boot SKODA RAPID 2013 1.G Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2013, Model line: RAPID, Model: SKODA RAPID 2013 1.GPages: 226, PDF Size: 15.16 MB

Page 122 of 226

Towing a trailer

Towing device

Introduction

This chapter contains information on the following subjects:

Description

119

Adjusting the ready position

120

Fitting the ball head

121

Check proper fitting

121

Removing the ball head

122

Use and care

122

If your vehicle has already been factory-fitted with a towing device or is fitted

with a towing device from ŠKODA Original Accessories, then it meets all of the

technical requirements and national legal regulations for towing a trailer.

Your vehicle is fitted with a 13-pin power socket for the electrical connection be-

tween the vehicle and trailer. If the trailer that is to be towed has a 7-pin connec-

tor , you can use a suitable adapter from ŠKODA Original Accessories.

The maximum trailer drawbar load is 50 kg.

WARNING■

Check that the tow bar is seated correctly and is secured in the mounting

recess before the start of every journey.■

Do not use the tow bar if it is not correctly inserted and secured in the

mounting recess.

■

Do not use the towing device if it is damaged or if there are parts missing.

■

Do not modify or adapt the towing device in any way.

■

Never release the tow bar while the trailer is still coupled.

CAUTION

Take care when handling the tow bar so as to avoid damaging the paintwork on

the bumper.

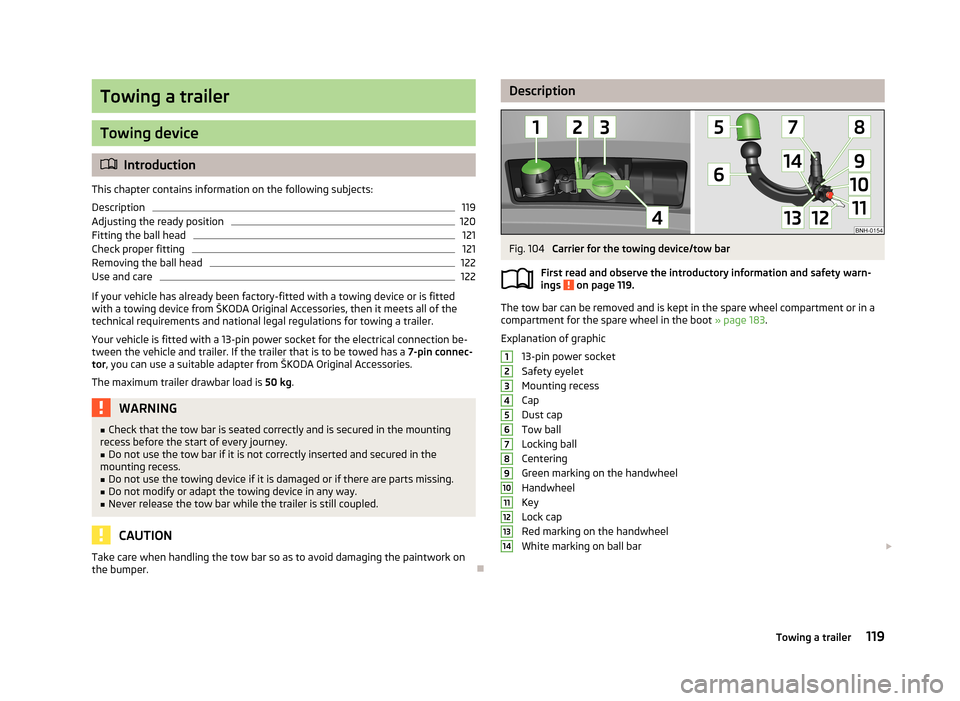

DescriptionFig. 104

Carrier for the towing device/tow bar

First read and observe the introductory information and safety warn-

ings

on page 119.

The tow bar can be removed and is kept in the spare wheel compartment or in a

compartment for the spare wheel in the boot » page 183.

Explanation of graphic 13-pin power socket

Safety eyelet

Mounting recess

Cap

Dust cap

Tow ball

Locking ball

Centering

Green marking on the handwheel

Handwheel

Key

Lock cap

Red marking on the handwheel

White marking on ball bar

1234567891011121314119Towing a trailer

Page 125 of 226

The handwheel is locked and the key is removed.

The cap B

is on the handwheel.

The tow bar does not come out of the mounting recess even after heavy

“shaking”.WARNINGDo not use the towing device unless the tow bar has been properly locked!

