boot SKODA OCTAVIA 2015 3.G / (5E) Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2015, Model line: OCTAVIA, Model: SKODA OCTAVIA 2015 3.G / (5E)Pages: 268, PDF Size: 37.54 MB

Page 107 of 268

CAUTION■When closing the boot lid, jamming and damage to the cover or the side trim

panel can occur if handled incorrectly. The following guidelines must be ob-

served. ■ The recesses in the cover B

» Fig. 118 must lock in the holders in the side

trim panel

C

.

■ The items which are transported must not exceed the height of the cover.

■ The cover must not be jammed in the surrounding seal of the luggage com-

partment lid when it is in the raised position. ■ There must be no object in the gap between the cover in the raise position

and the rear backrest.

Roll-up cover

Fig. 120

Roll-up cover: pull out/roll/remove

Fig. 121

Remove the side panels of the luggage compartment/stow the

roll-up luggage compartment cover

Read and observe and on page 101 first.

Extending

›

Grasp the cover on the handle

A

and pull it out in the direction of the arrow

1

until it clicks » Fig. 120.

Retracting

›

Push the cover in the area of handle

A

in the direction of the arrow

2

» Fig. 120 .

The cover rolls up automatically.

Removing/inserting

The fully rolled luggage compartment cover can be removed.

›

Press on the side of the cross bar in the direction of arrow

3

and remove

the cover in the arrow direction

4

» Fig. 120 .

Insertion takes place in reverse order.

Stowage

If the vehicle is equipped with the variable loading floor, then the removable

roll-up luggage compartment cover can be stowed in the recesses of the lug-

gage compartment side trim.

›

Fold the variable loading floor into the upper position » page 108.

›

Remove the side covers of the luggage compartment in the direction of the

arrow

1

» Fig. 121 .

›

Remove the roll-up luggage compartment cover » Fig. 120.

›

Insert the front part of the roll-up luggage compartment cover under a por-

tion of the side trim

D

» Fig. 121 on the left.

›

Fold the rear part of the roll-up luggage compartment cover in the direction

of arrow

2

» .

›

Replace the side trims of the luggage compartment in the opposite direction

of the arrow

1

.

›

Fold out the variable loading floor to the upper position » page 108.

WARNINGNo objects should be placed on the foldable boot cover. This could endan-

ger the vehicle occupants during sudden braking or vehicle impact.

CAUTION

If you want to stow the roll-up luggage compartment cover and the roof rack

at the same time , then it is necessary that the rear part of the roll-up luggage

compartment is covering the rear roof rack.105Transporting and practical equipment

Page 111 of 268

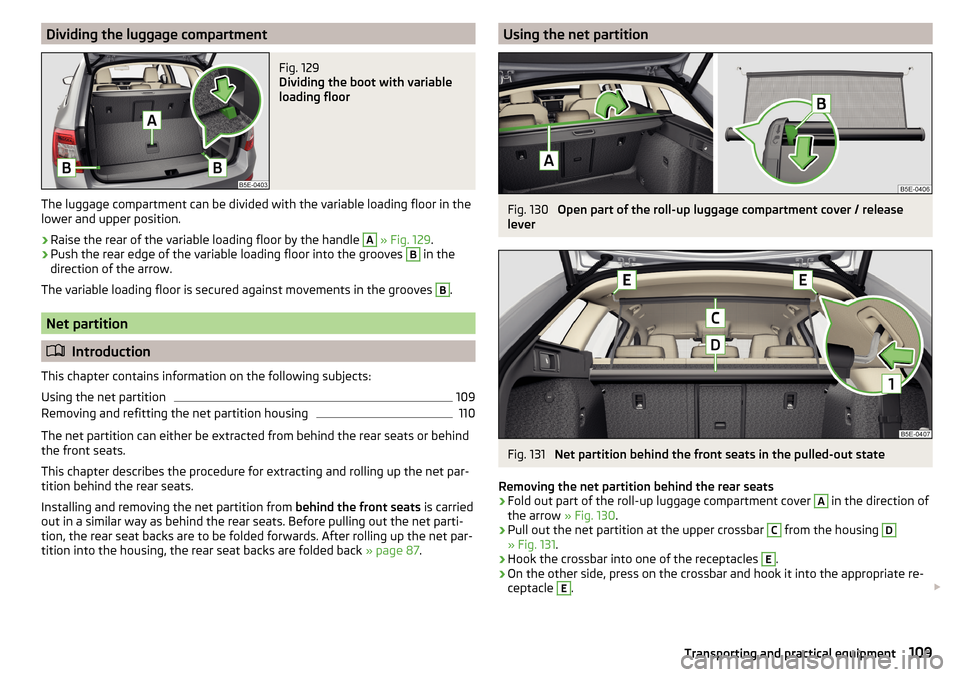

Dividing the luggage compartmentFig. 129

Dividing the boot with variable

loading floor

The luggage compartment can be divided with the variable loading floor in the

lower and upper position.

