tire pressure SKODA OCTAVIA 2015 3.G / (5E) Owner's Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2015, Model line: OCTAVIA, Model: SKODA OCTAVIA 2015 3.G / (5E)Pages: 268, PDF Size: 37.54 MB

Page 175 of 268

Exterior mirrors

You should have additional exterior mirrors fitted if you are not able to see the

traffic behind the trailer with the standard rear-view mirrors.

Headlights

The front of the vehicle may lift up when a trailer is being towed and the head-

lights may dazzle other road users.

Adjust the headlights using the headlight beam control » page 68, Operating

the lights 1)

.

Power to the trailer power grid

For the electrical connection between the vehicle and trailer, the trailer's pow-

er supply is provided by the vehicle.

The power supply works with ignition on or off.

With the ignition off, the battery of the towing vehicle is discharged by activa-

ted consumers.

At low charge state of the vehicle battery power to the trailer is interrupted.WARNING■ Improperly connected trailer electrical installations may cause accidents

or serious injury due to electric shock.■

Work on the electrical system must only be carried out by specialist ga-

rages.

■

Never directly connect the trailer's electrical system with the electrical

connections for the tail lights or other current sources.

WARNING (Continued)■ After attaching the trailer and connecting the power socket, check that

the rear lights on the trailer are working correctly.■

Never use the safety eye to tow a vehicle!

CAUTION

Improperly connected trailer electrical installations may cause malfunction of

the entire vehicle electronics.

Note

■ The total power consumption of all the connected consumers on the trailer

must not exceed 350 watts.■

Coat the ball head of the towing device with a suitable grease whenever

necessary.

Loading a trailer

Distribution of the cargo

Distribute the cargo in the trailer in such a way that heavy items are located as

close to the trailer axle as possible. Secure the items from slipping.

The distribution of the weight is very poor if your vehicle is unladen and the

trailer is laden. Drive at a particularly low speed if you cannot avoid driving

with this combination.

Tyre pressure

Correct the tyre inflation pressure on the vehicle for a “full load” » page 205.

WARNINGSliding cargo can significantly adversely affect stability and driving safety -

risk of accident!

Trailer load

The permissible trailer load must not be exceeded under any circumstances. 1)

Applies to vehicles with xenon headlights.

173Hitch and trailer

Page 185 of 268

WARNING■Vehicle care products may be harmful to your health if not used according

to the instructions.■

Always keep the vehicle care products safe from people who are not com-

pletely independent, e.g. children - there is a danger of poisoning!

■

Protect your hands and arms from sharp-edged metal parts when clean-

ing the underfloor, the inside of the wheel housings or the wheel trims –

risk of cuts!

CAUTION

■ Do not use any insect sponges, rough kitchen sponges or similar cleaning

products – risk of damaging the paintwork surface.■

Cleaner that contain solvents can damage the material being cleaned.

Note

Due to the special tools and knowledge required, and to avoid any potential

problems with the cleaning and care of your vehicle's exterior, we recommend

that the cleaning and care of your vehicle be carried out by a ŠKODA Service

Partner.

Vehicle paint work

Read and observe

and on page 183 first.

Preserving the vehicle paintwork

Thorough wax treatment is an effective way of protecting the paintwork from

harmful environmental influences.

The vehicle must be treated with a high-quality hard wax polish at the latest,

when no more drops form on the clean paintwork.

A new layer of a high-quality hard wax polish can be applied to the clean body- work after it has dried thoroughly.

Even if you use a wax preserver regularly we still recommend that you treat

the paintwork of the vehicle at least twice a year with hard wax.

Polishing

Polishing is necessary if the vehicle's paintwork has become unattractive and

if it is no longer possible to achieve a gloss with wax preservatives.

If the polish does not contain any preserving elements, the paint must be trea- ted with a preservative afterwards.

CAUTION■ Paint damage is to be repaired immediately.■Never apply wax to the windows.■

Mat painted or plastic parts must not be treated with polishing products or

hard waxes.

■

Do not polish the paintwork in a dusty environment - risk of paint scratches.

■

Do not apply any paint care products to door seals or window guides.

■

If possible, do not apply any paint care products to parts of the bodywork

that come into contact with door seals or window guides.

Films

Read and observe

and on page 183 first.

Cleaning

Films (e.g. roof, decorative, protective films, etc.) must be cleaned more care-

fully than the vehicle paint.

The films may not be washed with a high-pressure cleaner.

