boot SKODA RAPID SPACEBACK 2014 1.G Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2014, Model line: RAPID SPACEBACK, Model: SKODA RAPID SPACEBACK 2014 1.GPages: 204, PDF Size: 27.11 MB

Page 127 of 204

›Grasp the ball bar from

below » Fig. 120 .›Pull the hand wheel A in the direction of the arrow 1.›

Turn the hand wheel in the direction of the arrow

2

to the stop, and hold in

this position.

›

Remove the tow bar from the mounting recess downwards and in the direc-

tion of the arrow

3

.

At the same time, the ball head latches into the ready position and is thus

ready to be re-inserted into the mounting recess »

.

Subsequent steps

After removing the tow bar the following work must be carried out.

›

Fit the cover for the mounting recess

A

in the opposite direction to arrow

1

» Fig. 115 on page 122 .

WARNINGNever allow the tow bar to remain unsecured in the boot. This could cause

damage on sudden braking and could put the safety of the occupants at

risk!

CAUTION

■ If the hand wheel A is not turned all the way to the stop, then it will return

to its initial position when the tow bar is removed and will rest on the tow bar

and not engage into the ready position. The ball head then needs to be

brought into this position before the next time it is fitted » page 121, Adjusting

the ready position .■

The mounting recess must be closed with the cover following removal. This

prevents foreign bodies from getting into the mounting recess.

Note

Clean any dirt from the tow bar before stowing it away in the box with the ve-

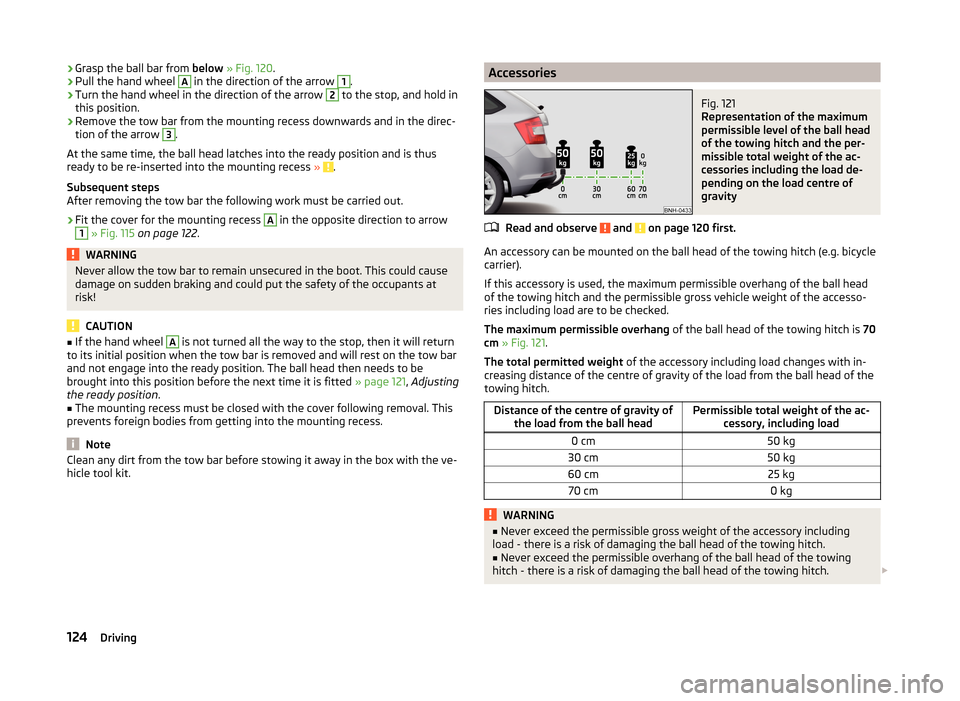

hicle tool kit.AccessoriesFig. 121

Representation of the maximum

permissible level of the ball head

of the towing hitch and the per-

missible total weight of the ac-

cessories including the load de-

pending on the load centre of

gravity

Read and observe and on page 120 first.

An accessory can be mounted on the ball head of the towing hitch (e.g. bicycle carrier).

If this accessory is used, the maximum permissible overhang of the ball head

of the towing hitch and the permissible gross vehicle weight of the accesso-

ries including load are to be checked.

