gearbox SKODA OCTAVIA 2006 Owner´s Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2006, Model line: OCTAVIA, Model: SKODA OCTAVIA 2006Pages: 218, PDF Size: 5.48 MB

Page 146 of 218

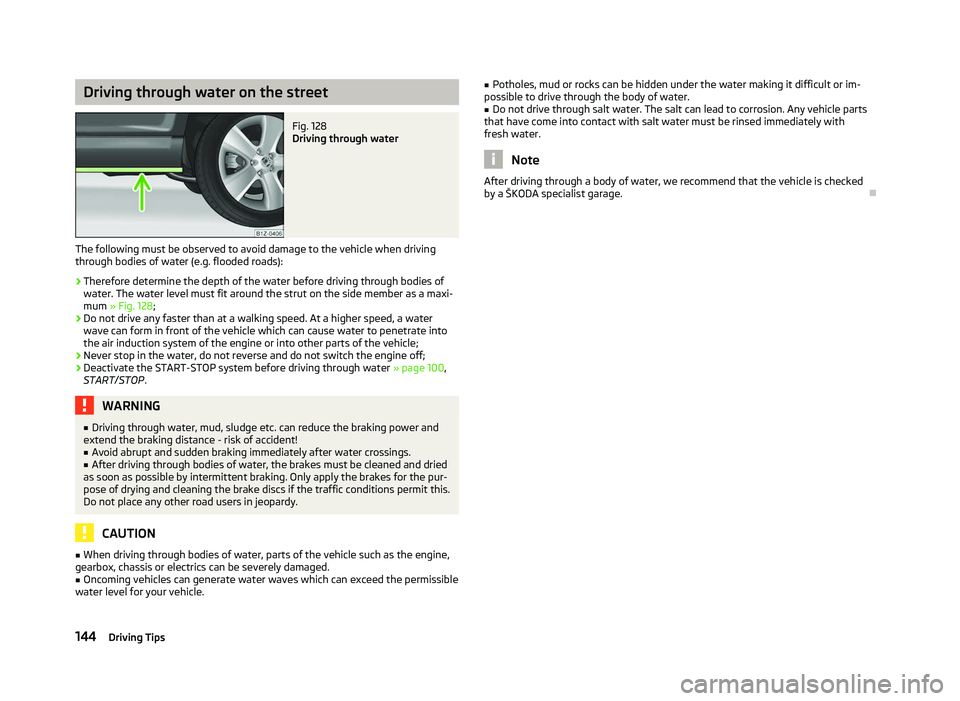

Driving through water on the street

Fig. 128

Driving through water

The following must be observed to avoid damage to the vehicle when driving

through bodies of water (e.g. flooded roads):

› Therefore determine the depth of the water before driving through bodies of

water. The water level must fit around the strut on the side member as a maxi-

mum » Fig. 128;

› Do not drive any faster than at a walking speed. At a higher speed, a water

wave can form in front of the vehicle which can cause water to penetrate into

the air induction system of the engine or into other parts of the vehicle;

› Never stop in the water, do not reverse and do not switch the engine off;

› Deactivate the START-STOP

system before driving through water » page 100,

START/STOP .WARNING

■ Driving through water, mud, sludge etc. can reduce the braking power and

extend the braking distance - risk of accident!

■ Avoid abrupt and sudden braking immediately after water crossings.

■ After driving through bodies of water, the brakes must be cleaned and dried

as soon as possible by intermittent braking. Only apply the brakes for the pur-

pose of drying and cleaning the brake discs if the traffic conditions permit this.

Do not place any other road users in jeopardy. CAUTION

■ When driving through bodies of water, parts of the vehicle such as the engine,

gearbox, chassis or electrics can be severely damaged.

■ Oncoming vehicles can generate water waves which can exceed the permissible

water level for your vehicle. ■

Potholes, mud or rocks can be hidden under the water making it difficult or im-

possible to drive through the body of water. ■ Do not drive through salt water. The salt can lead to corrosion. Any vehicle parts

that have come into contact with salt water must be rinsed immediately with

fresh water. Note

After driving through a body of water, we recommend that the vehicle is checked

by a

ŠKODA specialist garage. Ð144

Driving Tips

Page 160 of 218

Diesel fuel

First read and observe the introductory information and safety warn-

ings on page 155.

Your vehicle can only be operated with

diesel fuel, which complies with the

standard EN

590 (standard DIN 51628 in Germany, standard ÖNORM C 1590 in

Austria, GOST R 52368-2005/EN 590:2004 in Russia).

Operation in winter - Winter-grade diesel fuel

In the winter, only use diesel fuel, which complies with the standard EN 590

(standard DIN 51628 in Germany, standard ÖNORM C 1590 in Austria,

GOST R 52368-2005/EN 590:2004 in Russia). “Winter-grade diesel fuel” will still

operate properly even at a temperature of -20 °C.

It is often the case in countries with different climatic conditions that diesel fuels

available have a different temperature characteristic. The ŠKODA Service Partners

and filling stations in the relevant country will be able to provide you with infor-

mation regarding the diesel fuels available.

Preheating fuel

The vehicle is fitted with a fuel filter preheating system. This secures operation of

a vehicle using diesel fuel down to an environmental temperature of -25 °C.

Fuel additives

Fuel additives, so-called “flow improvers” (petrol and similar products) must not

be added to the diesel fuel. CAUTION

■ Just filling the tank once with diesel fuel that does not comply with the stand-

ard, can cause severe damage to parts of the engine, the fuel and exhaust sys-

tem!

