trailer SKODA FABIA 2013 2.G / 5J User Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2013, Model line: FABIA, Model: SKODA FABIA 2013 2.G / 5JPages: 223, PDF Size: 12.77 MB

Page 126 of 223

Note■After coupling the trailer and connecting up the power socket, check the rear

lights on the trailer to ensure they work.■

If there is an error in the trailer lighting system, check the fuses in the fuse box

in the dashboard » page 193.

■

If you tow a trailer frequently, you should also have your car inspected between

service intervals.

■

The handbrake on the towing vehicle must be applied when coupling and un-

coupling the trailer.

Anti-theft alarm system

First read and observe the introductory information and safety warn-

ings

on page 121.

When the vehicle is locked, the alarm is activated as soon as the electrical con- nection to the trailer is interrupted.

Always switch off the anti-theft alarm system before a trailer is coupled or uncou- pled » page 35 .

Conditions for including a trailer in the anti-theft alarm system. The vehicle is factory-fitted with an anti-theft alarm system and towingequipment.

The trailer is electrically connected to the towing vehicle by means of the

trailer socket.

The electrical system of the vehicle and trailer is functional. The vehicle is locked with the vehicle key and the anti-theft alarm system isactivated.

Note

For technical reasons, trailers with rear LED lights cannot be connected to the an-

ti-theft alarm system.

123Towing a trailer

Page 148 of 223

General Maintenance

Car care

Service intervals

Introduction

This chapter contains information on the following subjects:

Overview of service intervals

145

Fixed service intervals QI1 - QI4

146

Variable service interval QI6

146

Information about the ŠKODA service

146

The Service Interval Display in the instrument cluster will remind you to have ev- ery service specified by the manufacturer at the right time so that you never for- get a service.

A timely and adequate performance of servicing works is one of the requirements for the settlement of possible warranty claims.

The completion of services can be verified through the confirmed service certifi-

cation and the corresponding receipts.

The service intervals are appropriate for normal operating conditions.

In case of difficult operating conditions, it is necessary to have some servicing

work performed before the date of the next service or between the service inter- vals stated. This applies mainly to the cleaning or the replacement of the air filter

insert in regions with heavy dust pollution as well as checking and replacing the

toothed belt, but also vehicles with diesel particle filter which can use the engine

oil more intensely.

These severe conditions are:

› fuel containing sulphur;

› frequent short trips;

› longer idling mode of the engine (e.g. taxi vehicles);

› operation in areas with heavy dust pollution;

› frequent trailer towing;

›

predominantly stop-and-go traffic as tends to occur in city driving, for example;

› operation predominantly during winter.

A service adviser at the specialist garage will tell you whether your vehicle's oper- ating conditions make it necessary for such work to be carried out between the

normal service intervals.

Different service charges may apply, depending on the scope of necessary works

as well as the model, features and condition of your vehicle.

Note

■ The customer is responsible for covering the cost of all services including

changing or replenishing the operating fluid, even during the warranty period, un-

less the ŠKODA AUTO a.s. warranty terms or other agreements state otherwise.■

You will be informed about the scope of the service with regard to a particular

service event by the specialist garage.

