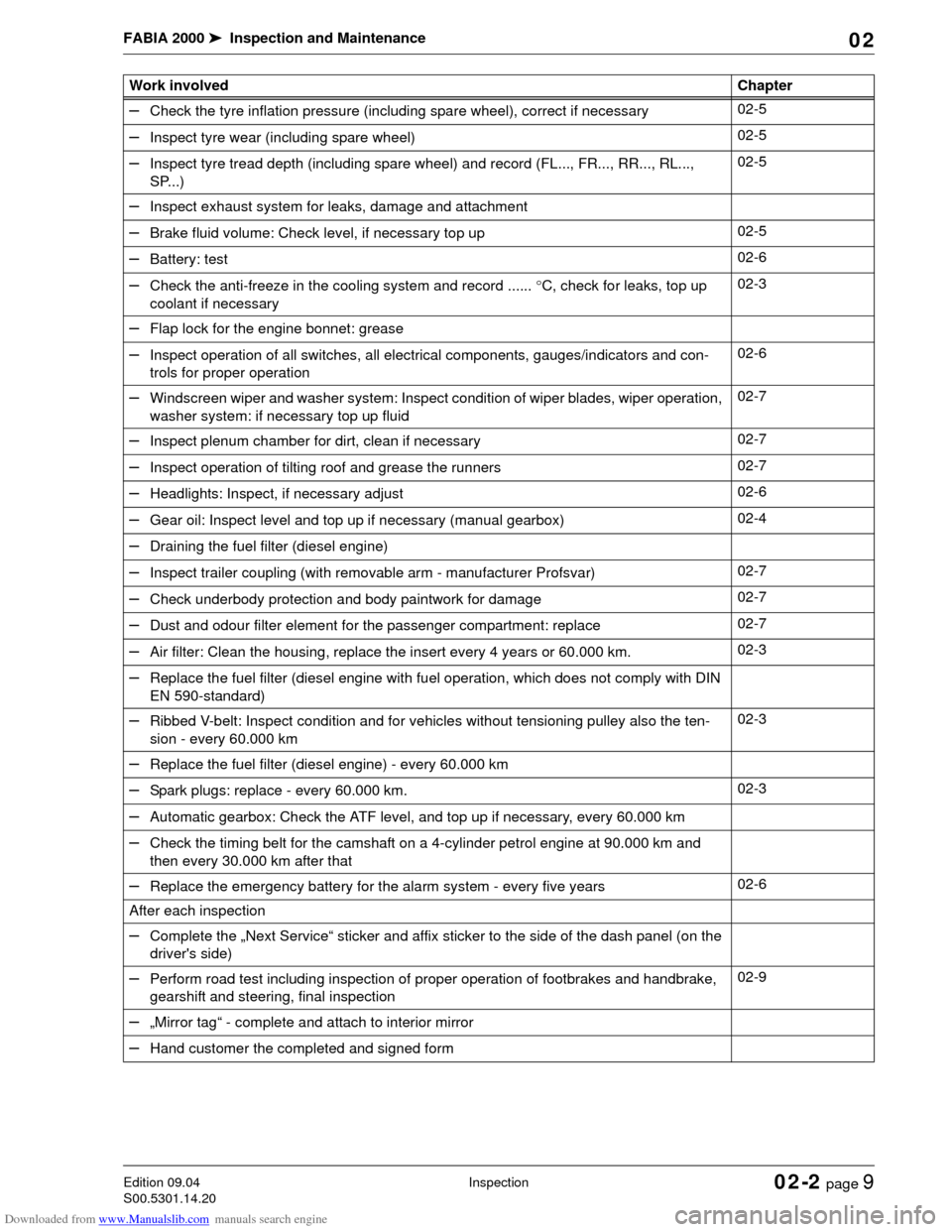

Routing of V-ribbed belt

1.0 litre/37 kW (ARV and AQV), 1.4 litre/44 kW (AZE

and AZF), 1.4 litre/50 kW (AME, ATZ and AQW) with-

out air-conditioning

1 - Crankshaft

2 - Tensioning pulley

3 - Coolant pump

4 - AC generator

Note

S02-0025

Note

Page 35 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 15 02