■ If a different fuel other than diesel fuel, which complies to the above mentioned

standards (e.g. petrol) is used by mistake do not start the engine or switch on the

ignition! Extensive damage to engine parts can occur! We recommend that the

fuel system is cleaned by a

ŠKODA Service Partner.

■ Water which has collected in the fuel filter can cause engine faults.

■ Your vehicle is not adapted for use of biofuel (RME), therefore this fuel must not

be refuelled and driven. The use of biofuel (RME) can cause considerable damage

to parts of the engine or fuel system. Ð

ä Engine compartment

ä

Introduction

This chapter contains information on the following subjects:

Opening and closing the bonnet 160

Engine compartment overview 160

Checking the engine oil level 161

Replenishing the engine oil 161

Changing engine oil 162

Coolant 162

Checking the coolant level 163

Replenishing the coolant 163

Radiator fan 164

Checking the brake fluid 164

Changing the brake fluid 164

Windscreen washer system 165

There is a risk of injuries, scalding, accidents and fire when working in the en-

gine compartment, e.g. inspecting and replenishing oil and other fluids. For this

reason, it is essential to comply with the warning instructions stated below and

with the general applicable rules of safety. The vehicle's engine compartment is

a hazardous area . WARNING

■ Never open the bonnet if you can see steam or coolant flowing out of the

engine compartment - risk of scalding! Wait until the steam or coolant has

stopped escaping.

■ Turn off the engine and withdraw the ignition key.

■ If the vehicle is fitted with a manual gearbox, move the gearshift lever into

Neutral, or if the vehicle is fitted with an automatic gearbox, move the selec-

tor lever into position P .

■ Firmly apply the handbrake.

■ Allow the engine to cool.

■ For safety reasons, the bonnet must always be properly closed when driving.

This is why after closing the bonnet, the lock must always be checked to en-

sure it has engaged properly. £

158 General Maintenance

Page 182 of 218

WARNING (Continued)

place the lifting jack on a solid surface or use a wide and stable base. Use a

non-slip base (e.g. a rubber foot mat) if the surface is smooth, such as cobbled

stones, tiled floor, etc.

■ Never start the engine with the vehicle sitting on the raised jack - danger of

suffering injury.

■ Only attach the lifting jack to the attachment points provided for this pur-

pose. CAUTION

■ The prescribed tightening torque of the wheel bolts for steel and light alloy

wheels is 120 Nm.

■ If the anti-theft wheel bolt is fastened too tightly, it can cause damage to the

anti-theft wheel bolt and adapter. Note

■ The anti-theft wheel bolt set and adapter can be purchased from a ŠKODA Serv-

ice Partner. ■ The national legal requirements must be observed when changing a wheel. ÐPreliminary work

First read and observe the introductory information and safety warn-

ings on page 179.

The following steps must be carried out before actually changing the wheel:

› In the event of a puncture, park the vehicle as far away as possible from the

flow of traffic. The place you choose should be level.

› Let all of the occupants get out.

While changing a tyre, the occupants of the

vehicle should not stand on the road (instead they should remain behind a crash

barrier).

› Switch off the engine and move the gearshift lever into

Neutral or move the

selector lever

for the automatic gearbox into position P .

› Firmly apply the

handbrake.

› If a trailer is connected, remove it.

› Remove the vehicle tool kit

» page 179 and the spare wheel » page 173 from

the boot. Ð

ä Changing a wheel

First read and observe the introductory information and safety warn-

ings on page 179.

Always change a wheel on a level surface as far as possible.

› Remove the full wheel trim

» page 174 or caps » page 174.

› In the case of light alloy wheel rims remove the wheel trim cap

» page 174.

› First of all slacken the anti-theft wheel bolt and then the other wheel

bolts » page 181.

› Jack up the vehicle until the wheel that needs changing is clear of the

ground » page 181.

› Unscrew the wheel bolts and place them on a clean surface (cloth, paper, etc.).

› Remove the wheel.

› Attach the spare wheel and slightly screw on the wheel bolts.

› Lower the vehicle.

› Alternately tighten the wheel bolts opposite each other using the wheel

wrench (crosswise) and then tighten the anti-theft wheel bolt » page 181.

› Reinstall the wheel trim/wheel trim cap or the caps. Note

■ All bolts must be clean and must turn easily.

■ Under no circumstances grease or oil the wheel bolts!

■ When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect »

page 170. Ð Subsequent steps

First read and observe the introductory information and safety warn-

ings on page 179.

The following steps must also be performed after changing the wheel.

› Stow and attach the replaced wheel in the spare wheel well using a special

screw » page 173 .

› Stow the vehicle tool kit in the space provided.

› Check

the tyre pressure

on the installed spare wheel as soon as possible.

› Have the

tightening torque of the wheel bolts checked with a torque wrench

as soon as possible.