Overview of service intervals

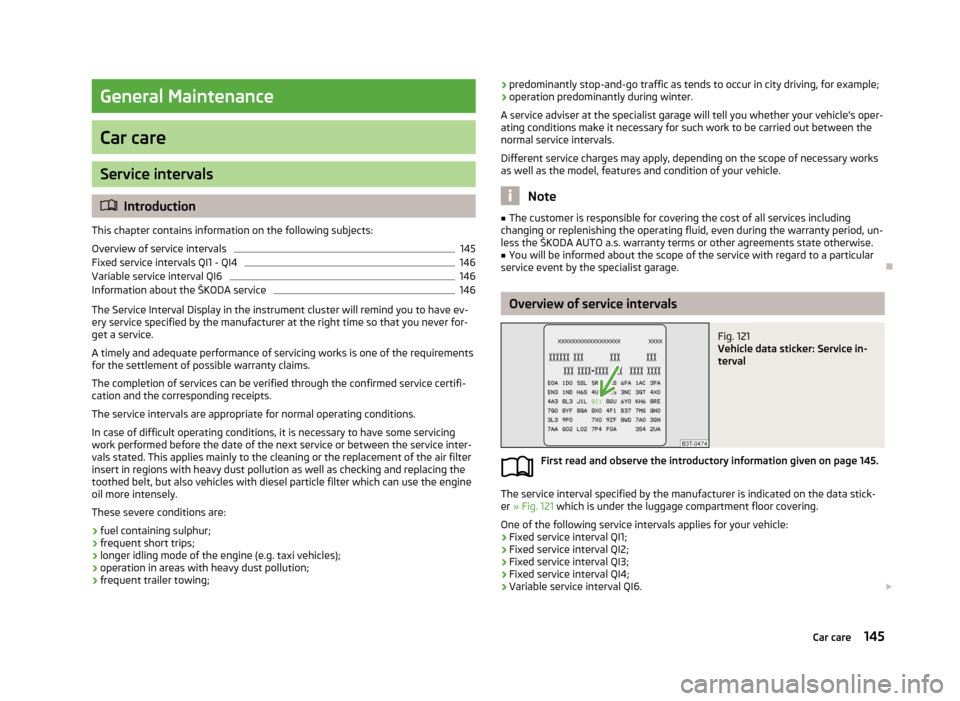

Fig. 121

Vehicle data sticker: Service in-

terval

First read and observe the introductory information given on page 145.

The service interval specified by the manufacturer is indicated on the data stick-

er » Fig. 121 which is under the luggage compartment floor covering.

One of the following service intervals applies for your vehicle: › Fixed service interval QI1;

› Fixed service interval QI2;

› Fixed service interval QI3;

› Fixed service interval QI4;

› Variable service interval QI6.

145Car care

Page 169 of 223

The oil level must be checked at regular intervals. We recommend it be checked

after each time you refuel or prior to making a long journey.

We recommend maintaining the oil level within the range A

, but not above , if

the engine has been operating at high loads, for example, during a lengthy motor-

way trip during the summer months, towing a trailer or negotiating a high moun- tain pass.

The warning light in the instrument cluster will indicate whether the oil level is too low » page 21 , Engine oil . Check the oil level using the dipstick as soon

as possible. Add oil accordingly.

CAUTION

■ Always check the oil level on vehicles with the 1.2 l/44 kW engine when the en-

gine is cold. Otherwise the measuring result is incorrect und oil could be incor-

rectly replenished - risk of engine damage!■

The oil level must never be above the

A

range » Fig. 127 – there is a risk of

damaging the exhaust system.

Note

Engine oil specifications » page 164.

Replenishing

First read and observe the introductory information and safety warn-

ings

on page 164.

›

Check the oil level » page 165.

›

Unscrew the cap of the engine oil filler opening.

›

Replenish the oil in portions of 0.5 litres in accordance with the correct specifi-

cations » page 164 .

›

Check the oil level » page 165.

›

Carefully screw on the oil filler opening cap and push the dipstick in fully.

Changing

First read and observe the introductory information and safety warn-ings

on page 164.

The engine oil must be changed at specified service intervals » page 145 or ac-

cording to the service interval display » page 16, Service Interval Display .

Coolant

Introduction

This chapter contains information on the following subjects:

Capacity

167

Checking the coolant level

167

Replenishing

168

The coolant consists of water with a concentration of coolant additive. This mix-

ture guarantees antifreeze protection, protects the cooling/heater system

against corrosion and prevents the formation of scale.

Vehicles exported to countries with a mild climate are already factory-filled with

a coolant which offers antifreeze protection down to about -25 ℃. In these coun-

tries the concentration of coolant additive should be at least 40 %.

Vehicles exported to countries with a cold climate are already factory-filled with a

coolant which offers antifreeze protection down to about -35 °C. In these coun-

tries the concentration of coolant additive should be at least 50 %.

If a higher concentration of antifreeze is required for climatic reasons, the amount

of coolant additive can only be increased up to a maximum of 60 % (antifreeze

protection down to approx. -40 °C).

When refilling, only use the same antifreeze identified on the coolant expansion vessel » Fig. 128 on page 167.

166General Maintenance

Page 179 of 223

530 kg

545 kg

615 kg

630 kg

650 kg

Speed symbol

This indicates the maximum permissible speed for a vehicle fitted with tyres in

the category concerned.

170 km/h

180 km/h

190 km/h

200 km/h

210 km/h

240 km/h

270 km/h

CAUTION

The information about the load index and the speed symbol for your vehicle are

listed in your vehicle documents.

Unidirectional tyres

First read and observe the introductory information and safety warn-

ings

on page 173.

The direction of rotation of the tyres is marked by arrows on the wall of the tyre.

The direction of rotation indicated must be complied with to obtain the best ben- efits from the characteristics of these tyres.

These characteristics are principally the following.

› Increased driving stability.

› Reduced risk of aquaplaning.

› Reduced tyre noise and reduced tyre wear.