›

Raise the rear of the variable loading floor by the handle

A

» Fig. 129 .

›

Push the rear edge of the variable loading floor into the grooves

B

in the

direction of the arrow.

The variable loading floor is secured against movements in the grooves

B

.

Net partition

Introduction

This chapter contains information on the following subjects:

Using the net partition

109

Removing and refitting the net partition housing

110

The net partition can either be extracted from behind the rear seats or behind

the front seats.

This chapter describes the procedure for extracting and rolling up the net par-

tition behind the rear seats.

Installing and removing the net partition from behind the front seats is carried

out in a similar way as behind the rear seats. Before pulling out the net parti-

tion, the rear seat backs are to be folded forwards. After rolling up the net par-

tition into the housing, the rear seat backs are folded back » page 87.

Using the net partitionFig. 130

Open part of the roll-up luggage compartment cover / release

lever

Fig. 131

Net partition behind the front seats in the pulled-out state

Removing the net partition behind the rear seats

›

Fold out part of the roll-up luggage compartment cover

A

in the direction of

the arrow » Fig. 130.

›

Pull out the net partition at the upper crossbar

C

from the housing

D

» Fig. 131.

›

Hook the crossbar into one of the receptacles

E

.

›

On the other side, press on the crossbar and hook it into the appropriate re-

ceptacle

E

.

109Transporting and practical equipment

Page 145 of 268

Automatic system activation when moving forwardFig. 161

Infotainment display: Display

with automatic activation

Read and observe and on page 140 first.

The automatic system activation occurs when moving forward at a speed be- low 10 km / h when the vehicle approaches an obstacle.

After activation, the following is shown in the left pane of the Infotainment

display » Fig. 161 .

Acoustic signals are sounded as of a distance from the obstacle of around

50 cm.

The automatic display can be enabled or disabled in the Infotainment » Owner

´s Manual Infotainment , chapter CAR - vehicle settings .

Rear View Camera

Introduction

This chapter contains information on the following subjects:

Operation

143

Guidelines and function keys

144

The rear view camera (hereinafter referred to as system) helps the driver when

parking and manoeuvring by displaying the area behind the vehicle in the Info-

tainment display (hereinafter referred to as display).

WARNING■ The general information relating to the use of assistance systems must

be observed » page 135, in section Introduction .■

Make sure that the camera lens is not dirty or covered, otherwise the sys-

tem function can be significantly impaired. For information on cleaning

» page 185 , Camera lens

CAUTION

■

The camera lens distorts and enlarges the field of view of the difference in

eye sight. The display is therefore only of limited use for estimating distances

to following vehicles.■

Some items, such as thin columns, chain link fences or lattice may not be

represented adequately in terms of display resolution.

■

It is only a two-dimensional display. Therefore, protruding objects or roadway

depressions, for example, may not be recognised due to lack of space depth.

■

In a crash or damage the vehicle's rear camera can possibly deviate from the

correct position. If this is the case, have the sensor checked by a specialist ga-

rage.

Operation

Fig. 162

Position of the camera / Monitored area

Read and observe

and on page 143 first.

The camera for capturing the area behind the vehicle is in the grip of the boot lid » Fig. 162 .

Supervised area » Fig. 162

Detection range of the camera.

Area outside the detection range of the camera.

AB143Assist systems

Page 173 of 268

WARNINGNever remove the tow bar while the trailer is still coupled.

Note

We recommend putting the protective cover onto the ball head before remov-

ing the tow bar.

