check engine SKODA RAPID 2014 1.G Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2014, Model line: RAPID, Model: SKODA RAPID 2014 1.GPages: 200, PDF Size: 25.57 MB

Page 146 of 200

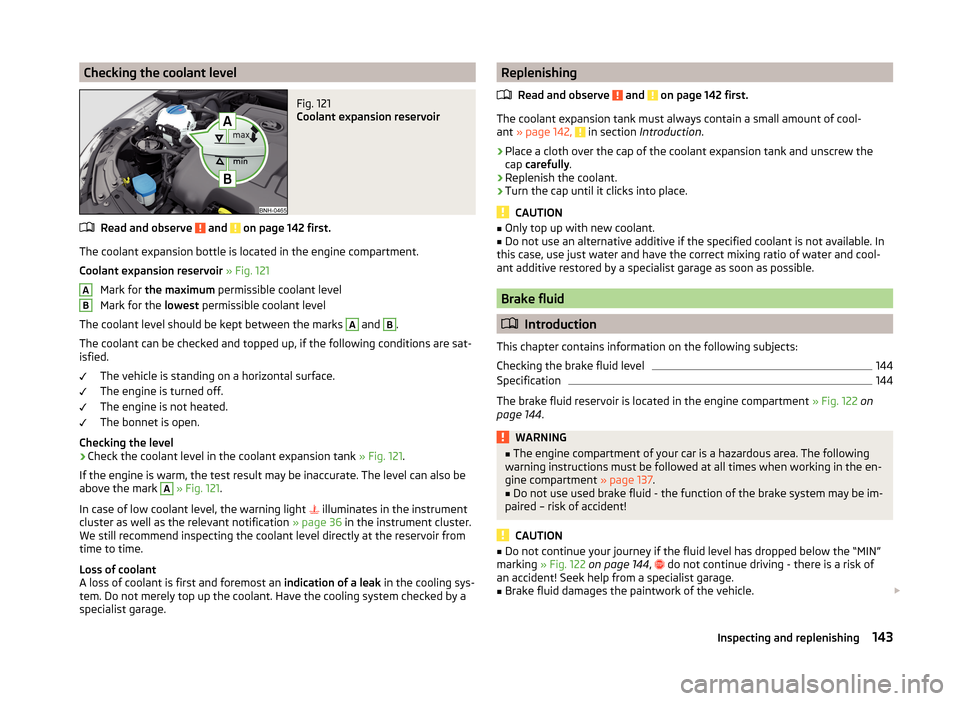

Checking the coolant levelFig. 121

Coolant expansion reservoir

Read and observe and on page 142 first.

The coolant expansion bottle is located in the engine compartment.

Coolant expansion reservoir » Fig. 121

Mark for the maximum permissible coolant level

Mark for the lowest permissible coolant level

The coolant level should be kept between the marks

A

and

B

.

The coolant can be checked and topped up, if the following conditions are sat-

isfied.

The vehicle is standing on a horizontal surface.

The engine is turned off.

The engine is not heated.

The bonnet is open.

Checking the level

›

Check the coolant level in the coolant expansion tank » Fig. 121.

If the engine is warm, the test result may be inaccurate. The level can also be

above the mark

A

» Fig. 121 .

In case of low coolant level, the warning light illuminates in the instrument

cluster as well as the relevant notification » page 36 in the instrument cluster.

We still recommend inspecting the coolant level directly at the reservoir from

time to time.

Loss of coolant

A loss of coolant is first and foremost an indication of a leak in the cooling sys-

tem. Do not merely top up the coolant. Have the cooling system checked by a

specialist garage.

ABReplenishing

Read and observe

and on page 142 first.

The coolant expansion tank must always contain a small amount of cool-

ant » page 142, in section Introduction .

›

Place a cloth over the cap of the coolant expansion tank and unscrew the

cap carefully .

›

Replenish the coolant.

›

Turn the cap until it clicks into place.

CAUTION

■

Only top up with new coolant.■Do not use an alternative additive if the specified coolant is not available. In

this case, use just water and have the correct mixing ratio of water and cool-

ant additive restored by a specialist garage as soon as possible.

Brake fluid

Introduction

This chapter contains information on the following subjects:

Checking the brake fluid level

144

Specification

144

The brake fluid reservoir is located in the engine compartment » Fig. 122 on

page 144 .

WARNING■

The engine compartment of your car is a hazardous area. The following

warning instructions must be followed at all times when working in the en-

gine compartment » page 137.■

Do not use used brake fluid - the function of the brake system may be im-

paired – risk of accident!