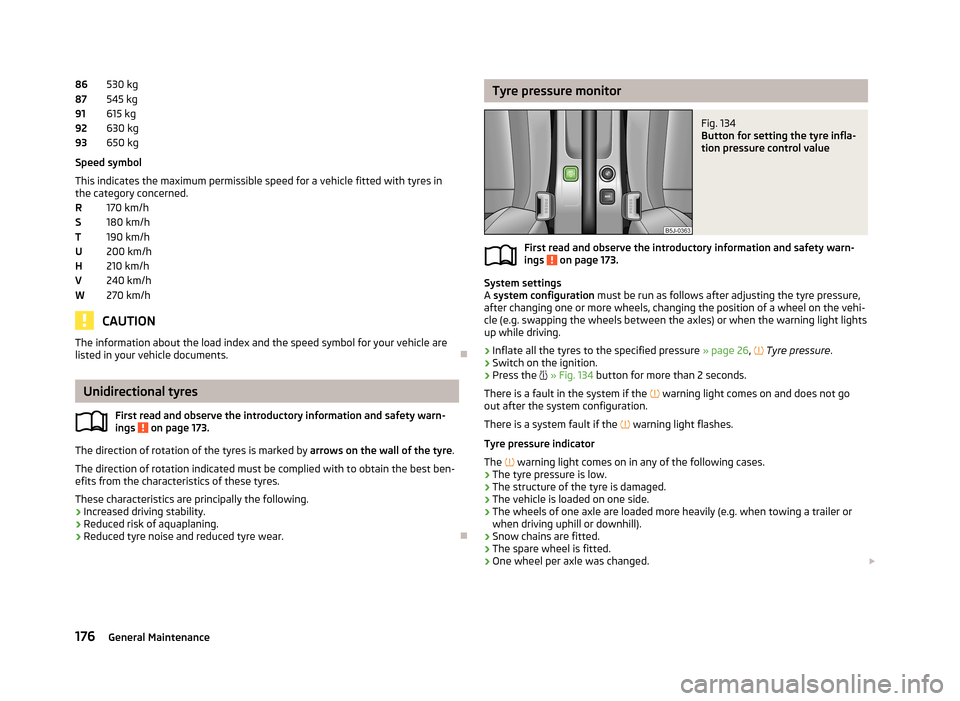

8687919293RSTUHVWTyre pressure monitorFig. 134

Button for setting the tyre infla-

tion pressure control value

First read and observe the introductory information and safety warn-

ings on page 173.

System settings

A system configuration must be run as follows after adjusting the tyre pressure,

after changing one or more wheels, changing the position of a wheel on the vehi- cle (e.g. swapping the wheels between the axles) or when the warning light lights

up while driving.

›

Inflate all the tyres to the specified pressure » page 26,

Tyre pressure .

›

Switch on the ignition.

›

Press the

» Fig. 134 button for more than 2 seconds.

There is a fault in the system if the

warning light comes on and does not go

out after the system configuration.

There is a system fault if the

warning light flashes.

Tyre pressure indicator

The

warning light comes on in any of the following cases.

› The tyre pressure is low.

› The structure of the tyre is damaged.

› The vehicle is loaded on one side.

› The wheels of one axle are loaded more heavily (e.g. when towing a trailer or

when driving uphill or downhill).

› Snow chains are fitted.

› The spare wheel is fitted.

› One wheel per axle was changed.

176General Maintenance

Page 184 of 223

Note■The fire extinguisher must comply with national legal requirements.■Pay attention to the expiration date of the fire extinguisher. Proper functioning

of the fire extinguisher is not assured once it has passed its expiry date.■

The fire extinguisher is part of the scope of delivery in certain countries only.

