abs SKODA OCTAVIA 2006 Owner´s Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2006, Model line: OCTAVIA, Model: SKODA OCTAVIA 2006Pages: 218, PDF Size: 5.48 MB

Page 148 of 218

Immediately reduce your speed as soon as even the slightest swaying of the trail-

er is detected. Never attempt to stop the trailer from “swaying” by accelerating.

Brakes

Apply the brakes in good time! If the trailer is fitted with a trailer brake, apply the

brakes gently at first, then brake firmly. This will avoid brake jolts resulting from

the trailer wheels locking. On downhill sections shift down a gear in good time to

also use the engine as a brake.

Trailer stabilisation

The trailer stabilisation is an extension of the stabilisation control that works in

conjunction with the counter-steering assistance to reduce the amount the trail-

er "sways". After turning on the ignition, the ESC warning light in the instru-

ment cluster lights up for about 2 seconds longer than the ABS warning light.

Prerequisites for stabilising the trailer.

› The towing device is factory-fitted or a compatible towing device has been ret-

rofitted.

› The ESC is active. The warning light

or in the instrument cluster is not illu-

minated.

› The trailer is electrically connected to the towing vehicle by means of the trailer

socket.

› The speed is higher than approx. 60 km/h.

› Trailers must have a fixed drawbar.

› The ESC works for both braked and unbraked trailers.

Trailer is connected to the anti-theft alarm system. › If the vehicle is factory-fitted with an anti-theft alarm system and a towing de-

vice.

› If the trailer is electrically connected to the towing vehicle by means of the trail-

er socket.

› If the electrical system of the vehicle and trailer is fully functional.

› If the vehicle is locked with the car key and the anti-theft alarm system is acti-

vated.

When the vehicle is locked, the alarm is activated as soon as the electrical con-

nection to the trailer is interrupted.

Always deactivate the anti-theft alarm system before a trailer is connected/dis-

connected. Otherwise, the anti-theft alarm system could accidentally be trig-

gered » page 31 , Anti-theft alarm system . Engine overheating

If the needle for the coolant temperature gauge moves into the right-hand area

or the red area of the scale, the speed must be reduced immediately. Stop and

switch off the engine if the warning light

in the instrument cluster starts to

flash. Wait a few minutes and check the level of coolant in the coolant expansion

bottle » page 163, Checking the coolant level .

The following guidelines must be observed » page 20, Coolant temperature/cool-

ant level .

The coolant temperature can be reduced by switching on the heating. WARNING

■ The increased safety offered by the trailer stabilisation must not tempt you

to take greater risks than otherwise. ■ Adapt your speed to the conditions of the road surface and to the traffic sit-

uation.

■ Improper or incorrectly connected electric cables can energise the trailer and

cause functional faults to the vehicle's entire electrical system as well as acci-

dents and severe injuries.

■ Any work on the electrical system must be carried out only by ŠKODA spe-

cialist garages.

■ Never directly connect the trailer's electrical system with the electrical con-

nections for the tail lights or other current sources. CAUTION

■ The trailer stabilisation need not be able to correctly detect all of driving situa-

tions.

■ Trailers that sway slightly are not always detected by the trailer stabilisation

and thus are not stabilised accordingly.

■ Release the pressure on the accelerator pedal if the system is being regulated.

■ Avoid abrupt and sudden driving/braking manoeuvres.

■ When the ball rod is removed, the mounting shaft must be sealed with an ap-

propriate cover. This prevents foreign matter from penetrating into the mounting

shaft. See the fitting instructions for the towing device. £

146 Driving Tips

Page 155 of 218

Artificial leather and materials

First read and observe the introductory information and safety warn-

ings on page 148.

The artificial leather can be cleaned using a damp cloth. If this does not prove to

be adequate, these parts can only be treated with special

solvent-free plastic

cleaning and care products .

Clean upholstery cover materials and cloth trims on doors, boot cover, etc. using

specific cleaning agents, e.g., dry foam. Use a soft sponge, brush, or commercially

available microfibre cloth. Use a cloth and a specific cleaning agent to clean the

roof trim.