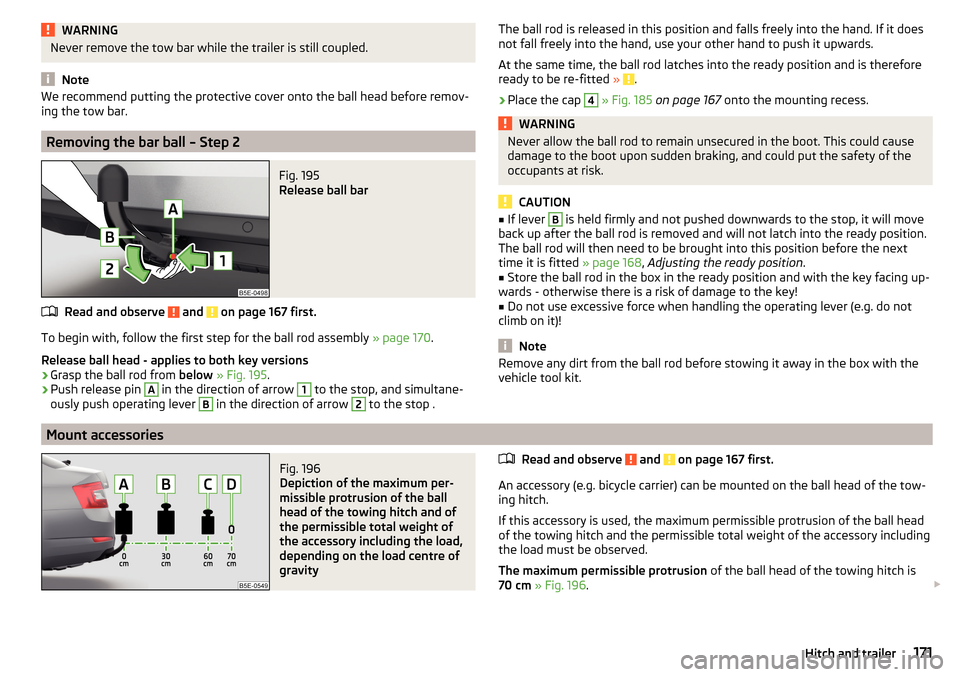

Removing the bar ball – Step 2

Fig. 195

Release ball bar

Read and observe and on page 167 first.

To begin with, follow the first step for the ball rod assembly » page 170.

Release ball head - applies to both key versions

›

Grasp the ball rod from below » Fig. 195 .

›

Push release pin

A

in the direction of arrow

1

to the stop, and simultane-

ously push operating lever

B

in the direction of arrow

2

to the stop .

The ball rod is released in this position and falls freely into the hand. If it does

not fall freely into the hand, use your other hand to push it upwards.

At the same time, the ball rod latches into the ready position and is therefore

ready to be re-fitted »

.

›

Place the cap

4

» Fig. 185 on page 167 onto the mounting recess.

WARNINGNever allow the ball rod to remain unsecured in the boot. This could cause

damage to the boot upon sudden braking, and could put the safety of the

occupants at risk.

CAUTION

■ If lever B is held firmly and not pushed downwards to the stop, it will move

back up after the ball rod is removed and will not latch into the ready position.

The ball rod will then need to be brought into this position before the next

time it is fitted » page 168, Adjusting the ready position .■

Store the ball rod in the box in the ready position and with the key facing up-

wards - otherwise there is a risk of damage to the key!

■

Do not use excessive force when handling the operating lever (e.g. do not

climb on it)!

Note

Remove any dirt from the ball rod before stowing it away in the box with the

vehicle tool kit.

Mount accessories

Fig. 196

Depiction of the maximum per-

missible protrusion of the ball

head of the towing hitch and of

the permissible total weight of

the accessory including the load,

depending on the load centre of

gravity

Read and observe and on page 167 first.

An accessory (e.g. bicycle carrier) can be mounted on the ball head of the tow-

ing hitch.

If this accessory is used, the maximum permissible protrusion of the ball head

of the towing hitch and the permissible total weight of the accessory including

the load must be observed.

The maximum permissible protrusion of the ball head of the towing hitch is

70 cm » Fig. 196 .

171Hitch and trailer

Page 188 of 268

Regularly remove salt and brake abrasion, otherwise the rim material will be

corroded.

Light alloy wheels

After washing thoroughly and treat the wheel rims with a protective product

for light alloy wheels.

For the treatment of wheel rims do not use products which may cause damage

to the paint on the rims.

CAUTION

■ Damage to the paint layer on the wheel rims must be touched up immediate-

ly.■

Severe layers of dirt on the wheels can also result in wheel imbalance. This

may show itself in the form of a wheel vibration which is transmitted to the

steering wheel which, in certain circumstances, can cause premature wear of

the steering. This means it is necessary to remove the dirt.

Towing hitch and mounting recess

Read and observe

and on page 183 first.

Seal the mounting recess with the cap to prevent any ingress of dirt.

In the event of dirt, clean the interior surfaces of the mounting recess and

treat with a suitable preservative.

Always check the ball head before attaching a trailer. Apply suitable grease

where necessary.

Include the protective cap when stowing away the ball rod to protect the boot

from getting contaminated.

CAUTION

Apply grease to the inner part of the mounting recess. Make sure you do not

remove any grease.

Under-body protection

Read and observe

and on page 183 first.

The underside of your vehicle is already permanently protected by the factory

against chemical and mechanical influences.

It is not possible to guarantee that the protective coating will not suffer any

damage as the vehicle is driven.

We recommend having the protective coating underneath the vehicle and the

chassis checked — preferably before the beginning of winter and at the end of winter.WARNINGNever use additional underbody protection or anti-corrosion agents for ex-

haust pipes, catalytic converters, diesel particle filters or heat shields.

When the engine reaches its operating temperature, these substances

might ignite - risk of fire!

