stop start SKODA RAPID 2014 1.G Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2014, Model line: RAPID, Model: SKODA RAPID 2014 1.GPages: 200, PDF Size: 25.57 MB

Page 149 of 200

Checking the battery electrolyte levelFig. 124

Electrolyte level indicator

Read and observe and on page 145 first.

On vehicles with a vehicle battery fitted with a colour indicator » Fig. 124, the

electrolyte level can be determined by looking at the change in colour of this

display.

Air bubbles can influence the colour of the indicator. For this reason carefully

knock on the indicator before carrying out the check.

› Black colour – electrolyte level is correct.

› Colourless or light yellow colour – electrolyte level too low, the battery must

be replaced.

Vehicles with a START-STOP system are fitted with a battery control unit for

checking the energy level for the recurring engine start.

We recommend that you have the acid level checked regularly by a specialist

garage, especially in the following cases.

› High external temperatures.

› Longer day trips.

› After each charge.

Winter time

The vehicle battery only has a proportion of the starting power in lower tem-

peratures. A discharged vehicle battery may already freeze at temperatures

just below 0 °C .

We therefore recommend that you have the battery checked and, if necessary,

recharged by a specialist garage before the start of the winter.

Note■ The battery acid level is also checked regularly by a specialist garage as part

of the inspection service.■

For technical reasons, on vehicles with the description “AGM”, the electrolyte

level cannot be checked.

Charging

Read and observe

and on page 145 first.

A properly charged vehicle battery is essential for reliably starting the engine.A charging operation can be performed if the following conditions are satis-

fied.

The engine is turned off.

The ignition is switched off.

All consumers are turned off.

The bonnet is open.

“Fast charging” with high currents

›

Disconnect both battery cables (first of all “negative”, then “positive”).

›

Attach the terminal clamps of the charger to the battery terminals (red =

“positive”, black = “negative”).

›

Plug the mains cable of the charger into the power socket and switch on the

device.

›

After charging has been successful: Switch off the charger and remove the

mains cable from the power socket.

›

Only then disconnect the charger's terminal clamps.

›

Reconnect the cables to the battery (first “positive”, then “negative”).

Charging with low voltages

It is not necessary to disconnect the cables from the battery if you recharge

the vehicle battery, for example from a mini-charger.

Refer to the instructions of the charger manufacturer .

A charging current of 0.1 multiple of the total vehicle battery capacity (or low-

er) must be used until full charging is achieved.

The vent plugs of the vehicle battery should not be opened for charging.

146General Maintenance

Page 150 of 200

WARNING■When you charge a battery, hydrogen is released, and a highly explosive

gas mixture is also produced. An explosion can be caused through sparkling

over during unclamping or loosening of the cable plug while the ignition is

on.■

Creating a bridge between the poles on the battery (e.g. with metal ob-

jects - cables) creates a short circuit - risk of damage to the battery, explo-

sion and burning of the battery, jets of acid spurting out.

■

Avoid creating sparks when working with cables and electrical devices.

Strong sparking represents a risk of injury.

■

Before carrying out any work on the electrical system, switch off the en-

gine, the ignition and all electrical consumers and disconnect the negative

terminal

.

■

“Quick-charging” the vehicle battery is dangerous and requires a special

charger and specialist knowledge.

■

We therefore recommend that vehicle batteries be “rapidly charged” by a

specialist garage.

CAUTION

On vehicles with the START/STOP system, the pole terminal of the charger

must not be connected directly to the negative terminal of the vehicle battery,

but only to the engine earth » page 163, Jump-starting using the battery from

another vehicle .

Replacing

Read and observe

and on page 145 first.

The new vehicle battery must have the same capacity, voltage, current and

size as the original battery. Suitable vehicle battery types can be purchased

from a specialist garage.

We recommend having the battery replaced by a specialist garage, where the

new vehicle battery will be installed properly and the original battery will be

disposed of in accordance with national regulations.