The maximum permissible overhang of the ball head of the towing hitch is 70

cm » Fig. 121 .

The total permitted weight of the accessory including load changes with in-

creasing distance of the centre of gravity of the load from the ball head of the

towing hitch.

Distance of the centre of gravity of the load from the ball headPermissible total weight of the ac- cessory, including load0 cm50 kg30 cm50 kg60 cm25 kg70 cm0 kgWARNING■Never exceed the permissible gross weight of the accessory including

load - there is a risk of damaging the ball head of the towing hitch.■

Never exceed the permissible overhang of the ball head of the towing

hitch - there is a risk of damaging the ball head of the towing hitch.

124Driving

Page 138 of 204

Door closing cylinderRead and observe

and on page 132 first.

Specific products must be used for de-icing door lock cylinders.

CAUTION

Make sure that as little water as possible gets into the locking cylinder when

washing the vehicle - there is a risk of freezing the lock cylinder!

Cavity protection

Read and observe

and on page 132 first.

All the cavities of your vehicle which are at risk from corrosion are protectedfor life by a layer of protective wax applied in the factory.

This wax protection does not need to be inspected or re-applied.

If any small amount of wax flow out of the cavities at high temperatures, these

must be removed with a plastic scraper and the stains cleaned using a petrole-

um cleaner.

WARNINGSafety regulations should be observed when using petroleum cleaner to re-

move wax – risk of fire!

Jack

Read and observe

and on page 132 first.

The jack is maintenance-free.

If necessary, the moving parts of the jack should be lubricated with a suitable lubricant.

Wheels

Read and observe

and on page 132 first.

Wheel rims

Also thoroughly wash the wheel rims when washing the vehicle on a regular basis.

Regularly remove salt and brake abrasion, otherwise the rim material will be

corroded.

Light alloy wheels

After washing thoroughly, treat the wheel rims with a protective product for

light alloy wheels.

For the treatment of wheel rims do not use products which may cause damage

to the paint on the rims.

CAUTION

■ Damage to the paint layer on the wheel rims must be touched up immediate-

ly.■

Severe layers of dirt on the wheels can also result in wheel imbalance. This

may show itself in the form of a wheel vibration which is transmitted to the

steering wheel which, in certain circumstances, can cause premature wear of

the steering. This means it is necessary to remove the dirt.

Towing device and mounting recess

Read and observe

and on page 132 first.

Close the mounting recess with the cover to prevent any dirt from getting in.

If dirt is present, clean the inner surfaces of the mounting recess and treat

with a suitable preservative.

Always check the ball head before hitching a trailer. Apply a suitable grease, if

necessary.

Use the protective cover when stowing away the tow bar, in order to stop the

boot from getting dirty.

CAUTION

Apply grease to the inner part of the mounting recess. Make sure you do not

remove any grease.

Under-body protection

Read and observe

and on page 132 first.

The underside of your vehicle is already permanently protected by the factory

against chemical and mechanical influences.

It is not possible to guarantee that the protective coating will not suffer any

damage as the vehicle is driven.

135Care and maintenance

Page 140 of 204

Dust and dirt in pores and creases cause abrasions on the surface and lead to

premature brittling of the leather surface. Therefore, they must be removed

regularly at short intervals with a cloth or vacuum cleaner.

Clean soiled leather surfaces with a water-dampened cotton or woollen cloth and then dry with a clean, dry cloth »

.

Clean severely soiled areas with a cloth soaked in a mild soap solution (2 ta-

blespoons of neutral soap to 1 litre of water).

To remove stains , use a cleaning agent specially designed for this purpose.

Treat the leather periodically with a suitable leather protector and use a skin

care cream with light blocker and impregnation after each cleaning.

CAUTION

■ Ensure that no part of the leather is soaked through during cleaning and that

no water gets into the seams! Otherwise, the leather could become brittle or

cracked.■

Avoid leaving the vehicle for lengthy periods in bright sunlight to avoid

bleaching the leather. If the vehicle is parked in the open for lengthy periods,

protect the leather from direct sunlight by covering it.

■

The use of an additional mechanical steering wheel lock may damage the

leather surface of the steering wheel.

