warning SKODA OCTAVIA 2010 2.G / (1Z) Owner's Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2010, Model line: OCTAVIA, Model: SKODA OCTAVIA 2010 2.G / (1Z)Pages: 275, PDF Size: 16.43 MB

Page 216 of 275

Breakdown assistance215

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

Breakdown assistanceBreakdown assistanceFirst-aid box* and Warning triangle* (Octavia)The first-aid box* is attached by a strap to the right-hand side of the luggage compart-

ment.

The warning triangle can be attached to th e trim panel of the rear wall with rubber

straps fig. 172 .

If you wish to equip your ve hicle additionally with a warning triangle, please contact a

specialist garage.

Note

Pay attention to the use-by-date of the contents of the first-aid box.

First-aid box* and warning triangle* (Estate car)For vehicles of the type estate car the firs t-aid box and the warning triangle are housed

in a compartment on the right side in th e luggage compartment. You can open the

compartment by turning the locks in the direction of arrow fig. 173 .

If you wish to equip your ve hicle additionally with a warning triangle, please contact a

specialist garage.

Note

Pay attention to the use-by-date of the contents of the first-aid box.Fire extinguisher*The fire extinguisher is attached with st raps in a holder under the driver seat.

Please read carefully the instructions whic h are attached to the fire extinguisher.

The fire extinguisher must be checked by an authorised person or company annually

(please observe the differing legal requirements).

Fig. 172 Placing of the warning triangle

(Octavia)

Fig. 173 Placing of the warning

triangle (Estate car)

s43s.1.book Page 215 Thursday, May 13, 2010 1:21 PM

Page 217 of 275

Breakdown assistance

216WARNING

If the fire extinguisher is not correctl y attached, in case of sudden manoeuvres

or an accident it can be “thrown” through the interior compartment and cause

injuries.

Note

The fire extinguisher must comply with the relevant and valid legal requirements.

Pay attention to the expiration date of the fire extinguisher. If the fire extinguisher

is used after the expiration date, its proper function is no longer assured.

The fire extinguisher is only supplied in certain countries within the scope of

delivery.

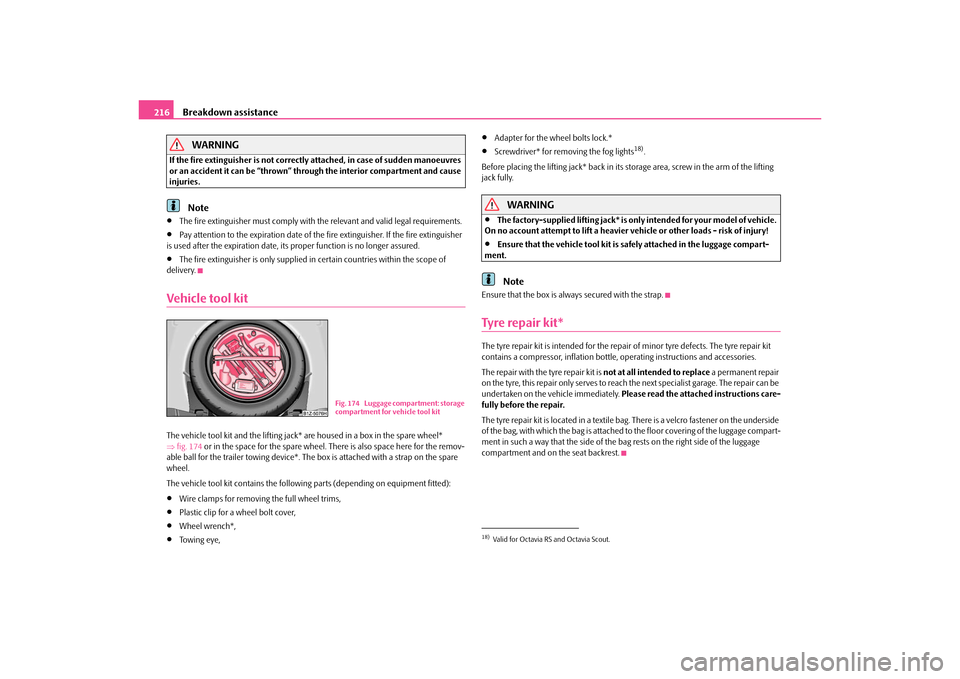

Vehicle tool kitThe vehicle tool kit and the lifting jack* are housed in a box in the spare wheel*

fig. 174 or in the space for the spare wheel. There is also space here for the remov-

able ball for the trailer towing device*. Th e box is attached with a strap on the spare

wheel.

The vehicle tool kit contains the following parts (depending on equipment fitted):

Wire clamps for removing the full wheel trims,

Plastic clip for a wheel bolt cover,

Wheel wrench*,

To w i n g e y e ,

Adapter for the wheel bolts lock.*

Screwdriver* for removing the fog lights

18).

Before placing the lifting jack* back in its storage area, screw in the arm of the lifting

jack fully.