Disconnecting and reconnecting

Read and observe

and on page 145 first.

Disconnecting

›

Switch off the ignition.

›First, disconnect the negative terminal

first, then the positive terminal

of the battery.

Connecting›

First, connect the positive

first, then the negative

battery terminal.

After disconnecting and re-connecting the vehicle battery, the following func-

tions or devices are partially or completely inoperative.

Function / deviceOperating measureRadio or navigation systemEnter code number » User radio

manual or » navigation system

user manualTime settings» page 33

CAUTION

■ Disconnect the vehicle battery only with the ignition turned off - there is a

risk of damaging the electrical system of the vehicle.■

Under no circumstances must the battery cables be connected incorrectly –

risk of a cable fire.

Note

■ After disconnecting and re-connecting the vehicle battery, we recommend

having the vehicle checked by a specialist to ensure that the full functionality

of all electrical systems is guaranteed.■

The data of the multi-function display will be reset.

Automatic load deactivation

Read and observe

and on page 145 first.

The vehicle voltage control unit automatically prevents the battery from dis-

charging when the battery is put under high levels of strain. This manifests it-

self by the following.

› The idling speed is raised to allow the generator to deliver more electricity to

the electrical system.

› Where necessary, large convenience consumers such as seat heaters and

rear window heaters have their power limited or are shut off completely in

the event of an emergency.

147Inspecting and replenishing

Page 162 of 200

›Grasp the end of the wrench and turn the bolt about

one turn in the direction

of the arrow » Fig. 133.

Tightening›

Push the wheel wrench onto the wheel bolt to the stop 1)

.

›

Grasp the end of the wrench and turn the bolt against the direction of the

arrow » Fig. 133 until it is tight.

After tightening the wheel bolts, the covering caps must be replaced.

WARNINGIf it proves difficult to undo the bolts, carefully apply pressure to the end of

the wrench with your foot. Keep hold of the vehicle when doing so, and

make sure you keep your footing.

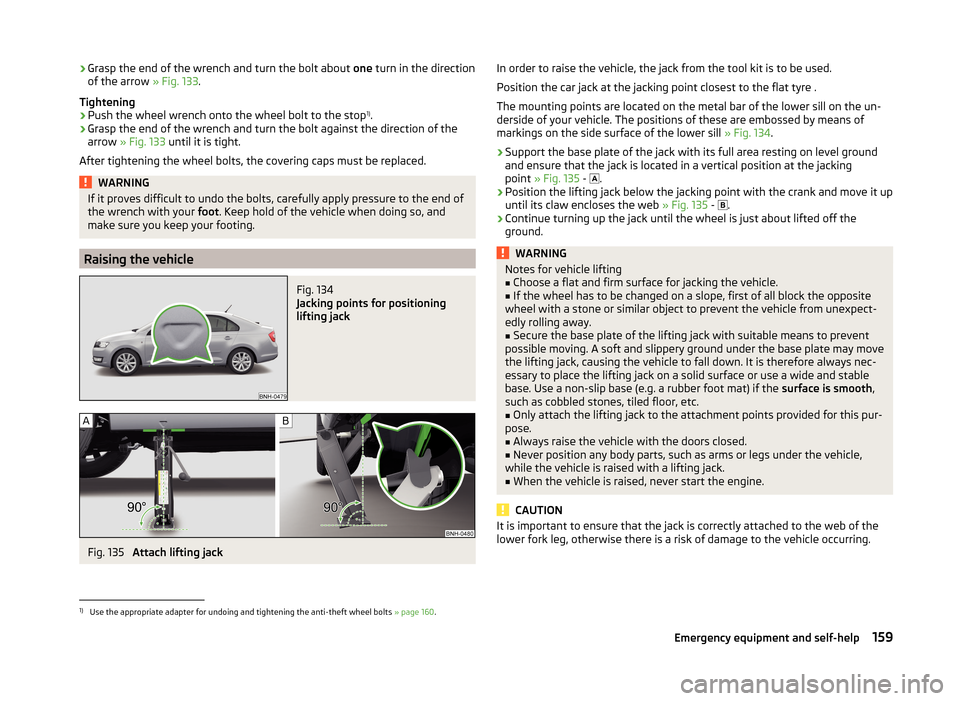

Raising the vehicle

Fig. 134

Jacking points for positioning

lifting jack

Fig. 135

Attach lifting jack

In order to raise the vehicle, the jack from the tool kit is to be used.