CAUTION

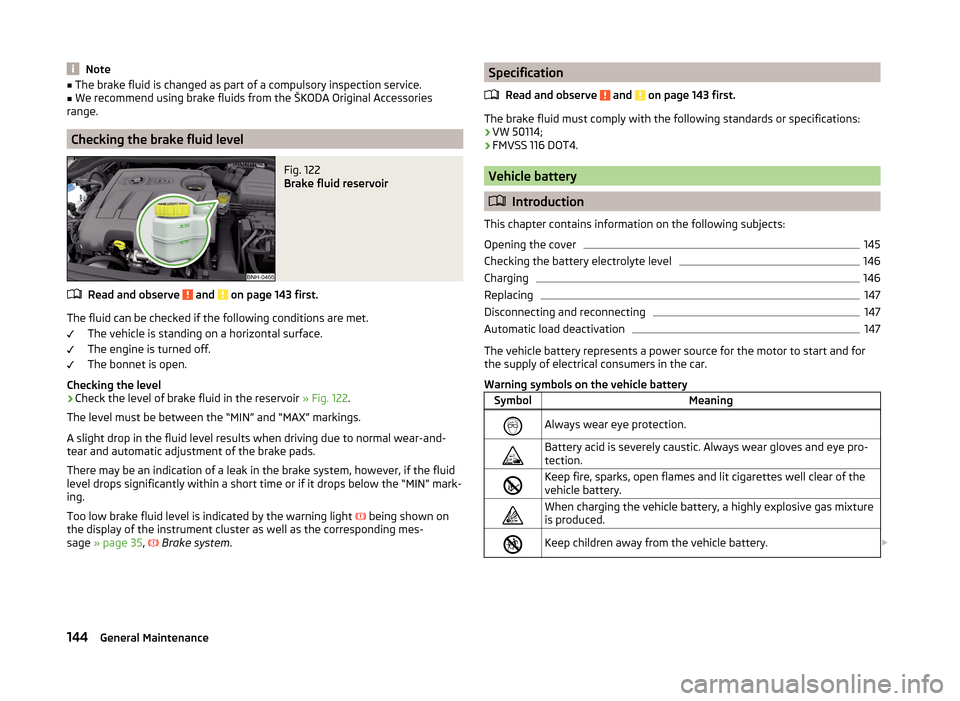

■ Do not continue your journey if the fluid level has dropped below the “MIN”

marking » Fig. 122 on page 144 , do not continue driving - there is a risk of

an accident! Seek help from a specialist garage.■

Brake fluid damages the paintwork of the vehicle.

143Inspecting and replenishing

Page 147 of 200

Note■The brake fluid is changed as part of a compulsory inspection service.■We recommend using brake fluids from the ŠKODA Original Accessories

range.

Checking the brake fluid level

Fig. 122

Brake fluid reservoir

Read and observe and on page 143 first.

The fluid can be checked if the following conditions are met.

The vehicle is standing on a horizontal surface.

The engine is turned off.

The bonnet is open.

Checking the level

›

Check the level of brake fluid in the reservoir » Fig. 122.

The level must be between the “MIN” and “MAX” markings.

A slight drop in the fluid level results when driving due to normal wear-and-

tear and automatic adjustment of the brake pads.

There may be an indication of a leak in the brake system, however, if the fluid

level drops significantly within a short time or if it drops below the “MIN” mark-

ing.

Too low brake fluid level is indicated by the warning light

being shown on

the display of the instrument cluster as well as the corresponding mes-

sage » page 35 ,

Brake system .

Specification

Read and observe

and on page 143 first.

The brake fluid must comply with the following standards or specifications:› VW 50114;

› FMVSS 116 DOT4.

Vehicle battery

Introduction

This chapter contains information on the following subjects:

Opening the cover

145

Checking the battery electrolyte level

146

Charging

146

Replacing

147

Disconnecting and reconnecting

147

Automatic load deactivation

147

The vehicle battery represents a power source for the motor to start and for

the supply of electrical consumers in the car.

Warning symbols on the vehicle battery

SymbolMeaningAlways wear eye protection.Battery acid is severely caustic. Always wear gloves and eye pro-

tection.Keep fire, sparks, open flames and lit cigarettes well clear of the

vehicle battery.When charging the vehicle battery, a highly explosive gas mixture

is produced.Keep children away from the vehicle battery. 144General Maintenance

Page 149 of 200

Checking the battery electrolyte levelFig. 124

Electrolyte level indicator

Read and observe and on page 145 first.

On vehicles with a vehicle battery fitted with a colour indicator » Fig. 124, the

electrolyte level can be determined by looking at the change in colour of this

display.

Air bubbles can influence the colour of the indicator. For this reason carefully

knock on the indicator before carrying out the check.

› Black colour – electrolyte level is correct.

› Colourless or light yellow colour – electrolyte level too low, the battery must

be replaced.