Removing the ball head

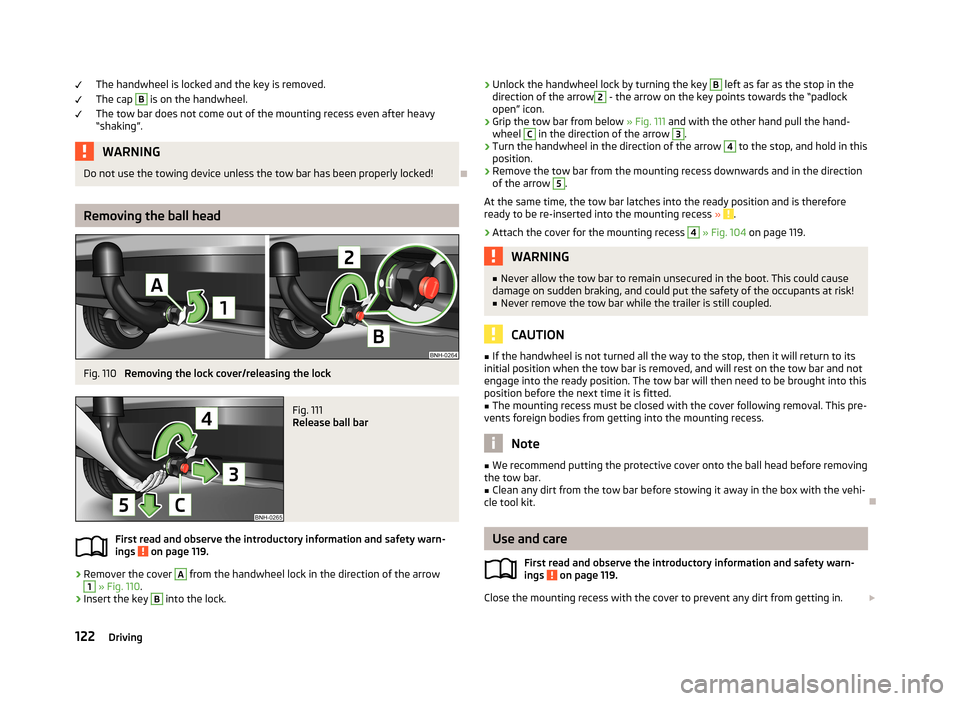

Fig. 110

Removing the lock cover/releasing the lock

Fig. 111

Release ball bar

First read and observe the introductory information and safety warn-

ings on page 119.

›

Remover the cover

A

from the handwheel lock in the direction of the arrow

1

» Fig. 110 .

›

Insert the key

B

into the lock.

›

Unlock the handwheel lock by turning the key B left as far as the stop in the

direction of the arrow2 - the arrow on the key points towards the “padlock

open” icon.›

Grip the tow bar from below » Fig. 111 and with the other hand pull the hand-

wheel

C

in the direction of the arrow

3

.

›

Turn the handwheel in the direction of the arrow

4

to the stop, and hold in this

position.

›

Remove the tow bar from the mounting recess downwards and in the direction

of the arrow

5

.

At the same time, the tow bar latches into the ready position and is therefore

ready to be re-inserted into the mounting recess »

.

›

Attach the cover for the mounting recess

4

» Fig. 104 on page 119.

WARNING■

Never allow the tow bar to remain unsecured in the boot. This could cause

damage on sudden braking, and could put the safety of the occupants at risk!■

Never remove the tow bar while the trailer is still coupled.

CAUTION

■ If the handwheel is not turned all the way to the stop, then it will return to its

initial position when the tow bar is removed, and will rest on the tow bar and not

engage into the ready position. The tow bar will then need to be brought into this position before the next time it is fitted.■

The mounting recess must be closed with the cover following removal. This pre-

vents foreign bodies from getting into the mounting recess.

Note

■ We recommend putting the protective cover onto the ball head before removing

the tow bar.■

Clean any dirt from the tow bar before stowing it away in the box with the vehi-

cle tool kit.

Use and care

First read and observe the introductory information and safety warn-

ings

on page 119.

Close the mounting recess with the cover to prevent any dirt from getting in.

122Driving

Page 126 of 226

Always check the tow bar before hitching a trailer. Apply suitable grease where

necessary.

Use the protective cover when stowing away the tow bar, in order to stop the

boot from getting dirty.

In the event of dirt, clean the surfaces of the mounting recess and treat with a

suitable preservative.

CAUTION

Apply grease to the upper part of the mounting recess. Make sure you do not re-

move any grease.

Trailer

Introduction

This chapter contains information on the following subjects:

Loading a trailer

123

Driving with a trailer

124

Anti-theft alarm system

125WARNINGAlways drive particularly carefully with the trailer.

Loading a trailer

First read and observe the introductory information and safety warn-

ings

on page 123.

The vehicle/trailer combination must be balanced, whereby the maximum permis-

sible drawbar load must be utilised. If the drawbar load is too low, it jeopardises the performance of the vehicle/trailer combination.

Distribution of the load

Distribute the load in the trailer in such a way that heavy items are located as close to the axle as possible. Secure the items from slipping.

The distribution of the weight is very poor if your vehicle is unladen and the trail-

er is laden. Maintain a particularly low speed if you cannot avoid driving with this

combination.