Some clothing materials, such as dark denim, do, in part, not have sufficient col-

our fastness. This can cause damage or clearly visible discolouration to seat cov-

ers (fabric or leather) even when used correctly. This particularly applies to light

seat covers (fabric or leather). This is not a defect in the seat cover, but poor col-

our fastness of the clothing textiles. ÐFabric covers on electrically heated seats

First read and observe the introductory information and safety warn-

ings on page 148.

Do not clean the seat covers

using moisture as this can damage the seat heating

system.

Use a specific cleaning agent such as dry foam or similar to clean the covers. ÐNatural leather

First read and observe the introductory information and safety warn-

ings on page 148.

Depending on the amount of wear-and-tear, the leather should be cleaned on a

regular basis.

Normal cleaning

Clean soiled areas of the leather with slightly moistened cotton or woollen cloth.

ä

ä

ä

Severe soiling

Ensure that the leather is not soaked through at any point and that no water gets

into the stitching of the seams.

Dry off the leather with a soft, dry cloth.

Removing stains

Remove fresh water-based stains (e.g., coffee, tea, juices, blood) with an absorb-

ent cloth or household cleaning paper. A specific cleaning agent is required for

dried-on stains.

Remove fresh grease-based stains (e.g. butter, mayonnaise, chocolate, etc.) with

an absorbent cloth, household cleaning paper, or use a suitable cleaner if the

stain has not yet penetrated into the surface.

Use a grease solvent for grease stains which have dried in .

Remove specific stains (e.g. ball-point pens, marker pen, nail varnish, dispersion

paint, shoe polish, etc.) with a special stain remover suitable for leather.

Leather care

Treat the leather roughly every six months with a suitable leather care product.

Apply only a small amount of the cleaning and care product.

Dry off the leather with a soft, dry cloth. CAUTION

■ Avoid leaving the vehicle for lengthy periods in bright sunlight to avoid the

leather from bleaching. If the vehicle is parked in the open for lengthy periods,

protect the leather from direct sunlight by covering it.

■ Sharp-edged objects on items of clothing such as zip fasteners, rivets, sharp-

edged belts, jewellery and pendants may leave permanent scratches or signs of

rubbing on the surface.

■ The use of a mechanical steering wheel lock may damage the leather surface of

the steering wheel. Note

■ Use a care cream with light blocker and impregnation effect on a regular basis

and each time after cleaning. The cream nourishes the leather, allows it to

breathe and keeps it supple and also provides moisture. It also creates surface

protection. ■ Clean the leather every 2 to 3 months, remove any fresh stains as they occur. £

153

Taking care of and cleaning the vehicle

Page 166 of 218

Radiator fan

First read and observe the introductory information and safety warn-

ings on page 158.

The radiator fan is driven by an electric motor and controlled according to the

coolant temperature.

After switching off the ignition, the radiator fan can intermittently continue to op-

erate for approx. 10 minutes.