Vehicles with a START-STOP system are fitted with a battery control unit for

checking the energy level for the recurring engine start.

We recommend that you have the acid level checked regularly by a specialist

garage, especially in the following cases.

› High external temperatures.

› Longer day trips.

› After each charge.

Winter time

The vehicle battery only has a proportion of the starting power in lower tem-

peratures. A discharged vehicle battery may already freeze at temperatures

just below 0 °C .

We therefore recommend that you have the battery checked and, if necessary,

recharged by a specialist garage before the start of the winter.

Note■ The battery acid level is also checked regularly by a specialist garage as part

of the inspection service.■

For technical reasons, on vehicles with the description “AGM”, the electrolyte

level cannot be checked.

Charging

Read and observe

and on page 145 first.

A properly charged vehicle battery is essential for reliably starting the engine.A charging operation can be performed if the following conditions are satis-

fied.

The engine is turned off.

The ignition is switched off.

All consumers are turned off.

The bonnet is open.

“Fast charging” with high currents

›

Disconnect both battery cables (first of all “negative”, then “positive”).

›

Attach the terminal clamps of the charger to the battery terminals (red =

“positive”, black = “negative”).

›

Plug the mains cable of the charger into the power socket and switch on the

device.

›

After charging has been successful: Switch off the charger and remove the

mains cable from the power socket.

›

Only then disconnect the charger's terminal clamps.

›

Reconnect the cables to the battery (first “positive”, then “negative”).

Charging with low voltages

It is not necessary to disconnect the cables from the battery if you recharge

the vehicle battery, for example from a mini-charger.

Refer to the instructions of the charger manufacturer .

A charging current of 0.1 multiple of the total vehicle battery capacity (or low-

er) must be used until full charging is achieved.

The vent plugs of the vehicle battery should not be opened for charging.

146General Maintenance

Page 150 of 200

WARNING■When you charge a battery, hydrogen is released, and a highly explosive

gas mixture is also produced. An explosion can be caused through sparkling

over during unclamping or loosening of the cable plug while the ignition is

on.■

Creating a bridge between the poles on the battery (e.g. with metal ob-

jects - cables) creates a short circuit - risk of damage to the battery, explo-

sion and burning of the battery, jets of acid spurting out.

■

Avoid creating sparks when working with cables and electrical devices.

Strong sparking represents a risk of injury.

■

Before carrying out any work on the electrical system, switch off the en-

gine, the ignition and all electrical consumers and disconnect the negative

terminal

.

■

“Quick-charging” the vehicle battery is dangerous and requires a special

charger and specialist knowledge.

■

We therefore recommend that vehicle batteries be “rapidly charged” by a

specialist garage.

CAUTION

On vehicles with the START/STOP system, the pole terminal of the charger

must not be connected directly to the negative terminal of the vehicle battery,

but only to the engine earth » page 163, Jump-starting using the battery from

another vehicle .

Replacing

Read and observe

and on page 145 first.

The new vehicle battery must have the same capacity, voltage, current and

size as the original battery. Suitable vehicle battery types can be purchased

from a specialist garage.

We recommend having the battery replaced by a specialist garage, where the

new vehicle battery will be installed properly and the original battery will be

disposed of in accordance with national regulations.

Disconnecting and reconnecting

Read and observe

and on page 145 first.

Disconnecting

›

Switch off the ignition.

›First, disconnect the negative terminal

first, then the positive terminal

of the battery.

Connecting›

First, connect the positive

first, then the negative

battery terminal.

After disconnecting and re-connecting the vehicle battery, the following func-

tions or devices are partially or completely inoperative.

Function / deviceOperating measureRadio or navigation systemEnter code number » User radio

manual or » navigation system

user manualTime settings» page 33

CAUTION

■ Disconnect the vehicle battery only with the ignition turned off - there is a

risk of damaging the electrical system of the vehicle.■

Under no circumstances must the battery cables be connected incorrectly –

risk of a cable fire.

Note

■ After disconnecting and re-connecting the vehicle battery, we recommend

having the vehicle checked by a specialist to ensure that the full functionality

of all electrical systems is guaranteed.■

The data of the multi-function display will be reset.

Automatic load deactivation

Read and observe

and on page 145 first.

The vehicle voltage control unit automatically prevents the battery from dis-

charging when the battery is put under high levels of strain. This manifests it-

self by the following.

› The idling speed is raised to allow the generator to deliver more electricity to

the electrical system.

› Where necessary, large convenience consumers such as seat heaters and

rear window heaters have their power limited or are shut off completely in

the event of an emergency.

147Inspecting and replenishing

Page 154 of 200

CAUTIONThe tyres must be protected from contact with substances such as oil, grease

and fuel, which could damage them. If the tyres come into contact with these

substances, then we recommend you have this checked out in a specialist

workshop.