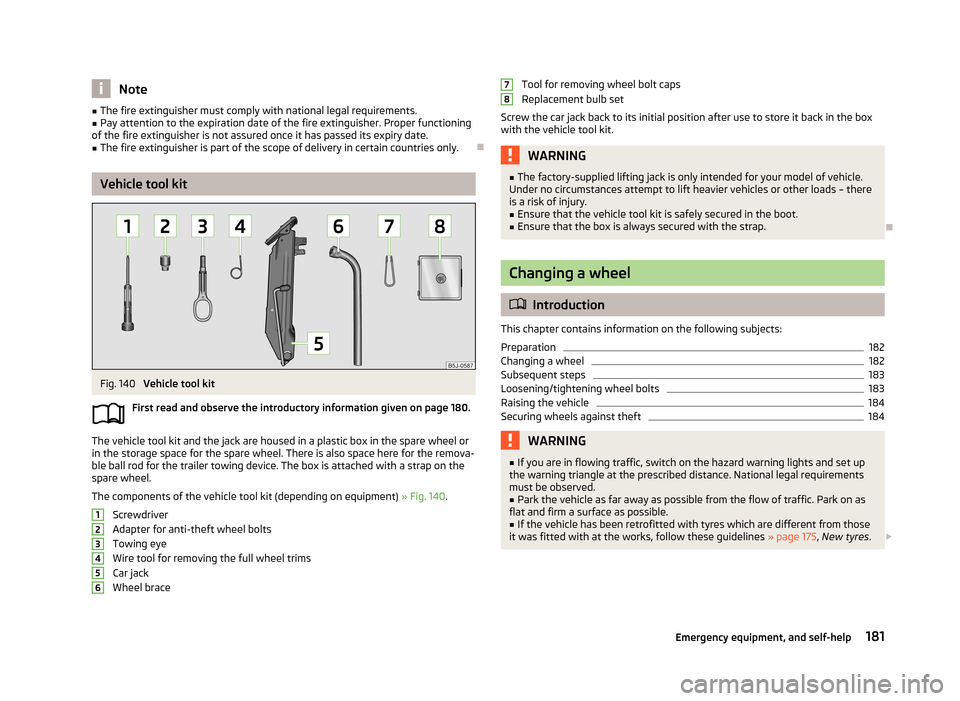

Vehicle tool kit

Fig. 140

Vehicle tool kit

First read and observe the introductory information given on page 180.

The vehicle tool kit and the jack are housed in a plastic box in the spare wheel or

in the storage space for the spare wheel. There is also space here for the remova-

ble ball rod for the trailer towing device. The box is attached with a strap on the spare wheel.

The components of the vehicle tool kit (depending on equipment) » Fig. 140.

Screwdriver

Adapter for anti-theft wheel bolts

Towing eye

Wire tool for removing the full wheel trims

Car jack

Wheel brace

123456Tool for removing wheel bolt caps

Replacement bulb set

Screw the car jack back to its initial position after use to store it back in the box with the vehicle tool kit.WARNING■ The factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances attempt to lift heavier vehicles or other loads – there

is a risk of injury.■

Ensure that the vehicle tool kit is safely secured in the boot.

■

Ensure that the box is always secured with the strap.

Changing a wheel

Introduction

This chapter contains information on the following subjects:

Preparation

182

Changing a wheel

182

Subsequent steps

183

Loosening/tightening wheel bolts

183

Raising the vehicle

184

Securing wheels against theft

184WARNING■ If you are in flowing traffic, switch on the hazard warning lights and set up

the warning triangle at the prescribed distance. National legal requirements

must be observed.■

Park the vehicle as far away as possible from the flow of traffic. Park on as

flat and firm a surface as possible.

■

If the vehicle has been retrofitted with tyres which are different from those

it was fitted with at the works, follow these guidelines » page 175, New tyres .

78181Emergency equipment, and self-help

Page 185 of 223

WARNINGObserve the following instructions for raising the vehicle.■If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpectedly

rolling away.■

Secure the base plate of the lifting jack with suitable means to prevent pos-

sible moving. A soft and slippery ground under the base plate may move the

lifting jack, causing the vehicle to fall down. It is therefore always necessary to

place the lifting jack on a solid surface or use a wide and stable base. Use a

non-slip base (e.g. a rubber foot mat) if the surface is smooth, such as cobbled

stones, tiled floor, etc.

■

Only attach the lifting jack to the attachment points provided for this pur-

pose.

■

Always raise the vehicle with the doors closed.

■

Never position any body parts, such as arms or legs under the vehicle, while

the vehicle is raised with a lifting jack.

■

Never start the engine with the vehicle sitting on the raised jack – there is a

risk of injury.

CAUTION

■ The tightening torque specified for the wheel bolts for steel and light alloy

wheels is 120 Nm.■

If the wheel bolts are fastened too tightly, this can cause damage to the anti-

theft wheel bolt or the adapter.

Note

■ The anti-theft wheel bolt set and adapter can be purchased from a ŠKODA Part-

ner.■

The national legal requirements must be observed when changing a wheel.

Preparation

First read and observe the introductory information and safety warn-

ings

on page 181.

Always change a wheel on a level surface as far as possible.

The following steps must be carried out before actually changing the wheel:

› Have

all the occupants get out. The passengers should not stand on the road

(instead they should remain behind a crash barrier, for instance) while the wheel is being changed.›

Switch off the engine.

›

Move the gearshift lever into Neutral or move the selector lever for the auto-

matic gearbox into position P.

›

Apply the handbrake firmly.

›

Uncouple any trailer.

›

Remove the vehicle tool kit » page 181 and the spare wheel » page 177 , Spare

wheel from the boot.

Changing a wheel

First read and observe the introductory information and safety warn-

ings

on page 181.

›

Remove the full wheel trim » page 178 or caps » page 178 .

›

In the case of light alloy wheel rims remove the wheel trim cap » page 178.

›

First of all slacken the anti-theft wheel bolt and then the other wheel

bolts » page 183 .

