check engine SKODA RAPID SPACEBACK 2013 1.G Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2013, Model line: RAPID SPACEBACK, Model: SKODA RAPID SPACEBACK 2013 1.GPages: 193, PDF Size: 14.8 MB

Page 135 of 193

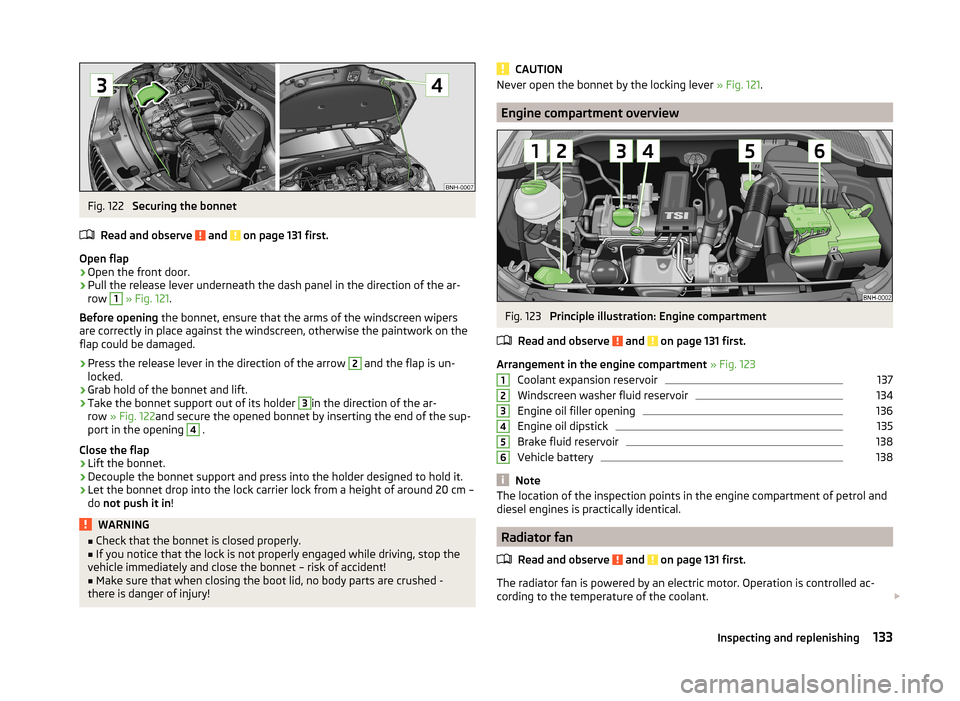

Fig. 122

Securing the bonnet

Read and observe

and on page 131 first.

Open flap

›

Open the front door.

›

Pull the release lever underneath the dash panel in the direction of the ar-

row

1

» Fig. 121 .

Before opening the bonnet, ensure that the arms of the windscreen wipers

are correctly in place against the windscreen, otherwise the paintwork on the

flap could be damaged.

›

Press the release lever in the direction of the arrow

2

and the flap is un-

locked.

›

Grab hold of the bonnet and lift.

›

Take the bonnet support out of its holder

3

in the direction of the ar-

row » Fig. 122 and secure the opened bonnet by inserting the end of the sup-

port in the opening

4

.

Close the flap

›

Lift the bonnet.

›

Decouple the bonnet support and press into the holder designed to hold it.

›

Let the bonnet drop into the lock carrier lock from a height of around 20 cm –

do not push it in !

WARNING■

Check that the bonnet is closed properly.■If you notice that the lock is not properly engaged while driving, stop the

vehicle immediately and close the bonnet – risk of accident!■

Make sure that when closing the boot lid, no body parts are crushed -

there is danger of injury!

CAUTIONNever open the bonnet by the locking lever » Fig. 121.

