tow SKODA RAPID SPACEBACK 2013 1.G Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2013, Model line: RAPID SPACEBACK, Model: SKODA RAPID SPACEBACK 2013 1.GPages: 193, PDF Size: 14.8 MB

Page 110 of 193

FunctionFig. 106

Range of sensors

Read and observe and on page 107 first.

Approximate range of sensors

Range » Fig. 106Distance behind the vehicle (in cm)A160B60

Acoustic signals and display

The interval between the acoustic signals becomes shorter as the clearance is

reduced. A continuous tone sounds from a distance of approx. 30 cm - danger

area. From this moment on, do not continue reversing!

Description of the indications in the radio or navigation system display, » the

radio instruction manual, navigation system user guide.

Activation/deactivation

Read and observe

and on page 107 first.

The system is activated automatically by engaging the reverse gear. This is

confirmed by a brief audible signal.

The system is deactivated by disengaging reverse gear.

Displaying an error

If a warning signal sounds for about 3 seconds after activating the system and

there is no obstacle close to your car, this indicates a system fault. Seek help

from a specialist garage.

NoteFor vehicles with a factory-fitted towing device, the system cannot be activa-

ted when towing a trailer.

Cruise Control System

Introduction

This chapter contains information on the following subjects:

Functioning

108

Operating Description

109

The Cruise Control System (CCS) maintains a set speed without you having to

actuate the accelerator pedal.

The status where the CCS maintains the speed is referred to hereinafter as the

control .

WARNING■

The CCS only serves as an assistance and does not relieve the driver of

the responsibility for the vehicle operation.■

Always adjust the speed and driving style to the current visibility, weath-

er, road and traffic conditions.

Functioning

Read and observe

on page 108 first.

Basic requirements for starting the control The CCS is activated.

On vehicles with a manual transmission , the second gear or higher must

be engaged.

On vehicles with an automatic transmission , the selector lever must be in

the D, S position or in the Tiptronic position.

The current speed must be higher than 20 km/hr.

This is only possible within the range which is permitted by the power output

and braking power of the engine.

108Driving

Page 114 of 193

Hitch and trailer

Hitch

Introduction

This chapter contains information on the following subjects:

Description

112

Adjusting the ready position

113

Fitting the ball head

113

Check proper fitting

114

Removing the ball head

115

Use and care

115

If your vehicle has already been factory-fitted with a towing device or is fitted

with a towing device from ŠKODA Original Accessories, then it meets all of the

technical requirements and national legal regulations for towing a trailer.

Your vehicle is fitted with a 13-pin power socket for the electrical connection

between the vehicle and trailer. If the trailer that is to be towed has a 7-pin

connector , you can use a suitable adapter from ŠKODA Original Accessories.

The maximum trailer drawbar load is 50 kg.

WARNING■

Check that the tow bar is seated correctly and is secured in the mounting

recess before the start of every journey.■

Do not use the tow bar if it is not correctly inserted and secured in the

mounting recess.

■

Do not use the towing device if it is damaged or if there are parts missing.

■

Do not modify or adapt the towing device in any way.

■

Never release the tow bar while the trailer is still coupled.

CAUTION

Take care when handling the tow bar so as to avoid damaging the paintwork

on the bumper.

Note

Tow the vehicle by means of the detachable ball rod » page 160.DescriptionFig. 110

Carrier for the towing device / tow bar

Read and observe

and on page 112 first.

The tow bar can be removed and is located in the spare wheel compartment or

in a compartment for the spare wheel in the boot » page 150.

Support for the towing device and tow bar » Fig. 110

13-pin power socket

Safety eyelet

Mounting recess

Cap

Protective cap

Ball head

Locking ball

Centring

Green marking on the hand wheel

Hand wheel

Key

Lock cap

Red marking on the hand wheel

White marking on ball head

Note

On the bottom of the key is a code number. If you lose a key, please contact a

specialist garage which will be able to use this code number to provide you

with a new one.1234567891011121314112Driving

Page 115 of 193

Adjusting the ready positionFig. 111

Setting the ready position

Fig. 112

Ready position

Read and observe

and on page 112 first.

Always adjust the ball head in the ready position before fitting.

›

Turn the key

A

in direction of the arrow

1

to the stop » Fig. 111.

›

Pull the hand wheel

B

in the direction of the arrow

2

and turn in the direc-

tion of the arrow

3

to the stop.