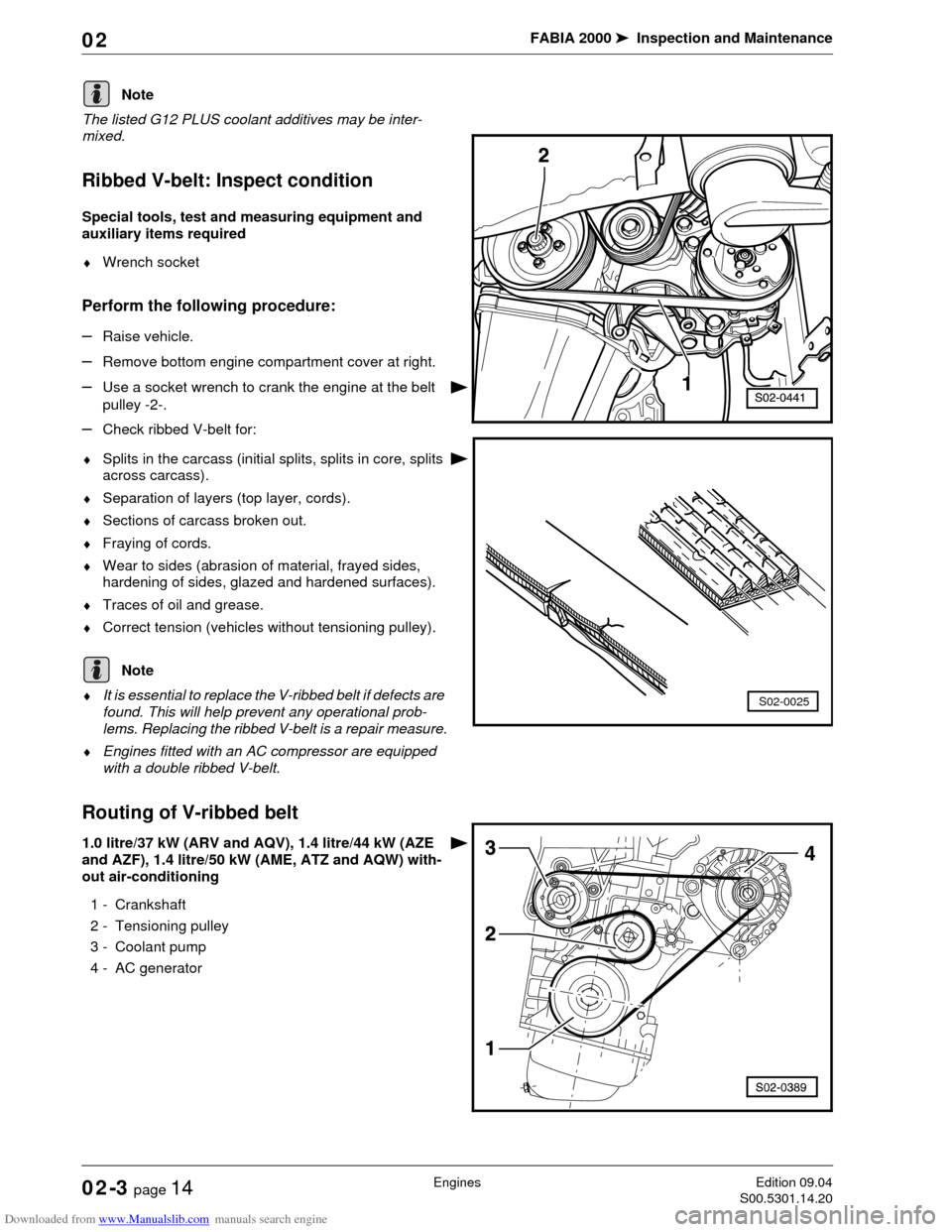

1.0 litre/37 kW (ARV and AQV), 1.4 litre/44 kW (AZE

and AZF), 1.4 litre/50 kW (AME, ATZ and AQW) with

air-conditioning

1 - Crankshaft

2 - Tensioning pulley

3 - Coolant pump

4- AC compressor

5 - Guide pulley

6 - AC generator

1.2 litre/40 kW (AWY, BMD), 1.2 litre/47 kW (AZQ)

