boot SKODA RAPID SPACEBACK 2015 1.G User Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2015, Model line: RAPID SPACEBACK, Model: SKODA RAPID SPACEBACK 2015 1.GPages: 208, PDF Size: 29.2 MB

Page 61 of 208

Lights and visibility

Lights

Introduction

This chapter contains information on the following subjects:

Operating the light function

59

Daytime running lights(DAY LIGHT)

60

Turn signal and main beam

60

Automatic driving lamp control

61

Front and rear fog lights

61

Fog lights with the CORNER function

62

COMING HOME / LEAVING HOME

62

Hazard warning light system

62

Parking light

63

Driving abroad

63

Unless otherwise stated, the lights only work when the ignition is switched on.

The layout of the controls on right-hand drive vehicles differs partially from

that shown in » Fig. 46 on page 59 . The symbols which mark the individual

positions of the controls are identical.

WARNINGThe automatic driving lamp control only operates as a support and

does not release the driver from his responsibility to check the lights and, if

necessary, to switch on the light depending on the prevailing light condi-

tions.

Note

■ The headlights may mist up temporarily. When the driving lights are switched

on, the light outlet surfaces are free from mist after a short period, although

the headlight lenses may still be misted up in the peripheral areas. This mist

has no influence on the life of the lighting system.■

If the visibility is poor and the lights are not on (except daytime running light)

the brightness of the instrument lighting reduces to alert the driver to switch

on the lights in due time.

■

The brightness of the instrument lighting with the lights on (except daytime

running lights) can be set in the Infotainment » Owner´s Manual Infotainment ,

chapter CAR - Vehicle Settings .

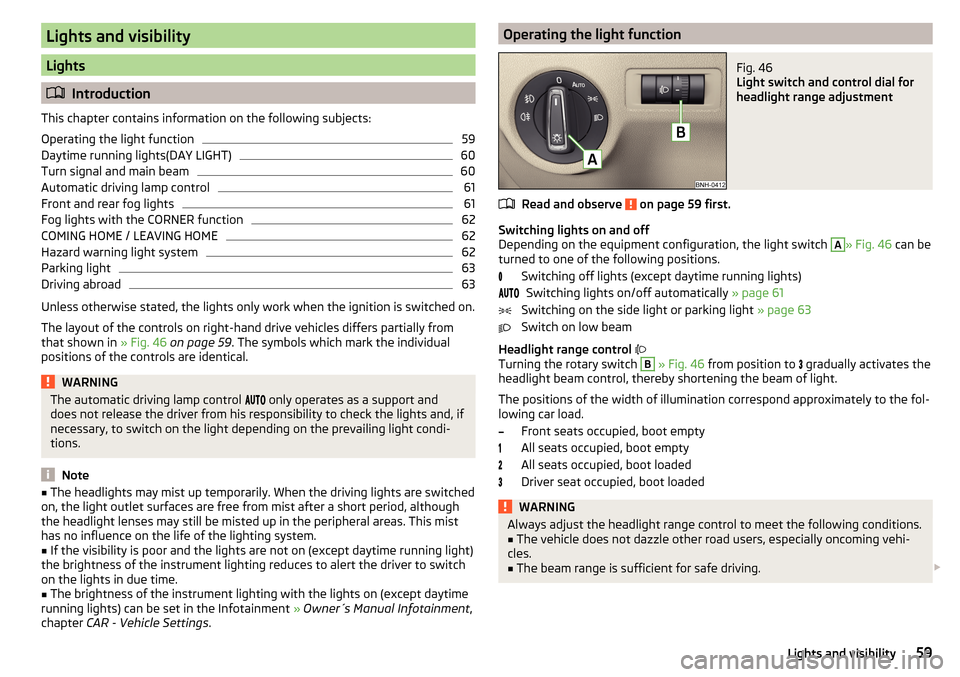

Operating the light functionFig. 46

Light switch and control dial for

headlight range adjustment

Read and observe on page 59 first.

Switching lights on and off

Depending on the equipment configuration, the light switch

A

» Fig. 46 can be

turned to one of the following positions.

Switching off lights (except daytime running lights)Switching lights on/off automatically » page 61

Switching on the side light or parking light » page 63

Switch on low beam

Headlight range control

Turning the rotary switch

B

» Fig. 46 from position to

gradually activates the

headlight beam control, thereby shortening the beam of light.