The hand wheel remains locked in this position.

Correctly adjusted standby position » Fig. 112

The key

C

is in the unlocked position - the arrow on the key points to the

“padlock open” icon . The key cannot be removed.

The locking balls

D

can be pushed fully into the tow bar.

The red marking E on the hand wheel points to the white marking on the

ball bar.

There is a clear gap of approx. 4 mm F

between the hand wheel and the

tow bar.

The ball bar is thus set ready for installation.

WARNINGIf the tow bar cannot be correctly placed in the ready position, then it must

not be used.

CAUTION

When in the ready position, the key cannot be removed from the hand wheel

lock.

Fitting the ball head

Fig. 113

Insert the ball bar / lock the lock and remove the key

113Hitch and trailer

Page 116 of 193

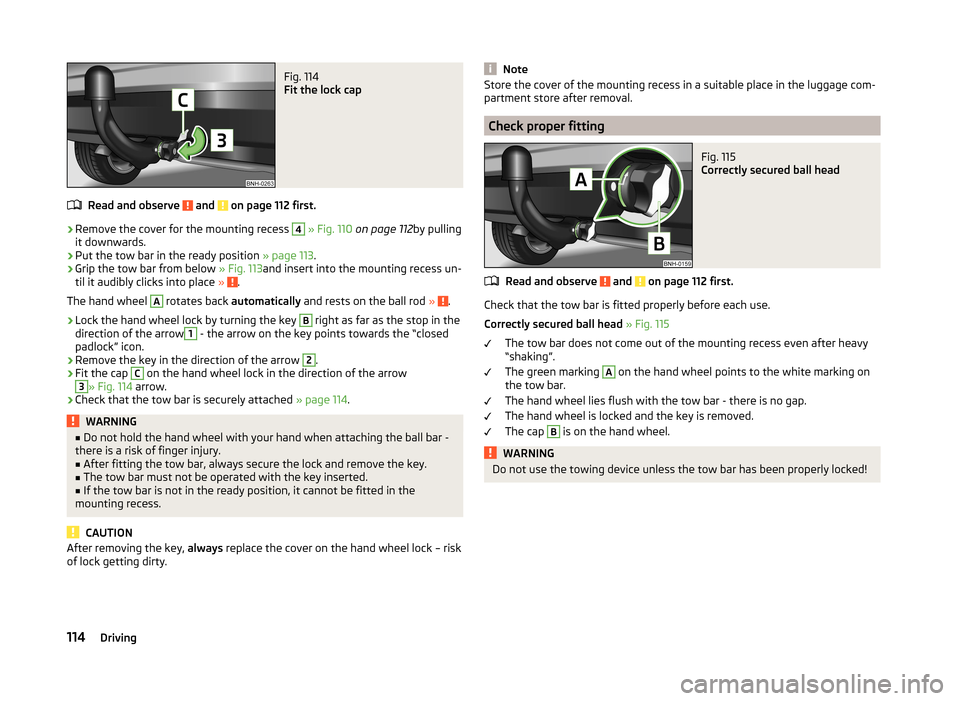

Fig. 114

Fit the lock cap

Read and observe and on page 112 first.

›

Remove the cover for the mounting recess

4

» Fig. 110 on page 112 by pulling

it downwards.

›

Put the tow bar in the ready position » page 113.

›

Grip the tow bar from below » Fig. 113and insert into the mounting recess un-

til it audibly clicks into place » .

The hand wheel

A

rotates back automatically and rests on the ball rod » .

›

Lock the hand wheel lock by turning the key

B

right as far as the stop in the

direction of the arrow

1

- the arrow on the key points towards the “closed

padlock” icon.

›

Remove the key in the direction of the arrow

2

.

›

Fit the cap

C

on the hand wheel lock in the direction of the arrow

3

» Fig. 114 arrow.

›

Check that the tow bar is securely attached » page 114.

WARNING■

Do not hold the hand wheel with your hand when attaching the ball bar -

there is a risk of finger injury.■

After fitting the tow bar, always secure the lock and remove the key.

■

The tow bar must not be operated with the key inserted.

■

If the tow bar is not in the ready position, it cannot be fitted in the

mounting recess.