Position the car jack at the jacking point closest to the flat tyre .

The mounting points are located on the metal bar of the lower sill on the un-

derside of your vehicle. The positions of these are embossed by means of

markings on the side surface of the lower sill » Fig. 134.›

Support the base plate of the jack with its full area resting on level ground

and ensure that the jack is located in a vertical position at the jacking

point » Fig. 135 -

.

›

Position the lifting jack below the jacking point with the crank and move it up

until its claw encloses the web » Fig. 135 -

.

›

Continue turning up the jack until the wheel is just about lifted off the

ground.

WARNINGNotes for vehicle lifting■Choose a flat and firm surface for jacking the vehicle.■

If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpect-

edly rolling away.

■

Secure the base plate of the lifting jack with suitable means to prevent

possible moving. A soft and slippery ground under the base plate may move

the lifting jack, causing the vehicle to fall down. It is therefore always nec-

essary to place the lifting jack on a solid surface or use a wide and stable

base. Use a non-slip base (e.g. a rubber foot mat) if the surface is smooth,

such as cobbled stones, tiled floor, etc.

■

Only attach the lifting jack to the attachment points provided for this pur-

pose.

■

Always raise the vehicle with the doors closed.

■

Never position any body parts, such as arms or legs under the vehicle,

while the vehicle is raised with a lifting jack.

■

When the vehicle is raised, never start the engine.

CAUTION

It is important to ensure that the jack is correctly attached to the web of the

lower fork leg, otherwise there is a risk of damage to the vehicle occurring.1)

Use the appropriate adapter for undoing and tightening the anti-theft wheel bolts » page 160.

159Emergency equipment and self-help

Page 166 of 200

The battery of another vehicle can be used to jump-start your vehicle if the en-

gine will not start because the battery is flat.WARNING■ Pay attention to the warning instructions relating to working in the en-

gine compartment » page 137.■

A discharged vehicle battery may already freeze at temperatures just be-

low 0 °C. If the battery is frozen, do not jump start with the battery of an-

other vehicle – there is a risk of explosion.

■

Keep any sources of ignition (naked flame, smouldering cigarettes, etc.)

away from the battery – risk of explosion!

■

Never jump-start vehicle batteries with insufficient acid levels – risk of

explosion and chemical burns.

■

The vent screws of the battery cells must be tightened firmly.

Note

We recommend you buy jump-start cables from a car battery specialist.

Jump-starting using the battery from another vehicle

Fig. 138

Jump-starting: A – flat battery, B

– battery providing current

Fig. 139

Engine earth: START-STOP system

Read and observe on page 163 first.

The starting process using the battery of another vehicle requires the use of

jumper cables.

The jump-start cables must be attached in the following sequence.

›

Attach clamp

1

to the positive terminal of the discharged battery

A

» Fig. 138 .

›

Attach clamp

2

to the positive terminal of the battery supplying power

B

.

›

Attach clamp

3

to the negative terminal of the battery supplying power

B

.

›

Attach the clamp

4

to a solid metal component firmly connected to the en-

gine block or to the engine block itself.

Starting engine

›

Start the engine on the vehicle providing the power and allow it to idle.

›

Start the engine of the vehicle with the discharged battery.

›

If the engine does not start, halt the attempt to start the engine after 10 sec-

onds and wait for 30 seconds before repeating the process.