WARNING

The factory-supplied lifting jack* is only intended for your model of vehicle.

On no account attempt to lift a heavier vehicle or other loads - risk of injury!

Ensure that the vehicle tool kit is sa fely attached in the luggage compart-

ment.Note

Ensure that the box is always secured with the strap.Tyre repair kit*The tyre repair kit is intended for the repair of minor tyre defects. The tyre repair kit

contains a compressor, inflation bottle, operating instructions and accessories.

The repair with the tyre repair kit is not at all intended to replace a permanent repair

on the tyre, this repair only serves to reach the next specialist garage. The repair can be

undertaken on the vehicle immediately. Please read the attached instructions care-

fully before the repair.

The tyre repair kit is located in a textile bag. There is a velcro fastener on the underside

of the bag, with which the bag is attached to the floor covering of the luggage compart-

ment in such a way that the side of the bag rests on the right side of the luggage

compartment and on the seat backrest.

Fig. 174 Luggage compartment: storage

compartment for vehicle tool kit

18)Valid for Octavia RS and Octavia Scout.

s43s.1.book Page 216 Thursday, May 13, 2010 1:21 PM

Page 218 of 275

Breakdown assistance217

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

Spare wheel*The spare wheel lies in a well under the floor covering of the luggage compartment and

is fixed in place using special screws fig. 175 .

Before removing the spare wheel, you must take out the box with the vehicle tool kit

box page 216, fig. 174.

One should check the inflation pressure in the spare wheel (at best when generally

checking the tyre air pressures - see sign on the fuel filler flap page 208) to ensure

that the spare wheel is always ready to use.

Temporary spare wheel

A warning label displayed on the rim of the temporary spare wheel indicates that your

vehicle is equippe d with a temporary spare wheel.

Please observe the following notes when driving with a temporary spare wheel:

The warning label must not be covered after installing the wheel.

Do not drive faster than 80 km/h with this spare wheel and pay particular attention

while driving. Avoid accelerating at full throttle, sharp braking and fast cornering.

The inflation pressure for this spare wheel is identical to the inflation pressure of

the standard tyres. The temporary spare wheel R 18 must have an inflation pressure of

420 kPa (4.2 bar)!

Use this spare wheel only to reach the nearest specialist garage as it is not intended

for continuous use.

No other summer or winter tyres must be mounted on the rim of the spare wheel

R 18.

Changing a wheelPreliminary workThe following steps should be carried ou t before actually changing the wheel.

– If it is necessary to change a wheel, park the vehicle as far away as possible from

the traffic flow. The place you choose should be level.

–Have all the occupants get out. While changing a wheel, the occupants of the

vehicle should not stand on the ro ad (e.g. behind a crash barrier).

– Apply the handbrake firmly.

–Engage 1st gear or if your vehicle is fitted with an automatic gearbox, position the

selector lever into position P .

– If a trailer is coupled, uncouple it.

–Take the vehicle tool kit page 216 and the spare wheel* page 217 out of the

luggage compartment.

WARNING

If you find yourself in flowing traffic switch on the hazard warning lights

system and place the warning triangle on the side of the road at the prescribed

distance from your vehicle while observin g all national legal provisions. In this

way you are protecting not only yourself but also other road users.

Never start the engine with the vehicle si tting on the raised jack - danger of

suffering injury.Caution

If you have to change a wheel on a slope fi rst block the opposite wheel with a stone or

similar object in order to secure the vehicle from unexpectedly rolling away.

Note

Comply with the national legal regulations.