■

Some clothing materials, e.g. dark denim, do not have sufficient colour fast-

ness. This can cause damage or clearly visible discolouration to seat covers,

even when used correctly. This applies particularly to light-coloured seat cov-

ers. This does not relate to a fault in the seat cover, but rather to poor colour

fastness of the clothing textiles.

■

Sharp-edged objects on items of clothing such as zip fasteners, rivets, sharp-

edged belts etc. may leave permanent scratches or signs of rubbing on the

surface or damage these. Such damage cannot be subsequently recognised as

a justified complaint.

Note

When using the vehicle, minor visible changes may occur to the leather parts

of the covers (e.g. wrinkles or creases) as a result of the stress applied to the

covers.Artificial leather, materials and Alcantara ®

Read and observe

and on page 136 first.

Artificial leather

Clean artificial leather with a damp cloth.

If this method does not completely clean the artificial leather, use a mild soap

solution or cleaning products specially designed for this purpose.

Fabric

Clean upholstery cover materials and cloth trims on doors, boot cover, etc. us-

ing specific cleaning agents, e.g., dry foam.

Use a soft sponge, brush, or commercially available microfibre cloth.

Use a cloth and a cleaning agent specifically designed for this purpose to clean

the roof trim.

Remove any lumps on the cover fabric and any fabric residue using a brush.

Remove stubborn hair using a “cleaning glove”.

Alcantara ®

Dust and dirt in pores, creases and seams may chafe and damage the surface.

Therefore, they must be removed regularly at short intervals with a cloth or

vacuum cleaner.

Minor changes in colour caused by use are normal.

CAUTION

■ For Alcantara ®

seat covers, do not use any solvents, floor wax, shoe cream,

stain remover, leather cleaners or similar agents.■

Avoid leaving the vehicle in bright sunlight for long periods of time in order

to stop the artificial leather, materials or Alcantara ®

from bleaching. During ex-

tended periods of standing outdoors, protect artificial leather, fabrics or Alcan-

tara ®

by covering.

■

Some clothing materials, e.g. dark denim, do not have sufficient colour fast-

ness. This can cause damage or clearly visible discolouration to seat covers,

even when used correctly. This applies particularly to light-coloured seat cov-

ers. This does not relate to a fault in the seat cover, but rather to poor colour

fastness of the clothing textiles.

137Care and maintenance

Page 161 of 204

Do-it-yourself

Emergency equipment and self-help

Emergency equipment

Introduction

This chapter contains information on the following subjects:

Placement of the first-aid kit and warning triangle

158

Placement of the reflective vest

158

fire extinguisher

158

Vehicle tool kit

159

Placement of the first-aid kit and warning triangle

Fig. 135

First-aid kit / warning triangle

The following information is for the first aid kit and warning triangle from the

ŠKODA Original accessories valid.

For another first aid kit and warning triangle the storage compartments may

possibly be too small.

First-aid box

The first-aid box can be attached by a strap to the right-hand side of the

boot » Fig. 135 .

Warning triangle

The warning triangle can be attached to the rear wall trim panel with rubber

straps » Fig. 135 .

WARNINGThe first-aid kit and warning triangle must always be secured safely so that

they do not come loose when making an emergency braking or in a vehicle

collision which could cause injuries to occupants.

Note

■ Pay attention to the expiration date of the first-aid kit.■We recommend using a first-aid kit from ŠKODA Original Accessories, which

are available from a ŠKODA Partner.

Placement of the reflective vest

Fig. 136

Reflective vest

The reflective vest can be stored in a bracket under the driver's seat » Fig. 136.

fire extinguisher

Fig. 137

Fire extinguisher

The fire extinguisher is attached by two straps in a holder underneath the driv-

er's seat.

Removing/attaching

›

Loosen the two straps by pulling the buckles in the direction of the ar-

row » Fig. 137 .

158Do-it-yourself

Page 162 of 204

›Remove the fire extinguisher.›For mounting, fit the fire extinguisher back into the holder and secure it with

straps.

Please read carefully the instructions which are attached to the fire extin-

guisher.

The fire extinguisher must be checked by an authorised person once a year.

