engine SKODA RAPID SPACEBACK 2014 1.G Repair Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2014, Model line: RAPID SPACEBACK, Model: SKODA RAPID SPACEBACK 2014 1.GPages: 204, PDF Size: 27.11 MB

Page 164 of 204

Raising the vehicle163Anti-theft wheel bolts164

For your own safety and the safety of the passengers, the following instruc-

tions must be observed before changing a wheel on the road.

Switch on the hazard warning lights system.

The warning triangle is to be set up at the prescribed distance - observe

the national legal provisions when doing so.

Park the vehicle as far away as possible from the flow of traffic.

Choose a location with a flat, solid surface.

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

The following instructions must be followed if the vehicle is subsequently fit- ted with tyres or rims that differ from the factory-fitted ones » page 155, Ex-

planation of the tyre labelling .

The national legal requirements must be observed when changing a wheel.

Preliminary work

Before changing the wheel, the following work must be carried out.

›

Switch off the engine.

›

Select the first gear or move the selector lever for the automatic gearbox

into position P .

›

Firmly apply the handbrake.

›

Uncouple any trailers.

›

Remove the vehicle tool kit » page 159 and the spare wheel » page 159 from

the boot.

Full wheel trim

Before removing the wheel bolts, remove the wheel cover.

Removing

›

Hook the clamp found in the vehicle tool kit » page 159into the reinforced

edge of the wheel trim.

›

Push the wheel wrench through the clamp, support on the tyre and pull off

the wheel trim.

Installing›Press the wheel trim onto the wheel rim at the designated valve open-

ing » .

›

Then press the trim into the wheel rim until its entire circumference locks

correctly in place.

CAUTION

Notes from the factory or from the ŠKODA Original accessory delivered trim..■When using an anti-theft wheel bolt, make sure that this has been fitted ac-

cording to the position marked on the back of the wheel cover position.■

On the back of the wheel cover, the position for the anti-theft wheel bolt is

marked by means of a symbol. If the wheel cover is set outside the position

marked for the anti-theft wheel bolt, there is a risk of damaging the wheel

cover.

CAUTION

■ Use the pressure of your hand only, do not strike the full wheel trim! The

cover could be damaged.■

If wheel trims are fitted, an adequate flow of air must be assured in order to

cool the brake system.

Note

We recommend that you use wheel trims from ŠKODA Original Accessories.

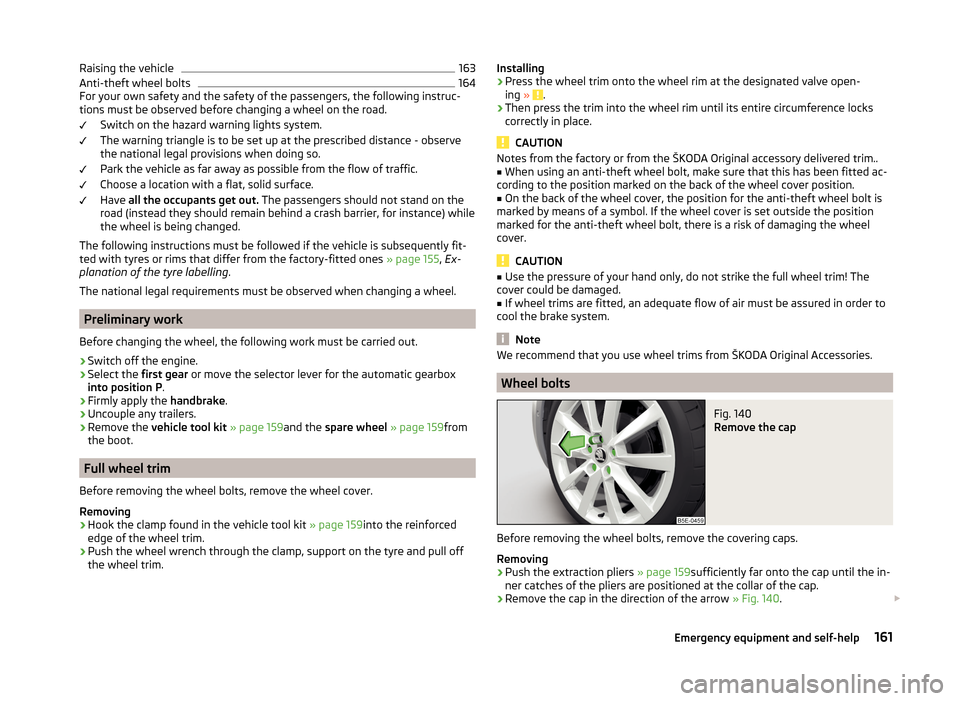

Wheel bolts

Fig. 140

Remove the cap

Before removing the wheel bolts, remove the covering caps.

Removing

›

Push the extraction pliers » page 159sufficiently far onto the cap until the in-

ner catches of the pliers are positioned at the collar of the cap.

›

Remove the cap in the direction of the arrow » Fig. 140.