›

Jack up the vehicle until the wheel that needs changing is clear of the

ground » page 184 .

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper, etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Tighten the opposite wheel bolts alternately (cross-wise) with the wheel

wrench. Tighten the anti-theft wheel bolt last » page 183.

›

Reinstall the wheel trim/wheel trim cap or the caps.

Note

■

All bolts must be clean and must turn easily.■Under no circumstances grease or oil the wheel bolts!■

When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect » page 176 , Unidirectional tyres .

182Do-it-yourself

Page 189 of 223

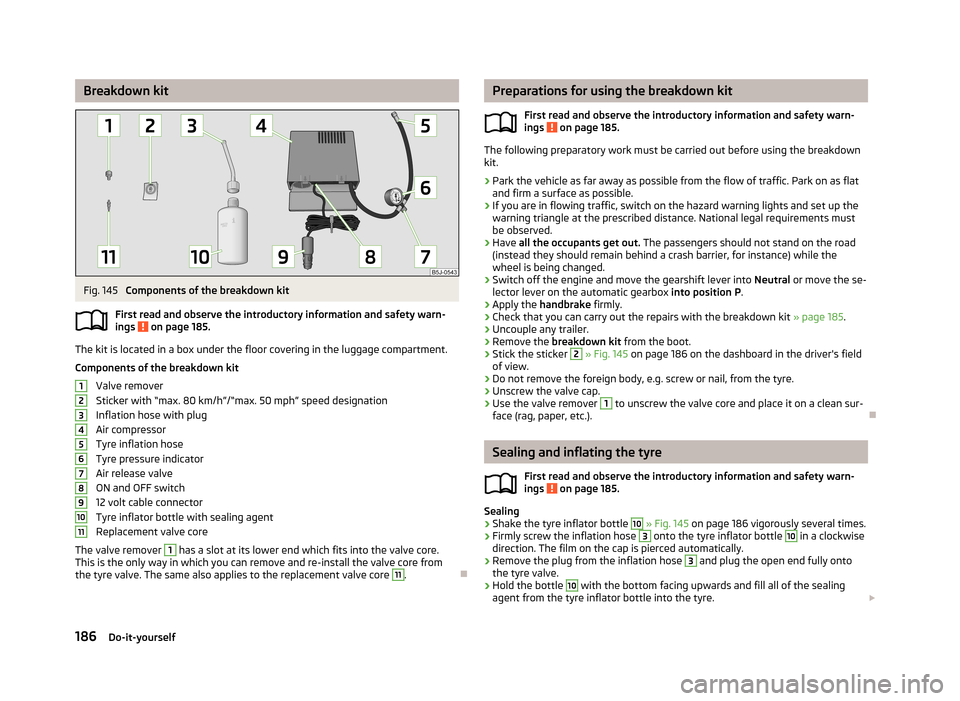

Breakdown kitFig. 145

Components of the breakdown kit

First read and observe the introductory information and safety warn-

ings

on page 185.

The kit is located in a box under the floor covering in the luggage compartment.

Components of the breakdown kit Valve remover

Sticker with “max. 80 km/h”/“max. 50 mph” speed designation

Inflation hose with plug

Air compressor

Tyre inflation hose

Tyre pressure indicator

Air release valve

ON and OFF switch

12 volt cable connector

Tyre inflator bottle with sealing agent

Replacement valve core

The valve remover

1

has a slot at its lower end which fits into the valve core.

This is the only way in which you can remove and re-install the valve core from

the tyre valve. The same also applies to the replacement valve core

11

.

1234567891011Preparations for using the breakdown kit

First read and observe the introductory information and safety warn-

ings

on page 185.

The following preparatory work must be carried out before using the breakdown

kit.

›

Park the vehicle as far away as possible from the flow of traffic. Park on as flat and firm a surface as possible.

›

If you are in flowing traffic, switch on the hazard warning lights and set up thewarning triangle at the prescribed distance. National legal requirements must

be observed.

›

Have all the occupants get out. The passengers should not stand on the road

(instead they should remain behind a crash barrier, for instance) while the wheel is being changed.

›

Switch off the engine and move the gearshift lever into Neutral or move the se-

lector lever on the automatic gearbox into position P.

›

Apply the handbrake firmly.

›

Check that you can carry out the repairs with the breakdown kit » page 185.

›

Uncouple any trailer.

›

Remove the breakdown kit from the boot.

›

Stick the sticker

2

» Fig. 145 on page 186 on the dashboard in the driver's field

of view.

›

Do not remove the foreign body, e.g. screw or nail, from the tyre.

›

Unscrew the valve cap.

›

Use the valve remover

1

to unscrew the valve core and place it on a clean sur-

face (rag, paper, etc.).