Fig. 175 Luggage compartment: Spare

wheel

s43s.1.book Page 217 Thursday, May 13, 2010 1:21 PM

Page 219 of 275

Breakdown assistance

218

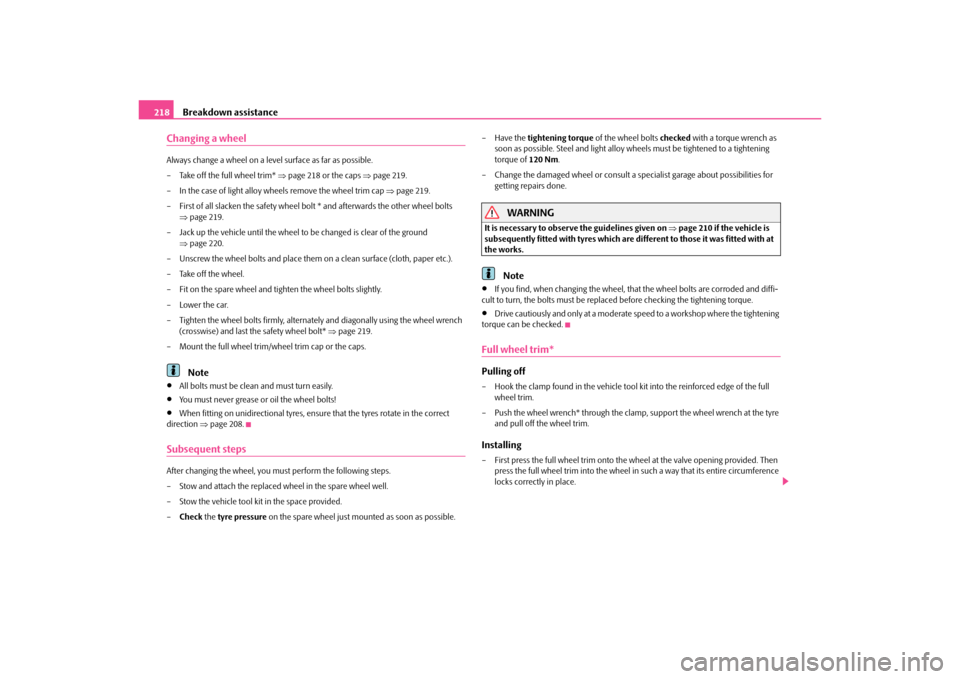

Changing a wheelAlways change a wheel on a level surface as far as possible.

– Take off the full wheel trim* page 218 or the caps page 219.

– In the case of light alloy wheels remove the wheel trim cap page 219.

– First of all slacken the safety wheel bolt * and afterwards the other wheel bolts page 219.

– Jack up the vehicle until the wheel to be changed is clear of the ground page 220.

– Unscrew the wheel bolts and place them on a clean surface (cloth, paper etc.).

– Take off the wheel.

– Fit on the spare wheel and ti ghten the wheel bolts slightly.

–Lower the car.

– Tighten the wheel bolts firmly, alternately and diagonally using the wheel wrench (crosswise) and last the safety wheel bolt* page 219.

– Mount the full wheel trim/wheel trim cap or the caps.

Note

All bolts must be clean and must turn easily.

You must never grease or oil the wheel bolts!

When fitting on unidirectional tyres, ensu re that the tyres rotate in the correct

direction page 208.

Subsequent stepsAfter changing the wheel, you must perform the following steps.

– Stow and attach the replaced wheel in the spare wheel well.

– Stow the vehicle tool kit in the space provided.

– Check the tyre pressure on the spare wheel just mounted as soon as possible. – Have the

tightening torque of the wheel bolts checked with a torque wrench as

soon as possible. Steel and light alloy wheels must be tightened to a tightening

torque of 120 Nm.

– Change the damaged wheel or consult a sp ecialist garage about possibilities for

getting repairs done.

WARNING

It is necessary to observe the guidelines given on page 210 if the vehicle is

subsequently fitted with tyres which are di fferent to those it was fitted with at

the works.

Note

If you find, when changing the wheel, that the wheel bolts are corroded and diffi-

cult to turn, the bolts must be replaced before checking the tightening torque.

Drive cautiously and only at a moderate speed to a workshop where the tightening

torque can be checked.

Full wheel trim*Pulling off– Hook the clamp found in the vehicle tool ki t into the reinforced edge of the full

wheel trim.

– Push the wheel wrench* through the clamp, support the wheel wrench at the tyre and pull off the wheel trim.Installing– First press the full wheel trim onto the wheel at the valve opening provided. Then

press the full wheel trim into the wheel in such a way that its entire circumference

locks correctly in place.

s43s.1.book Page 218 Thursday, May 13, 2010 1:21 PM

Page 221 of 275

Breakdown assistance

220

Tightening wheel bolts

– Push the wheel wrench* fully onto the wheel bolt

19).

– Grasp the end of the wrench* and turn the bolt to the right until it is tight.

WARNING

Slacken the wheel bolts only a little (about one turn) as long as the vehicle has

not yet been lifted with the lifting jack* - risk of accident!

Note

Apply pressure carefully with your foot to the end of the wrench* if it proves difficult

to slacken the bolts. Hold tight on the vehicl e when doing this and ensure that you have