Only wash the films with a soft cloth, mild soap solution and clean, warm wa-

ter.

Service life

Environmental influences (e.g. sunlight, humidity, air pollution, rockfall) affect

the life of the films.

Sunlight may also affect the strength of the film colour.

Films will age and become brittle – this is entirely normal; this is not a fault.

CAUTION

■ Never use aggressive cleaning agents or chemical solvents for the glued sur-

faces with films - there is a danger of film damage.■

Never use dirty cloths or chemical solvents for the glued surfaces with films -

there is a danger of damaging the film.

■

In the winter months, do not use an ice scraper to remove ice and snow from

the areas with films. Do not use any other objects to remove frozen layers of

snow or ice – risk of film damage.

■

Do not polish the films - risk of damage!

■

When transporting a load on the roof rack (e.g. roof box or similar), there is

an increased risk of film damage (e.g. of chipping from the secured load).

183Care and maintenance

Page 209 of 268

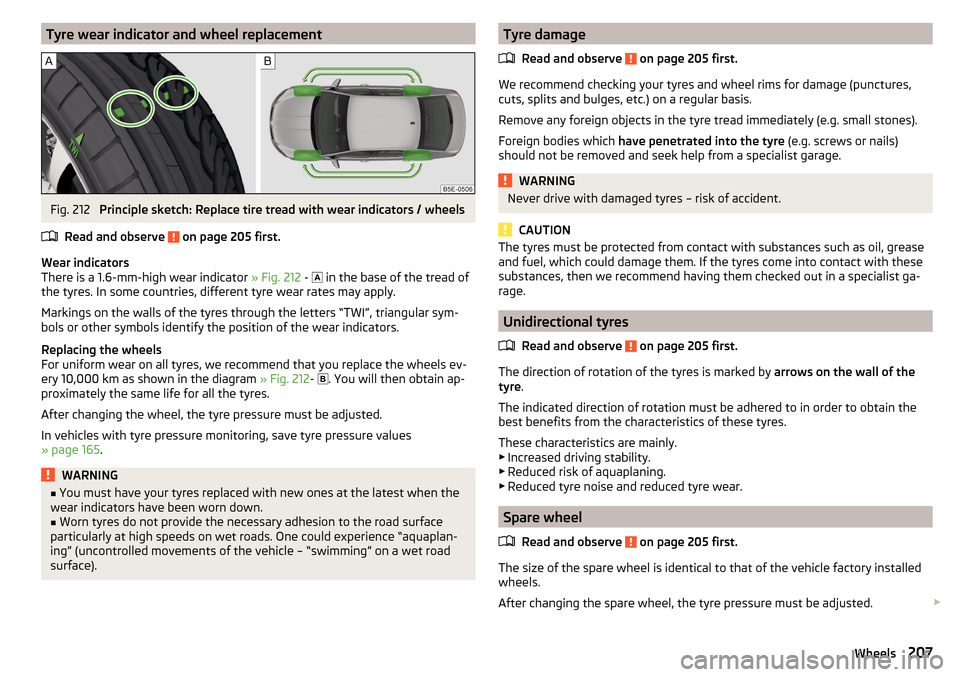

Tyre wear indicator and wheel replacementFig. 212

Principle sketch: Replace tire tread with wear indicators / wheels

Read and observe

on page 205 first.

Wear indicators

There is a 1.6-mm-high wear indicator » Fig. 212 -

in the base of the tread of

the tyres. In some countries, different tyre wear rates may apply.

Markings on the walls of the tyres through the letters “TWI”, triangular sym- bols or other symbols identify the position of the wear indicators.

Replacing the wheels

For uniform wear on all tyres, we recommend that you replace the wheels ev-

ery 10,000 km as shown in the diagram » Fig. 212-

. You will then obtain ap-

proximately the same life for all the tyres.

After changing the wheel, the tyre pressure must be adjusted.

In vehicles with tyre pressure monitoring, save tyre pressure values

» page 165 .

WARNING■

You must have your tyres replaced with new ones at the latest when the

wear indicators have been worn down.■

Worn tyres do not provide the necessary adhesion to the road surface

particularly at high speeds on wet roads. One could experience “aquaplan- ing” (uncontrolled movements of the vehicle – “swimming” on a wet road surface).

Tyre damage

Read and observe

on page 205 first.

We recommend checking your tyres and wheel rims for damage (punctures,

cuts, splits and bulges, etc.) on a regular basis.

Remove any foreign objects in the tyre tread immediately (e.g. small stones).