Wiper blades

Read and observe

and on page 183 first.

Clean the wiper blades regularly with a glass cleaner. The wiper blades should

be cleaned with a sponge or cloth if they are heavily soiled by insect residues,

for example.

The wiper blades can become soiled with wax residues after washing in auto-

matic vehicle wash systems for example.

Interior care

Introduction

This chapter contains information on the following subjects:

Natural leather

187

Artificial leather, materials and Alcantara ®

187

Seat covers

188

Safety belts

188

We recommend using vehicle care products from ŠKODA Original Accessories.

These are available from ŠKODA Partners. The usage instructions on the pack-

age must be observed.

186General Maintenance

Page 195 of 268

when the engine is restarted. This is not due to any system leakages but a

drop in pressure in the natural gas fuel tank due to technical reasons after a

cooling phase directly after refuelling.

The maximum lifetime of the gas tank is 20 years.

The capacity of the natural gas fuel tank is approximately 15 kg.

The capacity of the gasoline fuel tank is about 50 litres, of which about 6

lighters are in reserve.WARNING■

When refuelling, never get into the vehicle. If you have to get into your

vehicle in exceptional cases, touch a metal surface before you touch the

filling coupling again. This will avoid electrostatic discharges, which may

generate sparks. Sparks can cause a fire during refuelling.■

Natural gas is highly explosive and highly flammable.

Note

During the filling process sounds are heard which are harmless. If you are un-

sure which service station staff to use, ask the petrol station staff.

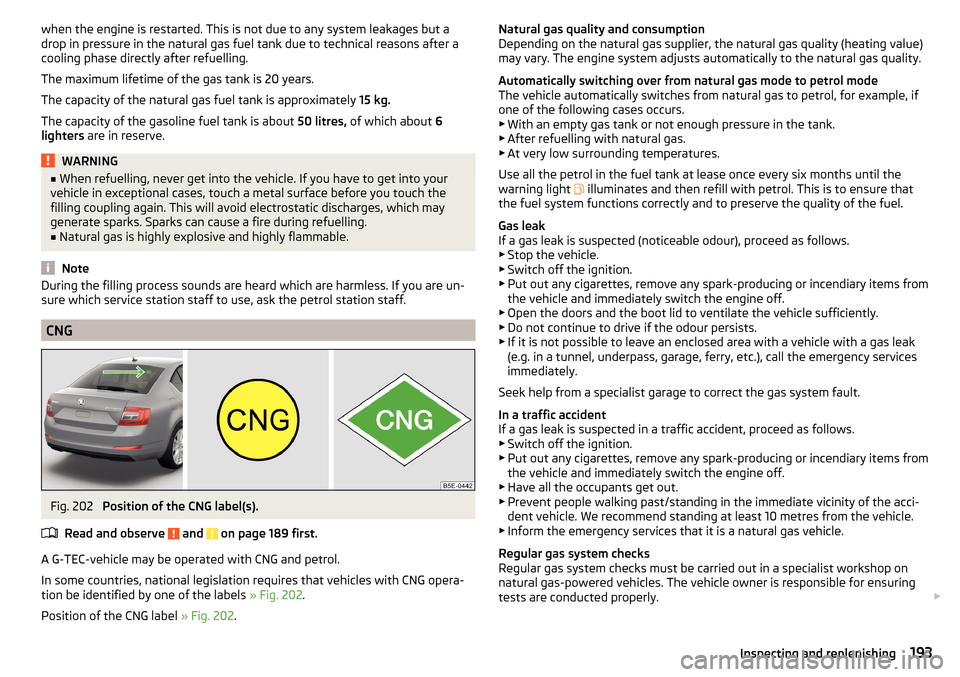

CNG

Fig. 202

Position of the CNG label(s).

Read and observe

and on page 189 first.

A G-TEC-vehicle may be operated with CNG and petrol.

In some countries, national legislation requires that vehicles with CNG opera-

tion be identified by one of the labels » Fig. 202.

Position of the CNG label » Fig. 202.

Natural gas quality and consumption

Depending on the natural gas supplier, the natural gas quality (heating value) may vary. The engine system adjusts automatically to the natural gas quality.

Automatically switching over from natural gas mode to petrol mode

The vehicle automatically switches from natural gas to petrol, for example, if

one of the following cases occurs. ▶ With an empty gas tank or not enough pressure in the tank.

▶ After refuelling with natural gas.

▶ At very low surrounding temperatures.

Use all the petrol in the fuel tank at lease once every six months until the

warning light

illuminates and then refill with petrol. This is to ensure that

the fuel system functions correctly and to preserve the quality of the fuel.

Gas leak

If a gas leak is suspected (noticeable odour), proceed as follows. ▶ Stop the vehicle.

▶ Switch off the ignition.