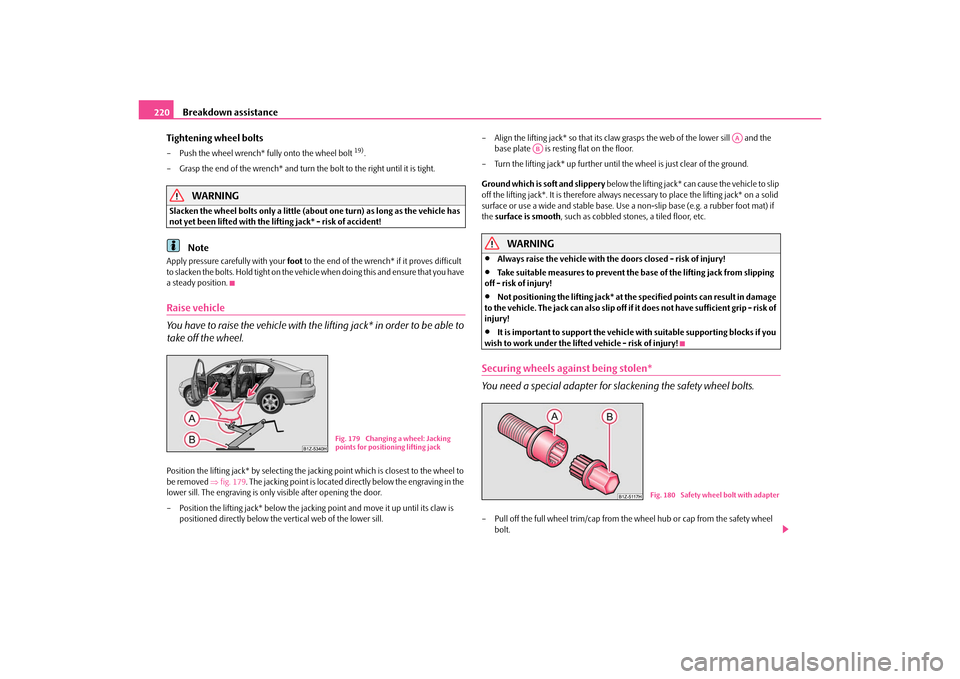

a steady position.Raise vehicle

You have to raise the vehicle with the lifting jack* in order to be able to

take off the wheel.Position the lifting jack* by selecting the ja cking point which is closest to the wheel to

be removed fig. 179 . The jacking point is located directly below the engraving in the

lower sill. The engraving is only visible after opening the door.

– Position the lifting jack* below the jacking point and move it up until its claw is

positioned directly below the vertical web of the lower sill. – Align the lifting jack* so that its claw

grasps the web of the lower sill and the

base plate is resting flat on the floor.

– Turn the lifting jack* up further until the wheel is just clear of the ground.

Ground which is soft and slippery below the lifting jack* can cause the vehicle to slip

off the lifting jack*. It is therefore always necessary to place the lifting jack* on a solid

surface or use a wide and stable base. Use a non-slip base (e.g. a rubber foot mat) if

the surface is smooth, such as cobbled stones, a tiled floor, etc.

WARNING

Always raise the vehicle with the doors closed - risk of injury!

Take suitable measures to prevent the ba se of the lifting jack from slipping

off - risk of injury!

Not positioning the lifting jack* at the specified points can result in damage

to the vehicle. The jack can al so slip off if it does not have sufficient grip - risk of

injury!

It is important to support the vehicle with suitable supporting blocks if you

wish to work under the lifted vehicle - risk of injury!

Securing wheels against being stolen*

You need a special adapter for sl ackening the safety wheel bolts.– Pull off the full wheel trim/cap from the wheel hub or cap from the safety wheel

bolt.

Fig. 179 Changing a wheel: Jacking

points for positioning lifting jack

AA

AB

Fig. 180 Safety wheel bolt with adapter

s43s.1.book Page 220 Thursday, May 13, 2010 1:21 PM

Page 222 of 275

Breakdown assistance221

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

– Insert the adapter with its toothed side fu

lly into the inner toothing of the safety

wheel bolt right down in such a way that only the outer hexagon is jutting out

page 220, fig. 180 .

– Insert the wheel wrench* fully onto the adapter .

– Slacken the wheel bolt, or tighten it firmly page 219.

– Reinstall the full wheel trim/wheel cap afte r removing the adapter or place the cap

onto the safety wheel bolt.

– Have the tightening torque checked with a torque wrench as soon as possible.

Steel and light alloy wheels must be tightened to a tightening torque of 120 Nm .

The safety wheel bolts on vehicles fitted wi th them (one safety wheel bolt per wheel)

can only be loosened or tighten up by using the adapter provided.

It is meaningful to note the code number hammered into the rear side of the adapter

or the rear side of the safety wheel bolts. You can obtain a replacement adapter from

an authorised Škoda Service Partner, if necessary, by quoting this number.

We recommend that you always carry the adapter for the wheel bolts with you in the

vehicle. It should be stow ed in the vehicle tool kit.

Caution

Damage can occur to the adapter and safety wh eel bolt if the safety wheel bolt is tight-

ened up too much.

Note

The set of safety wheel bolts can be obtained from an authorised Škoda Service

Par tner.Jump-startingInitial stepsYou can use the battery of another vehicle for jump-starting yours if the engine does

not start because the battery on your vehicle is flat. You will require jump-start cables

for this purpose. Both batteries must have a rated voltage of 12 V. The

capacity (Ah) of the battery

supplying the power must not be significantly less than the capacity of the discharged

battery in your vehicle.

Jump-start cables

Only use jump-start cables which have an adequately large cross-section and insu-

lated terminal clamps. Please pay attention to the manufacturer's instructions.

Positive cable - colour coding in the majority of cases red.

Negative cable - colour coding in the majority of cases black.

WARNING

A discharged battery may already freeze at temperatures just below 0°C. In

case of frozen battery carry out no jump-starting - risk of explosion!

Please pay attention to the warning instructions relating to working in the

engine compartment page 197, “Working in the engine compartment”.Note

There must not be any contact between the two vehicles otherwise current may

flow as soon as the negati ve terminals are connected.