The national legal requirements must be observed.WARNINGThe fire extinguisher must always be secured safely so that they do not

come loose when making an emergency braking or in a vehicle collision

which could cause injuries to occupants.

Note

■ The fire extinguisher must comply with national legal requirements.■Pay attention to the expiration date of the fire extinguisher. Proper function-

ing of the fire extinguisher is not assured once it has passed its expiry date.■

The fire extinguisher is part of the scope of delivery in certain countries only.

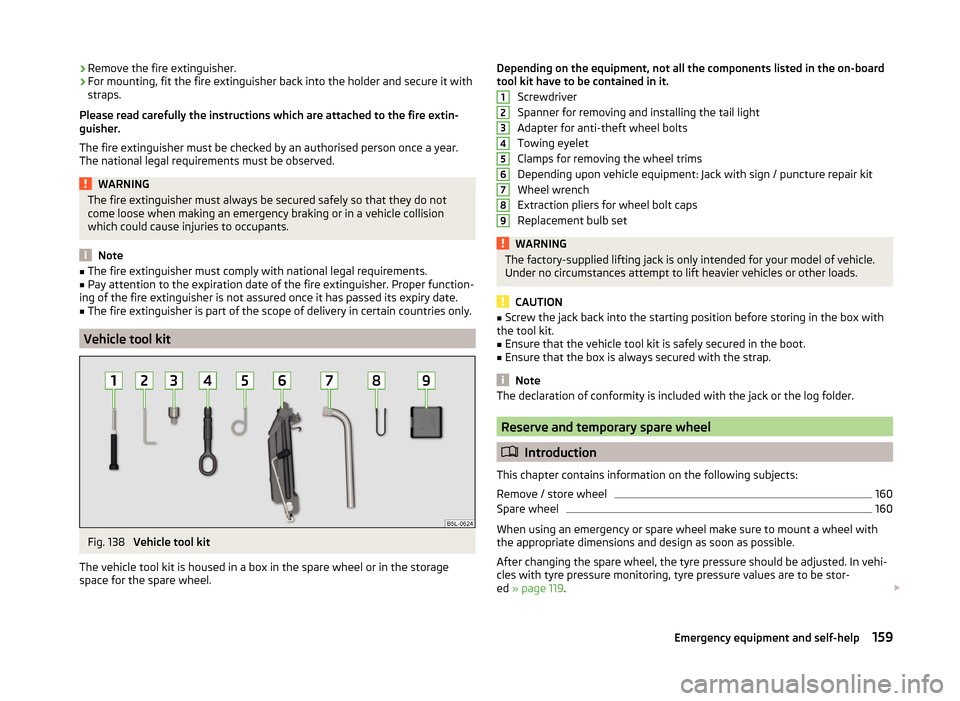

Vehicle tool kit

Fig. 138

Vehicle tool kit

The vehicle tool kit is housed in a box in the spare wheel or in the storage

space for the spare wheel.

Depending on the equipment, not all the components listed in the on-board

tool kit have to be contained in it.

Screwdriver

Spanner for removing and installing the tail light

Adapter for anti-theft wheel bolts

Towing eyelet

Clamps for removing the wheel trims

Depending upon vehicle equipment: Jack with sign / puncture repair kit

Wheel wrench

Extraction pliers for wheel bolt caps

Replacement bulb setWARNINGThe factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances attempt to lift heavier vehicles or other loads.

CAUTION

■ Screw the jack back into the starting position before storing in the box with

the tool kit.■

Ensure that the vehicle tool kit is safely secured in the boot.

■

Ensure that the box is always secured with the strap.

Note

The declaration of conformity is included with the jack or the log folder.

Reserve and temporary spare wheel

Introduction

This chapter contains information on the following subjects:

Remove / store wheel

160

Spare wheel

160

When using an emergency or spare wheel make sure to mount a wheel with

the appropriate dimensions and design as soon as possible.

After changing the spare wheel, the tyre pressure should be adjusted. In vehi- cles with tyre pressure monitoring, tyre pressure values are to be stor-

ed » page 119 .