▶ Put out any cigarettes, remove any spark-producing or incendiary items from

the vehicle and immediately switch the engine off.

▶ Open the doors and the boot lid to ventilate the vehicle sufficiently.

▶ Do not continue to drive if the odour persists.

▶ If it is not possible to leave an enclosed area with a vehicle with a gas leak

(e.g. in a tunnel, underpass, garage, ferry, etc.), call the emergency services

immediately.

Seek help from a specialist garage to correct the gas system fault.

In a traffic accident

If a gas leak is suspected in a traffic accident, proceed as follows.

▶ Switch off the ignition.

▶ Put out any cigarettes, remove any spark-producing or incendiary items from

the vehicle and immediately switch the engine off.

▶ Have all the occupants get out.

▶ Prevent people walking past/standing in the immediate vicinity of the acci-

dent vehicle. We recommend standing at least 10 metres from the vehicle.

▶ Inform the emergency services that it is a natural gas vehicle.

Regular gas system checks

Regular gas system checks must be carried out in a specialist workshop on

natural gas-powered vehicles. The vehicle owner is responsible for ensuring

tests are conducted properly. 193Inspecting and replenishing

Page 215 of 268

CAUTION■Screw the jack back into the starting position before storing in the box with

the vehicle tool kit.■

Ensure that the vehicle tool kit is safely secured in the luggage compart-

ment.

■

Ensure that the box is always secured with the strap.

Note

The declaration of conformity is included with the jack or the log folder.

Changing a wheel

Introduction

This chapter contains information on the following subjects:

Preparation

213

Removing/stowing the wheel

213

Full wheel trim

213

Wheel bolts

214

Anti-theft wheel bolts

214

Loosening/tightening wheel bolts

215

Raising the vehicle

215

Remove the wheel / fix

216

Follow-up tasks

216

For your own safety and the safety of your passengers, the following instruc-

tions must be observed before carrying out a wheel change on the road.

Switch on the hazard warning light.

Place the warning triangle at the prescribed distance.

Park the vehicle as far away as possible from flowing traffic.

Choose a location with a flat, solid surface.

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

Preparation

Before changing the wheel, the following work must be carried out.

›

Switch off the engine.

› For vehicles with

manual transmission select 1st gear.›On vehicles with automatic transmission , place the selector lever in the P

position.›

The parking brake switch.

›

Uncouple any trailers.

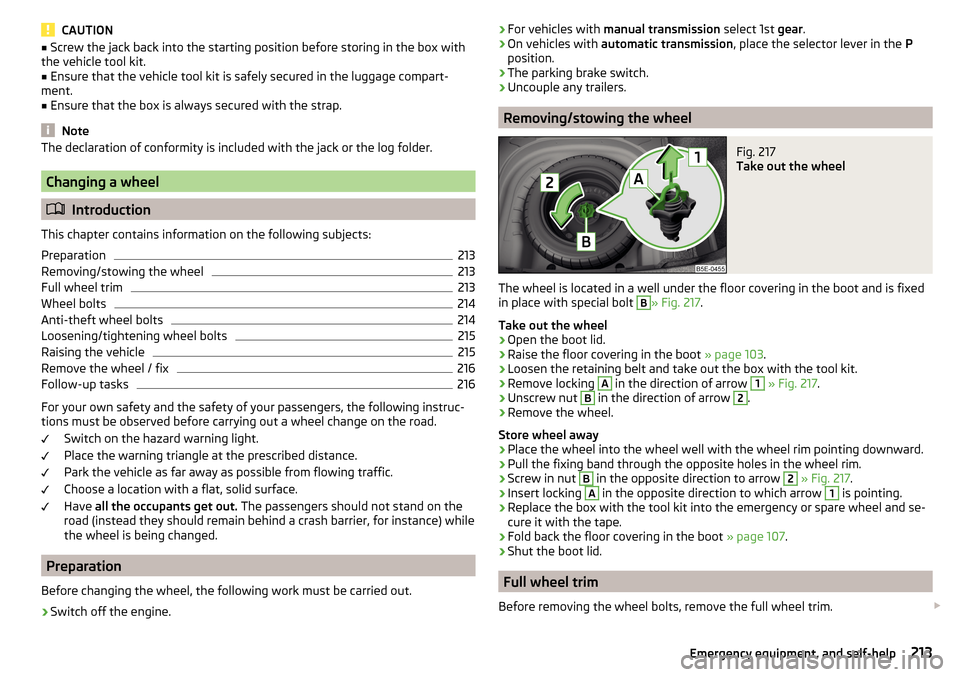

Removing/stowing the wheel

Fig. 217

Take out the wheel

The wheel is located in a well under the floor covering in the boot and is fixed

in place with special bolt

B

» Fig. 217 .

Take out the wheel

›

Open the boot lid.