Sealing and inflating the tyre

First read and observe the introductory information and safety warn-

ings

on page 185.

Sealing

›

Shake the tyre inflator bottle

10

» Fig. 145 on page 186 vigorously several times.

›

Firmly screw the inflation hose

3

onto the tyre inflator bottle

10

in a clockwise

direction. The film on the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and plug the open end fully onto

the tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

186Do-it-yourself

Page 192 of 223

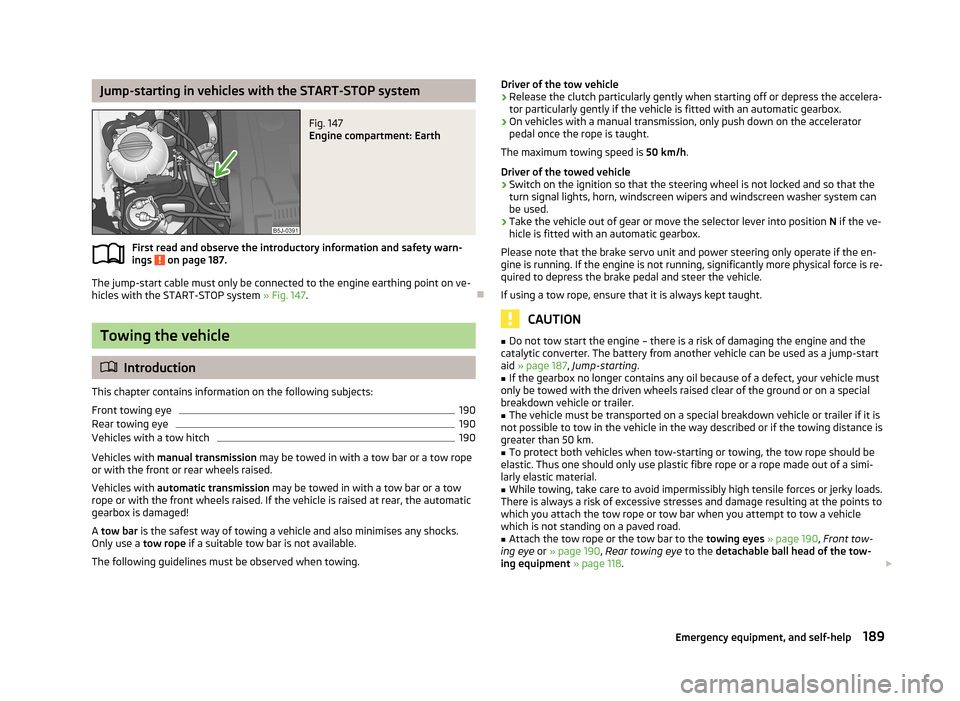

Jump-starting in vehicles with the START-STOP systemFig. 147

Engine compartment: Earth

First read and observe the introductory information and safety warn-ings on page 187.

The jump-start cable must only be connected to the engine earthing point on ve-

hicles with the START-STOP system » Fig. 147.

Towing the vehicle

Introduction

This chapter contains information on the following subjects:

Front towing eye

190

Rear towing eye

190

Vehicles with a tow hitch

190

Vehicles with manual transmission may be towed in with a tow bar or a tow rope

or with the front or rear wheels raised.

Vehicles with automatic transmission may be towed in with a tow bar or a tow

rope or with the front wheels raised. If the vehicle is raised at rear, the automatic

gearbox is damaged!

A tow bar is the safest way of towing a vehicle and also minimises any shocks.

Only use a tow rope if a suitable tow bar is not available.

The following guidelines must be observed when towing.

Driver of the tow vehicle›Release the clutch particularly gently when starting off or depress the accelera-

tor particularly gently if the vehicle is fitted with an automatic gearbox.›

On vehicles with a manual transmission, only push down on the accelerator pedal once the rope is taught.

The maximum towing speed is 50 km/h.

Driver of the towed vehicle

›

Switch on the ignition so that the steering wheel is not locked and so that the turn signal lights, horn, windscreen wipers and windscreen washer system can

be used.

›

Take the vehicle out of gear or move the selector lever into position N if the ve-

hicle is fitted with an automatic gearbox.

Please note that the brake servo unit and power steering only operate if the en-

gine is running. If the engine is not running, significantly more physical force is re-

quired to depress the brake pedal and steer the vehicle.

If using a tow rope, ensure that it is always kept taught.

CAUTION

■ Do not tow start the engine – there is a risk of damaging the engine and the

catalytic converter. The battery from another vehicle can be used as a jump-start

aid » page 187 , Jump-starting .■

If the gearbox no longer contains any oil because of a defect, your vehicle must

only be towed with the driven wheels raised clear of the ground or on a special

breakdown vehicle or trailer.