› Change the damaged wheel or consult a ŠKODA specialist garage about repair

possibilities. £

ä

ä

180 Do-it-yourself

Page 186 of 218

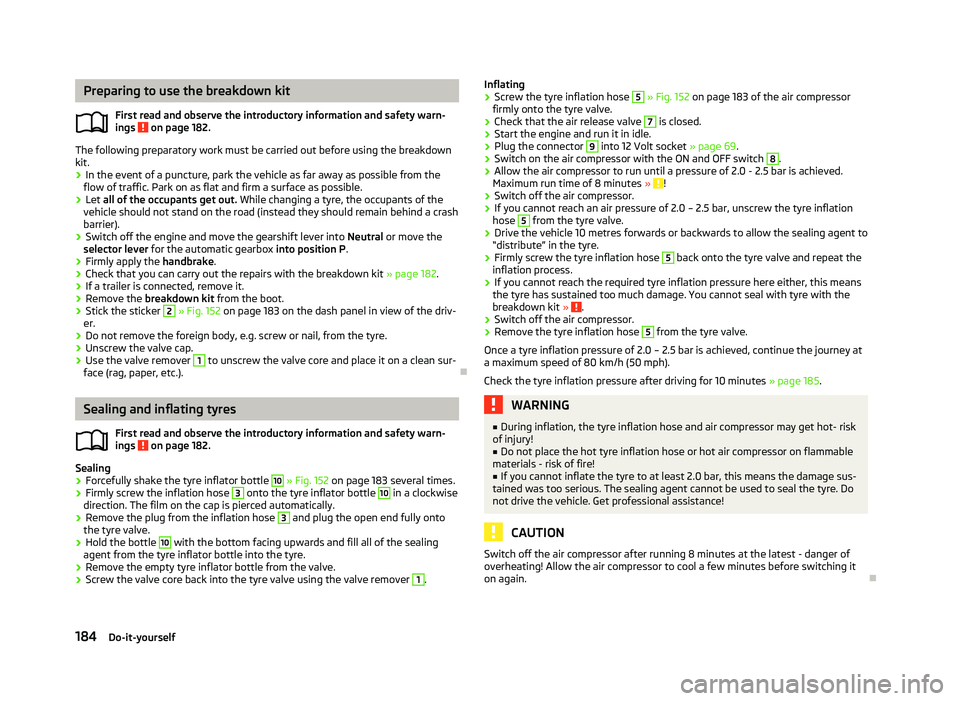

Preparing to use the breakdown kit

First read and observe the introductory information and safety warn-

ings on page 182.

The following preparatory work must be carried out before using the breakdown

kit.

›

In the event of a puncture, park the vehicle as far away as possible from the

flow of traffic. Park on as flat and firm a surface as possible.

› Let all of the occupants get out.

While changing a tyre, the occupants of the

vehicle should not stand on the road (instead they should remain behind a crash

barrier).

› Switch off the engine and move the gearshift lever into

Neutral or move the

selector lever for the automatic gearbox into position P .

› Firmly apply the

handbrake.

› Check that you can carry out the repairs with the breakdown kit

» page 182.

› If a trailer is connected, remove it.

› Remove the breakdown kit

from the boot.

› Stick the sticker 2

»

Fig. 152

on page 183 on the dash panel in view of the driv-

er.

› Do not remove the foreign body, e.g. screw or nail, from the tyre.

› Unscrew the valve cap.

› Use the valve remover 1

to unscrew the valve core and place it on a clean sur-

face (rag, paper, etc.). ÐSealing and inflating tyres

First read and observe the introductory information and safety warn-

ings on page 182.

Sealing

›

Forcefully shake the tyre inflator bottle 10

» Fig. 152 on page 183 several times.

› Firmly screw the inflation hose 3

onto the tyre inflator bottle 10

in a clockwise

direction. The film on the cap is pierced automatically.

› Remove the plug from the inflation hose 3

and plug the open end fully onto

the tyre valve.

› Hold the bottle 10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

› Remove the empty tyre inflator bottle from the valve.

› Screw the valve core back into the tyre valve using the valve remover 1

.

ä

ä

Inflating

› Screw the tyre inflation hose 5

» Fig. 152 on page 183 of the air compressor

firmly onto the tyre valve.

› Check that the air release valve 7

is closed.

› Start the engine and run it in idle.

› Plug the connector 9

into 12 Volt socket »

page 69.

› Switch on the air compressor with the ON and OFF switch 8

.

› Allow the air compressor to run until a pressure of 2.0 - 2.5 bar is achieved.

Maximum run time of 8 minutes » !

› Switch off the air compressor.

› If you cannot reach an air pressure of 2.0 – 2.5 bar, unscrew the tyre inflation

hose 5

from the tyre valve.

› Drive the vehicle 10 metres forwards or backwards to allow the sealing agent to

“distribute” in the tyre.

› Firmly screw the tyre inflation hose 5

back onto the tyre valve and repeat the

inflation process.

› If you cannot reach the required tyre inflation pressure here either, this means

the tyre has sustained too much damage. You cannot seal with tyre with the

breakdown kit » .

› Switch off the air compressor.

› Remove the tyre inflation hose 5

from the tyre valve.

Once a tyre inflation pressure of 2.0

– 2.5 bar is achieved, continue the journey at

a maximum speed of 80 km/h (50 mph).

Check the tyre inflation pressure after driving for 10 minutes » page 185. WARNING

■ During inflation, the tyre inflation hose and air compressor may get hot- risk

of injury!

■ Do not place the hot tyre inflation hose or hot air compressor on flammable

materials - risk of fire!