Engine compartment overview

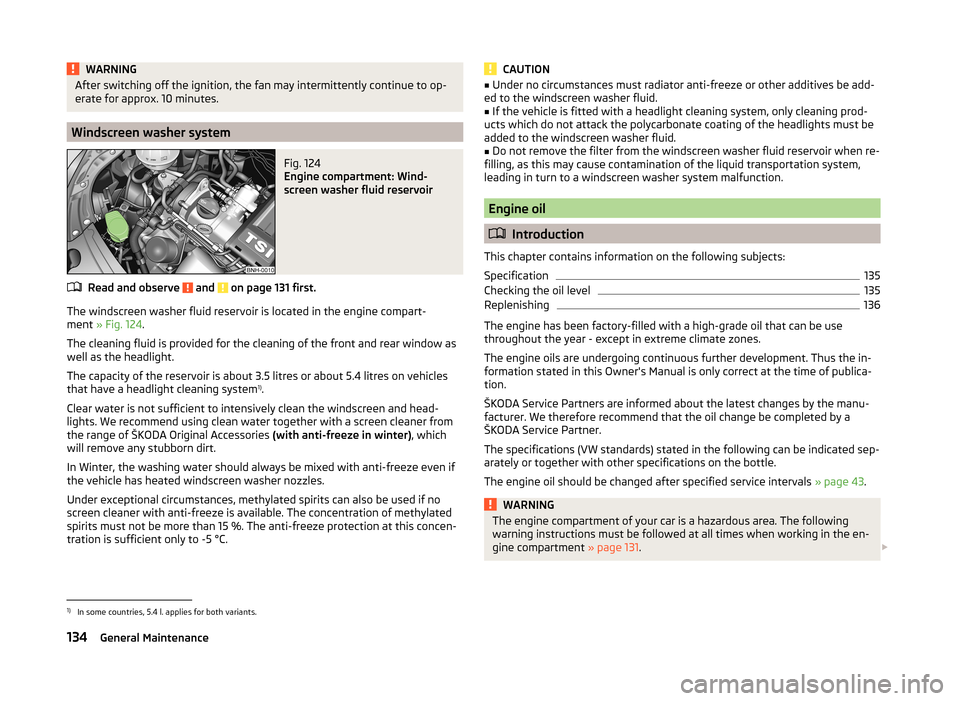

Fig. 123

Principle illustration: Engine compartment

Read and observe

and on page 131 first.

Arrangement in the engine compartment » Fig. 123

Coolant expansion reservoir

137

Windscreen washer fluid reservoir

134

Engine oil filler opening

136

Engine oil dipstick

135

Brake fluid reservoir

138

Vehicle battery

138

Note

The location of the inspection points in the engine compartment of petrol and

diesel engines is practically identical.

Radiator fan

Read and observe

and on page 131 first.

The radiator fan is powered by an electric motor. Operation is controlled ac-

cording to the temperature of the coolant.

123456133Inspecting and replenishing

Page 136 of 193

WARNINGAfter switching off the ignition, the fan may intermittently continue to op-

erate for approx. 10 minutes.

Windscreen washer system

Fig. 124

Engine compartment: Wind-

screen washer fluid reservoir

Read and observe and on page 131 first.

The windscreen washer fluid reservoir is located in the engine compart-

ment » Fig. 124 .

The cleaning fluid is provided for the cleaning of the front and rear window as

well as the headlight.

The capacity of the reservoir is about 3.5 litres or about 5.4 litres on vehicles

that have a headlight cleaning system 1)

.

Clear water is not sufficient to intensively clean the windscreen and head-

lights. We recommend using clean water together with a screen cleaner from

the range of ŠKODA Original Accessories (with anti-freeze in winter), which

will remove any stubborn dirt.

In Winter, the washing water should always be mixed with anti-freeze even if

the vehicle has heated windscreen washer nozzles.

Under exceptional circumstances, methylated spirits can also be used if no

screen cleaner with anti-freeze is available. The concentration of methylated

spirits must not be more than 15 %. The anti-freeze protection at this concen-

tration is sufficient only to -5 °C.

CAUTION■ Under no circumstances must radiator anti-freeze or other additives be add-

ed to the windscreen washer fluid.■

If the vehicle is fitted with a headlight cleaning system, only cleaning prod-

ucts which do not attack the polycarbonate coating of the headlights must be

added to the windscreen washer fluid.

■

Do not remove the filter from the windscreen washer fluid reservoir when re-

filling, as this may cause contamination of the liquid transportation system,

leading in turn to a windscreen washer system malfunction.

Engine oil

Introduction

This chapter contains information on the following subjects:

Specification

135

Checking the oil level

135

Replenishing

136

The engine has been factory-filled with a high-grade oil that can be use

throughout the year - except in extreme climate zones.