The discharged battery must be properly connected to the system of the vehicle.

Switch off any mobile phone, pay attention to the instructions for use of the mobile

phone in such a situation.

We recommend that you purchase the jump -starting cable in the specialist shops

of the battery manufacturers.

AB

AA

AB

s43s.1.book Page 221 Thursday, May 13, 2010 1:21 PM

Page 223 of 275

Breakdown assistance

222

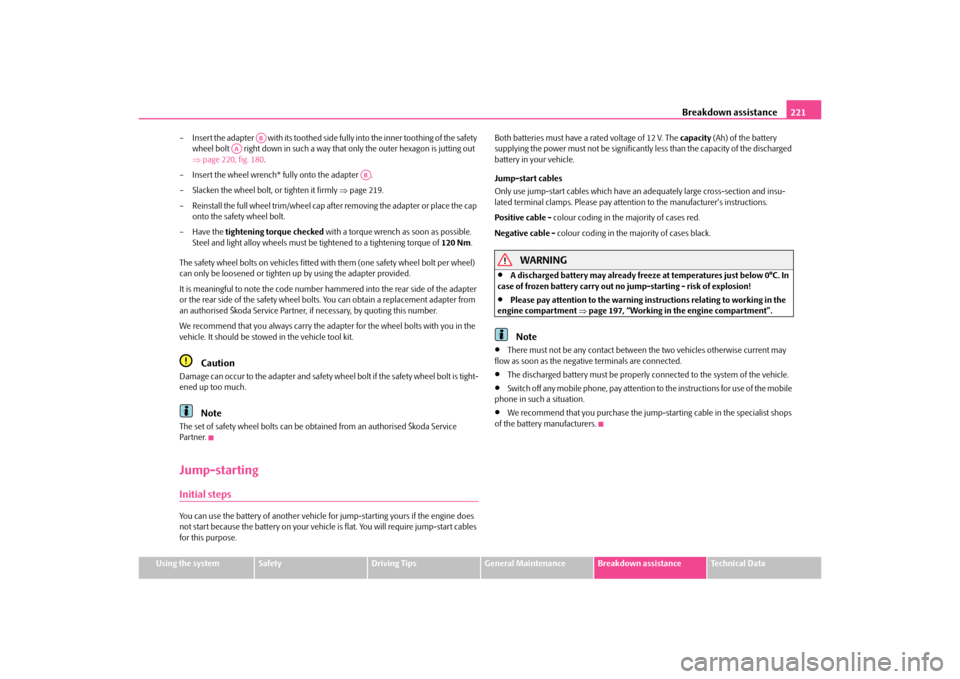

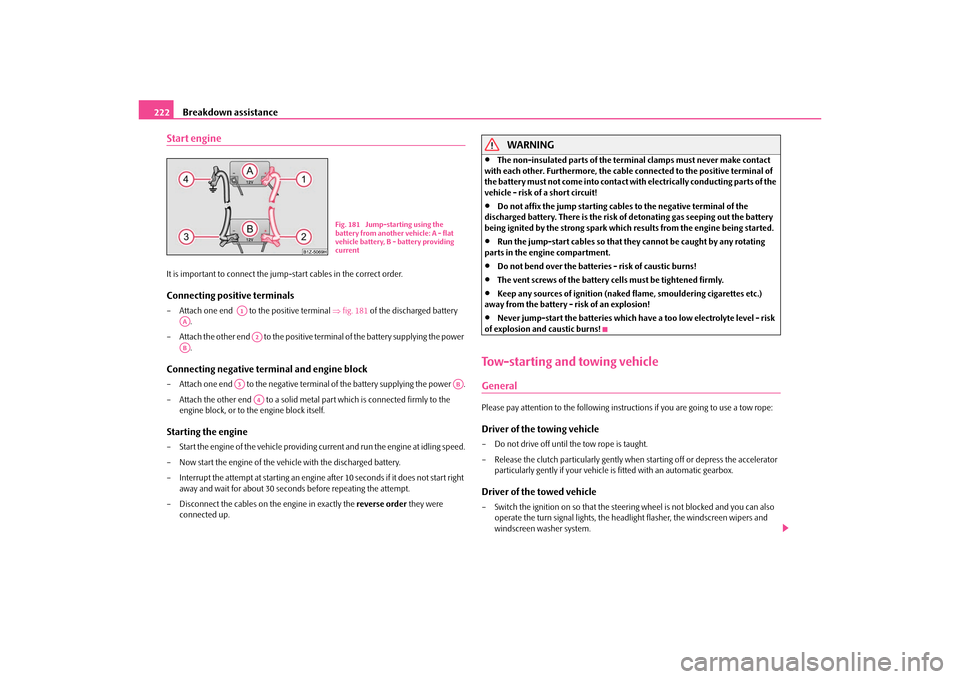

Start engineIt is important to connect the jump -start cables in the correct order.Connecting positive terminals– Attach one end to the positive terminal fig. 181 of the discharged battery

.