The positions of the width of illumination correspond approximately to the fol- lowing car load.

Front seats occupied, boot empty

All seats occupied, boot empty

All seats occupied, boot loaded

Driver seat occupied, boot loaded

WARNINGAlways adjust the headlight range control to meet the following conditions.■The vehicle does not dazzle other road users, especially oncoming vehi-

cles.■

The beam range is sufficient for safe driving.

59Lights and visibility

Page 83 of 208

Fig. 86

Removing the holder/removing the adapter

Read and observe

on page 80 first.

Installing

›

Attach the opened adapter to the guide rods of the headrest » Fig. 85.

›

Clip in the adapter in the direction of arrow

1

» .

›

Clip the holder into the adapter in the direction of arrow

2

.

Removing

›

Pull on the locking strap

A

in the direction of arrow

3

» Fig. 86 .

›

Remove the holder from the bracket in the direction of arrow

4

.

›

Press the adapter and remove it from the guide rods of the head rest in the

direction of arrow

5

.

WARNINGClip in the adapter carefully - there is a risk of injuring your finger.

Handling the holder

Fig. 87

Tilting and rotating the holder

Fig. 88

Adjusting the holder size

Read and observe on page 80 first.

Tilting and rotating the holder

The holder may be tilted 30° in the direction of arrow

1

and rotated through

360° in the direction of arrow

2

» Fig. 87 .

Adjusting the holder size

›

Pull out the securing tab

A

in the direction of arrow

3

and move part

B

in

direction of arrow

4

to the desired position » Fig. 88.

Luggage compartment and transport of cargo

Introduction

This chapter contains information on the following subjects:

Fastening elements

82

Fixing nets

83

Multifunction pocket

83

Hooks

83

Luggage compartment cover

84

“Parking position” of the boot cover

84

Storage compartment in the boot

85

Storage net bag

85

Cargo elements

85

Floor covering on both sides

86

Class N1 vehicles

86

81Transporting and practical equipment

Page 84 of 208

When transporting cargo the following the instructions must be adhered to

▶ When transporting heavy objects, the driving characteristics change due to

the shift in centre-of-gravity. The speed and style of driving must be adjus-

ted accordingly.

▶ The cargo is stowed in the luggage compartment. To prevent this from mov-

ing it should be secured with suitable lashing straps to the lashing eyes or

secured with fixing nets.

▶ Distribute loads as evenly as possible.

▶ Place heavy objects as far forward as possible.

▶ The transported items must be stowed in such a way that no objects are able

to slip forward on sudden driving or braking manoeuvres – risk of injury!

▶ Tyre pressure is to match the load.

▶ When transporting loads in the luggage compartment that has been en-

larged by folding the rear seats forward, ensure the safety of the passengers

transported on the other rear seats .

In the event of an accident, even small and light objects gain so much kinetic energy that they can cause severe injuries.

The magnitude of the kinetic energy is dependent on the speed at which the

vehicle is travelling and the weight of the object.

Example: In the event of a frontal collision at a speed of 50 km/h, an object

with a weight of 4.5 kg produces an energy, which corresponds to 20 times its

own weight. This means that it results in a weight of approx. 90 kg “ ”.

Luggage compartment light

The warning light turns on when tailgate is opened.

The warning light turns off when the tailgate is closed.

If the boot lid is open and the ignition switched off, the light will extinguish

automatically after around 10 minutes.WARNING■ Never exceed the maximum permissible load of the respective fasteners,

nets, hooks etc. as heavy objects are not e sufficiently secured - there is a

risk of injury!■

If the cargo is tied down with unsuitable or damaged lashing straps, inju-

ries can occur in the event of braking manoeuvres or accidents.

WARNING (Continued)■ Loose cargo can be thrown forward during a sudden manoeuvre or in case

of an accident and can injure the occupants or other road users.■

Loose cargo could hit a deployed airbag and injure occupants – danger of

death!

CAUTION

■ Never exceed the maximum permissible load of the respective fasteners,

nets, hooks etc. - these could be damaged.■

Please ensure that the heating elements for the rear window heater are not

damaged as a result of abrasive objects.