Foreign bodies which have penetrated into the tyre (e.g. screws or nails)

should not be removed and seek help from a specialist garage.

WARNINGNever drive with damaged tyres – risk of accident.

CAUTION

The tyres must be protected from contact with substances such as oil, grease

and fuel, which could damage them. If the tyres come into contact with these

substances, then we recommend having them checked out in a specialist ga-

rage.

Unidirectional tyres

Read and observe

on page 205 first.

The direction of rotation of the tyres is marked by arrows on the wall of the

tyre .

The indicated direction of rotation must be adhered to in order to obtain the

best benefits from the characteristics of these tyres.

These characteristics are mainly.

▶ Increased driving stability.

▶ Reduced risk of aquaplaning.

▶ Reduced tyre noise and reduced tyre wear.

Spare wheel

Read and observe

on page 205 first.

The size of the spare wheel is identical to that of the vehicle factory installedwheels.

After changing the spare wheel, the tyre pressure must be adjusted.

207Wheels

Page 216 of 268

Extracting›Hook the clamp found in the vehicle tool kit » page 212 into the reinforced

edge of the wheel trim.›

Push the wheel wrench through the clamp, support on the tyre and pull off

the wheel trim.

Installing

›

Press the wheel trim onto the wheel rim at the designated valve opening.

›

Then press the trim into the wheel rim until its entire circumference locks

correctly in place.

Notes on wheel trims supplied at the factory or from ŠKODAOriginal Accesso-

ries. ▶ When using an anti-theft wheel bolt, make sure that this has been fitted ac-

cording to the position marked on the back of the wheel cover position.

▶ On the back of the wheel cover, the position for the anti-theft wheel bolt is

marked by means of a symbol. If the wheel cover is set outside the position

marked for the anti-theft wheel bolt, there is a risk of damaging the wheel

cover.

If wheel trims are fitted, an adequate flow of air must be assured in order to

cool the brake system.

CAUTION

Use the pressure of your hand only, do not strike the full wheel trim. The cover

could be damaged.

Note

We recommend that you use hub caps from ŠKODA Original Accessories.

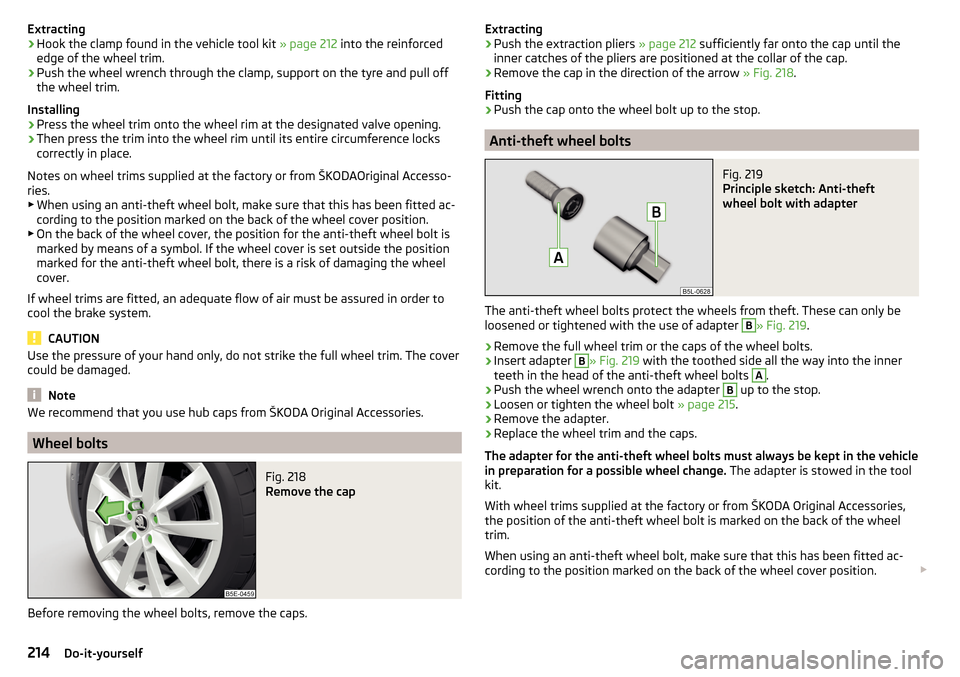

Wheel bolts

Fig. 218

Remove the cap

Before removing the wheel bolts, remove the caps.