›

Raise the floor covering in the boot » page 103.

›

Loosen the retaining belt and take out the box with the tool kit.

›

Remove locking

A

in the direction of arrow

1

» Fig. 217 .

›

Unscrew nut

B

in the direction of arrow

2

.

›

Remove the wheel.

Store wheel away

›

Place the wheel into the wheel well with the wheel rim pointing downward.

›

Pull the fixing band through the opposite holes in the wheel rim.

›

Screw in nut

B

in the opposite direction to arrow

2

» Fig. 217 .

›

Insert locking

A

in the opposite direction to which arrow

1

is pointing.

›

Replace the box with the tool kit into the emergency or spare wheel and se-

cure it with the tape.

›

Fold back the floor covering in the boot » page 107.

›

Shut the boot lid.

Full wheel trim

Before removing the wheel bolts, remove the full wheel trim.

213Emergency equipment, and self-help

Page 220 of 268

General informationRead and observe

on page 217 first.

For your own safety and the safety of your passengers, the following instruc-

tions must be observed before carrying out a wheel repair on the road.

Switch on the hazard warning light.

Place the warning triangle at the prescribed distance.

Park the vehicle as far away as possible from flowing traffic.

Choose a location with a flat, solid surface.

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

The breakdown kit must not be used under the following circumstances. ▶ The rim is damaged.

▶ The outside temperature is below -20 ° C.

▶ The cut or puncture is larger than 4 mm.

▶ The tyre wall is damaged.

▶ The expiration date has passed (see inflation bottle).

Preparations for using the breakdown kit

Read and observe

on page 217 first.

The following preparatory work must be carried out before using the puncture

repair kit.

›

Switch off the engine.

›

For vehicles with manual transmission select 1st gear.

›

On vehicles with

automatic transmission , place the selector lever in the P

position.

›

Firmly apply the handbrake.

›

Check that you can carry out the repairs with the breakdown kit » page 217.

›

Uncouple any trailers.

›

Remove the breakdown kit from the boot.

›

Stick the sticker

1

» Fig. 223 on page 217 on the dashboard in the driver's

field of view.

›

Unscrew the valve cap.

›

Use the valve remover

2

to unscrew the valve core and place it on a clean

surface (rag, paper, etc.).

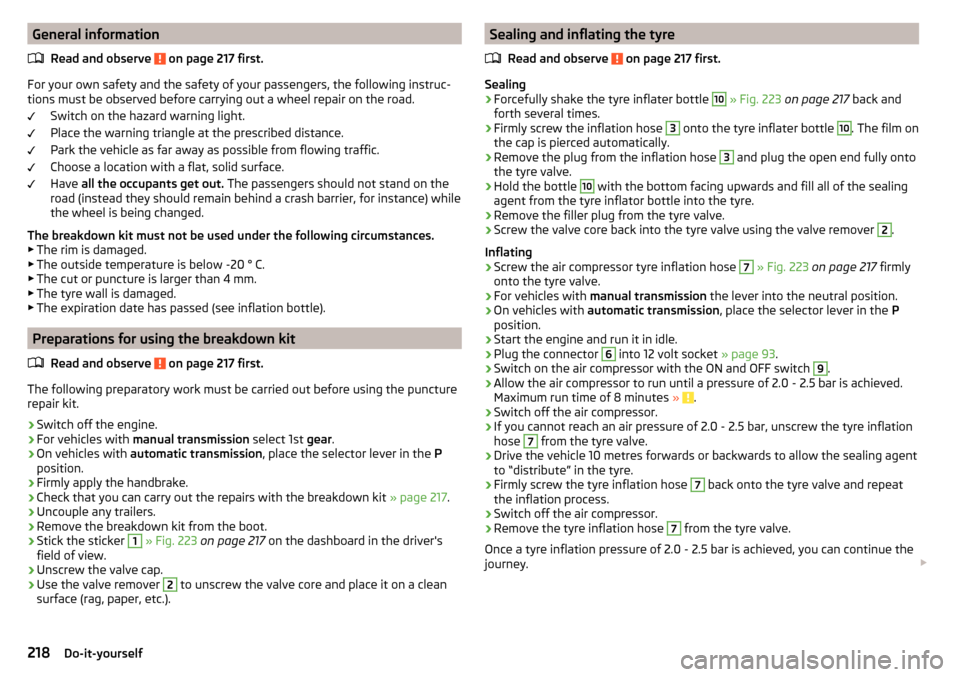

Sealing and inflating the tyre

Read and observe

on page 217 first.

Sealing

›

Forcefully shake the tyre inflater bottle

10

» Fig. 223 on page 217 back and

forth several times.

›

Firmly screw the inflation hose

3

onto the tyre inflater bottle

10

. The film on

the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and plug the open end fully onto

the tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

›

Remove the filler plug from the tyre valve.