123456789159Emergency equipment and self-help

Page 163 of 204

WARNING■If, in the case of puncture occurring, the spare tyre with a non-bound di-

rection or an opposite direction of rotation must be mounted, then drive

carefully. The best properties of the tyre are no longer present in this situa-

tion.■

If the dimensions or design of the spare wheel differ from the tyres fitted

to the vehicle (e.g. winter tyres or low-profile tyres), it must only be used

briefly in the event of a puncture and if an appropriately cautious style of

driving is adopted.

■

If the dimensions or design of the temporary spare wheel differ from the

fitted tyres, never drive faster than 80 km/h (or 50 mph).

■

Never use the temporary spare wheel if it is damaged.

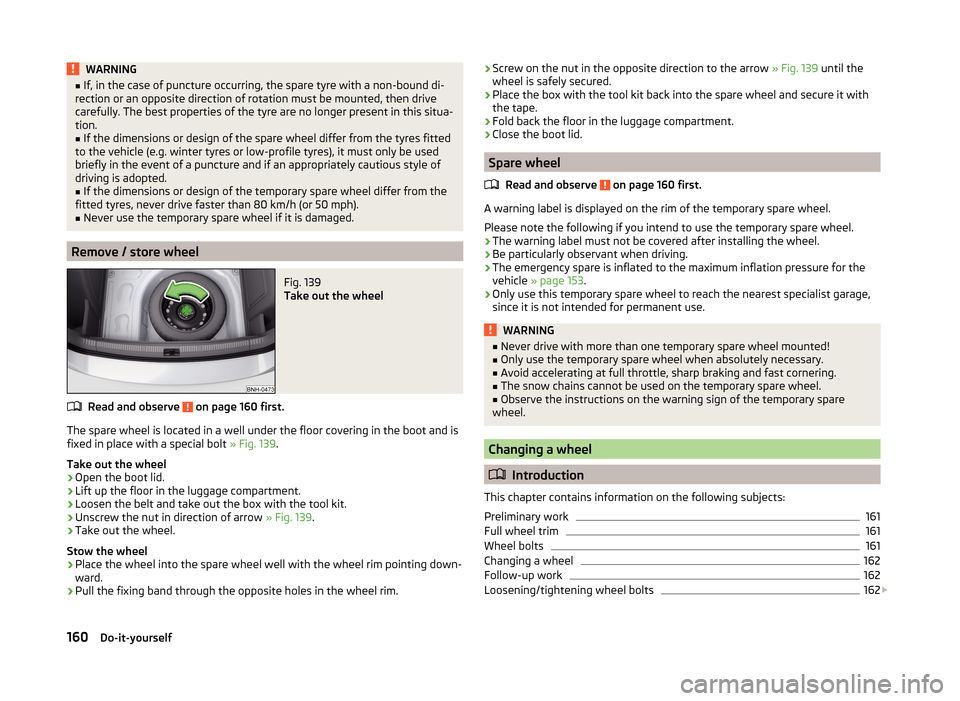

Remove / store wheel

Fig. 139

Take out the wheel

Read and observe on page 160 first.

The spare wheel is located in a well under the floor covering in the boot and is fixed in place with a special bolt » Fig. 139.

Take out the wheel

›

Open the boot lid.

›

Lift up the floor in the luggage compartment.

›

Loosen the belt and take out the box with the tool kit.

›

Unscrew the nut in direction of arrow » Fig. 139.

›

Take out the wheel.

Stow the wheel

›

Place the wheel into the spare wheel well with the wheel rim pointing down-

ward.

›

Pull the fixing band through the opposite holes in the wheel rim.

› Screw on the nut in the opposite direction to the arrow

» Fig. 139 until the

wheel is safely secured.›

Place the box with the tool kit back into the spare wheel and secure it with

the tape.

›

Fold back the floor in the luggage compartment.

›

Close the boot lid.

Spare wheel

Read and observe

on page 160 first.

A warning label is displayed on the rim of the temporary spare wheel.

Please note the following if you intend to use the temporary spare wheel. › The warning label must not be covered after installing the wheel.

› Be particularly observant when driving.

› The emergency spare is inflated to the maximum inflation pressure for the

vehicle » page 153 .

› Only use this temporary spare wheel to reach the nearest specialist garage,

since it is not intended for permanent use.