■ If you cannot inflate the tyre to at least 2.0 bar, this means the damage sus-

tained was too serious. The sealing agent cannot be used to seal the tyre. Do

not drive the vehicle. Get professional assistance! CAUTION

Switch off the air compressor after running 8 minutes at the latest - danger of

overheating! Allow the air compressor to cool a few minutes before switching it

on again. Ð

184 Do-it-yourself

Page 188 of 218

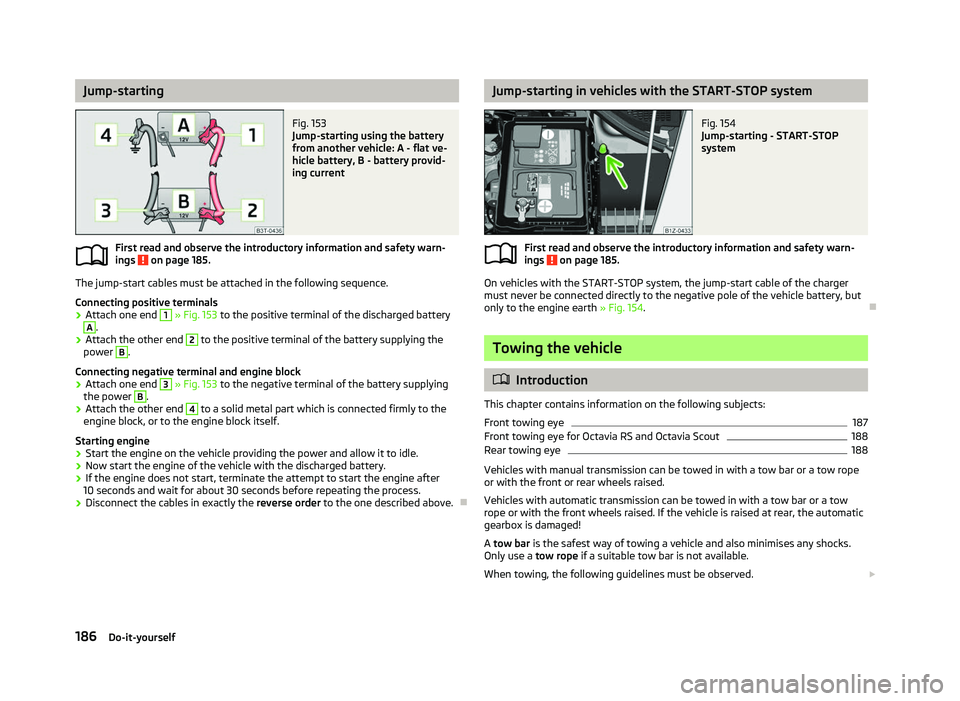

Jump-starting

Fig. 153

Jump-starting using the battery

from another vehicle: A - flat ve-

hicle battery, B - battery provid-

ing current

First read and observe the introductory information and safety warn-

ings on page 185.

The jump-start cables must be attached in the following sequence.

Connecting positive terminals

›

Attach one end 1

» Fig. 153

to the positive terminal of the discharged batteryA

.

› Attach the other end 2

to the positive terminal of the battery supplying the

power B

.

Connecting negative terminal and engine block

› Attach one end 3

»

Fig. 153

to the negative terminal of the battery supplying

the power B

.

› Attach the other end 4

to a solid metal part which is connected firmly to the

engine block, or to the engine block itself.

Starting engine

› Start the engine on the vehicle providing the power and allow it to idle.

› Now start the engine of the vehicle with the discharged battery.

› If the engine does not start, terminate the attempt to start the engine after

10 seconds and wait for about 30 seconds before repeating the process.

› Disconnect the cables in exactly the

reverse order to the one described above. Ð

ä Jump-starting in vehicles with the START-STOP system

Fig. 154

Jump-starting - START-STOP

system

First read and observe the introductory information and safety warn-

ings on page 185.

On vehicles with the START-STOP system, the jump-start cable of the charger

must never be connected directly to the negative pole of the vehicle battery, but

only to the engine earth » Fig. 154. Ð Towing the vehicle

ä

Introduction

This chapter contains information on the following subjects:

Front towing eye 187

Front towing eye for Octavia RS and Octavia Scout 188

Rear towing eye 188

Vehicles with manual transmission can be towed in with a tow bar or a tow rope

or with the front or rear wheels raised.

Vehicles with automatic transmission can be towed in with a tow bar or a tow

rope or with the front wheels raised. If the vehicle is raised at rear, the automatic

gearbox is damaged!

A tow bar is the safest way of towing a vehicle and also minimises any shocks.

Only use a tow rope if a suitable tow bar is not available.

When towing, the following guidelines must be observed. £

ä

186 Do-it-yourself

Page 189 of 218

Driver of the tow vehicle

›

Release the clutch particularly gently when starting off or depress the accelera-

tor particularly gently if the vehicle is fitted with an automatic gearbox.

› On vehicles with a manual transmission, only push down on the accelerator

pedal once the rope is taught.

The maximum towing speed is 50 km/h.

Driver of the towed vehicle

› Switch on the ignition so that the steering wheel is not blocked and so that the

turn signal lights, horn, windscreen wipers and windscreen washer system can

be switched on.

› Take the vehicle out of gear or move the selector lever into position

N if the

vehicle is fitted with an automatic gearbox.

Please note that the brake servo unit and power steering only operate if the en-

gine is running. If the engine is not running, significantly more physical force is re-

quired to depress the brake pedal and steer the vehicle.

If using a tow rope, ensure that it is always kept taught. CAUTION

■ Do not tow start the engine - danger of damaging the engine! On vehicles with

a catalytic converter, unburnt fuel may get into the catalytic converter where it

may ignite. This in turn may damage or destroy the catalytic converter. The bat-

tery from another vehicle can be used as a jump-start aid » page 185, Jump-start-

ing .

■ If the gearbox of your vehicle no longer contains any oil because of a defect,

your vehicle must only be towed in with the driven wheels raised clear of the

ground, or on a special vehicle transporter or trailer.