ÐChecking the brake fluid

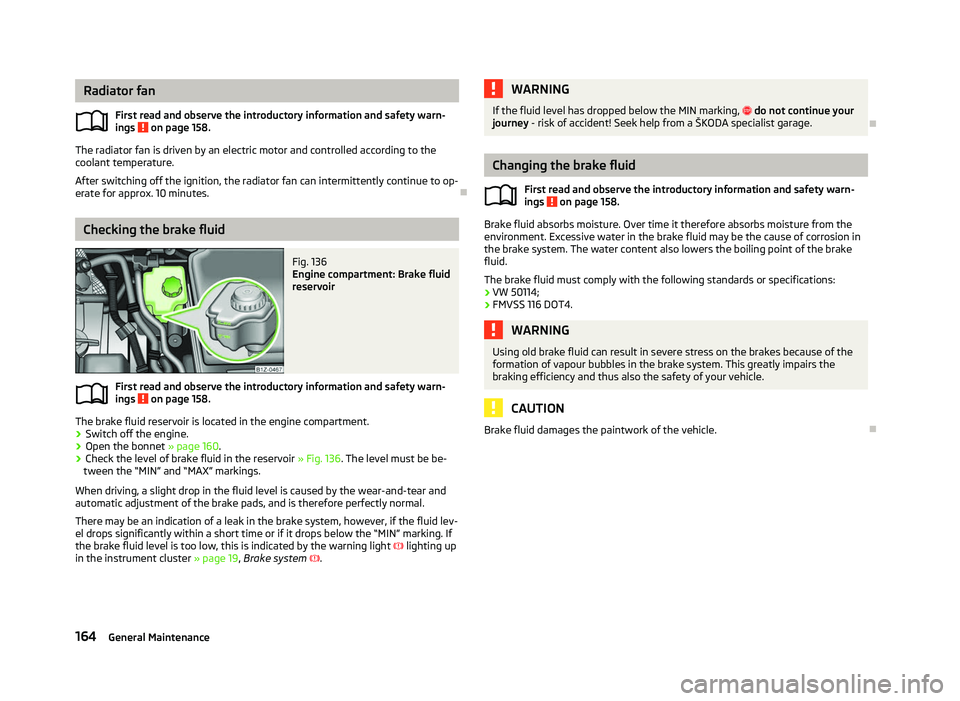

Fig. 136

Engine compartment: Brake fluid

reservoir

First read and observe the introductory information and safety warn-

ings on page 158.

The brake fluid reservoir is located in the engine compartment.

›

Switch off the engine.

› Open the bonnet

» page 160.

› Check the level of brake fluid in the reservoir

» Fig. 136. The level must be be-

tween the “MIN” and “MAX” markings.

When driving, a slight drop in the fluid level is caused by the wear-and-tear and

automatic adjustment of the brake pads, and is therefore perfectly normal.

There may be an indication of a leak in the brake system, however, if the fluid lev-

el drops significantly within a short time or if it drops below the “MIN” marking. If

the brake fluid level is too low, this is indicated by the warning light lighting up

in the instrument cluster » page 19, Brake system .

ä

ä WARNING

If the fluid level has dropped below the MIN marking, do not continue your

journey - risk of accident! Seek help from a

ŠKODA specialist garage.Ð Changing the brake fluid

First read and observe the introductory information and safety warn-

ings on page 158.

Brake fluid absorbs moisture. Over time it therefore absorbs moisture from the

environment. Excessive water in the brake fluid may be the cause of corrosion in

the brake system. The water content also lowers the boiling point of the brake

fluid.

The brake fluid must comply with the following standards or specifications:

› VW 50114;

› FMVSS 116 DOT4. WARNING

Using old brake fluid can result in severe stress on the brakes because of the

formation of vapour bubbles in the brake system. This greatly impairs the

braking efficiency and thus also the safety of your vehicle. CAUTION

Brake fluid damages the paintwork of the vehicle. Ð

ä

164 General Maintenance

Page 175 of 218

Unidirectional tyres

First read and observe the introductory information and safety warn-

ings on page 170.

The direction of rotation of the tyres is marked by arrows on the wall of the tyre

.

The so specified running direction must absolutely be complied with. Only then

are the tyres able to provide the optimal properties in terms of grip, low noise,

wear-and-tear and aquaplaning.

If, in the event of a puncture, it is necessary to fit a spare wheel with a tyre with-

out a dedicated running direction or the opposite running direction, drive carefully

as the optimum characteristics of the tyre are no longer applicable in this situa-