The engine oils are undergoing continuous further development. Thus the in- formation stated in this Owner's Manual is only correct at the time of publica-

tion.

ŠKODA Service Partners are informed about the latest changes by the manu-

facturer. We therefore recommend that the oil change be completed by a

ŠKODA Service Partner.

The specifications (VW standards) stated in the following can be indicated sep-

arately or together with other specifications on the bottle.

The engine oil should be changed after specified service intervals » page 43.

WARNINGThe engine compartment of your car is a hazardous area. The following

warning instructions must be followed at all times when working in the en-

gine compartment » page 131. 1)

In some countries, 5.4 l. applies for both variants.

134General Maintenance

Page 137 of 193

CAUTIONDo not pour any additives into the engine oil – risk of serious damage to the

engine parts!

Note

■ Before a long drive we recommend that you purchase and carry with you en-

gine oil which complies with the specification for your vehicle.■

We recommend that you use oils from ŠKODA Original Accessories.

■

If your skin has come into contact with oil, it must be washed thoroughly.

Specification

Read and observe

and on page 134 first.

Vehicles with variable service intervals

Petrol enginesSpecification1.2 litres/55 kWVW 503 00, VW 504 001.2 l/63 kW TSIVW 504 001.2 l/77 kW TSIVW 504 001.4 l/90 kW TSIVW 503 00, VW 504 00Diesel engine a)Specification1.6 l/66, 77 kW TDI CRVW 507 00a)

Engine oil VW 505 01 can optionally be used in diesel engines

without a DPF.

Vehicles with fixed service intervals

Petrol enginesSpecification1.2 litres/55 kWVW 501 01, VW 502 001.2 l/63 kW TSIVW 502 001.2 l/77 kW TSIVW 502 001.4 l/90 kW TSIVW 501 01, VW 502 001.6 litres/77 kWVW 501 01, VW 502 00

If the oils specified above are not available, oils according to ACEA A2 or

ACEA A3 can be used once for refilling.

Diesel engine a)Specification1.6 l/66, 77 kW TDI CRVW 507 00a)

Engine oil VW 505 01 can optionally be used in diesel engines

without a DPF.

If the oils specified above are not available, oils according to ACEA B3 or

ACEA B4 can be used once for refilling.

CAUTION

Only the above-mentioned oils can be used on vehicles with flexible service in-

tervals. We recommend always refilling with oil of the same specification since

this will maintain the properties of the oil. In exceptional cases, a maximum of

0.5 l of specification VW 502 00 (only for petrol engines) or specification

VW 505 01 (only for diesel engines) engine oil can be used to refill once. Other

engine oils must not be used - risk of engine damage!

Checking the oil level

Fig. 125

Principle illustration: Dipstick

Read and observe

and on page 134 first.

The dipstick indicates the engine oil level .

Dipstick » Fig. 125

The oil level must be within this range.

The oil can be checked and topped up, if the following conditions are satisfied. The vehicle is standing on a horizontal surface.

The engine operating temperature is reached.

The engine is turned off.

The bonnet is open.

Checking the level

›

Wait a few minutes until the engine oil flows back into the oil trough.

›

Pull out the dipstick.

›

Wipe the dipstick with a clean cloth and insert it again to the stop.

A135Inspecting and replenishing

Page 138 of 193

›Pull the dipstick out again and check the oil level.

The engine consumes a little oil. The oil consumption may be as much as 0.5 l/

1 000 km depending on your style of driving and the conditions under which

you operate your vehicle. Consumption may be slightly higher than this during

the first 5 000 km.

The oil level must be checked at regular intervals.

In case of low oil level, the display of the instrument cluster shows a check

mark

as well as the relevant notification » page 31. Check the oil level using

the dipstick as soon as possible. Add oil accordingly.

CAUTION

■ The oil level must never be above the range A» Fig. 125 - risk of damage to

the motor as well as the exhaust system!■

Do not continue your journey if for some reason it is not possible to top up

the engine oil!

Switch off the engine and seek assistance from a specialist

garage.

■

If the oil level is above level

A

» Fig. 125 ,

do not continue to drive! Switch

off the engine and seek assistance from a specialist garage.

Replenishing

Read and observe

and on page 134 first.

›

Unscrew the cap of the engine oil filler opening » Fig. 123 on page 133 .