■ The vehicle must be transported on a special vehicle or trailer if it is not possible

to tow in the vehicle in the way described or if the towing distance is greater than

50 km. ■ To protect both vehicles when tow-starting or towing, the tow rope should be

elastic. Thus one should only use plastic fibre rope or a rope made out of a simi-

larly elastic material.

■ One should be constantly vigilant not to allow impermissibly high towing forces

or jerky loadings. There is always a risk of excessive stresses and damage result-

ing at the points to which you attach the tow rope or tow bar when you attempt

to tow a vehicle which is not standing on a paved road.

■ Attach the tow rope or the tow bar to the towing eyes or to the detachable ball

head of the towing device » page 187

or » page 188. Note

■ We recommend using a tow rope from

ŠKODA Original Accessories available

from a ŠKODA Service Partner. ■ Towing another vehicle requires a certain amount of practice. Both drivers

should be familiar with the particular points about towing a vehicle. Unskilled

drivers should not attempt to tow in another vehicle or to be towed in. ■ When towing, respect the national legal provisions, especially those which re-

late to the identification of the towing vehicle and the vehicle being towed. ■ The tow rope must not be twisted as it may in certain circumstances result in

the front towing eye being unscrewed out of your vehicle. Ð Front towing eye

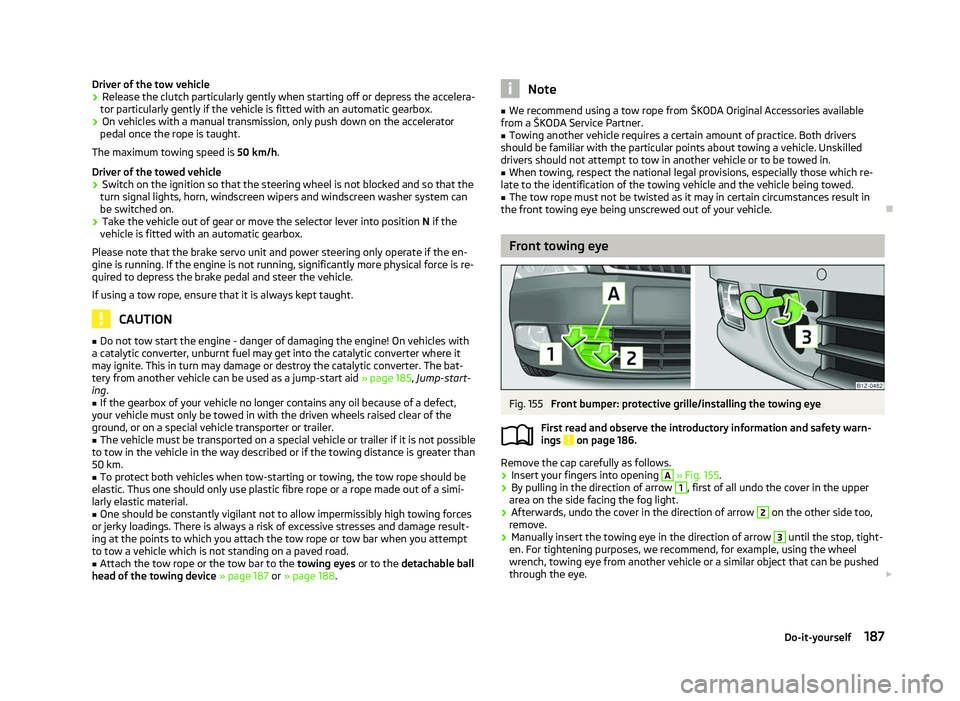

Fig. 155

Front bumper: protective grille/installing the towing eye

First read and observe the introductory information and safety warn-

ings on page 186.

Remove the cap carefully as follows.

›

Insert your fingers into opening A

» Fig. 155 .

› By pulling in the direction of arrow 1

, first of all undo the cover in the upper

area on the side facing the fog light.

› Afterwards, undo the cover in the direction of arrow 2

on the other side too,

remove.