tion. ÐSpare wheel

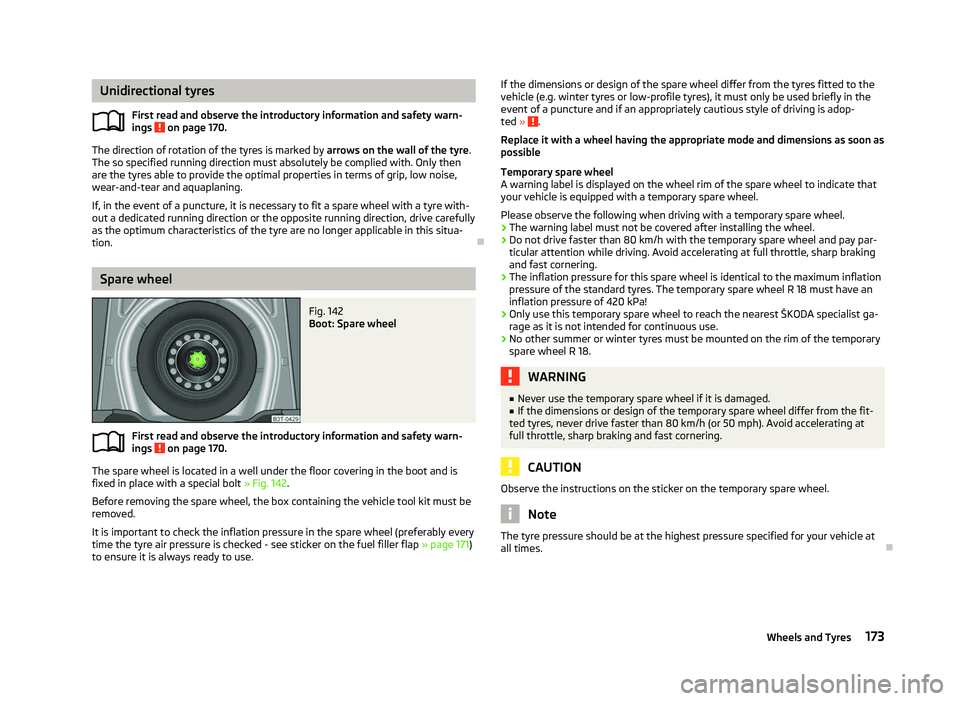

Fig. 142

Boot: Spare wheel

First read and observe the introductory information and safety warn-

ings on page 170.

The spare wheel is located in a well under the floor covering in the boot and is

fixed in place with a special bolt

» Fig. 142.

Before removing the spare wheel, the box containing the vehicle tool kit must be

removed.

It is important to check the inflation pressure in the spare wheel (preferably every

time the tyre air pressure is checked - see sticker on the fuel filler flap »

page 171)

to ensure it is always ready to use.

ä

ä

If the dimensions or design of the spare wheel differ from the tyres fitted to the

vehicle (e.g. winter tyres or low-profile tyres), it must only be used briefly in the

event of a puncture and if an appropriately cautious style of driving is adop-

ted » .

Replace it with a wheel having the appropriate mode and dimensions as soon as

possible

Temporary spare wheel

A warning label is displayed on the wheel rim of the spare wheel to indicate that

your vehicle is equipped with a temporary spare wheel.

Please observe the following when driving with a temporary spare wheel.

› The warning label must not be covered after installing the wheel.

› Do not drive faster than 80

km/h with the temporary spare wheel and pay par-

ticular attention while driving. Avoid accelerating at full throttle, sharp braking

and fast cornering.

› The inflation pressure for this spare wheel is identical to the maximum inflation

pressure of the standard tyres. The temporary spare wheel R 18 must have an

inflation pressure of 420 kPa!

› Only use this temporary spare wheel to reach the nearest ŠKODA specialist ga-

rage as it is not intended for continuous use.

› No other summer or winter tyres must be mounted on the rim of the temporary

spare wheel R 18. WARNING

■ Never use the temporary spare wheel if it is damaged.