Tyre pressure

Correct the tyre inflation pressure on your vehicle for a “full load” » page 176,

Service life of tyres .

Trailer load

The permissible trailer load must not be exceeded under any circumstan- ces » page 207 , Technical data .

The trailer loads specified apply only to altitudes up to 1 000 metres above mean

sea level.

The engine output falls as altitude increases, as does the vehicle's climbing pow-

er. Therefore, for every additional 1000 m in height (or part), the maximum per-

missible towed weight must be reduced by 10%.

The towed weight is made up of the actual weights of the loaded towing vehicle

and the loaded trailer.

The trailer and drawbar load information on the type plate of the towing device is

merely a test value for the towing device. The vehicle-specific values are detailed

in the vehicle documents.WARNING■ Do not exceed the maximum permissible axle and drawbar load and the

maximum permissible total or towed weight of the vehicle and the trailer –

risk of accident and serious injury!■

Slipping loads can significantly impair the stability and safety of the vehicle/

trailer combination – risk of accident and serious injury!

123Towing a trailer

Page 150 of 226

General Maintenance

Vehicle care

Service intervals

Introduction

This chapter contains information on the following subjects:

Overview of service intervals

147

Fixed service intervals QI1 - QI4

148

Variable service interval QI6

148

Information about the ŠKODA service

148

The service interval display in the instrument cluster will remind you to carry out every service stipulated by the manufacturer at the right time in order to prevent you from forgetting any.

Timely and proper performance of servicing works is one of the requirements for the settlement of potential warranty claims.

The completion of services can be verified by the validated service certificate and the corresponding receipts.

The specified service intervals are tailored to normal operating conditions.

In the case of difficult operating conditions, it is necessary to have some service

work performed before the date of the next service or between the specified

service intervals. This applies mainly to the cleaning or the replacement of the air

filter insert in regions with heavy dust pollution as well as checking and replacing

the toothed belt, but also to vehicles with diesel particle filters, which can put

greater strain on the engine oil.

These difficult conditions are: › Fuel with sulphur content;

› Frequent short trips;

› Longer periods of engine idling (e.g. taxis);

› Operation in areas with heavy dust pollution;

› Frequent trailer operation;

›

Predominantly stop-and-go traffic as is often the case in city driving, for exam-

ple;

› Operation predominantly during winter.

A service consultant at the specialist garage will tell you whether the operating conditions of your vehicle may make it necessary for service work to be carried

out between the normal service intervals.

Different service charges may apply from the particular scope of work required,

depending on the vehicle type and equipment and the status of your vehicle.

Note

■ The customer is responsible for covering the cost of all services including

changing or replenishing the oil, even during the warranty period, unless stated otherwise in the ŠKODA AUTO a.s. warranty terms or other agreements.■

You will be informed about the current service scopes for the particular service

work by the specialist garage.

Overview of service intervals

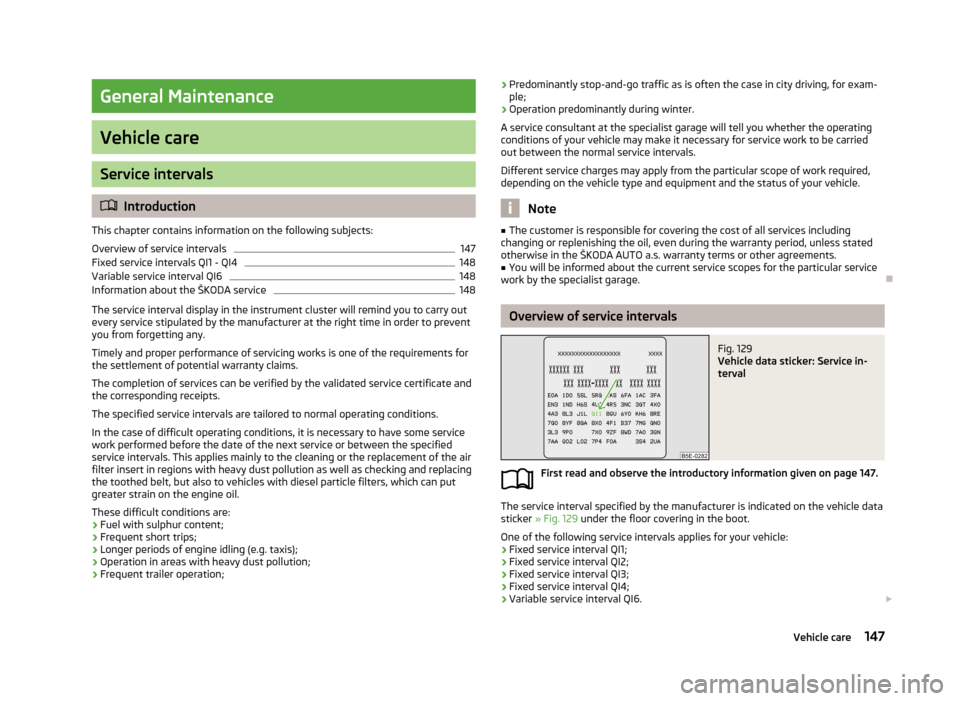

Fig. 129

Vehicle data sticker: Service in-

terval

First read and observe the introductory information given on page 147.