› Manually insert the towing eye in the direction of arrow 3

until the stop, tight-

en. For tightening purposes, we recommend, for example, using the wheel

wrench, towing eye from another vehicle or a similar object that can be pushed

through the eye. £

ä

187

Do-it-yourself

Page 192 of 218

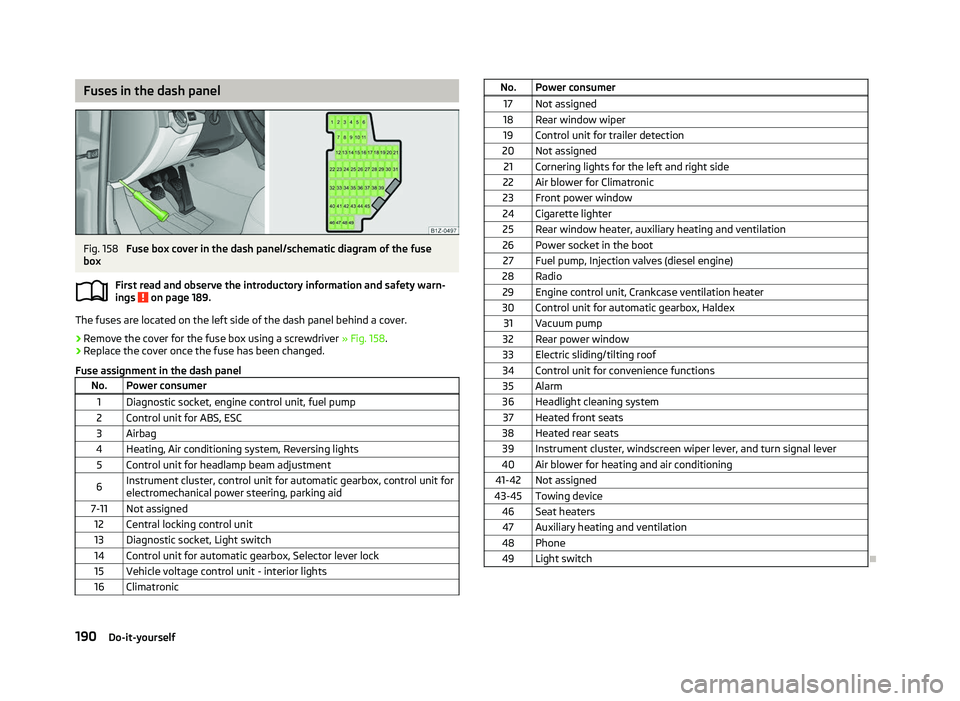

Fuses in the dash panel

Fig. 158

Fuse box cover in the dash panel/schematic diagram of the fuse

box

First read and observe the introductory information and safety warn-

ings on page 189.

The fuses are located on the left side of the dash panel behind a cover.

›

Remove the cover for the fuse box using a screwdriver

» Fig. 158.

› Replace the cover once the fuse has been changed.

Fuse assignment in the dash panel No. Power consumer

1 Diagnostic socket, engine control unit, fuel pump

2 Control unit for ABS, ESC

3 Airbag

4 Heating, Air conditioning system, Reversing lights 5 Control unit for headlamp beam adjustment

6 Instrument cluster, control unit for automatic gearbox, control unit for

electromechanical power steering, parking aid

7-11 Not assigned 12 Central locking control unit

13 Diagnostic socket, Light switch

14 Control unit for automatic gearbox, Selector lever lock 15 Vehicle voltage control unit - interior lights

16 Climatronic ä

No. Power consumer

17 Not assigned

18 Rear window wiper 19 Control unit for trailer detection

20 Not assigned 21 Cornering lights for the left and right side

22 Air blower for Climatronic

23 Front power window

24 Cigarette lighter 25 Rear window heater, auxiliary heating and ventilation

26 Power socket in the boot 27 Fuel pump, Injection valves (diesel engine)

28 Radio 29 Engine control unit, Crankcase ventilation heater

30 Control unit for automatic gearbox, Haldex 31 Vacuum pump

32 Rear power window

33 Electric sliding/tilting roof

34 Control unit for convenience functions 35 Alarm

36 Headlight cleaning system 37 Heated front seats

38 Heated rear seats 39 Instrument cluster, windscreen wiper lever, and turn signal lever

40 Air blower for heating and air conditioning

41-42 Not assigned

43-45 Towing device 46 Seat heaters47 Auxiliary heating and ventilation

48 Phone 49 Light switch Ð

190 Do-it-yourself

Page 193 of 218

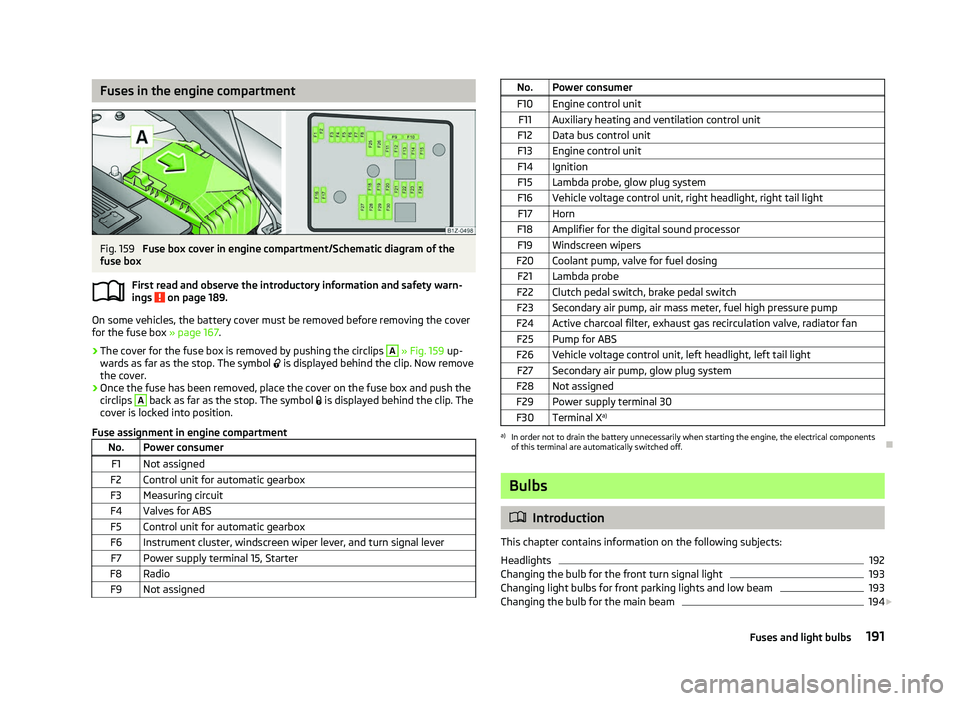

Fuses in the engine compartment

Fig. 159

Fuse box cover in engine compartment/Schematic diagram of the

fuse box

First read and observe the introductory information and safety warn-

ings on page 189.

On some vehicles, the battery cover must be removed before removing the cover

for the fuse box

» page 167.