WARNING■ Never drive with more than one temporary spare wheel mounted!■Only use the temporary spare wheel when absolutely necessary.■

Avoid accelerating at full throttle, sharp braking and fast cornering.

■

The snow chains cannot be used on the temporary spare wheel.

■

Observe the instructions on the warning sign of the temporary spare

wheel.

Changing a wheel

Introduction

This chapter contains information on the following subjects:

Preliminary work

161

Full wheel trim

161

Wheel bolts

161

Changing a wheel

162

Follow-up work

162

Loosening/tightening wheel bolts

162

160Do-it-yourself

Page 164 of 204

Raising the vehicle163Anti-theft wheel bolts164

For your own safety and the safety of the passengers, the following instruc-

tions must be observed before changing a wheel on the road.

Switch on the hazard warning lights system.

The warning triangle is to be set up at the prescribed distance - observe

the national legal provisions when doing so.

Park the vehicle as far away as possible from the flow of traffic.

Choose a location with a flat, solid surface.

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

The following instructions must be followed if the vehicle is subsequently fit- ted with tyres or rims that differ from the factory-fitted ones » page 155, Ex-

planation of the tyre labelling .

The national legal requirements must be observed when changing a wheel.

Preliminary work

Before changing the wheel, the following work must be carried out.

›

Switch off the engine.

›

Select the first gear or move the selector lever for the automatic gearbox

into position P .

›

Firmly apply the handbrake.

›

Uncouple any trailers.

›

Remove the vehicle tool kit » page 159 and the spare wheel » page 159 from

the boot.

Full wheel trim

Before removing the wheel bolts, remove the wheel cover.

Removing

›

Hook the clamp found in the vehicle tool kit » page 159into the reinforced

edge of the wheel trim.

›

Push the wheel wrench through the clamp, support on the tyre and pull off

the wheel trim.

Installing›Press the wheel trim onto the wheel rim at the designated valve open-

ing » .

›

Then press the trim into the wheel rim until its entire circumference locks

correctly in place.

CAUTION

Notes from the factory or from the ŠKODA Original accessory delivered trim..■When using an anti-theft wheel bolt, make sure that this has been fitted ac-

cording to the position marked on the back of the wheel cover position.■

On the back of the wheel cover, the position for the anti-theft wheel bolt is

marked by means of a symbol. If the wheel cover is set outside the position

marked for the anti-theft wheel bolt, there is a risk of damaging the wheel

cover.

CAUTION

■ Use the pressure of your hand only, do not strike the full wheel trim! The

cover could be damaged.■

If wheel trims are fitted, an adequate flow of air must be assured in order to

cool the brake system.

Note

We recommend that you use wheel trims from ŠKODA Original Accessories.