■ If the dimensions or design of the temporary spare wheel differ from the fit-

ted tyres, never drive faster than 80

km/h (or 50 mph). Avoid accelerating at

full throttle, sharp braking and fast cornering. CAUTION

Observe the instructions on the sticker on the temporary spare wheel. Note

The tyre pressure should be at the highest pressure specified for your vehicle at

all times. Ð

173

Wheels and Tyres

Page 177 of 218

Tyre control display

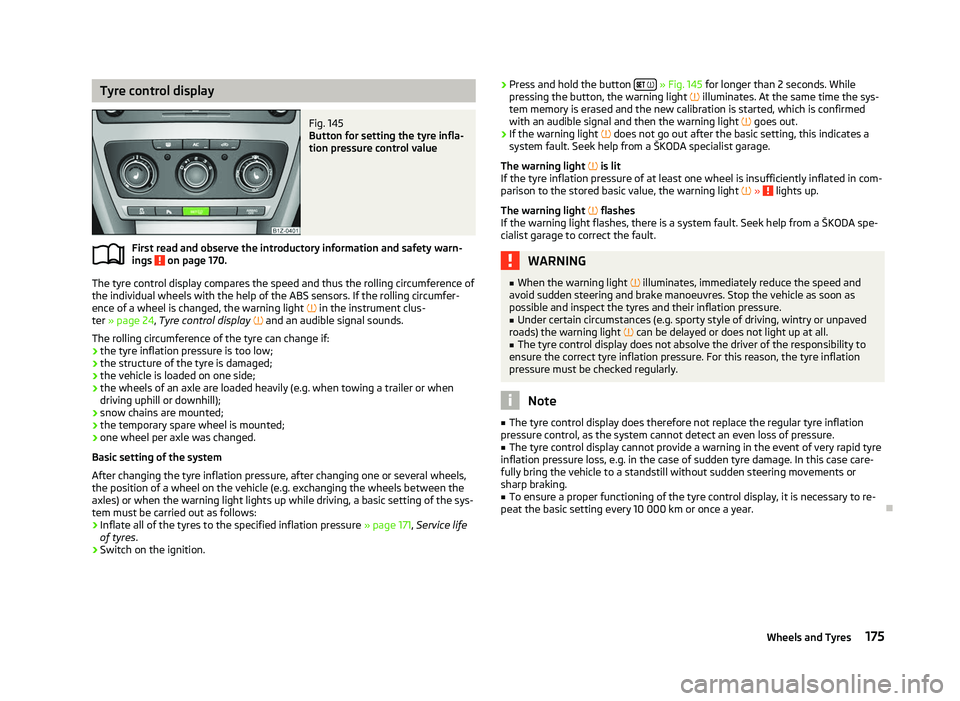

Fig. 145

Button for setting the tyre infla-

tion pressure control value

First read and observe the introductory information and safety warn-

ings on page 170.

The tyre control display compares the speed and thus the rolling circumference of

the individual wheels with the help of the ABS sensors. If the rolling circumfer-

ence of a wheel is changed, the warning light

in the instrument clus-

ter » page 24, Tyre control display and an audible signal sounds.

The rolling circumference of the tyre can change if: › the tyre inflation pressure is too low;

› the structure of the tyre is damaged;

› the vehicle is loaded on one side;

› the wheels of an axle are loaded heavily (e.g. when towing a trailer or when

driving uphill or downhill);

› snow chains are mounted;

› the temporary spare wheel is mounted;

› one wheel per axle was changed.

Basic setting of the system

After changing the tyre inflation pressure, after changing one or several wheels,

the position of a wheel on the vehicle (e.g. exchanging the wheels between the

axles) or when the warning light lights up while driving, a basic setting of the sys-

tem must be carried out as follows:

› Inflate all of the tyres to the specified inflation pressure

» page 171, Service life

of tyres .

› Switch on the ignition.

ä

›

Press and hold the button

» Fig. 145 for longer than 2

seconds. While

pressing the button, the warning light illuminates. At the same time the sys-

tem memory is erased and the new calibration is started, which is confirmed

with an audible signal and then the warning light goes out.

› If the warning light

does not go out after the basic setting, this indicates a

system fault. Seek help from a ŠKODA specialist garage.

The warning light is lit

If the tyre inflation pressure of at least one wheel is insufficiently inflated in com-

parison to the stored basic value, the warning light » lights up.

The warning light flashes

If the warning light flashes, there is a system fault. Seek help from a

ŠKODA spe-

cialist garage to correct the fault. WARNING

■ When the warning light illuminates, immediately reduce the speed and

avoid sudden steering and brake manoeuvres. Stop the vehicle as soon as

possible and inspect the tyres and their inflation pressure.