›

Replenish the oil in portions of 0.5 litres in accordance with the correct speci-

fications » page 135 .

›

Check the oil level » page 135.

›

Screw the lid of the engine oil filler closed carefully.

›

Pull the dipstick out as far as the stop.

Coolant

Introduction

This chapter contains information on the following subjects:

Checking the coolant level

137

Replenishing

137

The coolant provides cooling for the motor.

It consists of water and coolant additive with additives that protect the cooling

system against corrosion and prevents furring.

The coolant additive content in the coolant must be at least 40%.

The coolant additive may be increased to a maximum of 60%.

The correct mixing ratio of water and coolant additive is to be checked if nec-

essary by a specialist garage or is to be restored if necessary.

The description of the coolant is shown in the coolant expansion reser-

voir » Fig. 126 on page 137 .WARNINGThe engine compartment of your car is a hazardous area. The following

warning instructions must be followed at all times when working in the en- gine compartment » page 131.■

The coolant is harmful to health.

■

Avoid contact with the coolant.

■

Coolant vapours are harmful to health.

■

Never open the end cover of the coolant expansion reservoir while the

engine is still warm. The cooling system is pressurised!

■

When opening the end cover of the coolant expansion reservoir, cover it

with a cloth to protect your face, hands and arms from hot steam or hot

coolant.

■

If any coolant splashes into your eyes, immediately rinse out your eyes

with clear water and contact a doctor as soon as possible.

■

Always keep the coolant in the original container, safe from people who

are not completely independent, especially children - there is a danger of

poisoning!

■

If coolant is swallowed, consult a doctor immediately.

■

Never spill operating fluids over the hot engine - risk of fire.

CAUTION

■ Do not continue your journey if for some reason it is not possible to fill with

coolant under the current circumstances! Switch off the engine and seek as-

sistance from a specialist garage.■

The concentration of coolant additive in the coolant must never be under

40%.

■

Over 60% of coolant additive in the coolant reduces the antifreeze protec-

tion and cooling effect.

■

A coolant additive that does not comply with the correct specification can

significantly reduce the corrosion protection of the cooling system.

136General Maintenance

Page 139 of 193

■Any faults resulting from corrosion may cause a loss of coolant and can con-

sequently result in major engine damage!■

Do not fill the coolant above the mark

A

. » Fig. 126 on page 137

■

If an error occurs, leading to the engine overheating, the help of a professio-

nal garage is to be sought - there is a risk of serious engine damage occurring.

■

Additional headlights and other attached components in front of the air inlet

impair the cooling efficiency of the coolant.

■

Never cover the radiator - there is a risk of the engine overheating.