Extracting›Push the extraction pliers » page 212 sufficiently far onto the cap until the

inner catches of the pliers are positioned at the collar of the cap.›

Remove the cap in the direction of the arrow » Fig. 218.

Fitting

›

Push the cap onto the wheel bolt up to the stop.

Anti-theft wheel bolts

Fig. 219

Principle sketch: Anti-theft

wheel bolt with adapter

The anti-theft wheel bolts protect the wheels from theft. These can only be

loosened or tightened with the use of adapter

B

» Fig. 219 .

›

Remove the full wheel trim or the caps of the wheel bolts.

›

Insert adapter

B

» Fig. 219 with the toothed side all the way into the inner

teeth in the head of the anti-theft wheel bolts

A

.

›

Push the wheel wrench onto the adapter

B

up to the stop.

›

Loosen or tighten the wheel bolt » page 215.

›

Remove the adapter.

›

Replace the wheel trim and the caps.

The adapter for the anti-theft wheel bolts must always be kept in the vehicle

in preparation for a possible wheel change. The adapter is stowed in the tool

kit.

With wheel trims supplied at the factory or from ŠKODA Original Accessories,

the position of the anti-theft wheel bolt is marked on the back of the wheel

trim.

When using an anti-theft wheel bolt, make sure that this has been fitted ac-

cording to the position marked on the back of the wheel cover position.

214Do-it-yourself

Page 218 of 268

Raising the vehicle›Insert the crank 7 into the mount on the jack 6» page 212.›

Support the base plate of the jack with its entire surface resting on level

ground and ensure that the lever is positioned vertically to the jacking point

» Fig. 222 .

›

Use the crank to raise the jack until its claw encloses the bar » Fig. 222.

›

Continue to raise the jack until the wheel is just lifted off the ground.

WARNING■

If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpect-

edly rolling away.■

Secure the base plate of the lifting jack with suitable means to prevent

possible moving. A soft and slippery ground under the base plate may move

the lifting jack, causing the vehicle to fall down. It is therefore always nec-

essary to place the lifting jack on a solid surface or use a wide and stable

base. Use a non-slip base (e.g. a rubber foot mat) if the surface is smooth,

such as cobbled stones, tiled floor, etc.

■

Only attach the lifting jack to the attachment points provided for this pur-

pose.

■

Always raise the vehicle with the doors closed.

■

Never position any body parts, such as arms or legs under the vehicle,

while the vehicle is raised with a lifting jack.

■

When the vehicle is raised, never start the engine.

CAUTION

It is important to ensure that the jack is correctly attached to the bar of the

lower beam, as otherwise there is a risk of damage to the vehicle.

Remove the wheel / fix

When changing a wheel, the following instructions must be followed.

›

Remove the full wheel trim or the caps of the wheel bolts.

›

First of all slacken the anti-theft wheel bolt and then the other wheel bolts.

›

Jack up the vehicle until the wheel that needs changing is clear of the

ground.

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper,

etc.).

›

Remove the wheel carefully.

›

Attach the wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

› Tighten the wheel bolts opposite each other using the wheel wrench (alter-

nating crosswise). Tighten the anti-theft wheel bolt last.›

Replace the wheel trim and the caps.

When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect » page 207 .

All bolts must be clean and must turn easily.

If it is established when changing a wheel that the wheel bolts are corroded and difficult to move, then these must be replaced.

Under no circumstances grease or oil the wheel bolts!

WARNINGUndo the wheel bolts only a little (about one turn) as long as the vehicle

has not yet been jacked up. Otherwise the wheel could become loose and

fall off.

Follow-up tasks

After changing the wheel, the following work must be carried out.

›

Stow the replaced wheel in the wheel well and secure it with a special screw.

›

Stow the tool kit in the space provided and secure using the band.

›

Check the tyre pressure on the installed wheel as soon as possible.

›

Have the tightening torque of the wheel bolts checked with a torque wrench

as soon as possible.

After changing the wheel, the tyre pressure must be adjusted. In vehicles with

tyre pressure monitoring, save tyre pressure values » page 165.

Replace the damaged wheel or consult a specialist garage about repair op-

tions.

The prescribed tightening torque of the wheel bolts is 120 Nm.

WARNING■

If the wheel bolts are tightened to a too low tightening torque, the rim

can come loose when the car is moving. A tightening torque which is too

high can damage the bolts and threads and this can result in permanent

deformation of the contact surfaces on the rim.■

Drive cautiously and only at a moderate speed until the tightening torque

has been checked.

216Do-it-yourself