CAUTION

After removing the key, always replace the cover on the hand wheel lock – risk

of lock getting dirty.NoteStore the cover of the mounting recess in a suitable place in the luggage com-

partment store after removal.

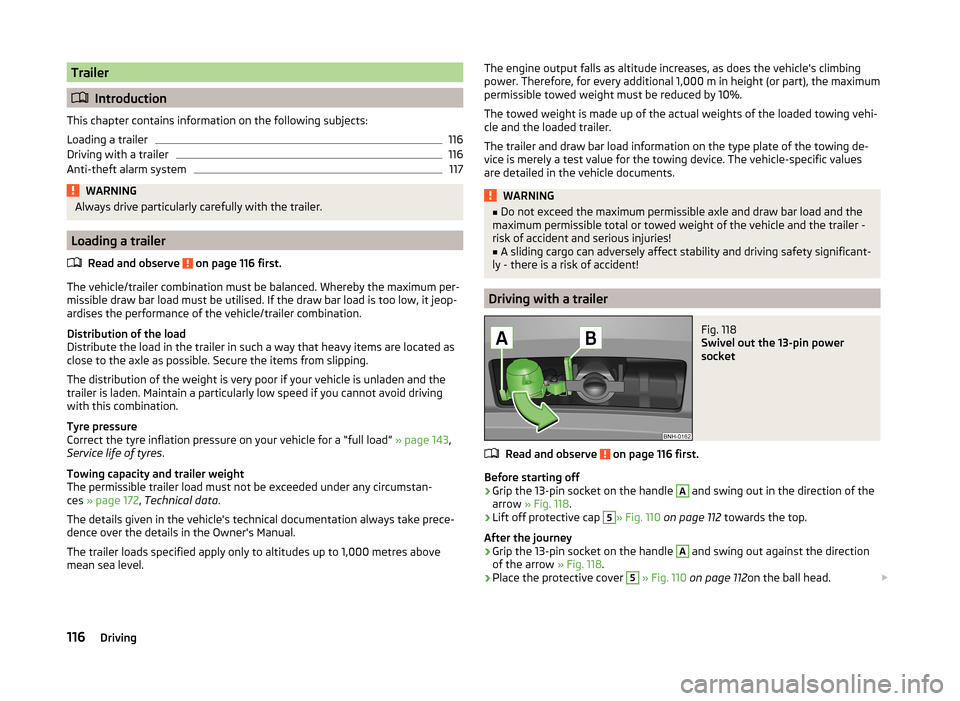

Check proper fitting

Fig. 115

Correctly secured ball head

Read and observe and on page 112 first.

Check that the tow bar is fitted properly before each use.

Correctly secured ball head » Fig. 115

The tow bar does not come out of the mounting recess even after heavy

“shaking”.

The green marking

A

on the hand wheel points to the white marking on

the tow bar.

The hand wheel lies flush with the tow bar - there is no gap.

The hand wheel is locked and the key is removed.

The cap

B

is on the hand wheel.

WARNINGDo not use the towing device unless the tow bar has been properly locked!114Driving

Page 117 of 193

Removing the ball headFig. 116

Removing the lock cover/releasing the lock

Fig. 117

Release tow bar

Read and observe and on page 112 first.

›

Remover the cover

A

from the hand wheel lock in the direction of the

1

» Fig. 116 arrow.

›

Insert the key

B

into the lock.

›

Unlock the hand wheel lock by turning the key

B

left as far as the stop in

the direction of the arrow

2

- the arrow on the key points towards the “pad-

lock open” icon.

›

Grip the tow bar from below » Fig. 117and with the other hand, pull the hand

wheel

C

in the direction of the arrow

3

accordingly.

›

Turn the hand wheel in the direction of the arrow

4

to the stop, and hold in

this position.

›

Remove the tow bar from the mounting recess downwards and in the direc-

tion of the arrow

5

.

At the same time, the tow bar latches into the ready position and is therefore

ready to be re-inserted into the mounting recess »

.

›Attach the cover for the mounting recess 4

» Fig. 110 on page 112 .WARNING■

Never allow the tow bar to remain unsecured in the boot. This could

cause damage on sudden braking and could put the safety of the occu-

pants at risk!■

Never remove the tow bar while the trailer is still coupled.