› The cover for the fuse box is removed by pushing the circlips A

» Fig. 159

up-

wards as far as the stop. The symbol is displayed behind the clip. Now remove

the cover.

› Once the fuse has been removed, place the cover on the fuse box and push the

circlips A

back as far as the stop. The symbol

is displayed behind the clip. The

cover is locked into position.

Fuse assignment in engine compartment No. Power consumer

F1 Not assigned

F2 Control unit for automatic gearbox

F3 Measuring circuit

F4 Valves for ABS F5 Control unit for automatic gearbox

F6 Instrument cluster, windscreen wiper lever, and turn signal lever F7 Power supply terminal 15, Starter

F8 Radio F9 Not assigned ä

No. Power consumer

F10 Engine control unit F11 Auxiliary heating and ventilation control unit

F12 Data bus control unit

F13 Engine control unit

F14 Ignition F15 Lambda probe, glow plug system

F16 Vehicle voltage control unit, right headlight, right tail light F17 Horn

F18 Amplifier for the digital sound processor F19 Windscreen wipers

F20 Coolant pump, valve for fuel dosing F21 Lambda probe

F22 Clutch pedal switch, brake pedal switch

F23 Secondary air pump, air mass meter, fuel high pressure pump

F24 Active charcoal filter, exhaust gas recirculation valve, radiator fan F25 Pump for ABS

F26 Vehicle voltage control unit, left headlight, left tail light F27 Secondary air pump, glow plug system

F28 Not assigned F29 Power supply terminal 30

F30 Terminal X a) a)

In order not to drain the battery unnecessarily when starting the engine, the electrical components

of this terminal are automatically switched off. Ð Bulbs

ä

Introduction

This chapter contains information on the following subjects:

Headlights 192

Changing the bulb for the front turn signal light 193

Changing light bulbs for front parking lights and low beam 193

Changing the bulb for the main beam 194

£

191

Fuses and light bulbs

Page 199 of 218

Technical data

Technical data

Introductory information

The details given in the vehicle's technical documentation always take prece-

dence over the details in the Owner's Manual. Please refer to the official vehicle

registration documents or consult a

ŠKODA Service Partner to determine which

engine your vehicle is equipped with.

The listed performance values were determined without performance-reducing

equipment, e.g. air conditioning system.

Vehicle identification number (VIN)

The vehicle identification number - VIN (vehicle body number) is stamped into the

engine compartment on the right hand suspension strut dome. This number is al-

so located on a sign on the lower left hand edge below the windscreen (together

with a VIN bar code).

Engine number

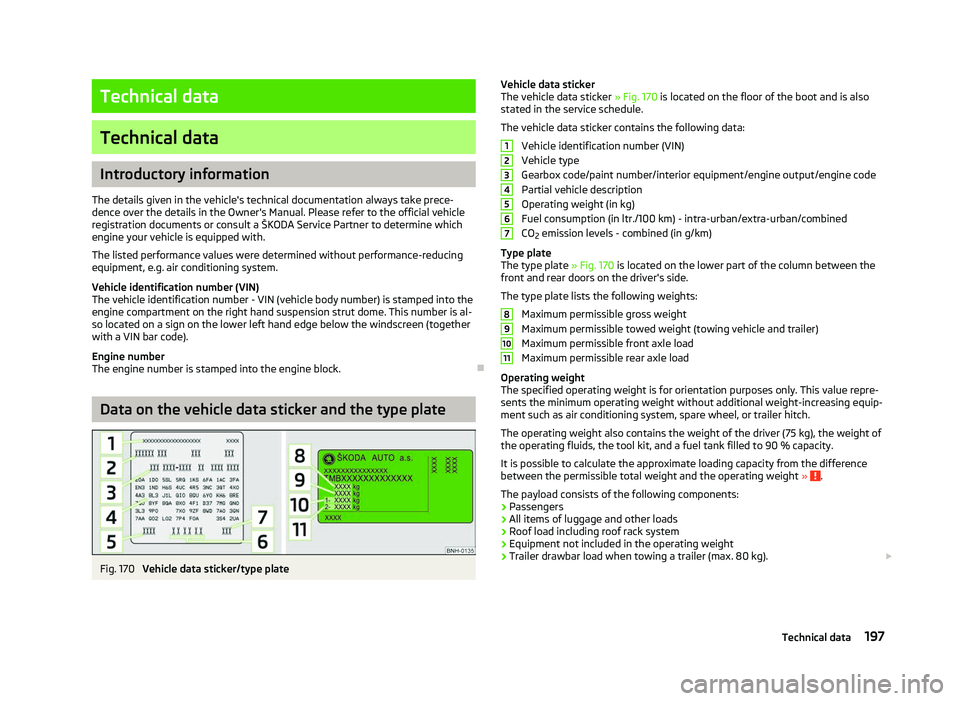

The engine number is stamped into the engine block. ÐData on the vehicle data sticker and the type plate

Fig. 170

Vehicle data sticker/type plate Vehicle data sticker

The vehicle data sticker

» Fig. 170 is located on the floor of the boot and is also

stated in the service schedule.

The vehicle data sticker contains the following data:

Vehicle identification number (VIN)

Vehicle type

Gearbox code/paint number/interior equipment/engine output/engine code

Partial vehicle description

Operating weight (in kg)

Fuel consumption (in ltr./100

km) - intra-urban/extra-urban/combined

CO 2 emission levels - combined (in g/km)

Type plate

The type plate » Fig. 170 is located on the lower part of the column between the

front and rear doors on the driver's side.