The service interval specified by the manufacturer is indicated on the vehicle data sticker » Fig. 129 under the floor covering in the boot.

One of the following service intervals applies for your vehicle: › Fixed service interval QI1;

› Fixed service interval QI2;

› Fixed service interval QI3;

› Fixed service interval QI4;

› Variable service interval QI6.

147Vehicle care

Page 161 of 226

Natural leatherFirst read and observe the introductory information and safety warn-

ings

on page 157.

Leather is a natural material with specific properties, and requires regular clean-

ing and maintenance.

The leather should be cleaned on a regular basis depending on the amount of

wear-and-tear.

Dust and dirt in the pores and folds act as abrasive materials. This leads to severe corrosion and the premature brittleness of the leather surface.

We recommend that you remove dust regularly and at short intervals using a

cloth or vacuum cleaner.

Clean soiled leather surfaces with a water-dampened cotton or woollen cloth and

then dry with a clean, dry cloth »

.

Clean severely soiled areas with a cloth soaked in a mild soap solution (2 table-

spoons of neutral soap to 1 litre of water).

To remove stains , use a cleaning agent specially designed for this purpose.

Treat the leather regularly and at suitable intervals using a suitable leather care

product.

CAUTION

■ Ensure that no part of the leather is soaked through during cleaning and that

no water gets into the seams. Otherwise, the leather could become brittle or

cracked.■

Avoid leaving the vehicle for lengthy periods in bright sunlight to avoid the

leather from bleaching. If the vehicle is parked in the open for lengthy periods, protect the leather from direct sunlight by covering it.

■

Sharp-edged objects on items of clothing such as zip fasteners, rivets, sharp-

edged belts, jewellery and pendants may leave permanent scratches or signs of

rubbing on the surface. Such damage cannot be subsequently recognised as a

justified complaint.

■

The use of a mechanical steering wheel lock may damage the leather surface of

the steering wheel.

■ Use a care cream with light blocker and impregnation effect on a regular basis

and each time after cleaning. The cream nourishes the leather, allows it to

breathe and keeps it supple and also provides moisture. It also creates surface

protection.■

Some clothing materials, e.g. dark denim, do not have sufficient colour fastness.

This can cause damage or clearly visible discolouration to seat covers, even when used correctly. This applies particularly to light-coloured seat covers. This does

not relate to a fault in the seat cover, but rather to poor colour fastness of the

clothing textiles.

Note

When using the vehicle, minor visible changes may occur to the leather parts of

the covers (e.g. wrinkles or creases) as a result of the stress applied to the covers.

Artificial leather, cloths and Alcantara ®

First read and observe the introductory information and safety warn- ings

on page 157.

Artificial leather

Clean artificial leather with a damp cloth.

If this method does not completely clean the artificial leather, use a mild soap sol- ution or cleaning products specially designed for this purpose.

Fabric

Clean upholstery cover materials and cloth trims on doors, boot cover, etc. using

specific cleaning agents, e.g., dry foam.

Use a soft sponge, brush, or commercially available microfibre cloth.

Use a cloth and a cleaning agent specifically designed for this purpose to clean

the roof trim.

Remove any lumps on the cover fabric and any fabric residue using a brush.

Remove stubborn hair using a “cleaning glove”.

Alcantara ®

Dust and fine dirt particles in pores, creases and seams may chafe and damage the surface.

If you leave your vehicle parked in the open for lengthy periods, protect the Al-

cantara ®

seat covers from the direct rays of the sun to prevent fading.

158General Maintenance

Page 182 of 226

WARNING■When the warning light illuminates, immediately reduce the speed and

avoid sudden steering and brake manoeuvres. Stop the vehicle as soon as

possible and inspect the tyres and their inflation pressure.■

Under certain circumstances (e.g. sporty style of driving, wintry or unpaved

roads) the warning light may light up after a delay, or not at all.

CAUTION

■

The tyre control display does therefore not replace the regular tyre inflation

pressure control, as the system cannot detect an even loss of pressure.■

The system cannot warn in case of very rapid tyre inflation pressure loss, e.g. in

case of sudden tyre damage. In this case carefully bring the vehicle to a standstill

without sudden steering movements or sharp braking.

■

To ensure a proper functioning of the tyre control display, it is necessary to re-

peat the basic setting every 10,000 km or once a year.