CAUTION

■ If the hand wheel is not turned all the way to the stop, then it will return to

its initial position when the tow bar is removed and will rest on the tow bar

and not engage into the ready position. The tow bar will then need to be

brought into this position before the next time it is fitted.■

The mounting recess must be closed with the cover following removal. This

prevents foreign bodies from getting into the mounting recess.

Note

■ We recommend putting the protective cover onto the ball head before re-

moving the tow bar.■

Clean any dirt from the tow bar before stowing it away in the box with the

vehicle tool kit.

Use and care

Read and observe

and on page 112 first.

Close the mounting recess with the cover to prevent any dirt from getting in.

Always check the tow bar before hitching a trailer. Apply suitable grease

where necessary.

Use the protective cover when stowing away the tow bar, in order to stop the

boot from getting dirty.

In the event of dirt, clean the surfaces of the mounting recess and treat with a

suitable preservative.

CAUTION

Apply grease to the upper part of the mounting recess. Make sure you do not

remove any grease.115Hitch and trailer

Page 118 of 193

Trailer

Introduction

This chapter contains information on the following subjects:

Loading a trailer

116

Driving with a trailer

116

Anti-theft alarm system

117WARNINGAlways drive particularly carefully with the trailer.

Loading a trailer

Read and observe

on page 116 first.

The vehicle/trailer combination must be balanced. Whereby the maximum per-missible draw bar load must be utilised. If the draw bar load is too low, it jeop-

ardises the performance of the vehicle/trailer combination.

Distribution of the load

Distribute the load in the trailer in such a way that heavy items are located as

close to the axle as possible. Secure the items from slipping.

The distribution of the weight is very poor if your vehicle is unladen and the

trailer is laden. Maintain a particularly low speed if you cannot avoid driving

with this combination.

Tyre pressure

Correct the tyre inflation pressure on your vehicle for a “full load” » page 143,

Service life of tyres .

Towing capacity and trailer weight

The permissible trailer load must not be exceeded under any circumstan-

ces » page 172 , Technical data .

The details given in the vehicle's technical documentation always take prece-

dence over the details in the Owner's Manual.

The trailer loads specified apply only to altitudes up to 1,000 metres above

mean sea level.

The engine output falls as altitude increases, as does the vehicle's climbing

power. Therefore, for every additional 1,000 m in height (or part), the maximum

permissible towed weight must be reduced by 10%.

The towed weight is made up of the actual weights of the loaded towing vehi-

cle and the loaded trailer.

The trailer and draw bar load information on the type plate of the towing de-

vice is merely a test value for the towing device. The vehicle-specific values

are detailed in the vehicle documents.WARNING■ Do not exceed the maximum permissible axle and draw bar load and the

maximum permissible total or towed weight of the vehicle and the trailer -

risk of accident and serious injuries!■

A sliding cargo can adversely affect stability and driving safety significant-

ly - there is a risk of accident!