Unidirectional tyres

Read and observe

on page 148 first.

The direction of rotation of the tyres is marked by arrows on the wall of the

tyre .

The indicated direction of rotation must be adhered to in order to ensure the

optimal characteristics of these tyres.

These characteristics mainly relate to the following: › Increased driving stability.

› Reduced risk of aquaplaning.

› Reduced tyre noise and tyre wear.

Manufacturer-approved tyre variants

Introduction

This chapter contains information on the following subjects:

Explanation of the tyre labelling

151

Rapid

152

Rapid Green Line

152

Rapid Green tec

152

Approved tyre variants are first to be selected for the model variant (e.g. Rapid

GreenLine), and then selected according to the engine size of your vehicle.

If the model variant of your vehicle cannot be found in the discrete module,

then the approved tyre variants are to be selected according to the engine size

of your vehicle in module » page 152, Rapid .

Only use radial tyres of the same type, size (rolling circumference) and tread pattern on one axle on all four wheels.

When mounting new tyres the tyres have to be replaced axle by axle.

The information listed in the table corresponds to the information available at the time of going to press.

The approved tyre / rim combinations for your car are given on the sales and

technical vehicle documentation.

Explanation of the tyre labelling

Explanation of tyre markings

For example, 225/50R 17 91 T means:

225Tyre width in mm50Height/width ratio in %RCode letter for the type of tyre – Radial17Diameter of wheel in inches91Load indexTSpeed symbol

The date of manufacture is stated on the tyre wall (possibly on the inside).

For example DOT ... 11 14... means, for example, that the tyre was manufac-

tured in the 11th week of 2014.

The marking M+Smeans that the associated tyre is suitable for winter use.

Load index

The load index indicates the maximum permissible load for each individual

tyre.

Load index838485868788Load

(In kg)487500515530545560

Speed symbol

The maximum speed symbol indicates the maximum permissible vehicle speed

with fitted tyres in each category.

Speed

symbolSTUHVWMaximum speed

(in km/h)180190200210240270

151Wheels

Page 164 of 200

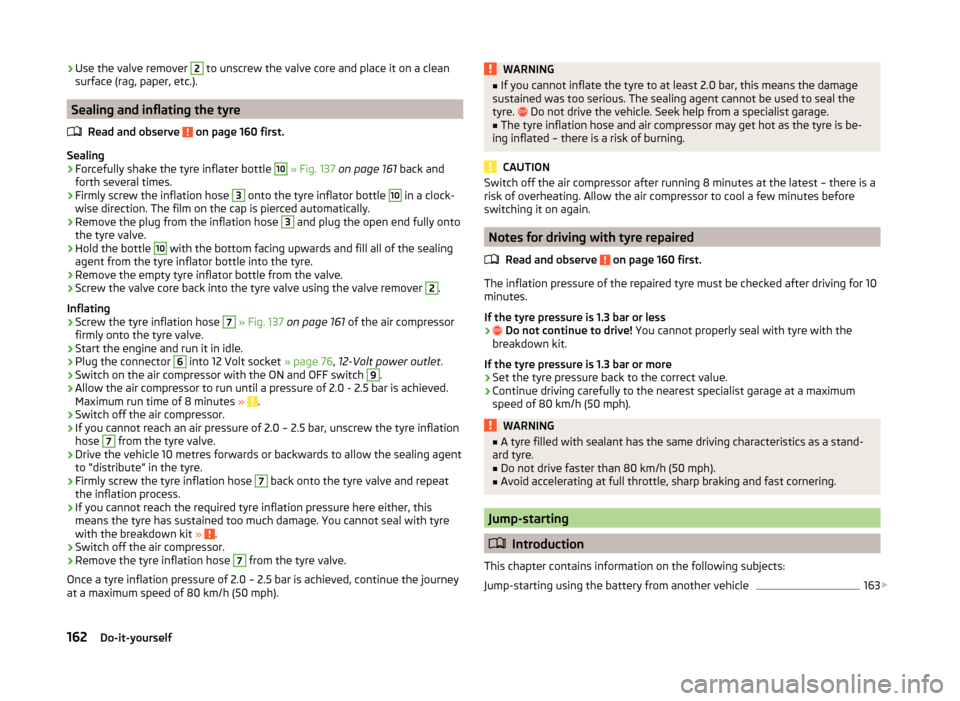

Components of the puncture repair kitsFig. 137

Principle sketch: Components of the breakdown kit

Read and observe

on page 160 first.