161Emergency equipment and self-help

Page 166 of 204

›Grasp the end of the wrench and turn the bolt about

one turn in the direction

of the arrow » Fig. 141.

Tightening›

Push the wheel wrench onto the wheel bolt to the stop 1)

.

›

Grasp the end of the wrench and turn the bolt against the direction of the

arrow » Fig. 141 until it is tight.

After tightening the wheel bolts, the covering caps must be replaced.

WARNINGIf it proves difficult to undo the bolts, carefully apply pressure to the end of

the wrench with your foot. Keep hold of the vehicle when doing so, and

make sure you keep your footing.

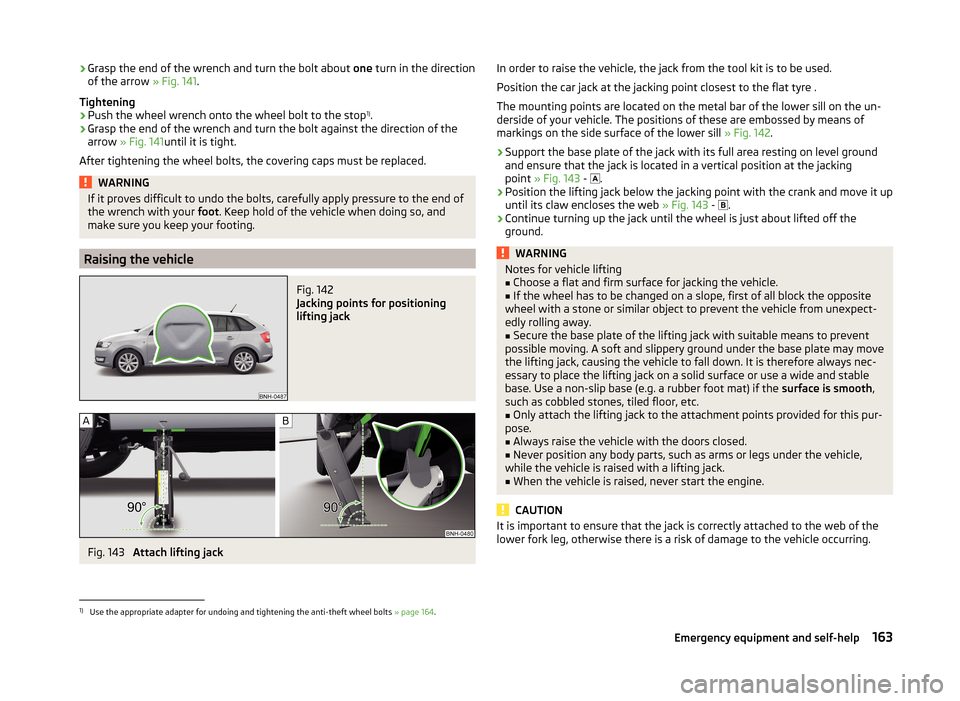

Raising the vehicle

Fig. 142

Jacking points for positioning

lifting jack

Fig. 143

Attach lifting jack

In order to raise the vehicle, the jack from the tool kit is to be used.

Position the car jack at the jacking point closest to the flat tyre .

The mounting points are located on the metal bar of the lower sill on the un-

derside of your vehicle. The positions of these are embossed by means of

markings on the side surface of the lower sill » Fig. 142.›

Support the base plate of the jack with its full area resting on level ground

and ensure that the jack is located in a vertical position at the jacking

point » Fig. 143 -

.

›

Position the lifting jack below the jacking point with the crank and move it up

until its claw encloses the web » Fig. 143 -

.

›

Continue turning up the jack until the wheel is just about lifted off the

ground.

WARNINGNotes for vehicle lifting■Choose a flat and firm surface for jacking the vehicle.■

If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpect-

edly rolling away.

■

Secure the base plate of the lifting jack with suitable means to prevent

possible moving. A soft and slippery ground under the base plate may move

the lifting jack, causing the vehicle to fall down. It is therefore always nec-

essary to place the lifting jack on a solid surface or use a wide and stable

base. Use a non-slip base (e.g. a rubber foot mat) if the surface is smooth,

such as cobbled stones, tiled floor, etc.

■

Only attach the lifting jack to the attachment points provided for this pur-

pose.

■

Always raise the vehicle with the doors closed.

■

Never position any body parts, such as arms or legs under the vehicle,

while the vehicle is raised with a lifting jack.

■

When the vehicle is raised, never start the engine.

CAUTION

It is important to ensure that the jack is correctly attached to the web of the

lower fork leg, otherwise there is a risk of damage to the vehicle occurring.1)

Use the appropriate adapter for undoing and tightening the anti-theft wheel bolts » page 164.

163Emergency equipment and self-help

Page 168 of 204

Components of the puncture repair kitsFig. 145

Principle sketch: Components of the breakdown kit

Read and observe

on page 164 first.