›

Remove the jumper cables exactly in the reverse sequence as for clamping.

On vehicles with the START-STOP system, the jump-start cable of the charger

must never be connected directly to the negative pole of the vehicle battery,

but only to the engine earth.

› 1.2 l/63 kW TSI and 1.2 l/77 kW TSI engines

» Fig. 139 -

› 1.4 l/90 kW engine

» Fig. 139 -

› 1.6 l/77 kW TDI CR engine

» Fig. 139 -

Both batteries must have a rated voltage of 12 V. The capacity (Ah) of the bat-

tery supplying the power must not be significantly less than the capacity of

the discharged battery in your vehicle.

Jump-start cables

Only use jump-start cables which have an adequately large cross-section and

insulated terminal clamps. Observe the instructions of the jumper lead manu-

facturer.

Positive cable – colour coding in the majority of cases is red.

Negative cable – colour coding in the majority of cases is black.

163Emergency equipment and self-help

Page 173 of 200

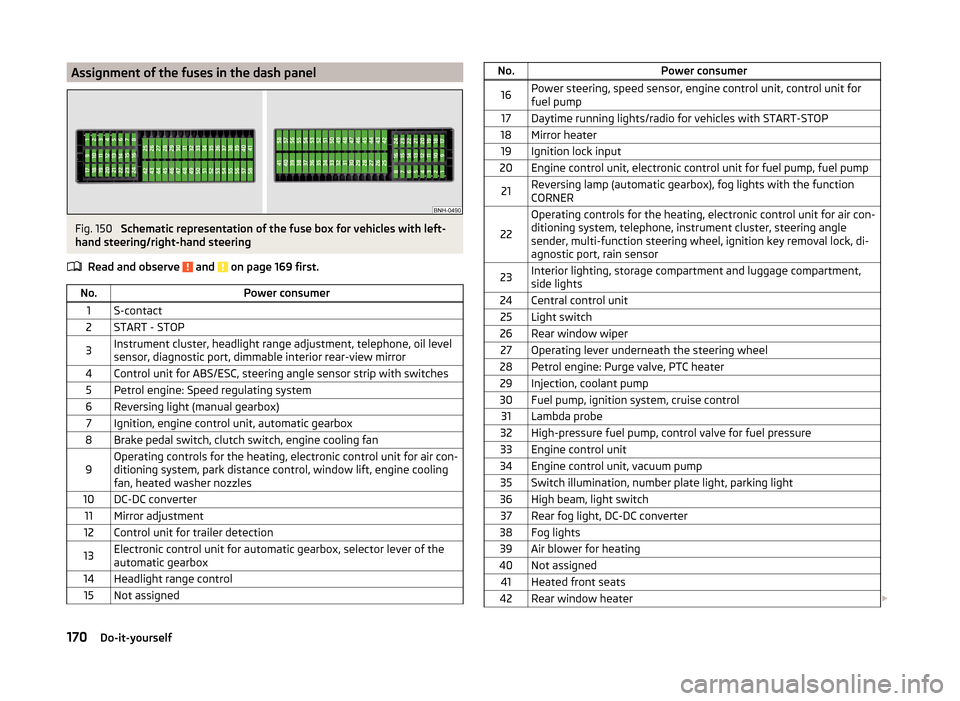

Assignment of the fuses in the dash panelFig. 150

Schematic representation of the fuse box for vehicles with left-

hand steering/right-hand steering

Read and observe

and on page 169 first.