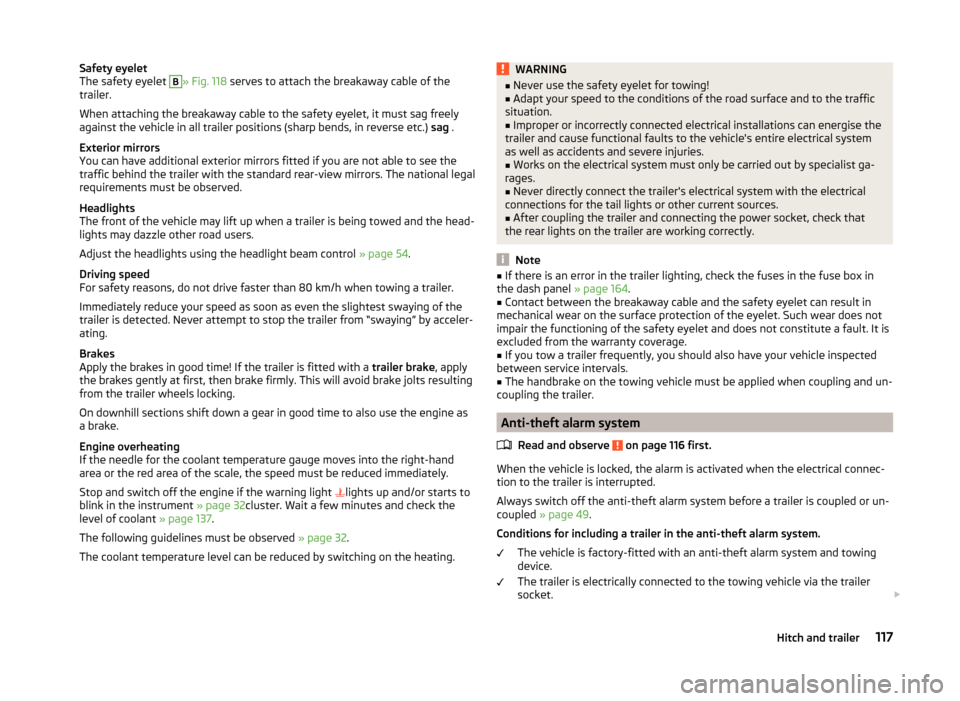

Driving with a trailer

Fig. 118

Swivel out the 13-pin power

socket

Read and observe on page 116 first.

Before starting off

›

Grip the 13-pin socket on the handle

A

and swing out in the direction of the

arrow » Fig. 118 .

›

Lift off protective cap

5

» Fig. 110 on page 112 towards the top.

After the journey

›

Grip the 13-pin socket on the handle

A

and swing out against the direction

of the arrow » Fig. 118.

›

Place the protective cover

5

» Fig. 110 on page 112 on the ball head.

116Driving

Page 119 of 193

Safety eyelet

The safety eyelet B» Fig. 118 serves to attach the breakaway cable of the

trailer.

When attaching the breakaway cable to the safety eyelet, it must sag freely

against the vehicle in all trailer positions (sharp bends, in reverse etc.) sag .

Exterior mirrors

You can have additional exterior mirrors fitted if you are not able to see the

traffic behind the trailer with the standard rear-view mirrors. The national legal

requirements must be observed.

Headlights

The front of the vehicle may lift up when a trailer is being towed and the head- lights may dazzle other road users.

Adjust the headlights using the headlight beam control » page 54.

Driving speed

For safety reasons, do not drive faster than 80 km/h when towing a trailer.

Immediately reduce your speed as soon as even the slightest swaying of the

trailer is detected. Never attempt to stop the trailer from “swaying” by acceler-

ating.

Brakes

Apply the brakes in good time! If the trailer is fitted with a trailer brake, apply

the brakes gently at first, then brake firmly. This will avoid brake jolts resulting

from the trailer wheels locking.

On downhill sections shift down a gear in good time to also use the engine as

a brake.

Engine overheating

If the needle for the coolant temperature gauge moves into the right-hand

area or the red area of the scale, the speed must be reduced immediately.

Stop and switch off the engine if the warning light lights up and/or starts to

blink in the instrument » page 32cluster. Wait a few minutes and check the

level of coolant » page 137.

The following guidelines must be observed » page 32.

The coolant temperature level can be reduced by switching on the heating.WARNING■ Never use the safety eyelet for towing!■Adapt your speed to the conditions of the road surface and to the traffic

situation.■

Improper or incorrectly connected electrical installations can energise the

trailer and cause functional faults to the vehicle's entire electrical system

as well as accidents and severe injuries.

■

Works on the electrical system must only be carried out by specialist ga-

rages.

■

Never directly connect the trailer's electrical system with the electrical

connections for the tail lights or other current sources.

■

After coupling the trailer and connecting the power socket, check that

the rear lights on the trailer are working correctly.

Note

■ If there is an error in the trailer lighting, check the fuses in the fuse box in

the dash panel » page 164.■

Contact between the breakaway cable and the safety eyelet can result in

mechanical wear on the surface protection of the eyelet. Such wear does not

impair the functioning of the safety eyelet and does not constitute a fault. It is

excluded from the warranty coverage.

■

If you tow a trailer frequently, you should also have your vehicle inspected

between service intervals.

■

The handbrake on the towing vehicle must be applied when coupling and un-

coupling the trailer.

Anti-theft alarm system

Read and observe

on page 116 first.

When the vehicle is locked, the alarm is activated when the electrical connec-tion to the trailer is interrupted.

Always switch off the anti-theft alarm system before a trailer is coupled or un-

coupled » page 49 .

Conditions for including a trailer in the anti-theft alarm system. The vehicle is factory-fitted with an anti-theft alarm system and towing

device.

The trailer is electrically connected to the towing vehicle via the trailer

socket.