Components of the set » Fig. 145

Sticker with speed designation “max. 80 km/h”/“max. 50 mph”

Valve remover

Inflation hose with plug

Air compressor

Button for releasing the tyre pressure

12 volt cable connector

Tyre inflation hose

Tyre inflation pressure indicator

ON and OFF switch

Tyre inflater bottle with sealing agent

Replacement valve core

The valve remover

2

has a slot at its lower end which fits into the valve core.

The kit is located in a box under the floor covering in the luggage compart-

ment. This contains a sealing means and an air compressor.

Note

The declaration of conformity is included with the air compressor or the log

folder.1234567891011General information

Read and observe

on page 164 first.

For your own safety and the safety of your passengers, the following instruc-

tions must be observed before carrying out a wheel repair on the road.

Switch on the hazard warning lights system.

The warning triangle is to be set up at the prescribed distance - observe

the national legal provisions when doing so.

Park the vehicle as far away as possible from the flow of traffic.

Choose a location with a flat, solid surface.

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

The national legal requirements must be observed when repairing a tyre.

The breakdown kit must not be used under the following circumstances. › The rim is damaged.

› The outside temperature is below -20 ° C.

› The cut or puncture is larger than 4 mm.

› The tyre wall is damaged.

› The result will be to drive with very low tyre pressure or with a completely

flat tyres.

› After the expiration date (see inflation bottle).

Preparations for using the breakdown kit

Read and observe

on page 164 first.

The following preparatory work must be carried out before using the puncturerepair kit.

›

Switch off the engine.

›

Select the first gear or move the selector lever for the automatic gearbox

into position P .

›

Firmly apply the handbrake.

›

Check that you can carry out the repairs with the breakdown kit » page 165,

General information .

›

Remove the breakdown kit from the boot.

›

Stick the sticker

1

» Fig. 145 on page 165 on the dashboard in the driver's

field of view.

›

Unscrew the valve cap.

165Emergency equipment and self-help

Page 169 of 204

›Use the valve remover 2 to unscrew the valve core and place it on a clean

surface (rag, paper, etc.).

Sealing and inflating the tyre

Read and observe

on page 164 first.

Sealing

›

Forcefully shake the tyre inflater bottle

10

» Fig. 145 on page 165 back and

forth several times.

›

Firmly screw the inflation hose

3

onto the tyre inflater bottle

10

in a clock-

wise direction. The film on the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and plug the open end fully onto

the tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflater bottle into the tyre.

›

Remove the empty tyre inflater bottle from the valve.

›

Screw the valve core back into the tyre valve using the valve remover

2

.

Inflating

›

Screw the tyre inflation hose

7

» Fig. 145 on page 165 of the air compressor

firmly onto the tyre valve.

›

Start the engine and run it in idle.

›

Plug the connector

6

into 12 Volt socket » page 76, 12-Volt power outlet .

›

Switch on the air compressor with the ON and OFF switch

9

.

›

Allow the air compressor to run until a pressure of 2.0-2.5 bar is achieved.

Maximum run time of 8 minutes » .

›

Switch off the air compressor.

›

If you cannot reach an air pressure of 2.0–2.5 bar, unscrew the tyre inflation

hose

7

from the tyre valve.

›

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent

to “distribute” in the tyre.

›

Firmly screw the tyre inflation hose

7

back onto the tyre valve and repeat

the inflation process.

›

If you cannot reach the required tyre inflation pressure here either, this

means the tyre has sustained too much damage. You cannot seal with tyre with the breakdown kit »

.

›

Switch off the air compressor.

›

Remove the tyre inflation hose

7

from the tyre valve.

Once a tyre inflation pressure of 2.0–2.5 bar is achieved, continue the journey

at a maximum speed of 80 km/h (50 mph).

WARNING■ If you cannot inflate the tyre to at least 2.0 bar, this means the damage

sustained was too serious. The sealing agent cannot be used to seal the

tyre.

Do not continue to drive! Seek help from a specialist garage.■

The tyre inflation hose and air compressor may get hot as the tyre is be-

ing inflated – there is a risk of burning.

CAUTION

Switch off the air compressor after running 8 minutes at the latest – there is a

risk of overheating! Allow the air compressor to cool a few minutes before

switching it on again.

Notes for driving with tyre repaired

Read and observe

on page 164 first.

The inflation pressure of the repaired tyre must be checked after driving for 10minutes.

If the tyre pressure is 1.3 bar or less

›

Do not drive the vehicle! You cannot properly seal with tyre with the

breakdown kit.

If the tyre pressure is 1.3 bar or more

›

Set the tyre pressure back to the correct value.

›

Continue driving carefully to the nearest specialist garage at a maximum speed of 80 km/h (50 mph).

WARNING■ A tyre filled with sealant has the same driving characteristics as a stand-

ard tyre.■

Do not drive faster than 80 km/h (50 mph).

■

Avoid accelerating at full throttle, sharp braking and fast cornering.