›

Screw the valve core back into the tyre valve using the valve remover

2

.

Inflating

›

Screw the air compressor tyre inflation hose

7

» Fig. 223 on page 217 firmly

onto the tyre valve.

›

For vehicles with manual transmission the lever into the neutral position.

›

On vehicles with automatic transmission , place the selector lever in the P

position.

›

Start the engine and run it in idle.

›

Plug the connector

6

into 12 volt socket » page 93.

›

Switch on the air compressor with the ON and OFF switch

9

.

›

Allow the air compressor to run until a pressure of 2.0 - 2.5 bar is achieved.

Maximum run time of 8 minutes » .

›

Switch off the air compressor.

›

If you cannot reach an air pressure of 2.0 - 2.5 bar, unscrew the tyre inflation

hose

7

from the tyre valve.

›

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent

to “distribute” in the tyre.

›

Firmly screw the tyre inflation hose

7

back onto the tyre valve and repeat

the inflation process.

›

Switch off the air compressor.

›

Remove the tyre inflation hose

7

from the tyre valve.

Once a tyre inflation pressure of 2.0 - 2.5 bar is achieved, you can continue the journey.

218Do-it-yourself

Page 226 of 268

Emergency unlocking/locking

Introduction

This chapter contains information on the following subjects:

Unlocking/locking the driver's door

224

Locking the door without a locking cylinder

224

Unlock the boot lid

224

Selector lever-emergency unlocking

225

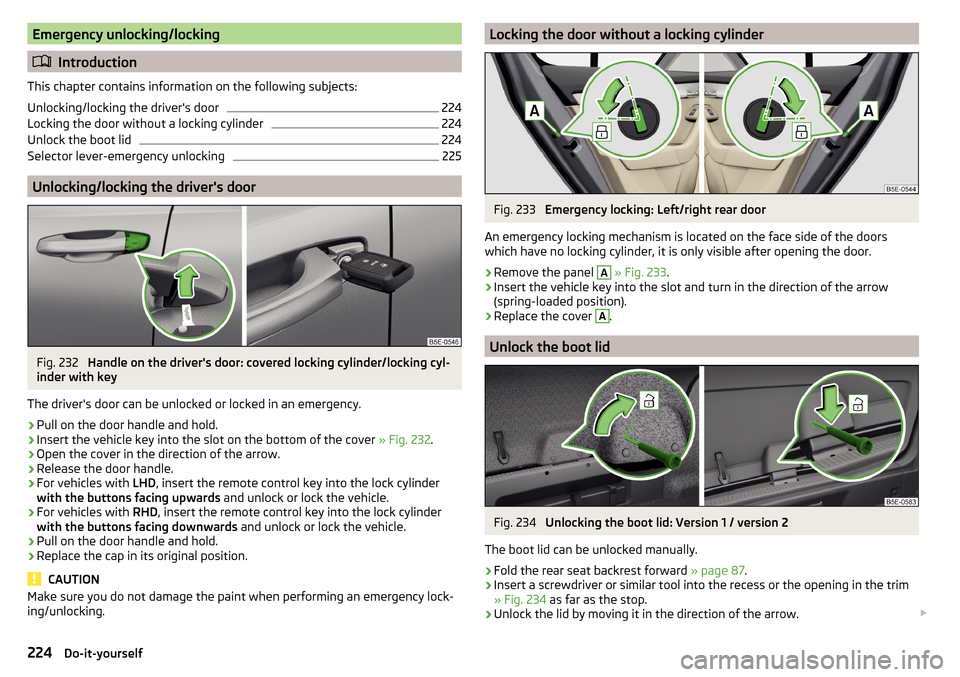

Unlocking/locking the driver's door

Fig. 232

Handle on the driver's door: covered locking cylinder/locking cyl-

inder with key

The driver's door can be unlocked or locked in an emergency.

›

Pull on the door handle and hold.

›

Insert the vehicle key into the slot on the bottom of the cover » Fig. 232.

›

Open the cover in the direction of the arrow.

›

Release the door handle.

›

For vehicles with LHD, insert the remote control key into the lock cylinder

with the buttons facing upwards and unlock or lock the vehicle.

›

For vehicles with RHD, insert the remote control key into the lock cylinder

with the buttons facing downwards and unlock or lock the vehicle.

›

Pull on the door handle and hold.

›

Replace the cap in its original position.

CAUTION

Make sure you do not damage the paint when performing an emergency lock-

ing/unlocking.Locking the door without a locking cylinderFig. 233

Emergency locking: Left/right rear door

An emergency locking mechanism is located on the face side of the doors

which have no locking cylinder, it is only visible after opening the door.

›

Remove the panel

A

» Fig. 233 .

›

Insert the vehicle key into the slot and turn in the direction of the arrow

(spring-loaded position).