without air-conditioning

1 - Coolant pump

2 - AC generator

3 - Crankshaft

4 - Tensioning pulley

1.2 litre/40 kW (AWY, BMD), 1.2 litre/47 kW (AZQ) with

air-conditioning

1 - AC generator

2 - Guide pulley

3- AC compressor

4 - Crankshaft

5 - Tensioning pulley

6 - Coolant pump

1

S02-0311

4

2

3

5

6

Page 36 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 16 02

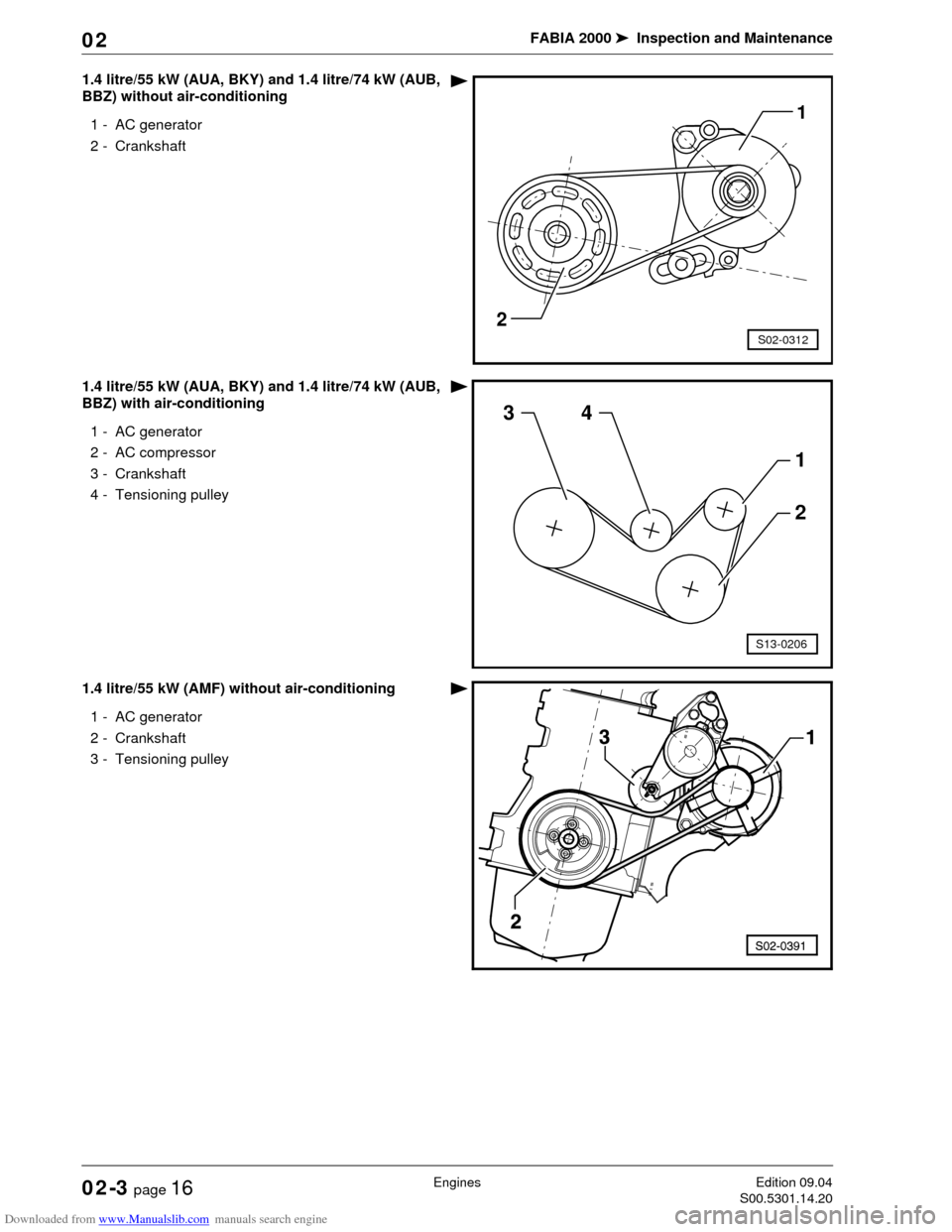

1.4 litre/55 kW (AUA, BKY) and 1.4 litre/74 kW (AUB,

BBZ) without air-conditioning

1 - AC generator

2 - Crankshaft

1.4 litre/55 kW (AUA, BKY) and 1.4 litre/74 kW (AUB,

BBZ) with air-conditioning

1 - AC generator

2 - AC compressor

3 - Crankshaft

4 - Tensioning pulley

1.4 litre/55 kW (AMF) without air-conditioning

1 - AC generator

2 - Crankshaft

3 - Tensioning pulley

1

S02-0312

2

S13-0206

34

2

1

Page 37 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 17 02