Jump-starting

Introduction

This chapter contains information on the following subjects:

Jump-starting using the battery from another vehicle

167

166Do-it-yourself

Page 170 of 204

The battery of another vehicle can be used to jump-start your vehicle if the en-

gine will not start because the battery is flat.WARNING■ Pay attention to the warning instructions relating to working in the en-

gine compartment » page 141.■

A discharged vehicle battery may already freeze at temperatures just be-

low 0 °C. If the battery is frozen, do not jump start with the battery of an-

other vehicle – there is a risk of explosion!

■

Keep any sources of ignition (naked flame, smouldering cigarettes, etc.)

away from the battery – risk of explosion!

■

Never jump-start vehicle batteries with insufficient acid levels – risk of

explosion and chemical burns.

■

The vent screws of the battery cells must be tightened firmly.

Note

We recommend you buy jump-start cables from a car battery specialist.

Jump-starting using the battery from another vehicle

Fig. 146

Jump-starting: A – flat battery, B

– battery providing current

Fig. 147

Engine earth: START-STOP system

Read and observe on page 167 first.

The starting process using the battery of another vehicle requires the use of

jumper cables.

The jump-start cables must be attached in the following sequence.

›

Attach clamp

1

to the positive terminal of the discharged battery

A

» Fig. 146 .

›

Attach clamp

2

to the positive terminal of the battery supplying power

B

.

›

Attach clamp

3

to the negative terminal of the battery supplying power

B

.

›

Attach the clamp

4

to a solid metal component firmly connected to the en-

gine block or to the engine block itself.

Starting engine

›

Start the engine on the vehicle providing the power and allow it to idle.

›

Start the engine of the vehicle with the discharged battery.

›

If the engine does not start, halt the attempt to start the engine after 10 sec-

onds and wait for thirty seconds before repeating the process.

›

Remove the jumper cables exactly in the reverse sequence as for clamping.

On vehicles with the START-STOP system, the jump-start cable of the charger

must never be connected directly to the negative pole of the vehicle battery,

but only to the engine earth.

› 1.2 l/63 kW TSI and 1.2 l/77 kW TSI engines

» Fig. 147 -

› 1.4 l./90 kW engine

» Fig. 147 -

› 1.6 l./77 kW TDI CR engine

» Fig. 147 -

Both batteries must have a rated voltage of 12 V. The capacity (Ah) of the bat-

tery supplying the power must not be significantly less than the capacity of

the discharged battery in your vehicle.

Jump-start cables

Only use jump-start cables which have an adequately large cross-section and

insulated terminal clamps. Observe the instructions of the jumper lead manu-

facturer.

Positive cable – colour coding in the majority of cases is red.

Negative cable – colour coding in the majority of cases is black.

167Emergency equipment and self-help

Page 171 of 204

WARNING■Do not clamp the jump-start cable to the negative terminal of the dis-

charged battery. There is the risk of detonating gas seeping out of the bat-

tery being ignited by the strong spark resulting from the engine being star-

ted.■

The non-insulated parts of the terminal clamps must never touch each

other – there is a risk of short circuit!

■

The jump-start cable connected to the positive terminal of the battery

must not come into contact with electrically conducting parts of the vehicle

– there is a risk of short circuit!

■

Route the jump-start cables so that they cannot be caught by any rotat-

ing parts in the engine compartment.

■

There must not be any contact between the two vehicles, otherwise cur-

rent may flow as soon as the negative terminals are connected.