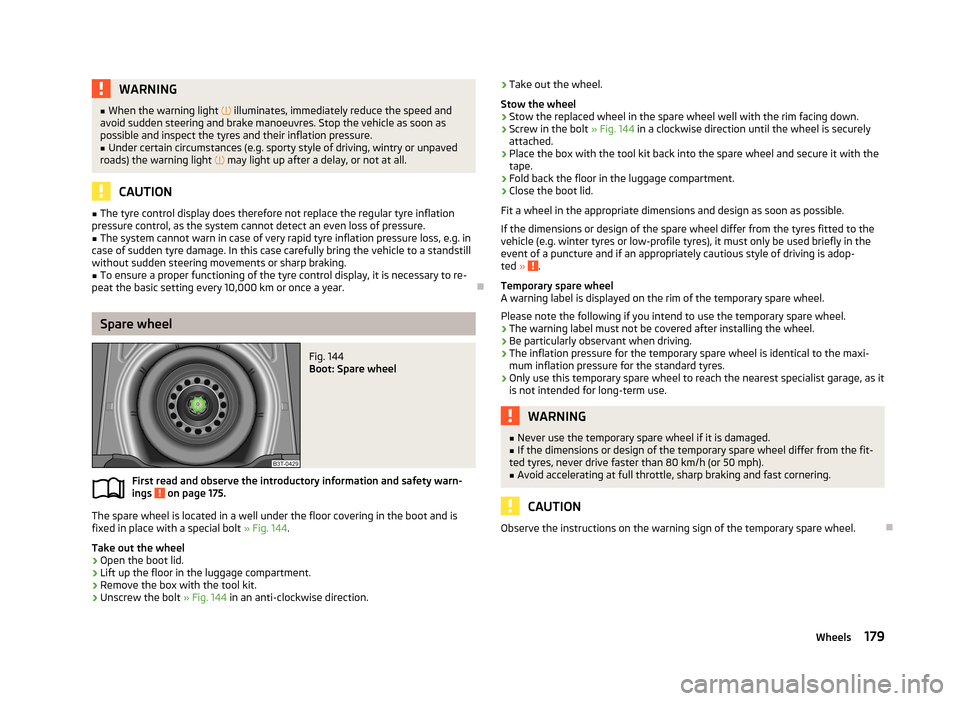

Spare wheel

Fig. 144

Boot: Spare wheel

First read and observe the introductory information and safety warn-

ings on page 175.

The spare wheel is located in a well under the floor covering in the boot and is

fixed in place with a special bolt » Fig. 144.

Take out the wheel

›

Open the boot lid.

›

Lift up the floor in the luggage compartment.

›

Remove the box with the tool kit.

›

Unscrew the bolt » Fig. 144 in an anti-clockwise direction.

›Take out the wheel.

Stow the wheel›

Stow the replaced wheel in the spare wheel well with the rim facing down.

›

Screw in the bolt » Fig. 144 in a clockwise direction until the wheel is securely

attached.

›

Place the box with the tool kit back into the spare wheel and secure it with the

tape.

›

Fold back the floor in the luggage compartment.

›

Close the boot lid.

Fit a wheel in the appropriate dimensions and design as soon as possible.

If the dimensions or design of the spare wheel differ from the tyres fitted to the

vehicle (e.g. winter tyres or low-profile tyres), it must only be used briefly in the

event of a puncture and if an appropriately cautious style of driving is adop-

ted »

.

Temporary spare wheel

A warning label is displayed on the rim of the temporary spare wheel.

Please note the following if you intend to use the temporary spare wheel. › The warning label must not be covered after installing the wheel.

› Be particularly observant when driving.

› The inflation pressure for the temporary spare wheel is identical to the maxi-

mum inflation pressure for the standard tyres.

› Only use this temporary spare wheel to reach the nearest specialist garage, as it

is not intended for long-term use.

WARNING■ Never use the temporary spare wheel if it is damaged.■If the dimensions or design of the temporary spare wheel differ from the fit-

ted tyres, never drive faster than 80 km/h (or 50 mph).■

Avoid accelerating at full throttle, sharp braking and fast cornering.

CAUTION

Observe the instructions on the warning sign of the temporary spare wheel.