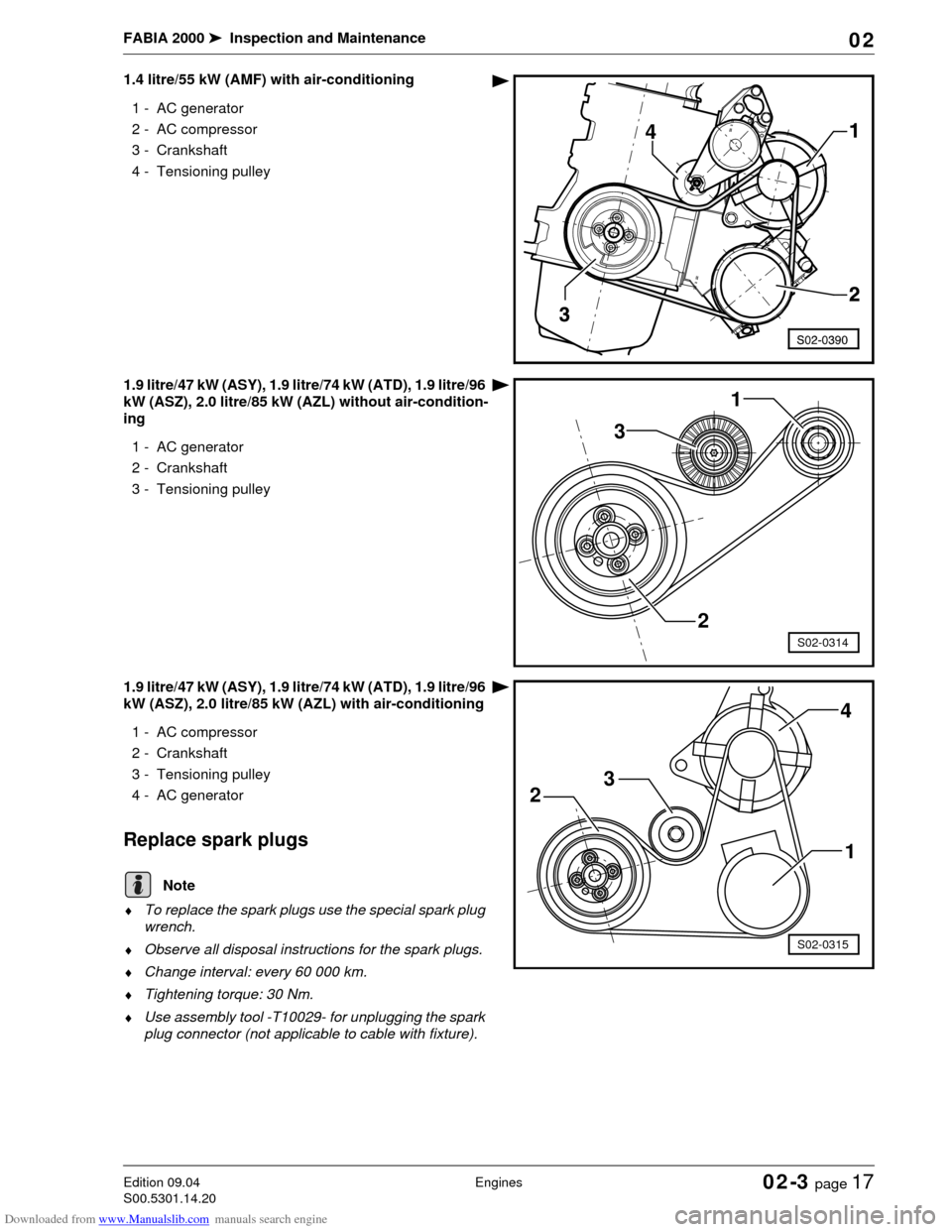

1.4 litre/55 kW (AMF) with air-conditioning

1 - AC generator

2- AC compressor

3 - Crankshaft

4 - Tensioning pulley

1.9 litre/47 kW (ASY), 1.9 litre/74 kW (ATD), 1.9 litre/96

kW (ASZ), 2.0 litre/85 kW (AZL) without air-condition-

ing

1 - AC generator

2 - Crankshaft

3 - Tensioning pulley

1.9 litre/47 kW (ASY), 1.9 litre/74 kW (ATD), 1.9 litre/96

kW (ASZ), 2.0 litre/85 kW (AZL) with air-conditioning

1- AC compressor

2 - Crankshaft

3 - Tensioning pulley

4 - AC generator

Replace spark plugs

♦To replace the spark plugs use the special spark plug

wrench.

♦Observe all disposal instructions for the spark plugs.

♦Change interval: every 60 000 km.

♦Tightening torque: 30 Nm.

♦Use assembly tool -T10029- for unplugging the spark

plug connector (not applicable to cable with fixture).

2

S02-0314

1

3

4

S02-0315

1 23

Note