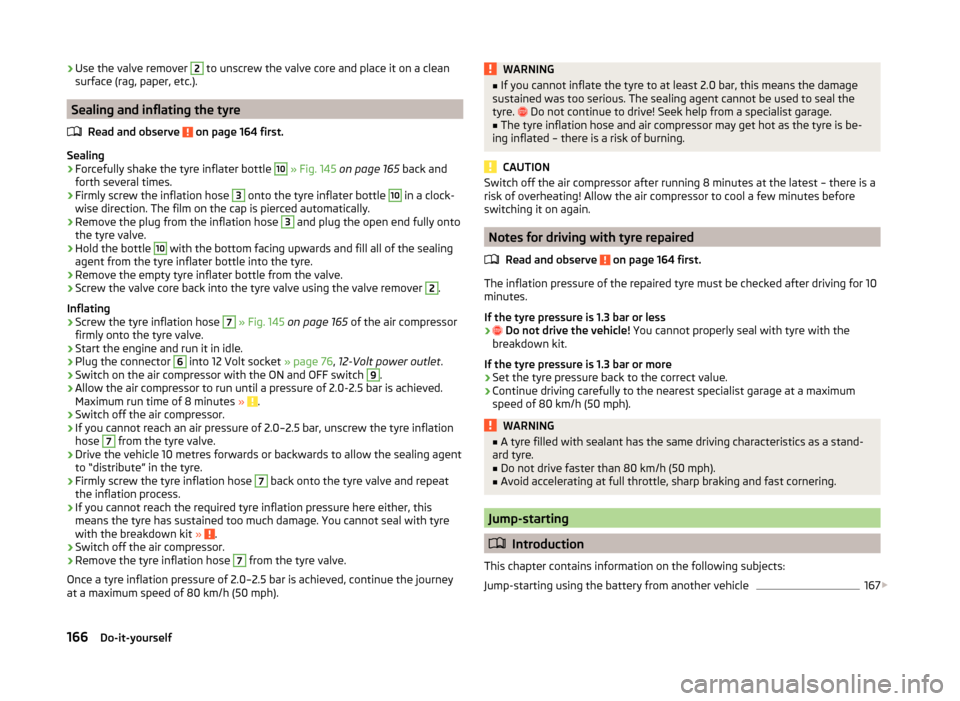

Towing the vehicle

Introduction

Fig. 148

Braided tow rope / Spiral tow rope

This chapter contains information on the following subjects:

Front towing eye

169

Rear towing eye

169

Vehicles with a tow hitch

169

For towing a braided tow rope is to be used » Fig. 148-

.

When towing, the following guidelines must be observed.

Vehicles with manual transmission may be towed in with a tow bar or a tow

rope or with the front or rear wheels raised.

Vehicles with automatic transmission may be towed in with a tow bar or a tow

rope or with the front wheels raised. If the vehicle is raised at the rear, the au-

tomatic gearbox will be damaged!

Driver of the tow vehicle›

Engage the clutch gently when starting off or depress the accelerator partic-

ularly gently if the vehicle is fitted with an automatic gearbox.

›

Only then, approach correctly when the rope is taut.

The maximum towing speed is 50 km/h.

Driver of the towed vehicle

›

Switch on the ignition so that the steering wheel is not locked and so that

the turn signal lights, windscreen wipers and windscreen washer system can

be used.

›

Take the vehicle out of gear or move the selector lever into position N if the

vehicle is fitted with an automatic gearbox.

Please note that the brake servo unit and power steering only operate if the

engine is running. If the engine is not running, significantly more physical force

is required to depress the brake pedal and steer the vehicle.

If using a tow rope, ensure that it is always kept taught.

Both drivers should be familiar with the problems which might possibly occur while a vehicle is being towed. Unskilled drivers should not attempt to tow an-

other vehicle or to be towed in one.

The vehicle must be transported on a special breakdown vehicle or trailer if it

is not possible to tow the vehicle in the way described or if the towing dis-

tance is greater than 50 km.

WARNING■ When towing, respect the national legal provisions, especially those

which relate to the identification of the towing vehicle and the vehicle be- ing towed.■

When towing, exercise increased caution.

■

For towing no spiral tow rope is to be used » Fig. 148-

, the towing eye

may unscrew out of the vehicle - there is a risk of accidents.

■

The tow rope should not be twisted - there is a risk of accidents.

168Do-it-yourself

Page 172 of 204

CAUTION■Do not start the engine by towing – there is a risk of damaging the engine

and the catalytic converter! The battery from another vehicle can be used as a

jump-start aid » page 166, Jump-starting .■

If the gearbox no longer contains any oil, your vehicle must only be towed

with the front axle raised clear of the ground or on a breakdown vehicle or

trailer.

■

To protect both vehicles when tow-starting or towing, the tow rope should

be elastic. Thus only plastic fibre rope or a rope made out of a similarly elastic

material should be used.

■

There is always a risk of excessive stresses and damage resulting at the

points to which you attach the tow rope or tow bar when you attempt to tow a

vehicle which is not standing on a paved road.

■

Attach the tow rope or the tow bar to the towing eyes » page 169

or » page 169 to the detachable ball head of the towing equip-

ment » page 120 .

Note

We recommend using a tow rope from ŠKODA Original Accessories, which is

available from a ŠKODA Partner.