No.Power consumer1S-contact2START - STOP3Instrument cluster, headlight range adjustment, telephone, oil level

sensor, diagnostic port, dimmable interior rear-view mirror4Control unit for ABS/ESC, steering angle sensor strip with switches5Petrol engine: Speed regulating system6Reversing light (manual gearbox)7Ignition, engine control unit, automatic gearbox8Brake pedal switch, clutch switch, engine cooling fan9Operating controls for the heating, electronic control unit for air con-

ditioning system, park distance control, window lift, engine cooling

fan, heated washer nozzles10DC-DC converter11Mirror adjustment12Control unit for trailer detection13Electronic control unit for automatic gearbox, selector lever of the

automatic gearbox14Headlight range control15Not assignedNo.Power consumer16Power steering, speed sensor, engine control unit, control unit for

fuel pump17Daytime running lights/radio for vehicles with START-STOP18Mirror heater19Ignition lock input20Engine control unit, electronic control unit for fuel pump, fuel pump21Reversing lamp (automatic gearbox), fog lights with the function

CORNER

22

Operating controls for the heating, electronic control unit for air con-

ditioning system, telephone, instrument cluster, steering angle

sender, multi-function steering wheel, ignition key removal lock, di-

agnostic port, rain sensor23Interior lighting, storage compartment and luggage compartment,

side lights24Central control unit25Light switch26Rear window wiper27Operating lever underneath the steering wheel28Petrol engine: Purge valve, PTC heater29Injection, coolant pump30Fuel pump, ignition system, cruise control31Lambda probe32High-pressure fuel pump, control valve for fuel pressure33Engine control unit34Engine control unit, vacuum pump35Switch illumination, number plate light, parking light36High beam, light switch37Rear fog light, DC-DC converter38Fog lights39Air blower for heating40Not assigned41Heated front seats42Rear window heater 170Do-it-yourself

Page 174 of 200

No.Power consumer43Horn44Windscreen wipers45Boot lid lock, central locking system46Alarm47Cigarette lighter48ABS49Turn signal lights, brake lights50DC-DC converter, radio51Electric windows (driver's window and rear left window)52Electric windows (front passenger's window and rear right)53Windscreen washer54START-STOP instrument cluster, operating lever under the steering

wheel, multifunction steering wheel55Control unit for automatic gearbox56Headlight cleaning system57Headlights front, rear58Headlights front, rear

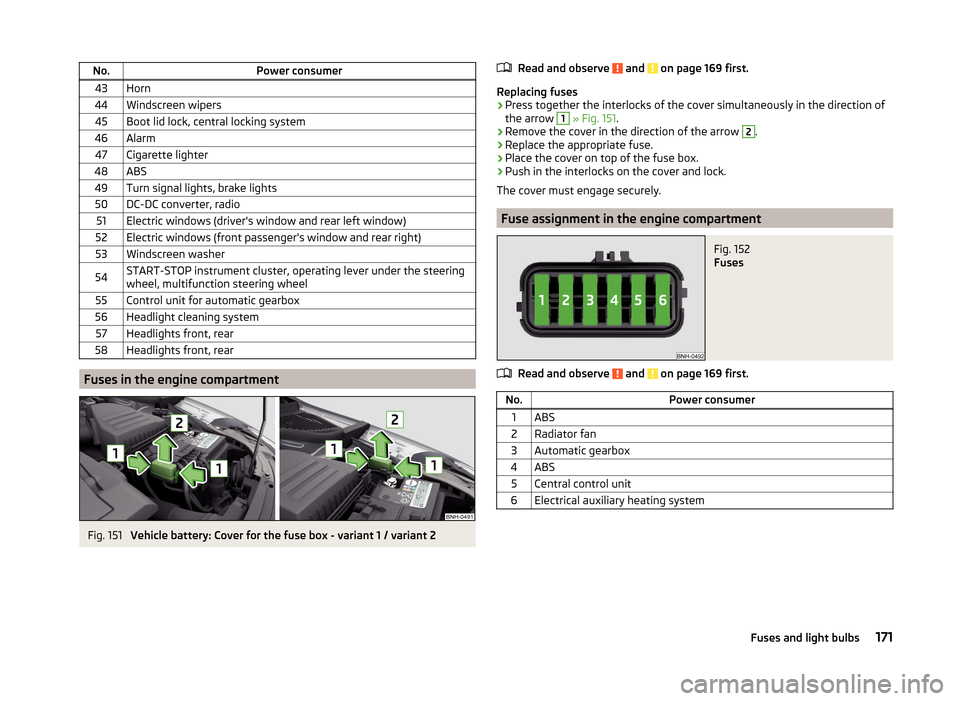

Fuses in the engine compartment

Fig. 151

Vehicle battery: Cover for the fuse box - variant 1 / variant 2

Read and observe and on page 169 first.