■

The vehicle must be transported on a special breakdown vehicle or trailer if it is

not possible to tow in the vehicle in the way described or if the towing distance is

greater than 50 km.

■

To protect both vehicles when tow-starting or towing, the tow rope should be

elastic. Thus one should only use plastic fibre rope or a rope made out of a simi-

larly elastic material.

■

While towing, take care to avoid impermissibly high tensile forces or jerky loads.

There is always a risk of excessive stresses and damage resulting at the points to

which you attach the tow rope or tow bar when you attempt to tow a vehicle

which is not standing on a paved road.

■

Attach the tow rope or the tow bar to the towing eyes » page 190 , Front tow-

ing eye or » page 190 , Rear towing eye to the detachable ball head of the tow-

ing equipment » page 118 .

189Emergency equipment, and self-help

Page 193 of 223

Note■We recommend using a tow rope from ŠKODA Original Accessories available

from a ŠKODA Partner.■

Towing another vehicle requires a certain amount of practice. Both drivers

should be familiar with the particular points about towing a vehicle. Unskilled

drivers should not attempt to tow in another vehicle or to be towed in.

■

When towing, respect the national legal provisions, especially those which re-

late to the identification of the towing vehicle and the vehicle being towed.

■

The tow rope must not be twisted as it may in certain circumstances result in

the front towing eye being unscrewed out of your vehicle.

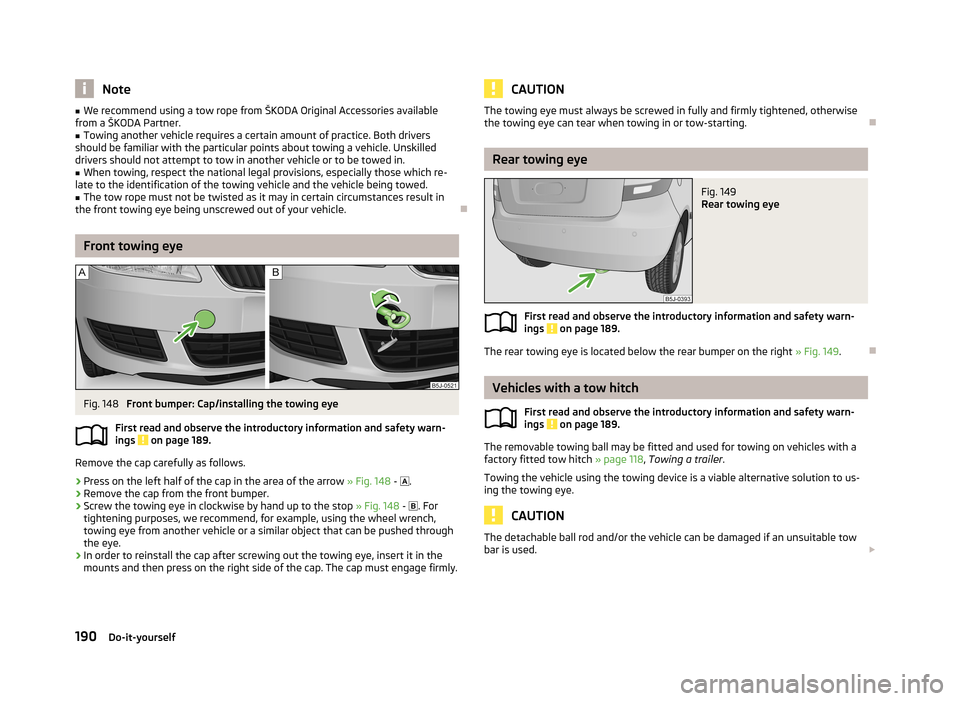

Front towing eye

Fig. 148

Front bumper: Cap/installing the towing eye

First read and observe the introductory information and safety warn- ings

on page 189.

Remove the cap carefully as follows.

›

Press on the left half of the cap in the area of the arrow » Fig. 148 -

.

›

Remove the cap from the front bumper.

›

Screw the towing eye in clockwise by hand up to the stop » Fig. 148 -

. For

tightening purposes, we recommend, for example, using the wheel wrench, towing eye from another vehicle or a similar object that can be pushed through

the eye.

›

In order to reinstall the cap after screwing out the towing eye, insert it in the

mounts and then press on the right side of the cap. The cap must engage firmly.

CAUTIONThe towing eye must always be screwed in fully and firmly tightened, otherwise

the towing eye can tear when towing in or tow-starting.

Rear towing eye

Fig. 149

Rear towing eye

First read and observe the introductory information and safety warn-

ings on page 189.

The rear towing eye is located below the rear bumper on the right » Fig. 149.