– Attach the other end to the positive term inal of the battery supplying the power

.Connecting negative terminal and engine block– Attach one end to the negative termin al of the battery supplying the power .

– Attach the other end to a solid metal part which is connected firmly to the

engine block, or to the engine block itself.Starting the engine– Start the engine of the vehicle providing current and run the engine at idling speed.

– Now start the engine of the vehicle with the discharged battery.

– Interrupt the attempt at starting an engine after 10 seconds if it does not start right

away and wait for about 30 seconds before repeating the attempt.

– Disconnect the cables on the engine in exactly the reverse order they were

connected up.

WARNING

The non-insulated parts of the terminal clamps must never make contact

with each other. Furthermore, the cable connected to the positive terminal of

the battery must not come into contact with electrically conducting parts of the

vehicle - risk of a short circuit!

Do not affix the jump starting cables to the negative terminal of the

discharged battery. There is the risk of detonating gas seeping out the battery

being ignited by the strong spark which results from the engine being started.

Run the jump-start cables so that they cannot be caught by any rotating

parts in the engine compartment.

Do not bend over the batteries - risk of caustic burns!

The vent screws of the battery cells must be tightened firmly.

Keep any sources of ignition (naked flame, smouldering cigarettes etc.)

away from the battery - risk of an explosion!

Never jump-start the batteries which ha ve a too low electrolyte level - risk

of explosion and caustic burns!

Tow-starting and towing vehicleGeneralPlease pay attention to the following instru ctions if you are going to use a tow rope:Driver of the towing vehicle– Do not drive off until the tow rope is taught.

– Release the clutch particularly gently wh en starting off or depress the accelerator

particularly gently if yo ur vehicle is fitted with an automatic gearbox.Driver of the towed vehicle– Switch the ignition on so that the steeri ng wheel is not blocked and you can also

operate the turn signal lights, the headlight flasher, the windscreen wipers and

windscreen washer system.

Fig. 181 Jump-starting using the

battery from another vehicle: A - flat

vehicle battery, B - battery providing

current

A1

AA

A2

AB

A3

AB

A4

s43s.1.book Page 222 Thursday, May 13, 2010 1:21 PM

Page 231 of 275

Fuses and light bulbs

230

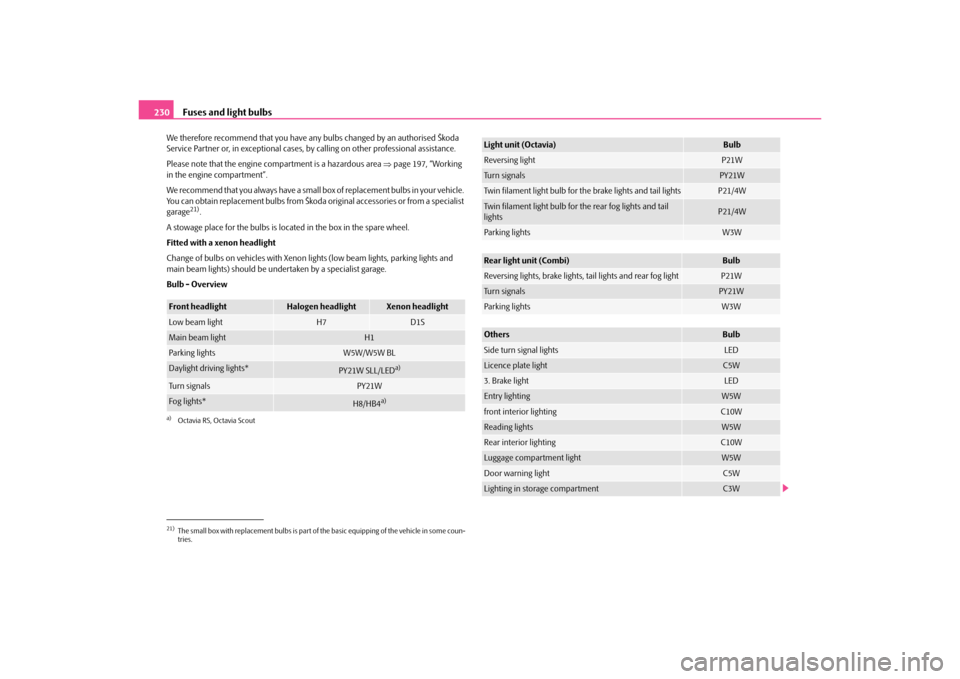

We therefore recommend that you have an y bulbs changed by an authorised Škoda

Service Partner or, in exceptional cases, by calling on other professional assistance.

Please note that the engine compartment is a hazardous area page 197, “Working

in the engine compartment”.

We recommend that you always have a small box of replacement bulbs in your vehicle.

You can obtain replacement bulbs from Škoda original accessories or from a specialist

garage

21).

A stowage place for the bulbs is located in the box in the spare wheel.

Fitted with a xenon headlight

Change of bulbs on vehicles with Xenon lights (low beam lights, parking lights and

main beam lights) should be und ertaken by a specialist garage.