179Wheels

Page 185 of 226

Do-it-yourself

Emergency equipment and self-help

Emergency equipment

Introduction

This chapter contains information on the following subjects:

First aid kit and warning triangle

182

fire extinguisher

183

Vehicle tool kit

183

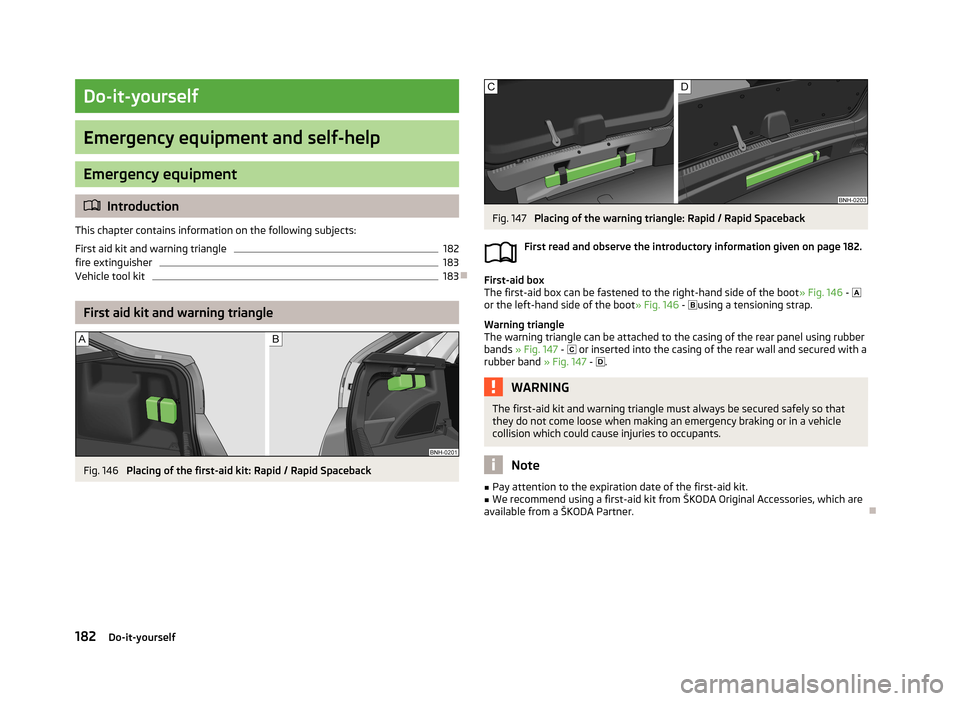

First aid kit and warning triangle

Fig. 146

Placing of the first-aid kit: Rapid / Rapid Spaceback

Fig. 147

Placing of the warning triangle: Rapid / Rapid Spaceback

First read and observe the introductory information given on page 182.

First-aid box

The first-aid box can be fastened to the right-hand side of the boot » Fig. 146 -

or the left-hand side of the boot » Fig. 146 -

using a tensioning strap.

Warning triangle

The warning triangle can be attached to the casing of the rear panel using rubber bands » Fig. 147 -

or inserted into the casing of the rear wall and secured with a

rubber band » Fig. 147 -

.

WARNINGThe first-aid kit and warning triangle must always be secured safely so that

they do not come loose when making an emergency braking or in a vehicle

collision which could cause injuries to occupants.

Note

■ Pay attention to the expiration date of the first-aid kit.■We recommend using a first-aid kit from ŠKODA Original Accessories, which are

available from a ŠKODA Partner.

182Do-it-yourself

Page 187 of 226

WARNING■The factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances use it to lift heavier vehicles or other loads – risk of

injury!■

Ensure that the vehicle tool kit is safely secured in the boot.

■

Ensure that the box is always secured with the strap.

Changing a wheel

Introduction

This chapter contains information on the following subjects:

Preliminary work

184

Changing a wheel

185

Follow-up work

185

Loosening/tightening wheel bolts

185

Raising the vehicle

186

Securing wheels against theft

186WARNING■ If you are in flowing traffic, switch on the hazard warning light system and

set up the warning triangle at the prescribed distance! The national legal re-

quirements must be observed.■

Park the vehicle as far away as possible from the flow of traffic. Park on as

flat and firm a surface as possible.

■

The following instructions must be followed if the vehicle is subsequently

fitted with tyres or rims that differ from the factory-fitted ones » page 177,

New tyres .

WARNINGObserve the following instructions for lifting the vehicle.■If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpectedly

rolling away.■

Secure the base plate of the lifting jack with suitable means to prevent pos-

sible moving. A soft and slippery ground under the base plate may move the lifting jack, causing the vehicle to fall down. It is therefore always necessary to

place the lifting jack on a solid surface or use a wide and stable base. Use a non-slip base (e.g. a rubber foot mat) if the surface is smooth, such as cobbled

stones, tiled floor, etc.

■

Only attach the lifting jack to the attachment points provided for this pur-

pose.

■

Always raise the vehicle with the doors closed.

■

Never position any body parts, such as arms or legs under the vehicle, while

the vehicle is raised with a lifting jack.

■

Never start the engine when the vehicle is raised – risk of injury.

CAUTION

■ The prescribed tightening torque of the wheel bolts for steel and light alloy

wheels is 120 Nm.■

If the wheel bolts are fastened too tightly, this can cause damage to the anti-

theft wheel bolt or the adapter.

Note

The national legal requirements must be observed when changing a wheel.