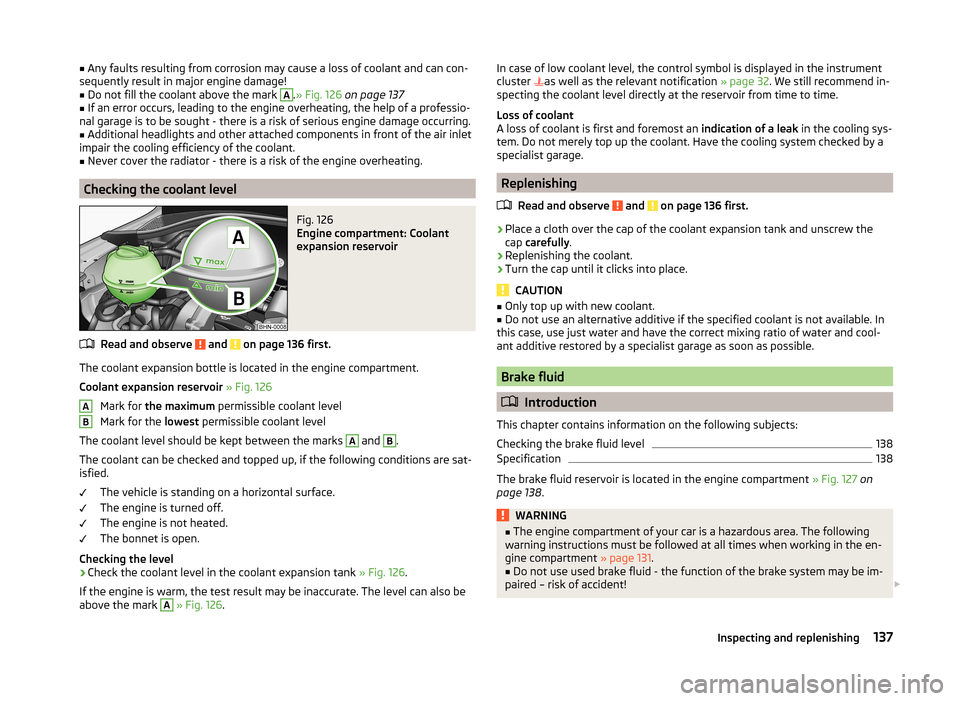

Checking the coolant level

Fig. 126

Engine compartment: Coolant

expansion reservoir

Read and observe and on page 136 first.

The coolant expansion bottle is located in the engine compartment.

Coolant expansion reservoir » Fig. 126

Mark for the maximum permissible coolant level

Mark for the lowest permissible coolant level

The coolant level should be kept between the marks

A

and

B

.

The coolant can be checked and topped up, if the following conditions are sat-

isfied.

The vehicle is standing on a horizontal surface.

The engine is turned off.

The engine is not heated.

The bonnet is open.

Checking the level

›

Check the coolant level in the coolant expansion tank » Fig. 126.

If the engine is warm, the test result may be inaccurate. The level can also be

above the mark

A

» Fig. 126 .

ABIn case of low coolant level, the control symbol is displayed in the instrument

cluster as well as the relevant notification » page 32. We still recommend in-

specting the coolant level directly at the reservoir from time to time.

Loss of coolant

A loss of coolant is first and foremost an indication of a leak in the cooling sys-

tem. Do not merely top up the coolant. Have the cooling system checked by a

specialist garage.

Replenishing

Read and observe

and on page 136 first.

›

Place a cloth over the cap of the coolant expansion tank and unscrew the

cap carefully .

›

Replenishing the coolant.

›

Turn the cap until it clicks into place.

CAUTION

■

Only top up with new coolant.■Do not use an alternative additive if the specified coolant is not available. In

this case, use just water and have the correct mixing ratio of water and cool-

ant additive restored by a specialist garage as soon as possible.

Brake fluid

Introduction

This chapter contains information on the following subjects:

Checking the brake fluid level

138

Specification

138

The brake fluid reservoir is located in the engine compartment » Fig. 127 on

page 138 .

WARNING■

The engine compartment of your car is a hazardous area. The following

warning instructions must be followed at all times when working in the en-

gine compartment » page 131.■

Do not use used brake fluid - the function of the brake system may be im-

paired – risk of accident!

137Inspecting and replenishing

Page 140 of 193

CAUTION■Do not continue your journey if the fluid level has dropped below the “MIN”

marking » Fig. 127 on page 138 , do not continue to drive - risk of accidents!

Seek help from a specialist garage.■

Brake fluid damages the paintwork of the vehicle.

Note

■ The brake fluid is changed as part of a compulsory inspection service.■We recommend using brake fluids from the ŠKODA Original Accessories

range.

Checking the brake fluid level

Fig. 127

Engine compartment: Brake fluid

reservoir

Read and observe and on page 137 first.

The fluid can be checked if the following conditions are met.

The vehicle is standing on a horizontal surface.

The engine is turned off.

The bonnet is open.

Checking the level

›

Check the level of brake fluid in the reservoir » Fig. 127.

The level must be between the “MIN” and “MAX” markings.

A slight drop in the fluid level results when driving due to normal wear-and-

tear and automatic adjustment of the brake pads.

There may be an indication of a leak in the brake system, however, if the fluid

level drops significantly within a short time or if it drops below the “MIN” mark-

ing.

Too low brake fluid level is indicated by the warning light lighting up in the

instrument cluster as well as the relevant notification being dis-

played » page 31 ,

Brake system .

Specification

Read and observe

and on page 137 first.

The brake fluid must comply with the following standards or specifications:› VW 50114;

› FMVSS 116 DOT4.

Vehicle battery

Introduction

This chapter contains information on the following subjects:

Opening the cover

139

Checking the battery electrolyte level

140

Charging

140

Replacing

141

Disconnecting and reconnecting

141

Automatic load deactivation

141

The vehicle battery represents a power source for the motor to start and for

the supply of electrical consumers in the car.