Bulb - Overview

21)The small box with replacement bulbs is part of the basic equipping of the vehicle in some coun-

tries.Front headlight

Halogen headlight

Xenon headlight

Low beam light

H7

D1S

Main beam light

H1

Parking lights

W5W/W5W BL

Daylight driving lights*

PY21W SLL/LED

a)

a)Octavia RS, Octavia ScoutTu r n s i g n a l s

PY21W

Fog lights*

H8/HB4

a)

Light unit (Octavia)

Bulb

Reversing light

P21W

Turn signals

PY21W

Twin filament light bulb for th e brake lights and tail lights

P21/4W

Twin filament light bulb for the rear fog lights and tail

lights

P21/4W

Parking lights

W3W

Rear light unit (Combi)

Bulb

Reversing lights, brake lights, tail lights and rear fog light

P21W

Turn signals

PY21W

Parking lights

W3W

Others

Bulb

Side turn signal lights

LED

Licence plate light

C5W

3. Brake light

LED

Entry lighting

W5W

front interior lighting

C10W

Reading lights

W5W

Rear interior lighting

C10W

Luggage compartment light

W5W

Door warning light

C5W

Lighting in storage compartment

C3W

s43s.1.book Page 230 Thursday, May 13, 2010 1:21 PM

Page 232 of 275

Fuses and light bulbs231

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

WARNING

Bulbs H7 and H1 are pressurised and may burst when changing the bulb -

risk of injury!

It is recommended to wear gloves and safety glasses when changing a bulb.

Gas discharge bulbs* (xenon bulbs) operate with a high voltage, profes-

sional knowledge is required - danger to life!Caution

Do not take hold of the glass bulb with naked fingers (even the smallest amount of dirt

reduces the working life of the light bulb). Use a clean cloth, serviette or something

similar.

Note

This Owner's Manual only describes the replacement of bulbs where it is assumed that

no major complications will arise. Other light bulbs should be replaced by your

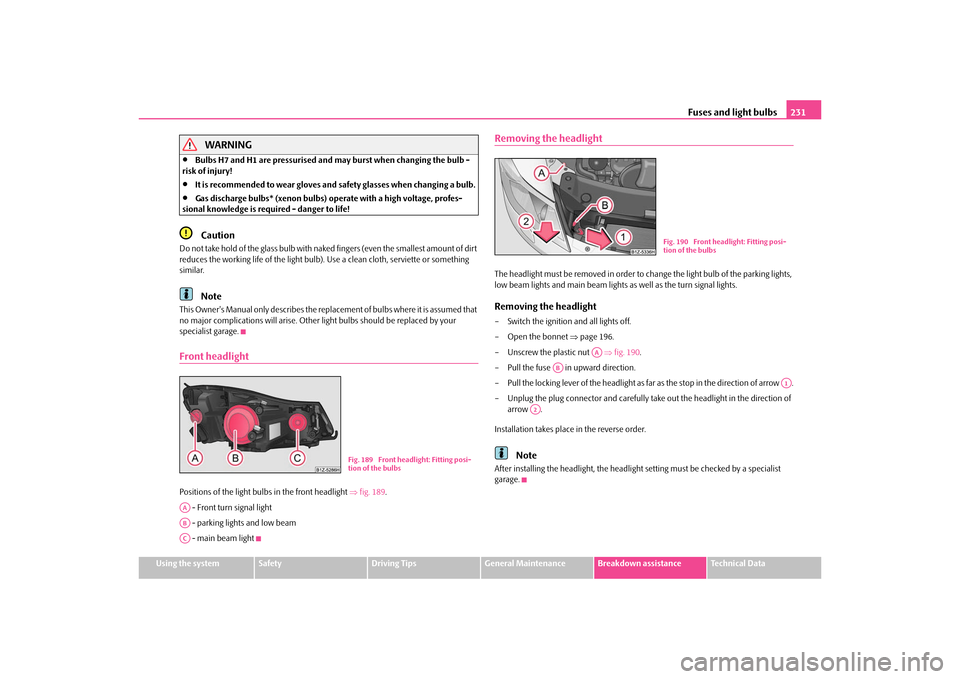

specialist garage.Front headlightPositions of the light bulbs in the front headlight fig. 189 .

- Front turn signal light

- parking lights and low beam

- main beam light

Removing the headlightThe headlight must be removed in order to ch ange the light bulb of the parking lights,

low beam lights and main beam lights as well as the turn signal lights.Removing the headlight– Switch the ignition and all lights off.

– Open the bonnet page 196.

– Unscrew the plastic nut fig. 190 .

– Pull the fuse in upward direction.

– Pull the locking lever of the headlight as far as the stop in the direction of arrow .

– Unplug the plug connector and carefully ta ke out the headlight in the direction of

arrow .

Installation takes place in the reverse order.

Note

After installing the headlight, the headligh t setting must be checked by a specialist

garage.