Components of the set » Fig. 137

Sticker with speed designation “max. 80 km/h”/“max. 50 mph”

Valve remover

Inflation hose with plug

Air compressor

Button for releasing the tyre pressure

12 volt cable connector

Tyre inflation hose

Tyre inflation pressure indicator

ON and OFF switch

Tyre inflator bottle with sealing agent

Replacement valve core

The valve remover

2

has a slot at its lower end which fits into the valve core.

The kit is located in a box under the floor covering in the luggage compart-

ment. This contains a sealing means and an air compressor.

Note

The declaration of conformity is included with the air compressor or the log

folder.1234567891011General information

Read and observe

on page 160 first.

For your own safety and the safety of your passengers, the following instruc-

tions must be observed before carrying out a wheel repair on the road.

Switch on the hazard warning lights system.

The warning triangle must be set up at the prescribed distance - observe

the national legal provisions when doing so.

Park the vehicle as far away as possible from the flow of traffic.

Choose a location with a flat, solid surface.

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

The national legal requirements must be observed when repairing a tyre.

The breakdown kit must not be used under the following circumstances. › The rim is damaged.

› The outside temperature is below -20 ° C.

› The cut or puncture is larger than 4 mm.

› The tyre wall is damaged.

› The result will be to drive with very low tyre pressure or with a completely

flat tyres.

› After the expiration date (see inflation bottle).

Preparations for using the breakdown kit

Read and observe

on page 160 first.

The following preparatory work must be carried out before using the puncturerepair kit.

›

Switch off the engine.

›

Engage the 1st gear or place the selector lever of the automatic transmission

in the P-position .

›

Firmly apply the handbrake.

›

Check that you can carry out the repairs with the breakdown kit » page 161,

General information .

›

Remove the breakdown kit from the boot.

›

Stick the sticker

1

» Fig. 137 on page 161 on the dashboard in the driver's

field of view.

›

Unscrew the valve cap.

161Emergency equipment and self-help

Page 165 of 200

›Use the valve remover 2 to unscrew the valve core and place it on a clean

surface (rag, paper, etc.).

Sealing and inflating the tyre

Read and observe

on page 160 first.

Sealing

›

Forcefully shake the tyre inflater bottle

10

» Fig. 137 on page 161 back and

forth several times.

›

Firmly screw the inflation hose

3

onto the tyre inflator bottle

10

in a clock-

wise direction. The film on the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and plug the open end fully onto

the tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

›

Remove the empty tyre inflator bottle from the valve.

›

Screw the valve core back into the tyre valve using the valve remover

2

.

Inflating

›

Screw the tyre inflation hose

7

» Fig. 137 on page 161 of the air compressor

firmly onto the tyre valve.

›

Start the engine and run it in idle.

›

Plug the connector

6

into 12 Volt socket » page 76, 12-Volt power outlet .

›

Switch on the air compressor with the ON and OFF switch

9

.

›

Allow the air compressor to run until a pressure of 2.0 - 2.5 bar is achieved.

Maximum run time of 8 minutes » .

›

Switch off the air compressor.

›

If you cannot reach an air pressure of 2.0 – 2.5 bar, unscrew the tyre inflation

hose

7

from the tyre valve.

›

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent

to “distribute” in the tyre.

›

Firmly screw the tyre inflation hose

7

back onto the tyre valve and repeat

the inflation process.

›

If you cannot reach the required tyre inflation pressure here either, this

means the tyre has sustained too much damage. You cannot seal with tyre with the breakdown kit »

.

›

Switch off the air compressor.

›

Remove the tyre inflation hose

7

from the tyre valve.

Once a tyre inflation pressure of 2.0 – 2.5 bar is achieved, continue the journey

at a maximum speed of 80 km/h (50 mph).

WARNING■ If you cannot inflate the tyre to at least 2.0 bar, this means the damage

sustained was too serious. The sealing agent cannot be used to seal the

tyre.

Do not drive the vehicle. Seek help from a specialist garage.■

The tyre inflation hose and air compressor may get hot as the tyre is be-

ing inflated – there is a risk of burning.

CAUTION

Switch off the air compressor after running 8 minutes at the latest – there is a

risk of overheating. Allow the air compressor to cool a few minutes before

switching it on again.

Notes for driving with tyre repaired

Read and observe

on page 160 first.

The inflation pressure of the repaired tyre must be checked after driving for 10minutes.

If the tyre pressure is 1.3 bar or less

›

Do not continue to drive! You cannot properly seal with tyre with the

breakdown kit.

If the tyre pressure is 1.3 bar or more

›

Set the tyre pressure back to the correct value.

›

Continue driving carefully to the nearest specialist garage at a maximum speed of 80 km/h (50 mph).

WARNING■ A tyre filled with sealant has the same driving characteristics as a stand-

ard tyre.■

Do not drive faster than 80 km/h (50 mph).