Replacing fuses

›

Press together the interlocks of the cover simultaneously in the direction of

the arrow

1

» Fig. 151 .

›

Remove the cover in the direction of the arrow

2

.

›

Replace the appropriate fuse.

›

Place the cover on top of the fuse box.

›

Push in the interlocks on the cover and lock.

The cover must engage securely.

Fuse assignment in the engine compartment

Fig. 152

Fuses

Read and observe and on page 169 first.

No.Power consumer1ABS2Radiator fan3Automatic gearbox4ABS5Central control unit6Electrical auxiliary heating system171Fuses and light bulbs

Page 188 of 200

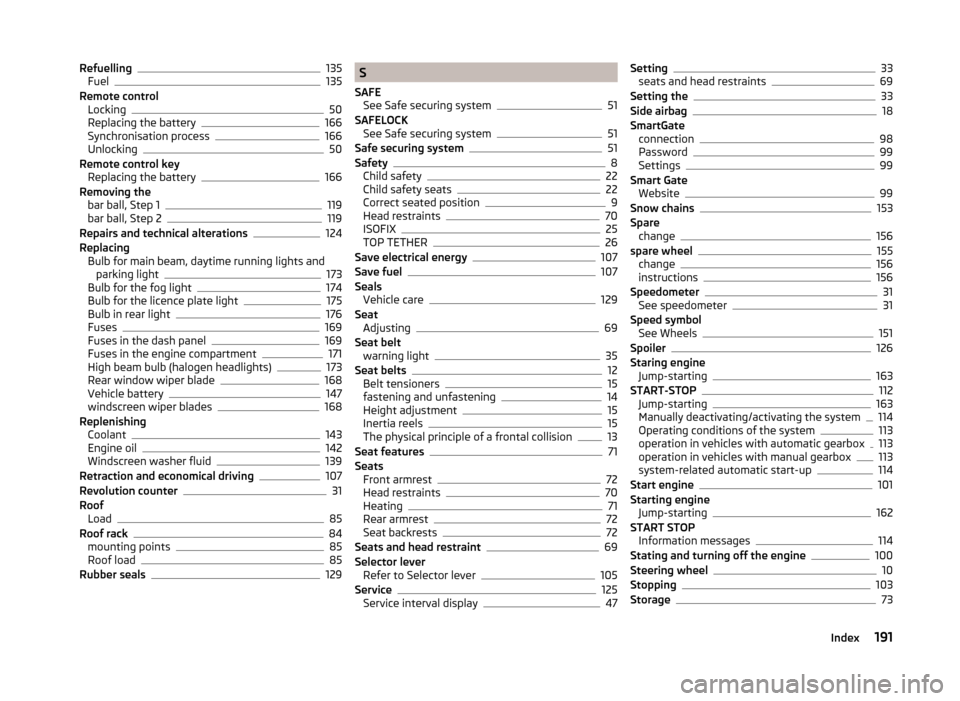

Index

A

abroad lead-free petrol

135

Abroad Headlights

63

ABS Function

109

Warning light37

Acceptance and recycling of used vehicles127

Accessories124

Adjusting Belt height

15

Exterior mirror68

head restraints70

Interior mirror67

Seat69

Steering wheel10

Adjusting the seats9

Adjustment Beam range

58

Air-conditioning system Air outlet vents

86

Airbag16

Deactivating20

Deactivating the front passenger airbag20

Deployment16

Front airbag17

Head airbag19

Indicator light39

Modifications and damage to the airbag system 126 Side airbag

18

Airbag system16

Air conditioning85

Air distribution control87

Climatronic88

manual air conditioning88

Air distribution control87

Air outlet vents86

Alarm Switching off

53

Triggering53

Alcantara cleaning

133

Anti-theft alarm system Activating/deactivating

54

Trailer122

Anti-theft wheel bolts160

Antilock Braking System109

Armrest Front

72

Rear72

artificial leather133

Ashtray76

ASR warning light

37

Assembling the bar ball, Step 1

118

bar ball, Step 2118

Assist system ABS

109

Assist systems109

ABS37

ASR37

Cruise Control System111

EDL110

ESC37, 109

HBA110

HHC110

Parking aid110

START-STOP112

TCS109

Audio see radio / navigation system

4

Auto Check Control33

Automatic driving lamp control60

Automatic gearbox104

Manual shifting of gears106

Selector lever-emergency unlocking167

Selector lever lock105

Starting-off and driving106

Tiptronic106

Using the selector lever105

Automatic gearbox modes105

Automatic load deactivation147

automatic transmission selector lever lock defect

106

Automatic transmission Kickdown

106

Selector lever lock105

AUX97

B

Ball head Check fitting

119

Ready position117

Battery In the remote control key

166

Belts12

Belt tensioners15

Bonnet Closing

138

Opening138

Boot Cargo element

83