Fig. 189 Front headlight: Fitting posi-

tion of the bulbs

AAABAC

Fig. 190 Front headlight: Fitting posi-

tion of the bulbs

AA

AB

A1

A2

s43s.1.book Page 231 Thursday, May 13, 2010 1:21 PM

Page 264 of 275

Index263

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

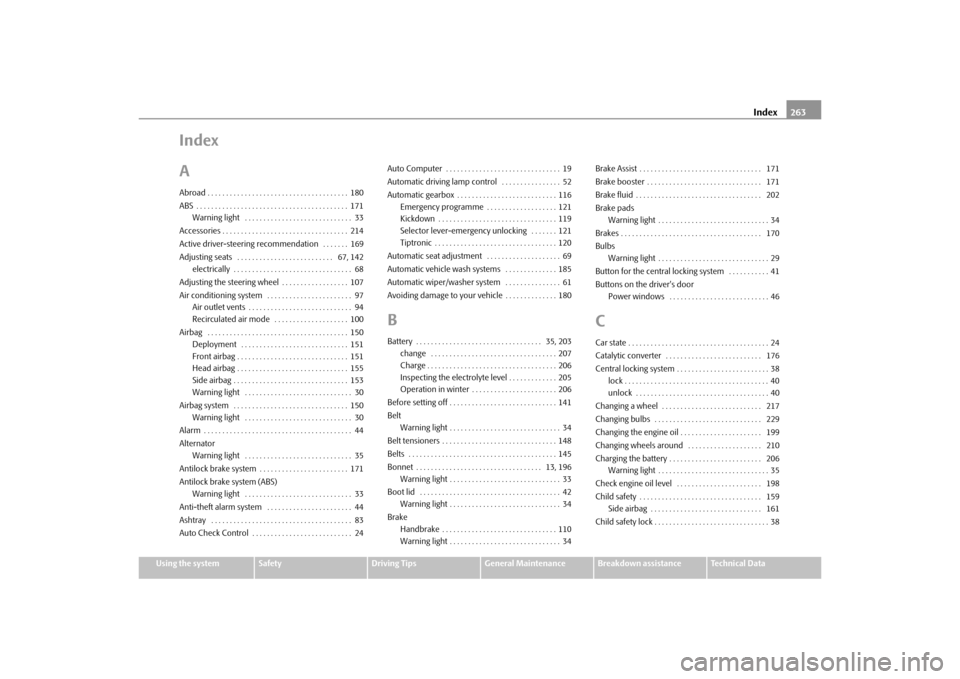

Index

AAbroad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

ABS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Active driver-steering recommendation . . . . . . . 169

Adjusting seats . . . . . . . . . . . . . . . . . . . . . . . . . . 67, 142 electrically . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Adjusting the steering wheel . . . . . . . . . . . . . . . . . . 107

Air conditioning system . . . . . . . . . . . . . . . . . . . . . . . 97 Air outlet vents . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Recirculated air mode . . . . . . . . . . . . . . . . . . . . 100

Airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150 Deployment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Front airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Head airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Side airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Airbag system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150 Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Alternator Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Antilock brake system . . . . . . . . . . . . . . . . . . . . . . . . 171

Antilock brake system (ABS) Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Anti-theft alarm system . . . . . . . . . . . . . . . . . . . . . . . 44

Ashtray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Auto Check Control . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 Auto Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Automatic driving lamp control . . . . . . . . . . . . . . . . 52

Automatic gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Emergency programme . . . . . . . . . . . . . . . . . . . 121

Kickdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Selector lever-emergency unlocking . . . . . . . 121

Tiptronic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Automatic seat adjustment . . . . . . . . . . . . . . . . . . . . 69

Automatic vehicle wash systems . . . . . . . . . . . . . . 185

Automatic wiper/washer system . . . . . . . . . . . . . . . 61

Avoiding damage to your vehicle . . . . . . . . . . . . . . 180

BBattery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35, 203 change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Inspecting the electrolyte level . . . . . . . . . . . . . 205

Operation in winter . . . . . . . . . . . . . . . . . . . . . . . 206

Before setting off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Belt Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Belt tensioners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Bonnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13, 196 Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Boot lid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Brake Handbrake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 Brake Assist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Brake booster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Brake fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Brake pads

Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Bulbs Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Button for the central locking system . . . . . . . . . . . 41

Buttons on the driver's door Power windows . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

CCar state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Catalytic converter . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Central locking system . . . . . . . . . . . . . . . . . . . . . . . . . 38lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

unlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Changing a wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Changing bulbs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Changing the engine oil . . . . . . . . . . . . . . . . . . . . . . 199

Changing wheels around . . . . . . . . . . . . . . . . . . . . 210

Charging the battery . . . . . . . . . . . . . . . . . . . . . . . . . 206 Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Check engine oil level . . . . . . . . . . . . . . . . . . . . . . . 198

Child safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159 Side airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Child safety lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

s43s.1.book Page 263 Thursday, May 13, 2010 1:21 PM