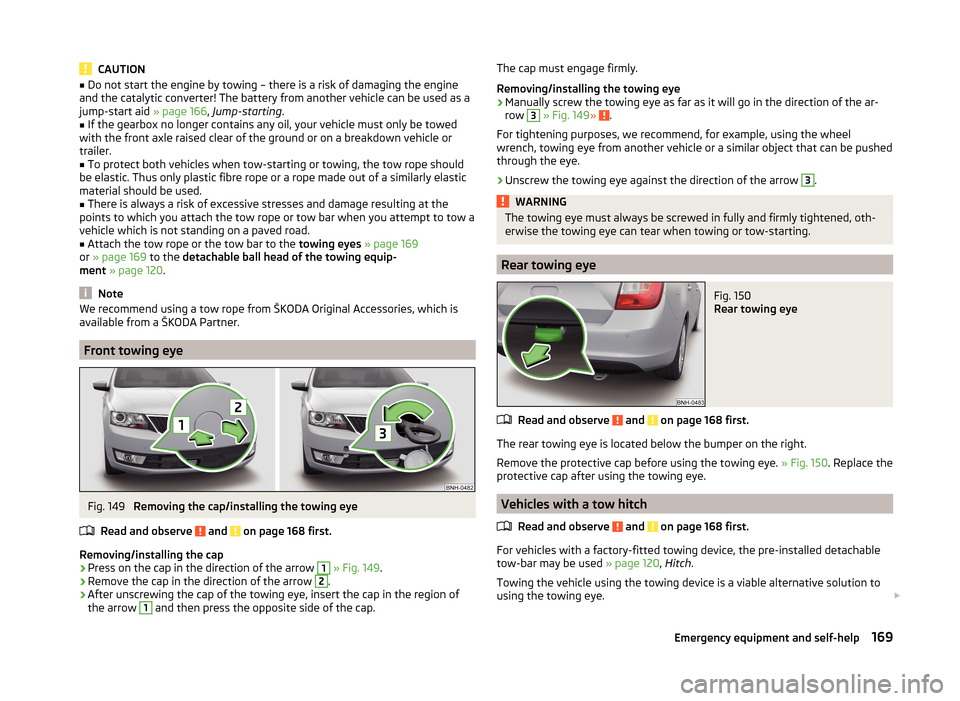

Front towing eye

Fig. 149

Removing the cap/installing the towing eye

Read and observe

and on page 168 first.

Removing/installing the cap

›

Press on the cap in the direction of the arrow

1

» Fig. 149 .

›

Remove the cap in the direction of the arrow

2

.

›

After unscrewing the cap of the towing eye, insert the cap in the region of

the arrow

1

and then press the opposite side of the cap.

The cap must engage firmly.

Removing/installing the towing eye›

Manually screw the towing eye as far as it will go in the direction of the ar-

row

3

» Fig. 149 » .

For tightening purposes, we recommend, for example, using the wheel

wrench, towing eye from another vehicle or a similar object that can be pushed through the eye.

›

Unscrew the towing eye against the direction of the arrow

3

.

WARNINGThe towing eye must always be screwed in fully and firmly tightened, oth-

erwise the towing eye can tear when towing or tow-starting.

Rear towing eye

Fig. 150

Rear towing eye

Read and observe and on page 168 first.

The rear towing eye is located below the bumper on the right.

Remove the protective cap before using the towing eye. » Fig. 150. Replace the

protective cap after using the towing eye.

Vehicles with a tow hitch

Read and observe

and on page 168 first.

For vehicles with a factory-fitted towing device, the pre-installed detachable

tow-bar may be used » page 120, Hitch .

Towing the vehicle using the towing device is a viable alternative solution to

using the towing eye.

169Emergency equipment and self-help

Page 176 of 204

Fuses and light bulbs

Fuses

Introduction

This chapter contains information on the following subjects:

Fuses in the dash panel

173

Assignment of the fuses in the dash panel

174

Fuses in the engine compartment

175

Fuse assignment in the engine compartment

175

Individual electrical circuits are protected by fuses.

Switch off the ignition and the corresponding power consuming device before

replacing a fuse.

Find out which fuse belongs to the component that is not operat-

ing » page 174 , Assignment of the fuses in the dash panel or » page 175 ,

Fuse assignment in the engine compartment .

Fuse colourMaximum amperagelight brown5dark brown7.5red10blue15yellow20white25green30orange40WARNINGAlways read and observe the warning notes before completing any work in

the engine compartment » page 141, Engine compartment .CAUTION■

“Never repair” fuses, and do not replace them with fuses of a higher amper-

age – risk of fire! This may also cause damage at other points in the electrical

system.■

A blown fuse is recognisable by the molten metal strip. Replace the faulty

fuse with a new one of the same amperage.

■

If a newly inserted fuse burns through again, then a specialist should be con-

sulted immediately.

Note

■ We recommend always carrying replacement fuses in the vehicle. A box of

replacement fuses can be purchased from ŠKODA Original Accessories.■

There can be several power-consuming devices for one fuse.

■

Multiple fuses may exist for a single power-consuming device.