■ Under certain circumstances (e.g. sporty style of driving, wintry or unpaved

roads) the warning light can be delayed or does not light up at all.

■ The tyre control display does not absolve the driver of the responsibility to

ensure the correct tyre inflation pressure. For this reason, the tyre inflation

pressure must be checked regularly. Note

■ The tyre control display does therefore not replace the regular tyre inflation

pressure control, as the system cannot detect an even loss of pressure. ■ The tyre control display cannot provide a warning in the event of very rapid tyre

inflation pressure loss, e.g. in the case of sudden tyre damage. In this case care-

fully bring the vehicle to a standstill without sudden steering movements or

sharp braking.

■ To ensure a proper functioning of the tyre control display, it is necessary to re-

peat the basic setting every 10 000 km or once a year. Ð

175

Wheels and Tyres

Page 192 of 218

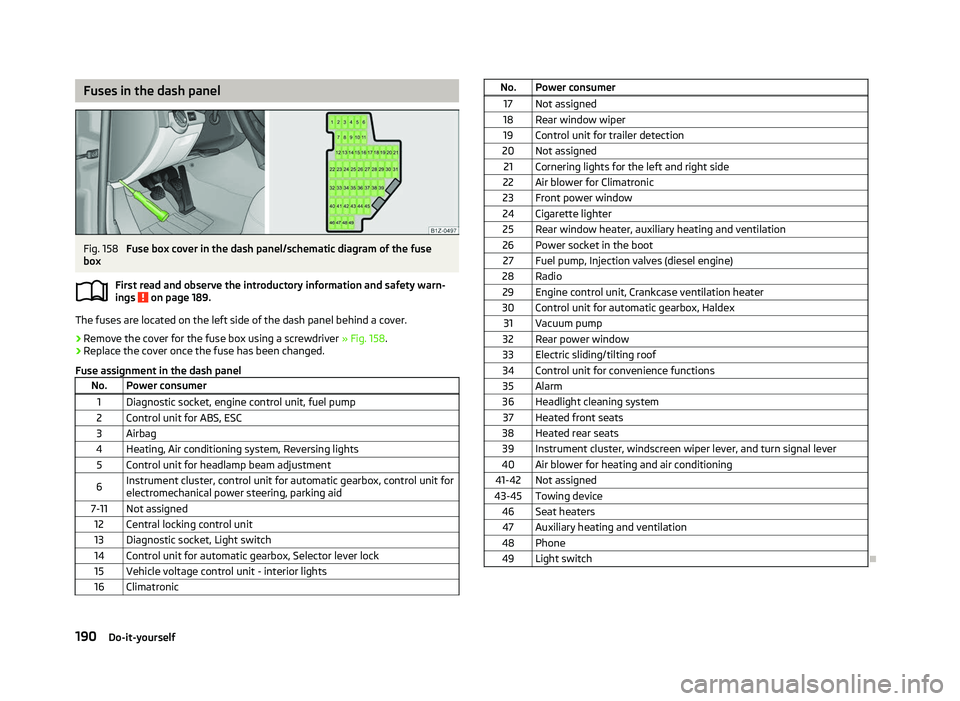

Fuses in the dash panel

Fig. 158

Fuse box cover in the dash panel/schematic diagram of the fuse

box

First read and observe the introductory information and safety warn-

ings on page 189.

The fuses are located on the left side of the dash panel behind a cover.

›

Remove the cover for the fuse box using a screwdriver

» Fig. 158.

› Replace the cover once the fuse has been changed.