Preliminary work

First read and observe the introductory information and safety warn-ings

on page 184.

Always change a wheel on a level surface as far as possible.

The following steps must be carried out before actually changing the wheel:

›

Have all of the occupants get out of the vehicle. While changing a tyre, the oc-

cupants of the vehicle should not stand on the road (they should instead remain

behind a crash barrier).

184Do-it-yourself

Page 188 of 226

›Switch off the engine.›Move the gearshift lever into

Neutral or move the selector lever for the auto-

matic gearbox into position P .›

Firmly apply the handbrake.

›

Uncouple any trailers.

›

Remove the vehicle tool kit » page 183 and the spare wheel » page 179 from

the boot.

Changing a wheel

First read and observe the introductory information and safety warn-

ings

on page 184.

›

Remove the full wheel trim » page 180 or caps » page 180 .

›

First of all slacken the anti-theft wheel bolt and then the other wheel

bolts » page 185 .

›

Jack up the vehicle until the wheel that needs changing is clear of the

ground » page 186 .

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper, etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Alternately tighten wheel bolts opposite (diagonally) with the wheel wrench.

Tighten the anti-theft wheel bolt last » page 185.

›

Replace the wheel trim or the caps.

Note

■

All bolts must be clean and must turn easily.■Under no circumstances grease or oil the wheel bolts!■

When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect » page 178 .

Follow-up work

First read and observe the introductory information and safety warn-

ings

on page 184.

The following steps must also be performed after changing the wheel.

› Stow and attach the replaced wheel in the spare wheel well using a special

bolt » page 179 , Spare wheel .›

Stow the tool kit in the space provided and secure using the band.

›

Check the tyre pressure on the installed spare wheel as soon as possible.

›

Have the tightening torque of the wheel bolts checked with a torque wrench

as soon as possible.

›

Replace the damaged wheel or consult a specialist garage about repair options.

Note

■ If it is determined that the wheel bolts are corroded and difficult to turn when

changing the wheel, the bolts must be replaced before checking the tightening

torque.■

Drive cautiously and only at a moderate speed until the tightening torque has

been checked.

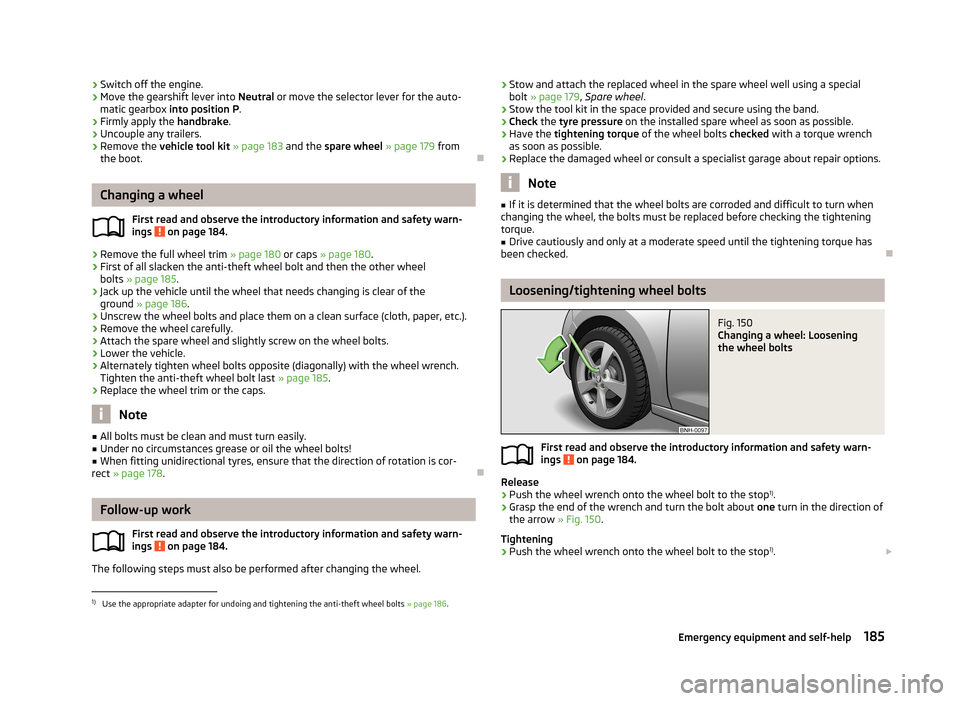

Loosening/tightening wheel bolts

Fig. 150

Changing a wheel: Loosening

the wheel bolts

First read and observe the introductory information and safety warn- ings on page 184.

Release

›

Push the wheel wrench onto the wheel bolt to the stop 1)

.

›

Grasp the end of the wrench and turn the bolt about one turn in the direction of

the arrow » Fig. 150.

Tightening

›

Push the wheel wrench onto the wheel bolt to the stop 1)

.