Warning symbols on the vehicle battery

SymbolMeaningAlways wear eye protection!Battery acid is severely caustic. Always wear gloves and eye pro-

tection!Keep fire, sparks, open flames and lit cigarettes well clear of the

vehicle battery!When charging the vehicle battery, a highly explosive gas mixture

is produced!Keep children away from the vehicle battery! 138General Maintenance

Page 142 of 193

Checking the battery electrolyte levelFig. 129

Vehicle battery: Electrolyte level

indicator

Read and observe and on page 139 first.

On vehicles with a vehicle battery fitted with a colour indicator, » Fig. 129the

colouring of the display can indicate the acidic level.

Air bubbles can influence the colour of the indicator. For this reason carefully knock on the indicator before carrying out the check.

› Black colour – electrolyte level is correct.

› Colourless or light yellow colour – electrolyte level too low, the battery must

be replaced.

Vehicles with a START-STOP system are fitted with a battery control unit for

checking the energy level for the recurring engine start.

We recommend that you have the acid level checked regularly by a specialist garage, especially in the following cases.

› High external temperatures.

› Longer day trips.

› After each charge.

Winter time

The vehicle battery only has a proportion of the starting power in lower tem-

peratures. A discharged vehicle battery may already freeze at temperatures

just below 0 °C .

We therefore recommend that you have the battery checked and, if necessary,

recharged by a specialist garage before the start of the winter.

Note■ The battery acid level is also checked regularly by a specialist garage as part

of the inspection service.■

For technical reasons, on vehicles with the description “AGM”, the electrolyte

level cannot be checked.

Charging

Read and observe

and on page 139 first.

A properly charged vehicle battery is essential for reliably starting the engine.

A charging operation can be performed if the following conditions are satis-

fied.

The engine is turned off.

The ignition is switched off.

All consumers are turned off.

The bonnet is open.

“Fast charging” with high currents

›

Disconnect both battery cables (first of all “negative”, then “positive”).

›

Attach the terminal clamps of the charger to the battery terminals (red =

“positive”, black = “negative”).

›

Plug the mains cable of the charger into the power socket and switch on the

device.

›

After charging has been successful: Switch off the charger and remove the

mains cable from the power socket.

›

Only then disconnect the charger's terminal clamps.

›

Reconnect the cables to the battery (first “positive”, then “negative”).

Charging with low voltages

It is not necessary to disconnect the cables from the battery if you recharge

the vehicle battery, for example from a mini-charger.

Refer to the instructions of the charger manufacturer .

A charging current of 0.1 multiple of the total vehicle battery capacity (or low-

er) must be used until full charging is achieved.

The vent plugs of the vehicle battery should not be opened for charging.

140General Maintenance

Page 143 of 193

WARNING■When you charge a battery, hydrogen is released, and a highly explosive

gas mixture is also produced. An explosion can be caused through sparkling

over during unclamping or loosening of the cable plug while the ignition is

on.■

Creating a bridge between the poles on the battery (e.g. with metal ob-

jects - cables) creates a short circuit - risk of damage to the battery, explo-

sion and burning of the battery, jets of acid spurting out.

■

Avoid creating sparks when working with cables and electrical devices.

Strong sparking represents a risk of injury.

■

Before carrying out any work on the electrical system, switch off the en-

gine, the ignition and all electrical consumers and disconnect the negative

terminal (-).

■

“Quick-charging” the vehicle battery is dangerous and requires a special

charger and specialist knowledge.

■

We therefore recommend that vehicle batteries be “rapidly charged” by a

specialist garage.

CAUTION

On vehicles with the START-STOP system, the pole terminal of the charger

must not be connected directly to the negative terminal of the vehicle battery,

but only to the engine earth » page 158, Jump-starting in vehicles with the

START-STOP system .