■

Avoid accelerating at full throttle, sharp braking and fast cornering.

Jump-starting

Introduction

This chapter contains information on the following subjects:

Jump-starting using the battery from another vehicle

163

162Do-it-yourself

Page 175 of 200

Replacing bulbs

Introduction

This chapter contains information on the following subjects:

Bulb arrangement in the headlights

172

Replacing the high beam bulb (halogen headlights)

173

Replacing bulb for main beam, daytime running lights and parking light

173

Changing the front turn signal bulb

174

Replacing the bulb for the fog light

174

Replacing the bulb for the licence plate light

175

Rear Light

175

Replacing bulbs in rear light

176

Some manual skills are required to change a bulb. For this reason, we recom-

mend having bulbs replaced by a specialist garage or seeking other expert help

in the event of any uncertainties.

› Switch off the ignition and all of the lights before replacing a bulb.

› Faulty bulbs must only be replaced with the same type of bulbs. The designa-

tion is located on the light socket or the glass bulb.

› A stowage compartment for replacement bulbs is located in a plastic box in

the spare wheel or underneath the floor covering in the boot.

WARNING■ Always read and observe the warning notes before completing any work

in the engine compartment » page 137.■

Accidents can be caused if the road in front of the vehicle is not suffi-

ciently illuminated and the vehicle cannot or can only be seen with difficul-

ty by other road users.

■

H7 and H15 bulbs are pressurised and may burst when changing the bulb -

risk of injury! We therefore recommended wearing gloves and safety

glasses when changing a bulb.

■

Gas discharge bulbs (xenon bulbs) operate with a high voltage, professio-

nal knowledge is required – risk of death!

■

Switch off the respective vehicle light when changing the bulb.

CAUTION

Do not take hold of the glass bulb with naked fingers (even the smallest

amount of dirt reduces the working life of the light bulb). Use a clean cloth,

napkin, or similar.Note■ This Owner's Manual only describes the replacement of bulbs where it is pos-

sible to replace the bulbs on your own without any complications arising. Other

bulbs must be replaced by a specialist garage.■

We recommend that a box of replacement bulbs always be carried in the ve-

hicle. Replacement bulbs can be purchased from ŠKODAOriginal Accessories.

■

We recommend having the headlight settings checked by a specialist garage

after replacing a bulb in the main, low or fog beam.

■

In case of failure of a xenon gas discharge lamp or an LED diode, visit a spe-

cialist garage.

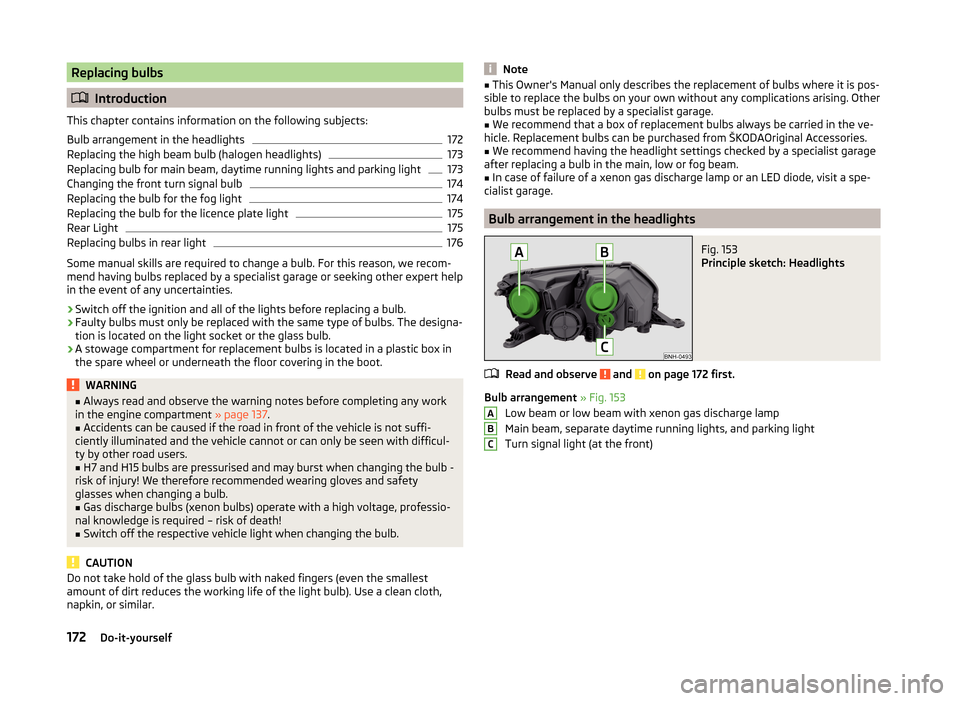

Bulb arrangement in the headlights

Fig. 153

Principle sketch: Headlights

Read and observe and on page 172 first.