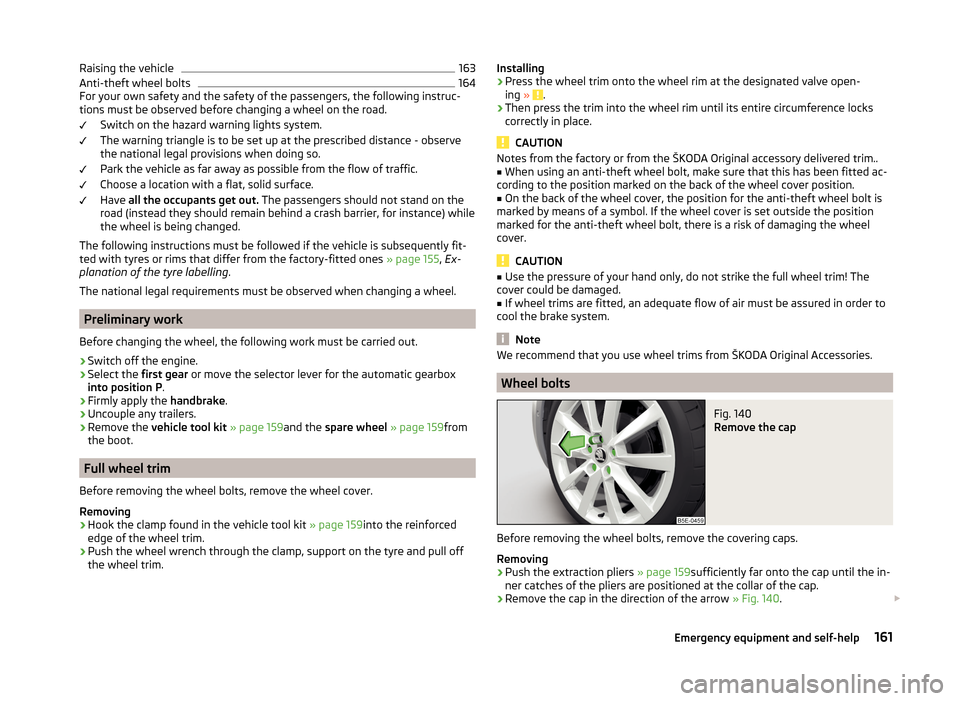

Wheel bolts

Fig. 140

Remove the cap

Before removing the wheel bolts, remove the covering caps.

Removing

›

Push the extraction pliers » page 159sufficiently far onto the cap until the in-

ner catches of the pliers are positioned at the collar of the cap.

›

Remove the cap in the direction of the arrow » Fig. 140.

161Emergency equipment and self-help

Page 168 of 204

Components of the puncture repair kitsFig. 145

Principle sketch: Components of the breakdown kit

Read and observe

on page 164 first.

Components of the set » Fig. 145

Sticker with speed designation “max. 80 km/h”/“max. 50 mph”

Valve remover

Inflation hose with plug

Air compressor

Button for releasing the tyre pressure

12 volt cable connector

Tyre inflation hose

Tyre inflation pressure indicator

ON and OFF switch

Tyre inflater bottle with sealing agent

Replacement valve core

The valve remover

2

has a slot at its lower end which fits into the valve core.

The kit is located in a box under the floor covering in the luggage compart-

ment. This contains a sealing means and an air compressor.

Note

The declaration of conformity is included with the air compressor or the log

folder.1234567891011General information

Read and observe

on page 164 first.

For your own safety and the safety of your passengers, the following instruc-

tions must be observed before carrying out a wheel repair on the road.

Switch on the hazard warning lights system.

The warning triangle is to be set up at the prescribed distance - observe

the national legal provisions when doing so.

Park the vehicle as far away as possible from the flow of traffic.

Choose a location with a flat, solid surface.

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

The national legal requirements must be observed when repairing a tyre.

The breakdown kit must not be used under the following circumstances. › The rim is damaged.

› The outside temperature is below -20 ° C.

› The cut or puncture is larger than 4 mm.

› The tyre wall is damaged.

› The result will be to drive with very low tyre pressure or with a completely

flat tyres.

› After the expiration date (see inflation bottle).

Preparations for using the breakdown kit

Read and observe

on page 164 first.

The following preparatory work must be carried out before using the puncturerepair kit.

›

Switch off the engine.

›

Select the first gear or move the selector lever for the automatic gearbox

into position P .

›

Firmly apply the handbrake.

›

Check that you can carry out the repairs with the breakdown kit » page 165,

General information .

›

Remove the breakdown kit from the boot.

›

Stick the sticker

1

» Fig. 145 on page 165 on the dashboard in the driver's

field of view.

›

Unscrew the valve cap.

165Emergency equipment and self-help

Page 174 of 204

Locking the door without a locking cylinderFig. 152

Emergency locking: Left/right rear door

An emergency locking mechanism is located on the face side of the doors

which have no locking cylinder. It is only visible after opening the door.

›

Remove the cover

A

» Fig. 152 .

›

Insert the vehicle key into the slot and turn in the direction of the arrow

(sprung position).

›

Replace the cover

A

.

Unlocking the tailgate

Fig. 153

Emergency unlocking of the boot

lid

The boot lid can be unlocked manually in an emergency.

›

Insert the vehicle key into the slot in the trim panel » Fig. 153 as far as it will

go.

›

Unlock the lid by moving it in the direction of the arrow.

›

Open the boot lid.

Selector lever-emergency unlockingFig. 154

Selector lever-emergency unlocking

›

Firmly apply the handbrake.

›

With one hand on the edge of the cover, push in direction of arrow

1

» Fig. 154 .