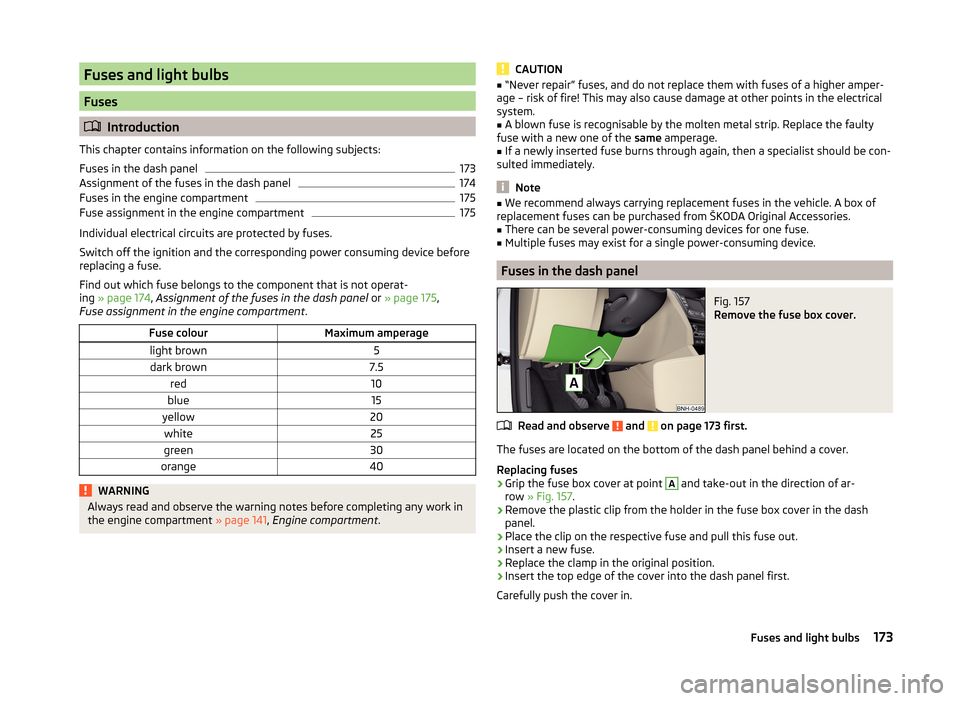

Fuses in the dash panel

Fig. 157

Remove the fuse box cover.

Read and observe and on page 173 first.

The fuses are located on the bottom of the dash panel behind a cover.

Replacing fuses

›

Grip the fuse box cover at point

A

and take-out in the direction of ar-

row » Fig. 157 .

›

Remove the plastic clip from the holder in the fuse box cover in the dash

panel.

›

Place the clip on the respective fuse and pull this fuse out.

›

Insert a new fuse.

›

Replace the clamp in the original position.

›

Insert the top edge of the cover into the dash panel first.

Carefully push the cover in.

173Fuses and light bulbs

Page 177 of 204

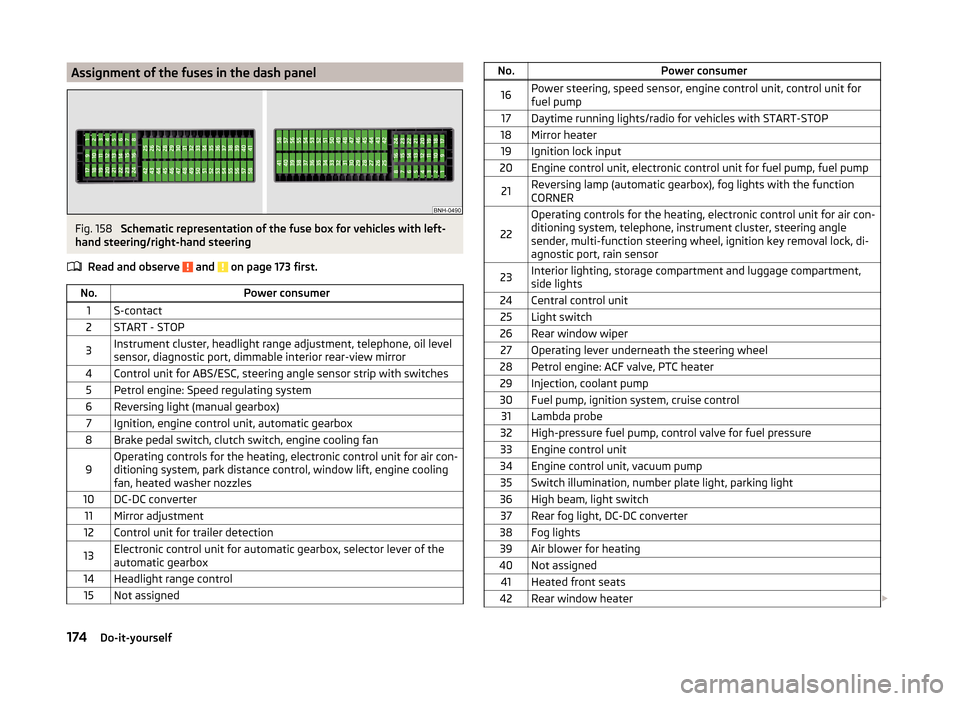

Assignment of the fuses in the dash panelFig. 158

Schematic representation of the fuse box for vehicles with left-

hand steering/right-hand steering

Read and observe

and on page 173 first.