›

Replace the cover

A

.

Unlock the boot lid

Fig. 234

Unlocking the boot lid: Version 1 / version 2

The boot lid can be unlocked manually.

›

Fold the rear seat backrest forward » page 87.

›

Insert a screwdriver or similar tool into the recess or the opening in the trim

» Fig. 234 as far as the stop.

›

Unlock the lid by moving it in the direction of the arrow.

224Do-it-yourself

Page 227 of 268

›Open the boot lid.

Selector lever-emergency unlocking

Fig. 235

Selector lever-emergency unlocking

›

Firmly apply the handbrake.

›

Open the stowage compartment in the front centre console

» page 91.

›

Grab hold of the cover

A

in the area of the arrows and carefully raise it for-

wards in the direction of the arrow

1

and then backwards » Fig. 235.

›

Use a finger to press the yellow plastic part in the direction of the arrow

2

.

›

At the same time, press the locking button in the selector lever and move

the selector lever to position N.

If the selector lever is moved again to position P, it is once again blocked.

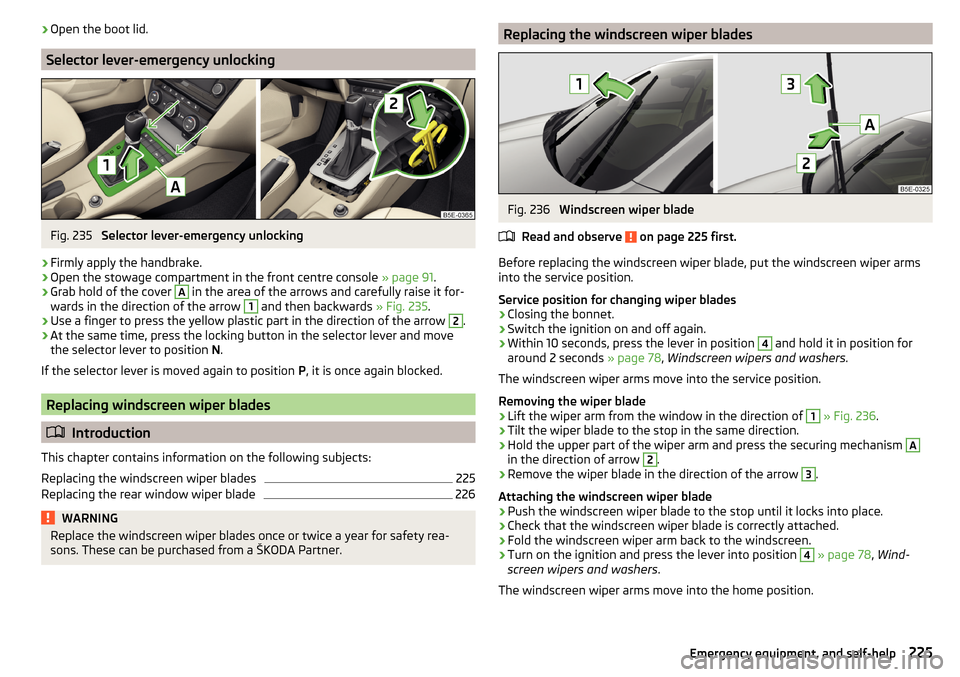

Replacing windscreen wiper blades

Introduction

This chapter contains information on the following subjects:

Replacing the windscreen wiper blades

225

Replacing the rear window wiper blade

226WARNINGReplace the windscreen wiper blades once or twice a year for safety rea-

sons. These can be purchased from a ŠKODA Partner.Replacing the windscreen wiper bladesFig. 236

Windscreen wiper blade

Read and observe

on page 225 first.

Before replacing the windscreen wiper blade, put the windscreen wiper arms

into the service position.

Service position for changing wiper blades

›

Closing the bonnet.

›

Switch the ignition on and off again.

›

Within 10 seconds, press the lever in position

4

and hold it in position for

around 2 seconds » page 78, Windscreen wipers and washers .

The windscreen wiper arms move into the service position.

Removing the wiper blade

›

Lift the wiper arm from the window in the direction of

1

» Fig. 236 .

›

Tilt the wiper blade to the stop in the same direction.

›

Hold the upper part of the wiper arm and press the securing mechanism

A

in the direction of arrow

2

.

›

Remove the wiper blade in the direction of the arrow

3

.

Attaching the windscreen wiper blade

›

Push the windscreen wiper blade to the stop until it locks into place.

›

Check that the windscreen wiper blade is correctly attached.

›

Fold the windscreen wiper arm back to the windscreen.

›

Turn on the ignition and press the lever into position

4

» page 78 , Wind-

screen wipers and washers .

The windscreen wiper arms move into the home position.

225Emergency equipment, and self-help