117Hitch and trailer

Page 148 of 193

SettingFig. 132

Button for setting the tyre infla-

tion pressure control value

Read and observe and on page 145 first.

›

Inflate all of the tyres to the specified inflation pressure » page 143.

›

Switch on the ignition.

›

Press the symbol button

» Fig. 132 for longer than 2 seconds.

If the warning light in the instrument cluster lights up and does not go out

after the system configuration, this indicates a system fault.

If there is a blinking light in the instrument cluster, then there is a system

fault.

Display

Read and observe

and on page 145 first.

The control light in the instrument cluster lights up when any of the follow-

ing conditions are met.

› The tyre inflation pressure is low.

› The structure of the tyre is damaged.

› The vehicle is loaded on one side.

› The wheels of one axle are loaded more heavily (e.g. when towing a trailer or

when driving uphill or downhill).

› Snow chains are mounted.

› The spare wheel is mounted.

› One wheel per axle was changed.

WARNING■

When illuminated control lights light up in the instrument cluster lights,

immediately reduce speed and avoid violent steering and brake manoeu-

vres. Stop the vehicle as soon as possible and inspect the tyres and their

inflation pressure.■

Under certain circumstances (e.g. sporty style of driving, wintry or un-

paved roads) the warning light

in the instrument cluster may be delayed

or not light up at all.

Reserve and temporary spare wheel

Introduction

This chapter contains information on the following subjects:

Change

147

Spare wheel

147

Fit a wheel in the appropriate dimensions and design as soon as possible.

WARNING■ If, in the event of a puncture, it is necessary to fit a spare wheel with a

tyre without a dedicated running direction or with the opposite direction of

rotation, drive carefully as the optimal characteristics of the tyre are no lon-

ger applicable in this situation.■

If the dimensions or design of the spare wheel differ from the tyres fitted

to the vehicle (e.g. winter tyres or low-profile tyres), it must only be used

briefly in the event of a puncture and if an appropriately cautious style of

driving is adopted.

146General Maintenance

Page 149 of 193

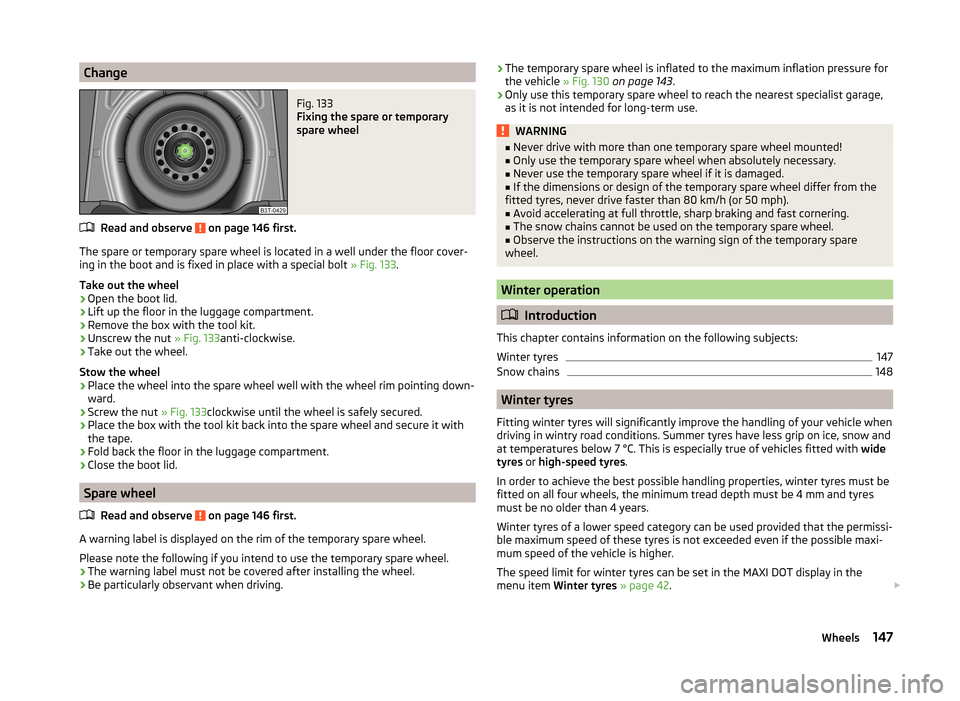

ChangeFig. 133

Fixing the spare or temporary

spare wheel

Read and observe on page 146 first.