Bulb arrangement » Fig. 153

Low beam or low beam with xenon gas discharge lamp

Main beam, separate daytime running lights, and parking light

Turn signal light (at the front)

ABC172Do-it-yourself

Page 189 of 200

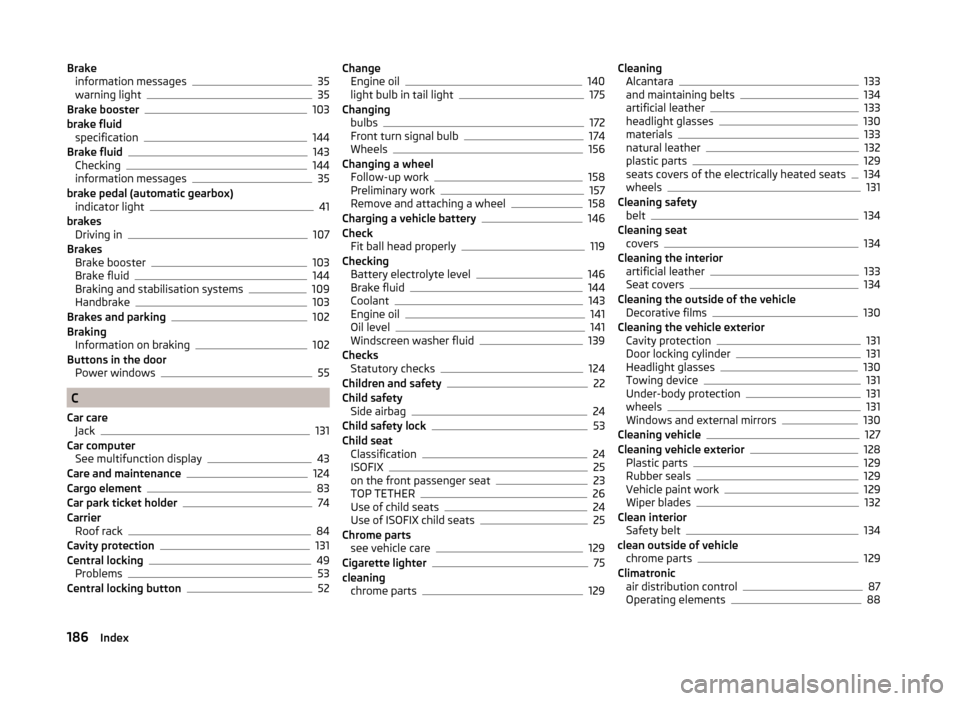

Brakeinformation messages35

warning light35

Brake booster103

brake fluid specification

144

Brake fluid143

Checking144

information messages35

brake pedal (automatic gearbox) indicator light

41

brakes Driving in

107

Brakes Brake booster

103

Brake fluid144

Braking and stabilisation systems109

Handbrake103

Brakes and parking102

Braking Information on braking

102

Buttons in the door Power windows

55

C

Car care Jack

131

Car computer See multifunction display

43

Care and maintenance124

Cargo element83

Car park ticket holder74

Carrier Roof rack

84

Cavity protection131

Central locking49

Problems53

Central locking button52

Change Engine oil140

light bulb in tail light175

Changing bulbs

172

Front turn signal bulb174

Wheels156

Changing a wheel Follow-up work

158

Preliminary work157

Remove and attaching a wheel158

Charging a vehicle battery146

Check Fit ball head properly

119

Checking Battery electrolyte level

146

Brake fluid144

Coolant143

Engine oil141

Oil level141

Windscreen washer fluid139

Checks Statutory checks

124

Children and safety22

Child safety Side airbag

24

Child safety lock53

Child seat Classification

24

ISOFIX25

on the front passenger seat23

TOP TETHER26

Use of child seats24

Use of ISOFIX child seats25

Chrome parts see vehicle care

129

Cigarette lighter75

cleaning chrome parts

129

CleaningAlcantara133

and maintaining belts134

artificial leather133

headlight glasses130

materials133

natural leather132

plastic parts129

seats covers of the electrically heated seats134

wheels131

Cleaning safety belt

134

Cleaning seat covers

134

Cleaning the interior artificial leather

133

Seat covers134

Cleaning the outside of the vehicle Decorative films

130

Cleaning the vehicle exterior Cavity protection

131

Door locking cylinder131

Headlight glasses130

Towing device131

Under-body protection131

wheels131

Windows and external mirrors130

Cleaning vehicle127

Cleaning vehicle exterior128

Plastic parts129

Rubber seals129

Vehicle paint work129

Wiper blades132

Clean interior Safety belt

134

clean outside of vehicle chrome parts

129

Climatronic air distribution control