Fuse assignment in the dash panel No. Power consumer

1 Diagnostic socket, engine control unit, fuel pump

2 Control unit for ABS, ESC

3 Airbag

4 Heating, Air conditioning system, Reversing lights 5 Control unit for headlamp beam adjustment

6 Instrument cluster, control unit for automatic gearbox, control unit for

electromechanical power steering, parking aid

7-11 Not assigned 12 Central locking control unit

13 Diagnostic socket, Light switch

14 Control unit for automatic gearbox, Selector lever lock 15 Vehicle voltage control unit - interior lights

16 Climatronic ä

No. Power consumer

17 Not assigned

18 Rear window wiper 19 Control unit for trailer detection

20 Not assigned 21 Cornering lights for the left and right side

22 Air blower for Climatronic

23 Front power window

24 Cigarette lighter 25 Rear window heater, auxiliary heating and ventilation

26 Power socket in the boot 27 Fuel pump, Injection valves (diesel engine)

28 Radio 29 Engine control unit, Crankcase ventilation heater

30 Control unit for automatic gearbox, Haldex 31 Vacuum pump

32 Rear power window

33 Electric sliding/tilting roof

34 Control unit for convenience functions 35 Alarm

36 Headlight cleaning system 37 Heated front seats

38 Heated rear seats 39 Instrument cluster, windscreen wiper lever, and turn signal lever

40 Air blower for heating and air conditioning

41-42 Not assigned

43-45 Towing device 46 Seat heaters47 Auxiliary heating and ventilation

48 Phone 49 Light switch Ð

190 Do-it-yourself

Page 193 of 218

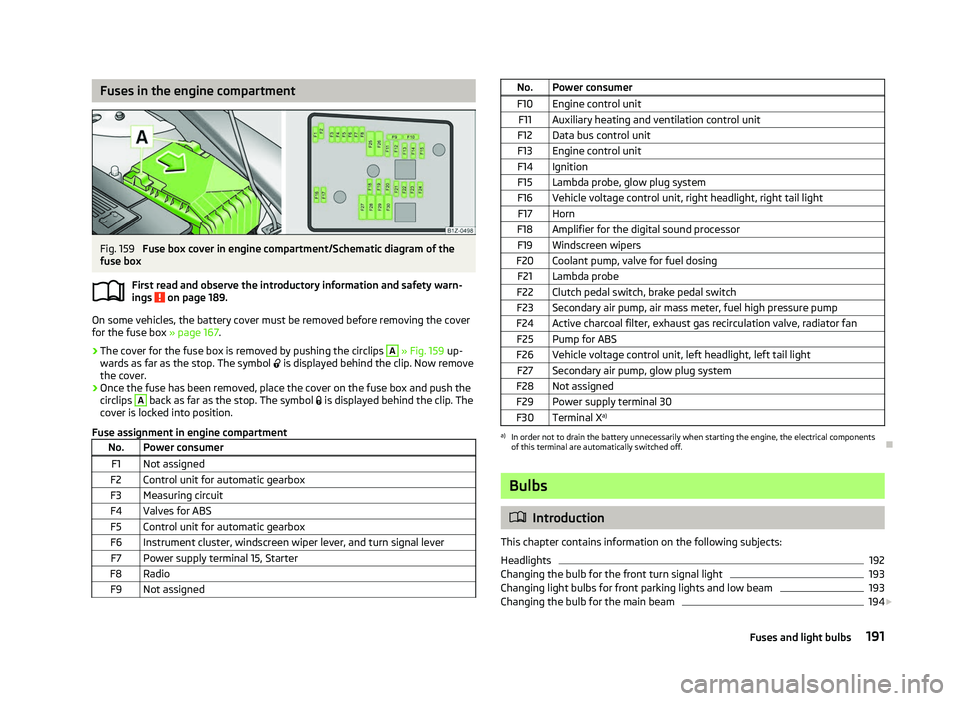

Fuses in the engine compartment

Fig. 159

Fuse box cover in engine compartment/Schematic diagram of the

fuse box

First read and observe the introductory information and safety warn-

ings on page 189.

On some vehicles, the battery cover must be removed before removing the cover

for the fuse box

» page 167.

› The cover for the fuse box is removed by pushing the circlips A

» Fig. 159

up-

wards as far as the stop. The symbol is displayed behind the clip. Now remove

the cover.

› Once the fuse has been removed, place the cover on the fuse box and push the

circlips A

back as far as the stop. The symbol

is displayed behind the clip. The

cover is locked into position.