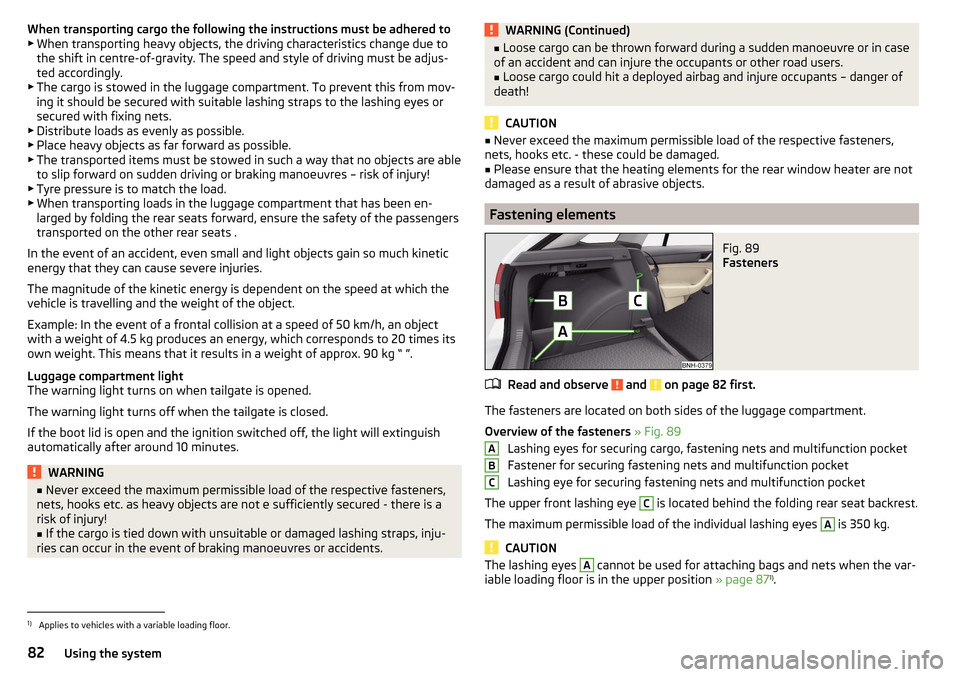

Fastening elements

Fig. 89

Fasteners

Read and observe and on page 82 first.

The fasteners are located on both sides of the luggage compartment.

Overview of the fasteners » Fig. 89

Lashing eyes for securing cargo, fastening nets and multifunction pocket

Fastener for securing fastening nets and multifunction pocket

Lashing eye for securing fastening nets and multifunction pocket

The upper front lashing eye

C

is located behind the folding rear seat backrest.

The maximum permissible load of the individual lashing eyes

A

is 350 kg.

CAUTION

The lashing eyes A cannot be used for attaching bags and nets when the var-

iable loading floor is in the upper position » page 871)

.ABC1)

Applies to vehicles with a variable loading floor.

82Using the system

Page 86 of 208

The maximum permissible load of the hook is 7.5 kg.

Luggage compartment cover

Fig. 94

Remove the luggage compartment cover

Read and observe

and on page 82 first.

If the support straps

A

» Fig. 94 are attached to the boot lid, then opening the

lid will raise the boot lid cover (hereafter referred to as the cover).

If you want to carry bulky goods, the cover can be removed from the vehicle

and if required can be stored behind the rear seat backrest in the “Park posi-

tion” » Fig. 95 on page 84 .

The maximum permissible load of the cover is 1 kg.

Removing

›

On both sides of the boot lid unhook the straps

A

in direction of arrow

1

» Fig. 94 .

›

Hold the raised cover.

›

Press on the two sides to the underside of the cover in the region of the

studs

C

.

›

Remove the cover in the direction of the arrow

2

.

Installing

›

Place the cover on the contact surfaces of the side trim panel.

›

Position the mounts on the cover

B

onto the side trim panel via pins

C

» Fig. 94 .

›

On both sides, press on the top of the cover in the area of the studs

C

.

The fixture

B

must lock into place on the studs

C

on both sides of the lug-

gage compartment.

›

Hook in the straps

A

on both sides of the boot lid.

WARNINGNo objects should be placed on the cover. This could endanger the vehicle

occupants during sudden braking or vehicle impact.