1)

Use the appropriate adapter for undoing and tightening the anti-theft wheel bolts

» page 186.

185Emergency equipment and self-help

Page 191 of 226

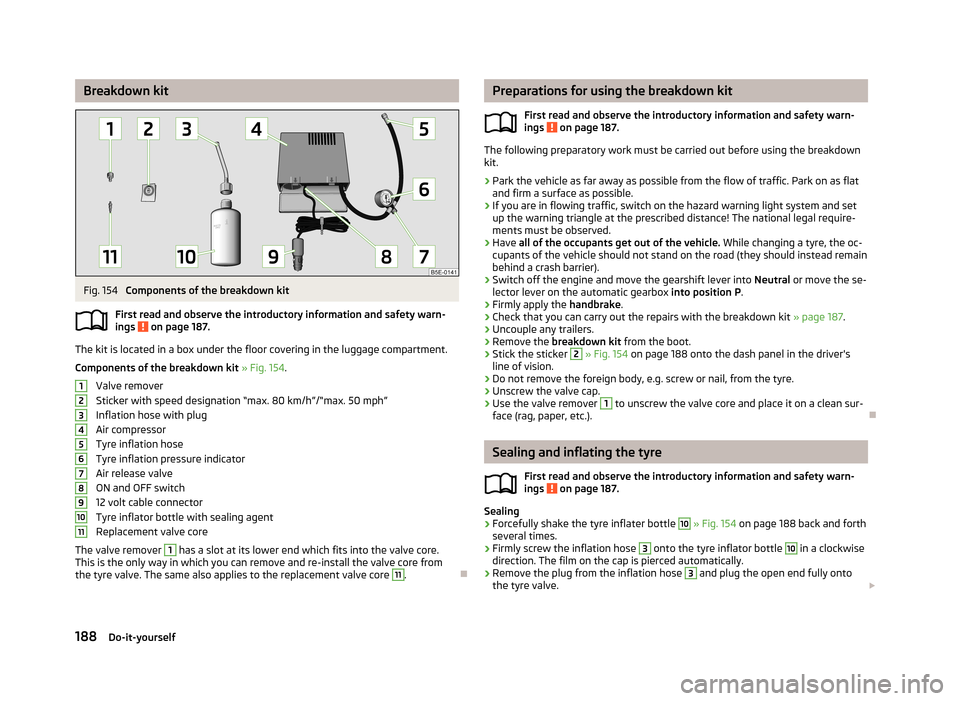

Breakdown kitFig. 154

Components of the breakdown kit

First read and observe the introductory information and safety warn-

ings

on page 187.

The kit is located in a box under the floor covering in the luggage compartment.

Components of the breakdown kit » Fig. 154 .

Valve remover

Sticker with speed designation “max. 80 km/h”/“max. 50 mph”

Inflation hose with plug

Air compressor

Tyre inflation hose

Tyre inflation pressure indicator

Air release valve

ON and OFF switch

12 volt cable connector

Tyre inflator bottle with sealing agent

Replacement valve core

The valve remover

1

has a slot at its lower end which fits into the valve core.

This is the only way in which you can remove and re-install the valve core from

the tyre valve. The same also applies to the replacement valve core

11

.

1234567891011Preparations for using the breakdown kit

First read and observe the introductory information and safety warn-

ings

on page 187.

The following preparatory work must be carried out before using the breakdown kit.

›

Park the vehicle as far away as possible from the flow of traffic. Park on as flat and firm a surface as possible.

›

If you are in flowing traffic, switch on the hazard warning light system and setup the warning triangle at the prescribed distance! The national legal require-

ments must be observed.

›

Have all of the occupants get out of the vehicle. While changing a tyre, the oc-

cupants of the vehicle should not stand on the road (they should instead remain

behind a crash barrier).

›

Switch off the engine and move the gearshift lever into Neutral or move the se-

lector lever on the automatic gearbox into position P.

›

Firmly apply the handbrake.

›

Check that you can carry out the repairs with the breakdown kit » page 187.

›

Uncouple any trailers.

›

Remove the breakdown kit from the boot.

›

Stick the sticker

2

» Fig. 154 on page 188 onto the dash panel in the driver's

line of vision.

›

Do not remove the foreign body, e.g. screw or nail, from the tyre.

›

Unscrew the valve cap.

›

Use the valve remover

1

to unscrew the valve core and place it on a clean sur-

face (rag, paper, etc.).

Sealing and inflating the tyre

First read and observe the introductory information and safety warn-

ings

on page 187.

Sealing

›

Forcefully shake the tyre inflater bottle

10

» Fig. 154 on page 188 back and forth

several times.

›

Firmly screw the inflation hose

3

onto the tyre inflator bottle

10

in a clockwise

direction. The film on the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and plug the open end fully onto

the tyre valve.

188Do-it-yourself