Fuse assignment in engine compartment No. Power consumer

F1 Not assigned

F2 Control unit for automatic gearbox

F3 Measuring circuit

F4 Valves for ABS F5 Control unit for automatic gearbox

F6 Instrument cluster, windscreen wiper lever, and turn signal lever F7 Power supply terminal 15, Starter

F8 Radio F9 Not assigned ä

No. Power consumer

F10 Engine control unit F11 Auxiliary heating and ventilation control unit

F12 Data bus control unit

F13 Engine control unit

F14 Ignition F15 Lambda probe, glow plug system

F16 Vehicle voltage control unit, right headlight, right tail light F17 Horn

F18 Amplifier for the digital sound processor F19 Windscreen wipers

F20 Coolant pump, valve for fuel dosing F21 Lambda probe

F22 Clutch pedal switch, brake pedal switch

F23 Secondary air pump, air mass meter, fuel high pressure pump

F24 Active charcoal filter, exhaust gas recirculation valve, radiator fan F25 Pump for ABS

F26 Vehicle voltage control unit, left headlight, left tail light F27 Secondary air pump, glow plug system

F28 Not assigned F29 Power supply terminal 30

F30 Terminal X a) a)

In order not to drain the battery unnecessarily when starting the engine, the electrical components

of this terminal are automatically switched off. Ð Bulbs

ä

Introduction

This chapter contains information on the following subjects:

Headlights 192

Changing the bulb for the front turn signal light 193

Changing light bulbs for front parking lights and low beam 193

Changing the bulb for the main beam 194

£

191

Fuses and light bulbs

Page 210 of 218

Index

A

ABS 96

Warning light 22

Accessories 177

Active steering support 95

Adjusting Exterior mirror 52

Adjusting seats 122

Adjustment Seat 55

Aerial 149

see Radio reception 151

Airbag 129

Deployment 129

Front airbag 130

Head airbag 132

Side airbag 131

Airbag system 129

Air conditioning system Air outlet vents 80

Climatronic 85

Manual air conditioning system 82

Alarm 31

Anti-theft alarm system 31

Antilock brake system 96

Armrest Front 74

rear 60, 75

Ashtray 68

Assistance systems ESC 95

Assist systems ABS 22, 96

Cruise control systems (CCS) 99

EDS and XDS 97

ESC 22Parking aid 98

START/STOP 100

TCS 21, 96

Auto Check Control 17

Automatic driving lamp control 40

Automatic gearbox 102

Dynamic shift programme 105

Emergency programme 106

Information for driving 102

Kickdown 105

Manual shifting of gears on the multifunction steering wheel 104

Parking 103

Selector lever-emergency unlocking 106

Selector lever lock 105

Selector lever positions 103

Starting off 103

Stopping 103

Tiptronic 104

Automatic load deactivation 169

Auxiliary heating (auxiliary heating and ventila- tion) 87

Avoiding damage to your vehicle 143

B

Before setting off 121

Belt tensioners 128

Bonnet Closing 160

Opening 160

Warning light 20

Boot Class

N1 vehicles 61

Cover 63

Emergency unlocking 34

Fastening elements 61

Fixing nets 62

Fixing of the floor covering 63

foldable boot cover (Combi) 64

Light 47see Boot lid 33

Unlocking the boot lid 34

Variable loading floor 64

Boot lid 33

Automatic locking 33

Warning light 21

Brake booster 95

Brake fluid Checking 164

Brakes Brake assist systems 93

Handbrake 95

Running in 139

Warning light 19

Braking Brake fluid 164

Braking assistant 95

Breakdown kit 182

Bulbs Replacing 191

Button in the driver's door Electric power windows 34

C

Car computer see Multifunction display 12

Car jack 179

Carrier 66

Catalytic converter 139

CD changer 119

Central locking button 29

Central locking system 27

lock 29

unlock 28

Changes 177

Changing Engine oil 162

Wheel 179

Charging a vehicle battery 168

208 Index