87

Operating elements88

186Index

Page 190 of 200

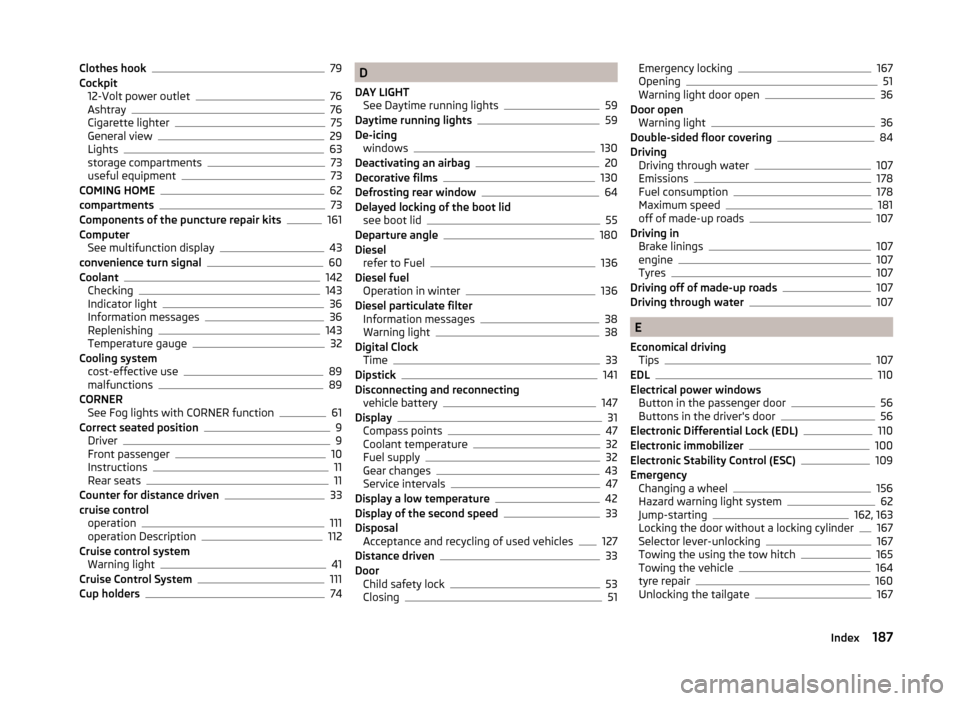

Clothes hook79

Cockpit 12-Volt power outlet

76

Ashtray76

Cigarette lighter75

General view29

Lights63

storage compartments73

useful equipment73

COMING HOME62

compartments73

Components of the puncture repair kits161

Computer See multifunction display

43

convenience turn signal60

Coolant142

Checking143

Indicator light36

Information messages36

Replenishing143

Temperature gauge32

Cooling system cost-effective use

89

malfunctions89

CORNER See Fog lights with CORNER function

61

Correct seated position9

Driver9

Front passenger10

Instructions11

Rear seats11

Counter for distance driven33

cruise control operation

111

operation Description112

Cruise control system Warning light

41

Cruise Control System111

Cup holders74

D

DAY LIGHT See Daytime running lights

59

Daytime running lights59

De-icing windows

130

Deactivating an airbag20

Decorative films130

Defrosting rear window64

Delayed locking of the boot lid see boot lid

55

Departure angle180

Diesel refer to Fuel

136

Diesel fuel Operation in winter

136

Diesel particulate filter Information messages

38

Warning light38

Digital Clock Time

33

Dipstick141

Disconnecting and reconnecting vehicle battery

147

Display31

Compass points47

Coolant temperature32

Fuel supply32

Gear changes43

Service intervals47

Display a low temperature42

Display of the second speed33

Disposal Acceptance and recycling of used vehicles

127

Distance driven33

Door Child safety lock

53

Closing51

Emergency locking167

Opening51

Warning light door open36

Door open Warning light

36

Double-sided floor covering84

Driving Driving through water

107

Emissions178

Fuel consumption178

Maximum speed181

off of made-up roads107

Driving in Brake linings

107

engine107

Tyres107

Driving off of made-up roads107

Driving through water107

E

Economical driving Tips

107

EDL110

Electrical power windows Button in the passenger door

56

Buttons in the driver's door56

Electronic Differential Lock (EDL)110

Electronic immobilizer100

Electronic Stability Control (ESC)109

Emergency Changing a wheel

156

Hazard warning light system62

Jump-starting162, 163

Locking the door without a locking cylinder167

Selector lever-unlocking167

Towing the using the tow hitch165

Towing the vehicle164

tyre repair160

Unlocking the tailgate167

187Index