The type plate lists the following weights:

Maximum permissible gross weight

Maximum permissible towed weight (towing vehicle and trailer)

Maximum permissible front axle load

Maximum permissible rear axle load

Operating weight

The specified operating weight is for orientation purposes only. This value repre-

sents the minimum operating weight without additional weight-increasing equip-

ment such as air conditioning system, spare wheel, or trailer hitch.

The operating weight also contains the weight of the driver (75 kg), the weight of

the operating fluids, the tool kit, and a fuel tank filled to 90 % capacity.

It is possible to calculate the approximate loading capacity from the difference

between the permissible total weight and the operating weight » .

The payload consists of the following components:

› Passengers

› All items of luggage and other loads

› Roof load including roof rack system

› Equipment not included in the operating weight

› Trailer drawbar load when towing a trailer (max. 80 kg).

£ 1

2

3

4

5

6

7

8

9

10

11

197

Technical data

Page 210 of 218

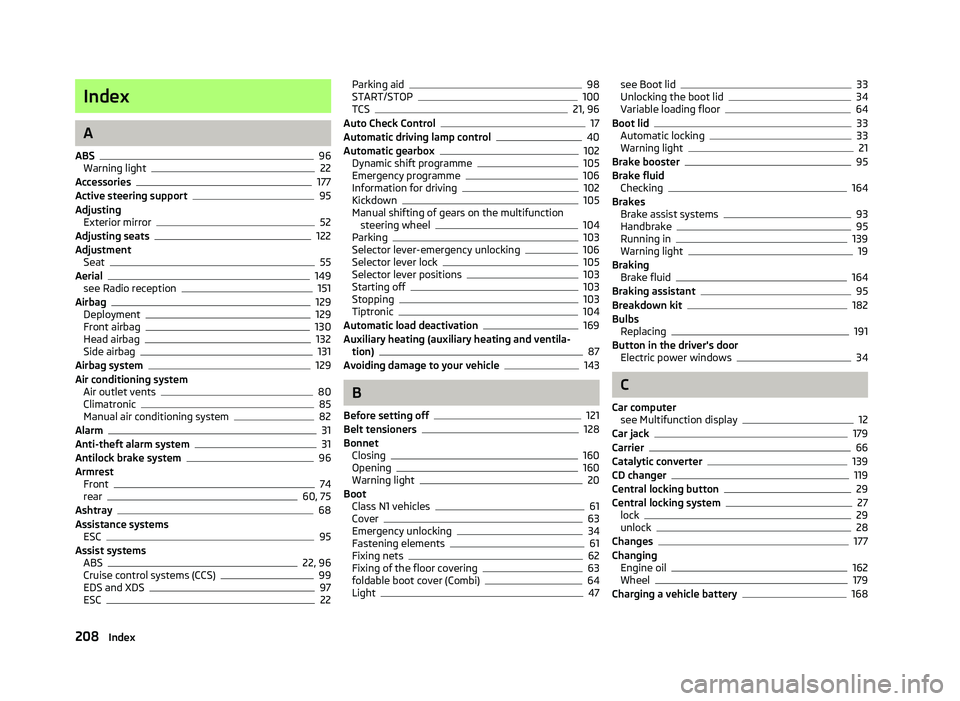

Index

A

ABS 96

Warning light 22

Accessories 177

Active steering support 95

Adjusting Exterior mirror 52

Adjusting seats 122

Adjustment Seat 55

Aerial 149

see Radio reception 151

Airbag 129

Deployment 129

Front airbag 130

Head airbag 132

Side airbag 131

Airbag system 129

Air conditioning system Air outlet vents 80

Climatronic 85

Manual air conditioning system 82

Alarm 31

Anti-theft alarm system 31

Antilock brake system 96

Armrest Front 74

rear 60, 75

Ashtray 68

Assistance systems ESC 95

Assist systems ABS 22, 96

Cruise control systems (CCS) 99

EDS and XDS 97

ESC 22Parking aid 98

START/STOP 100

TCS 21, 96

Auto Check Control 17

Automatic driving lamp control 40

Automatic gearbox 102

Dynamic shift programme 105

Emergency programme 106

Information for driving 102

Kickdown 105

Manual shifting of gears on the multifunction steering wheel 104

Parking 103

Selector lever-emergency unlocking 106

Selector lever lock 105

Selector lever positions 103

Starting off 103

Stopping 103

Tiptronic 104

Automatic load deactivation 169

Auxiliary heating (auxiliary heating and ventila- tion) 87

Avoiding damage to your vehicle 143

B

Before setting off 121

Belt tensioners 128

Bonnet Closing 160

Opening 160

Warning light 20

Boot Class

N1 vehicles 61

Cover 63

Emergency unlocking 34

Fastening elements 61

Fixing nets 62

Fixing of the floor covering 63

foldable boot cover (Combi) 64

Light 47see Boot lid 33

Unlocking the boot lid 34

Variable loading floor 64

Boot lid 33

Automatic locking 33

Warning light 21

Brake booster 95

Brake fluid Checking 164

Brakes Brake assist systems 93

Handbrake 95

Running in 139

Warning light 19

Braking Brake fluid 164

Braking assistant 95

Breakdown kit 182

Bulbs Replacing 191

Button in the driver's door Electric power windows 34

C

Car computer see Multifunction display 12

Car jack 179

Carrier 66

Catalytic converter 139

CD changer 119

Central locking button 29

Central locking system 27

lock 29

unlock 28

Changes 177

Changing Engine oil 162

Wheel 179

Charging a vehicle battery 168

208 Index