The spare or temporary spare wheel is located in a well under the floor cover-

ing in the boot and is fixed in place with a special bolt » Fig. 133.

Take out the wheel

›

Open the boot lid.

›

Lift up the floor in the luggage compartment.

›

Remove the box with the tool kit.

›

Unscrew the nut » Fig. 133anti-clockwise.

›

Take out the wheel.

Stow the wheel

›

Place the wheel into the spare wheel well with the wheel rim pointing down-

ward.

›

Screw the nut » Fig. 133clockwise until the wheel is safely secured.

›

Place the box with the tool kit back into the spare wheel and secure it with

the tape.

›

Fold back the floor in the luggage compartment.

›

Close the boot lid.

Spare wheel

Read and observe

on page 146 first.

A warning label is displayed on the rim of the temporary spare wheel.

Please note the following if you intend to use the temporary spare wheel. › The warning label must not be covered after installing the wheel.

› Be particularly observant when driving.

› The temporary spare wheel is inflated to the maximum inflation pressure for

the vehicle » Fig. 130 on page 143 .

› Only use this temporary spare wheel to reach the nearest specialist garage,

as it is not intended for long-term use.WARNING■ Never drive with more than one temporary spare wheel mounted!■Only use the temporary spare wheel when absolutely necessary.■

Never use the temporary spare wheel if it is damaged.

■

If the dimensions or design of the temporary spare wheel differ from the

fitted tyres, never drive faster than 80 km/h (or 50 mph).

■

Avoid accelerating at full throttle, sharp braking and fast cornering.

■

The snow chains cannot be used on the temporary spare wheel.

■

Observe the instructions on the warning sign of the temporary spare

wheel.

Winter operation

Introduction

This chapter contains information on the following subjects:

Winter tyres

147

Snow chains

148

Winter tyres

Fitting winter tyres will significantly improve the handling of your vehicle when

driving in wintry road conditions. Summer tyres have less grip on ice, snow and

at temperatures below 7 °C. This is especially true of vehicles fitted with wide

tyres or high-speed tyres .

In order to achieve the best possible handling properties, winter tyres must be

fitted on all four wheels, the minimum tread depth must be 4 mm and tyres

must be no older than 4 years.

Winter tyres of a lower speed category can be used provided that the permissi-

ble maximum speed of these tyres is not exceeded even if the possible maxi-

mum speed of the vehicle is higher.

The speed limit for winter tyres can be set in the MAXI DOT display in the

menu item Winter tyres » page 42 .

147Wheels

Page 152 of 193

fire extinguisherFig. 136

Fire extinguisher

The fire extinguisher is attached by two straps in a holder underneath the driv-

er's seat.

Removing/attaching

›

Loosen the two straps by pulling the buckles in the direction of the ar-

row » Fig. 136 .

›

Remove the fire extinguisher.

Follow these steps in the reverse order for attachment.

Please read carefully the instructions which are attached to the fire extin-

guisher.

The fire extinguisher must be checked by an authorised person once a year.

The national legal requirements must be observed.

WARNINGThe fire extinguisher must always be secured safely so that they do not

come loose when making an emergency braking or in a vehicle collision

which could cause injuries to occupants.

Note

■ The fire extinguisher must comply with national legal requirements.■Pay attention to the expiration date of the fire extinguisher. Proper function-

ing of the fire extinguisher is not assured once it has passed its expiry date.■

The fire extinguisher is part of the scope of delivery in certain countries only.

Vehicle tool kitFig. 137

Vehicle tool kit

The vehicle tool kit and the jack with sticker are housed in a plastic box in the

spare wheel or in the storage space for the spare wheel. There is also space

here for the removable ball rod for the trailer towing device. The box is attach-

ed with a strap on the spare wheel.

Depending on the equipment, not all the components listed in the on-board

tool kit have to be contained in it.

Possible components of the on-board tool kit » Fig. 137

Screwdriver

Spanner for removing and installing the tail light

Adapter for anti-theft wheel bolts

Towing eyelet

Clamps for removing the wheel trims

Car jack

Wheel wrench

Extraction pliers for wheel bolt caps

Replacement bulb set

Screw the car jack back into its initial position after use in order to store it back

in the box with the vehicle tool kit.

123456789150Do-it-yourself