Class N1 vehicles84

Double-sided floor covering84

Hooks82

See Boot lid55

Storage compartments83

Boot cover Parking position

83

Boot lid automatic locking

55

Closing55

Opening55

185Index

Page 194 of 200

Refuelling135

Fuel135

Remote control Locking

50

Replacing the battery166

Synchronisation process166

Unlocking50

Remote control key Replacing the battery

166

Removing the bar ball, Step 1

119

bar ball, Step 2119

Repairs and technical alterations124

Replacing Bulb for main beam, daytime running lights andparking light

173

Bulb for the fog light174

Bulb for the licence plate light175

Bulb in rear light176

Fuses169

Fuses in the dash panel169

Fuses in the engine compartment171

High beam bulb (halogen headlights)173

Rear window wiper blade168

Vehicle battery147

windscreen wiper blades168

Replenishing Coolant

143

Engine oil142

Windscreen washer fluid139

Retraction and economical driving107

Revolution counter31

Roof Load

85

Roof rack84

mounting points85

Roof load85

Rubber seals129

S

SAFE See Safe securing system

51

SAFELOCK See Safe securing system

51

Safe securing system51

Safety8

Child safety22

Child safety seats22

Correct seated position9

Head restraints70

ISOFIX25

TOP TETHER26

Save electrical energy107

Save fuel107

Seals Vehicle care

129

Seat Adjusting

69

Seat belt warning light

35

Seat belts12

Belt tensioners15

fastening and unfastening14

Height adjustment15

Inertia reels15

The physical principle of a frontal collision13

Seat features71

Seats Front armrest

72

Head restraints70

Heating71

Rear armrest72

Seat backrests72

Seats and head restraint69

Selector lever Refer to Selector lever

105

Service125

Service interval display47

Setting33

seats and head restraints69

Setting the33

Side airbag18

SmartGate connection

98

Password99

Settings99

Smart Gate Website

99

Snow chains153

Spare change

156

spare wheel155

change156

instructions156

Speedometer31

See speedometer31

Speed symbol See Wheels

151

Spoiler126

Staring engine Jump-starting

163

START-STOP112

Jump-starting163

Manually deactivating/activating the system114

Operating conditions of the system113

operation in vehicles with automatic gearbox113

operation in vehicles with manual gearbox113

system-related automatic start-up114

Start engine101

Starting engine Jump-starting

162

START STOP Information messages

114

Stating and turning off the engine100

Steering wheel10

Stopping103

Storage73

191Index