No.Power consumer1S-contact2START - STOP3Instrument cluster, headlight range adjustment, telephone, oil level

sensor, diagnostic port, dimmable interior rear-view mirror4Control unit for ABS/ESC, steering angle sensor strip with switches5Petrol engine: Speed regulating system6Reversing light (manual gearbox)7Ignition, engine control unit, automatic gearbox8Brake pedal switch, clutch switch, engine cooling fan9Operating controls for the heating, electronic control unit for air con-

ditioning system, park distance control, window lift, engine cooling

fan, heated washer nozzles10DC-DC converter11Mirror adjustment12Control unit for trailer detection13Electronic control unit for automatic gearbox, selector lever of the

automatic gearbox14Headlight range control15Not assignedNo.Power consumer16Power steering, speed sensor, engine control unit, control unit for

fuel pump17Daytime running lights/radio for vehicles with START-STOP18Mirror heater19Ignition lock input20Engine control unit, electronic control unit for fuel pump, fuel pump21Reversing lamp (automatic gearbox), fog lights with the function

CORNER

22

Operating controls for the heating, electronic control unit for air con-

ditioning system, telephone, instrument cluster, steering angle

sender, multi-function steering wheel, ignition key removal lock, di-

agnostic port, rain sensor23Interior lighting, storage compartment and luggage compartment,

side lights24Central control unit25Light switch26Rear window wiper27Operating lever underneath the steering wheel28Petrol engine: ACF valve, PTC heater29Injection, coolant pump30Fuel pump, ignition system, cruise control31Lambda probe32High-pressure fuel pump, control valve for fuel pressure33Engine control unit34Engine control unit, vacuum pump35Switch illumination, number plate light, parking light36High beam, light switch37Rear fog light, DC-DC converter38Fog lights39Air blower for heating40Not assigned41Heated front seats42Rear window heater 174Do-it-yourself

Page 178 of 204

No.Power consumer43Horn44Windscreen wipers45Boot lid lock, central locking system46Alarm47Cigarette lighter48ABS49Turn signal lights, brake lights50DC-DC converter, radio51Electric windows (driver's window and rear left window)52Electric windows (front passenger's window and rear right)53Windscreen washer54START-STOP instrument cluster, operating lever under the steering

wheel, multifunction steering wheel55Control unit for automatic gearbox56Headlight cleaning system57Headlights front, rear58Headlights front, rear

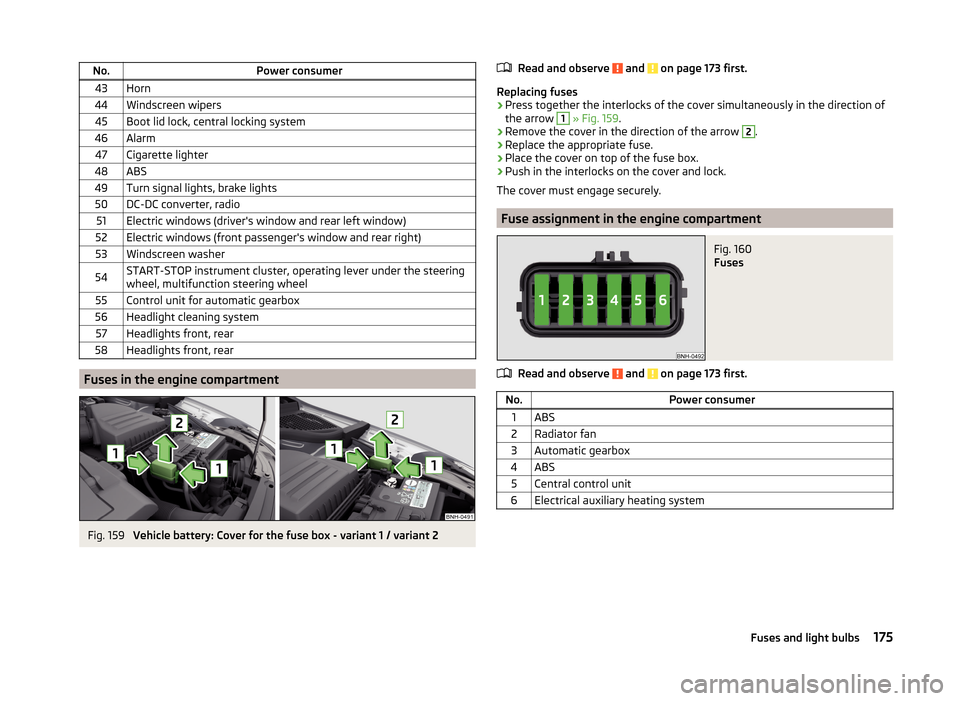

Fuses in the engine compartment

Fig. 159

Vehicle battery: Cover for the fuse box - variant 1 / variant 2

Read and observe and on page 173 first.

Replacing fuses

›

Press together the interlocks of the cover simultaneously in the direction of

the arrow

1

» Fig. 159 .

›

Remove the cover in the direction of the arrow

2

.

›

Replace the appropriate fuse.

›

Place the cover on top of the fuse box.

›

Push in the interlocks on the cover and lock.

The cover must engage securely.

Fuse assignment in the engine compartment

Fig. 160

Fuses

Read and observe and on page 173 first.

No.Power consumer1ABS2Radiator fan3Automatic gearbox4ABS5Central control unit6Electrical auxiliary heating system175Fuses and light bulbs