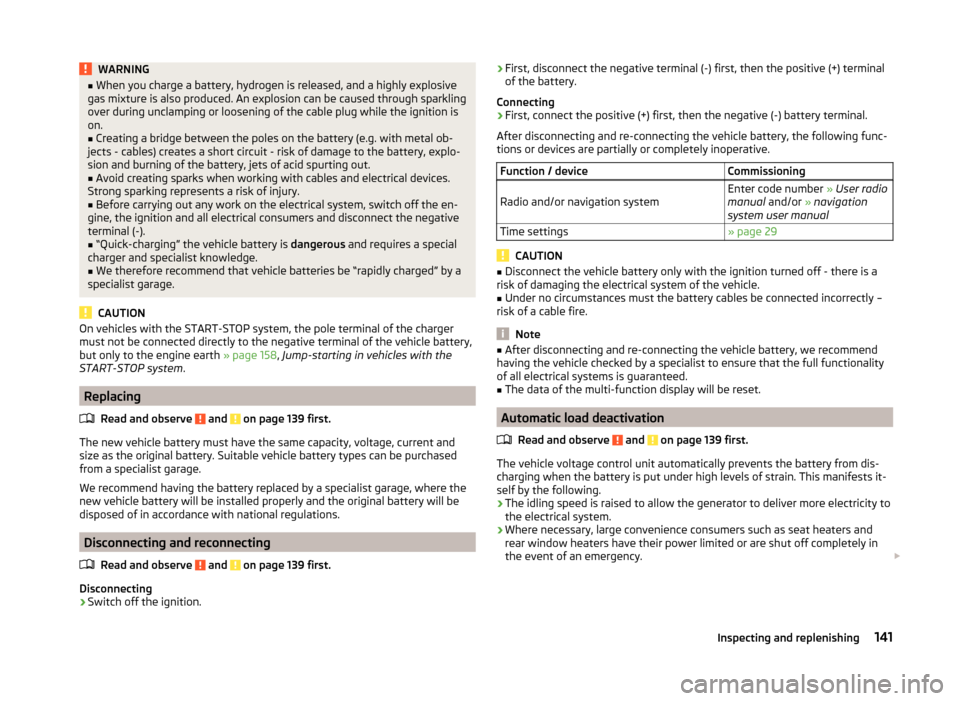

Replacing

Read and observe

and on page 139 first.

The new vehicle battery must have the same capacity, voltage, current and

size as the original battery. Suitable vehicle battery types can be purchased

from a specialist garage.

We recommend having the battery replaced by a specialist garage, where the

new vehicle battery will be installed properly and the original battery will be

disposed of in accordance with national regulations.

Disconnecting and reconnecting

Read and observe

and on page 139 first.

Disconnecting

›

Switch off the ignition.

›First, disconnect the negative terminal (-) first, then the positive (+) terminal

of the battery.

Connecting›

First, connect the positive (+) first, then the negative (-) battery terminal.

After disconnecting and re-connecting the vehicle battery, the following func-

tions or devices are partially or completely inoperative.

Function / deviceCommissioningRadio and/or navigation systemEnter code number » User radio

manual and/or » navigation

system user manualTime settings» page 29

CAUTION

■ Disconnect the vehicle battery only with the ignition turned off - there is a

risk of damaging the electrical system of the vehicle.■

Under no circumstances must the battery cables be connected incorrectly –

risk of a cable fire.

Note

■ After disconnecting and re-connecting the vehicle battery, we recommend

having the vehicle checked by a specialist to ensure that the full functionality

of all electrical systems is guaranteed.■

The data of the multi-function display will be reset.

Automatic load deactivation

Read and observe

and on page 139 first.

The vehicle voltage control unit automatically prevents the battery from dis-

charging when the battery is put under high levels of strain. This manifests it-

self by the following.

› The idling speed is raised to allow the generator to deliver more electricity to

the electrical system.

› Where necessary, large convenience consumers such as seat heaters and

rear window heaters have their power limited or are shut off completely in

the event of an emergency.

141Inspecting and replenishing

Page 144 of 193

CAUTION■Despite such intervention by the vehicle electric system management, the

vehicle battery may be drained. For example, when the ignition is switched on

a long time with the engine turned off or the side or parking lights are turned

on during longer parking.■

Consumers that are supplied via a 12-V power socket can cause the vehicle

battery to discharge when the ignition is switched off.

Note

Driving comfort is not impaired by consumers being deactivated. The driver is

often not aware of it having taken place.Wheels

Tyres and wheel rims

Introduction

This chapter contains information on the following subjects:

Service life of tyres

143

New tyres

144

Unidirectional tyres

145WARNINGThe national legal regulations must be observed for the use of tyres.WARNINGInstructions for the use of tyres■For the first 500 km, new tyres do not yet provide optimum grip, and ap-

propriate care should therefore be taken when driving – risk of accident!■

Only use radial tyres of the same type, size (rolling circumference) and

tread pattern on all four wheels.