Vehicles with a tow hitch

First read and observe the introductory information and safety warn-

ings

on page 189.

The removable towing ball may be fitted and used for towing on vehicles with a

factory fitted tow hitch » page 118, Towing a trailer .

Towing the vehicle using the towing device is a viable alternative solution to us-

ing the towing eye.

CAUTION

The detachable ball rod and/or the vehicle can be damaged if an unsuitable tow bar is used. 190Do-it-yourself

Page 196 of 223

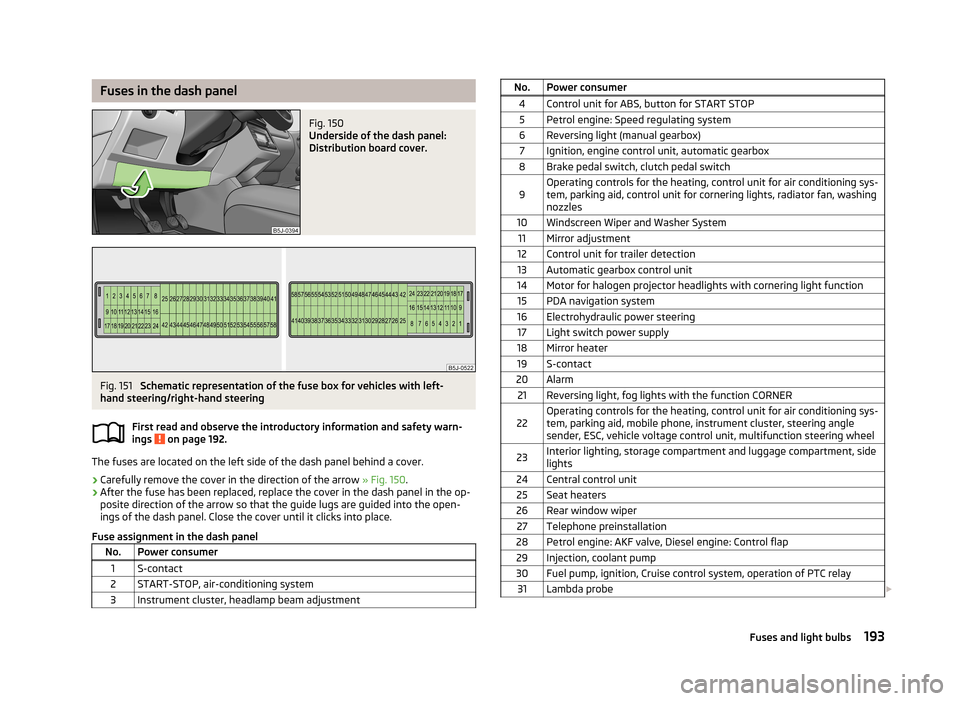

Fuses in the dash panelFig. 150

Underside of the dash panel:

Distribution board cover.

Fig. 151

Schematic representation of the fuse box for vehicles with left-

hand steering/right-hand steering

First read and observe the introductory information and safety warn-

ings

on page 192.

The fuses are located on the left side of the dash panel behind a cover.

› Carefully remove the cover in the direction of the arrow

» Fig. 150.

› After the fuse has been replaced, replace the cover in the dash panel in the op-

posite direction of the arrow so that the guide lugs are guided into the open- ings of the dash panel. Close the cover until it clicks into place.

Fuse assignment in the dash panel

No.Power consumer1S-contact2START-STOP, air-conditioning system3Instrument cluster, headlamp beam adjustmentNo.Power consumer4Control unit for ABS, button for START STOP5Petrol engine: Speed regulating system6Reversing light (manual gearbox)7Ignition, engine control unit, automatic gearbox8Brake pedal switch, clutch pedal switch9Operating controls for the heating, control unit for air conditioning sys-

tem, parking aid, control unit for cornering lights, radiator fan, washing nozzles10Windscreen Wiper and Washer System11Mirror adjustment12Control unit for trailer detection13Automatic gearbox control unit14Motor for halogen projector headlights with cornering light function15PDA navigation system16Electrohydraulic power steering17Light switch power supply18Mirror heater19S-contact20Alarm21Reversing light, fog lights with the function CORNER22Operating controls for the heating, control unit for air conditioning sys-

tem, parking aid, mobile phone, instrument cluster, steering angle

sender, ESC, vehicle voltage control unit, multifunction steering wheel23Interior lighting, storage compartment and luggage compartment, side

lights24Central control unit25Seat heaters26Rear window wiper27Telephone preinstallation28Petrol engine: AKF valve, Diesel engine: Control flap29Injection, coolant pump30Fuel pump, ignition, Cruise control system, operation of PTC relay31Lambda probe 193Fuses and light bulbs