›

At the same time lift the cover on the selector lever gaiter with the other

hand in direction of arrow

2

.

›

With one finger, push the yellow plastic element in the direction of arrow

3

down to the stop.

›

At the same time, press the locking button in the selector lever and movethe selector lever to position N.

If the selector lever is moved again to position P, it is once again blocked.

Replacing windscreen wiper blades

Introduction

This chapter contains information on the following subjects:

Replacing the windscreen wiper blades

172

Replacing the rear window wiper blade

172WARNINGReplace the windscreen wiper blades once or twice a year for safety rea-

sons. These can be purchased from a ŠKODA Partner.171Emergency equipment and self-help

Page 178 of 204

No.Power consumer43Horn44Windscreen wipers45Boot lid lock, central locking system46Alarm47Cigarette lighter48ABS49Turn signal lights, brake lights50DC-DC converter, radio51Electric windows (driver's window and rear left window)52Electric windows (front passenger's window and rear right)53Windscreen washer54START-STOP instrument cluster, operating lever under the steering

wheel, multifunction steering wheel55Control unit for automatic gearbox56Headlight cleaning system57Headlights front, rear58Headlights front, rear

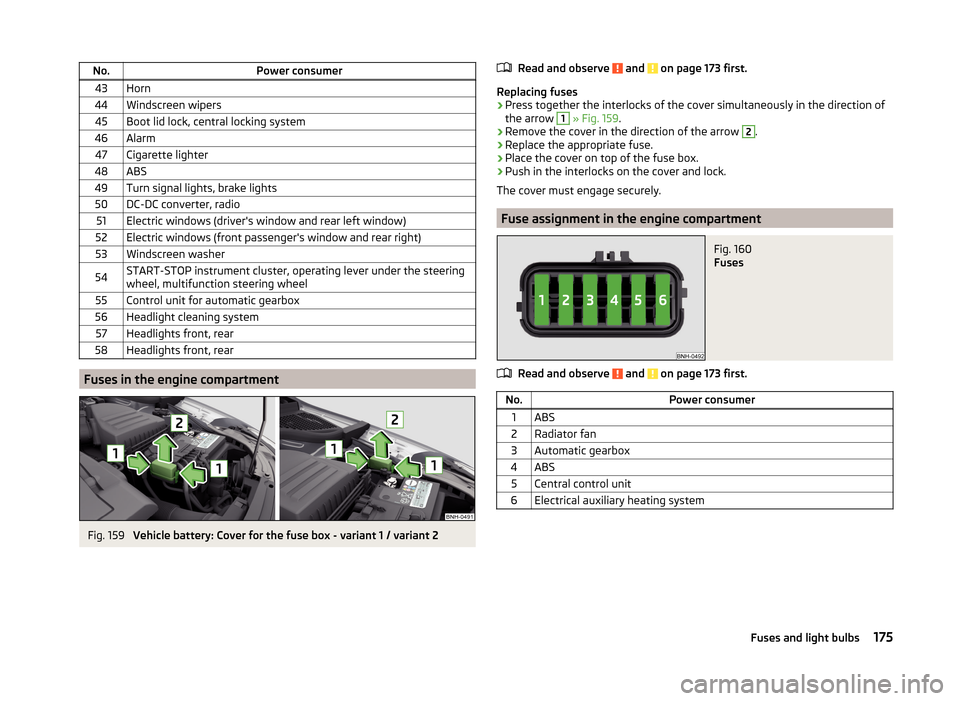

Fuses in the engine compartment

Fig. 159

Vehicle battery: Cover for the fuse box - variant 1 / variant 2

Read and observe and on page 173 first.

Replacing fuses

›

Press together the interlocks of the cover simultaneously in the direction of

the arrow

1

» Fig. 159 .

›

Remove the cover in the direction of the arrow

2

.

›

Replace the appropriate fuse.

›

Place the cover on top of the fuse box.

›

Push in the interlocks on the cover and lock.

The cover must engage securely.

Fuse assignment in the engine compartment

Fig. 160

Fuses

Read and observe and on page 173 first.

No.Power consumer1ABS2Radiator fan3Automatic gearbox4ABS5Central control unit6Electrical auxiliary heating system175Fuses and light bulbs