■

For reasons of driving safety, do not replace tyres individually.

■

Never exceed the maximum permissible load bearing capacity of moun-

ted tyres.

■

Never exceed the maximum permissible speed for the mounted tyres.

■

An incorrect wheel alignment at the front or rear impairs handling.

■

Unusual vibrations or pulling of the vehicle to one side could be a sign of

tyre damage. If there is any suspicion that a wheel is damaged, immediately

reduce your speed and stop! If no external damage is evident, drive slowly

and carefully to the nearest specialist garage to have the vehicle checked.

■

Only use tyres or wheel rims that have been approved by ŠKODA for your

model of vehicle. Failure to observe this instruction will adversely affect the

road safety of your vehicle.

WARNINGInformation regarding tyre damage or wear■Never use tyres if you do not know anything about the condition and age.■

Never drive with damaged tyres.

■

Immediately replace damaged wheel rims or tyres.

142General Maintenance

Page 158 of 193

Inflation hose with plug

Air compressor

Button for releasing the tyre pressure

12 volt cable connector

Tyre inflation hose

Tyre inflation pressure indicator

ON and OFF switch

Tyre inflater bottle with sealing agent

Replacement valve core

The valve remover 2

has a slot at its lower end which fits into the valve core.

Preparations for using the breakdown kit

Read and observe

on page 155 first.

Always change a wheel on a level surface as far as possible.

The following preparatory work must be carried out before using the break-

down kit.

›

Have all of the occupants get out of the vehicle. While changing a tyre, the

occupants of the vehicle should not stand on the road (they should instead

remain behind a crash barrier).

›

Switch off the engine.

›

Move the gear shift lever into Neutral or move the selector lever for the au-

tomatic gearbox into position P.

›

Firmly apply the handbrake.

›

Check that you can carry out the repairs with the breakdown kit » page 155.

›

Uncouple any trailers.

›

Remove the breakdown kit from the boot.

›

Stick the sticker

1

» Fig. 143 on page 155 on the dashboard in the driver's

field of view.

›

Do not remove the foreign body, e.g. screw or nail, from the tyre.

›

Unscrew the valve cap.

›

Use the valve remover

2

to unscrew the valve core and place it on a clean

surface (rag, paper, etc.).

34567891011Sealing and inflating the tyre

Read and observe

on page 155 first.

Sealing

›

Forcefully shake the tyre inflater bottle

10

» Fig. 143 on page 155 back and

forth several times.

›

Firmly screw the inflation hose

3

onto the tyre inflater bottle

10

in a clock-

wise direction. The film on the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and plug the open end fully onto

the tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflater bottle into the tyre.

›

Remove the empty tyre inflater bottle from the valve.

›

Screw the valve core back into the tyre valve using the valve remover

2

.

Inflating

›

Screw the tyre inflation hose

7

» Fig. 143 on page 155 of the air compressor

firmly onto the tyre valve.

›

Start the engine and run it in idle.

›

Plug the connector

6

into 12 Volt socket » page 71, 12-Volt power outlet .

›

Switch on the air compressor with the ON and OFF switch

9

.

›

Allow the air compressor to run until a pressure of 2.0-2.5 bar is achieved.

Maximum run time of 8 minutes »

›

Switch off the air compressor.

›

If you cannot reach an air pressure of 2.0–2.5 bar, unscrew the tyre inflation

hose

7

from the tyre valve.

›

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent

to “distribute” in the tyre.

›

Firmly screw the tyre inflation hose

7

back onto the tyre valve and repeat

the inflation process.

›

If you cannot reach the required tyre inflation pressure here either, this

means the tyre has sustained too much damage. You cannot seal with tyre with the breakdown kit »

.

›

Switch off the air compressor.

›

Remove the tyre inflation hose

7

from the tyre valve.

Once a tyre inflation pressure of 2.0–2.5 bar is achieved, continue the journey

at a maximum speed of 80 km/h (50 mph).

Check the tyre inflation pressure after driving for 10 minutes » page 157.

156Do-it-yourself