CAUTION

■ When closing the boot lid, jamming and damage to the cover or the side trim

panel can occur if handled incorrectly. The following guidelines must be ob-

served. ■ The holders B

on the cover must be resting completely on the pins

C

on

the side panel » Fig. 94.

■ The items which are transported must not exceed the height of the cover.

■ The cover must not be jammed in the surrounding seal of the luggage com-

partment lid when it is in the raised position. ■ There must be no object in the gap between the cover in the raise position

and the rear backrest.

■

After removing the cover, store it in such a way that it cannot be damaged or

soiled.

“Parking position” of the boot cover

Fig. 95

Luggage compartment cover

stowed behind the rear seats

Read and observe and on page 82 first.

The boot cover can be stowed behind the seat backrest.

›

Slide the dismantled cover between bolt

A

and contact surface

B

of the

side panel » Fig. 95.

WARNINGWhen adjusting the “parking position”, the boot cover must be between

the bolt A and the rear seat backrest - risk of damaging the rear seat

backrest and the boot cover. 84Using the system

Page 87 of 208

CAUTION■Before setting the “parking position” of the luggage compartment cover, the

variable loading floor must be put in the upper or lower position » page 86.■

If the luggage compartment cover is in the “parking position”, the “parking

position” of the variable loading floor cannot be set » page 88.

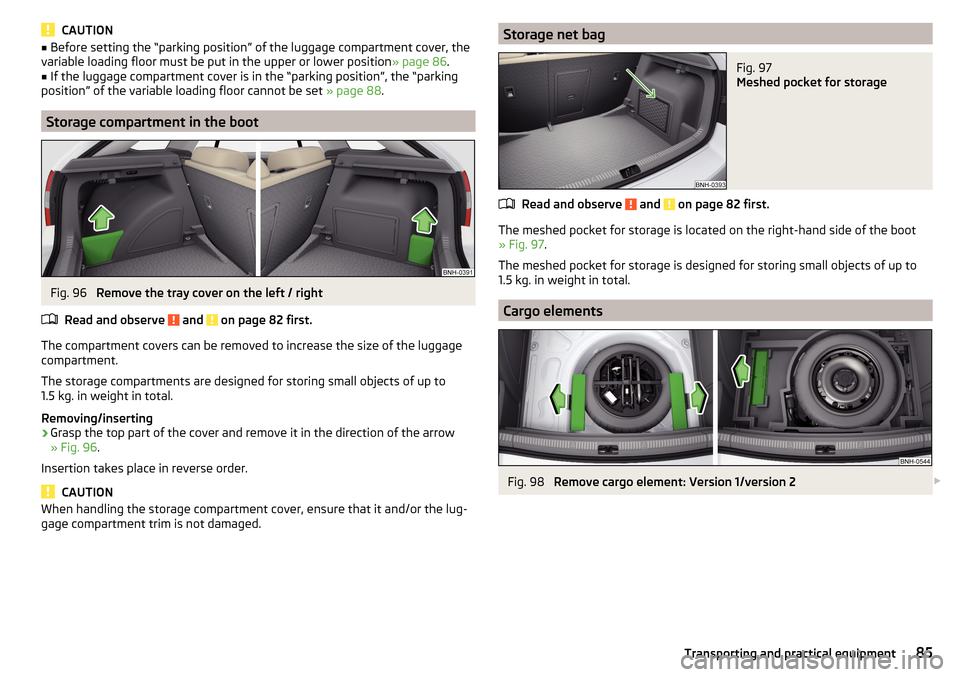

Storage compartment in the boot

Fig. 96

Remove the tray cover on the left / right

Read and observe

and on page 82 first.

The compartment covers can be removed to increase the size of the luggage

compartment.

The storage compartments are designed for storing small objects of up to

1.5 kg. in weight in total.

Removing/inserting

›

Grasp the top part of the cover and remove it in the direction of the arrow

» Fig. 96 .

Insertion takes place in reverse order.

CAUTION

When handling the storage compartment cover, ensure that it and/or the lug-

gage compartment trim is not damaged.Storage net bagFig. 97

Meshed pocket for storage

Read and observe and on page 82 first.

The meshed pocket for storage is located on the right-hand side of the boot

» Fig. 97 .

The meshed pocket for storage is designed for storing small objects of up to

1.5 kg. in weight in total.

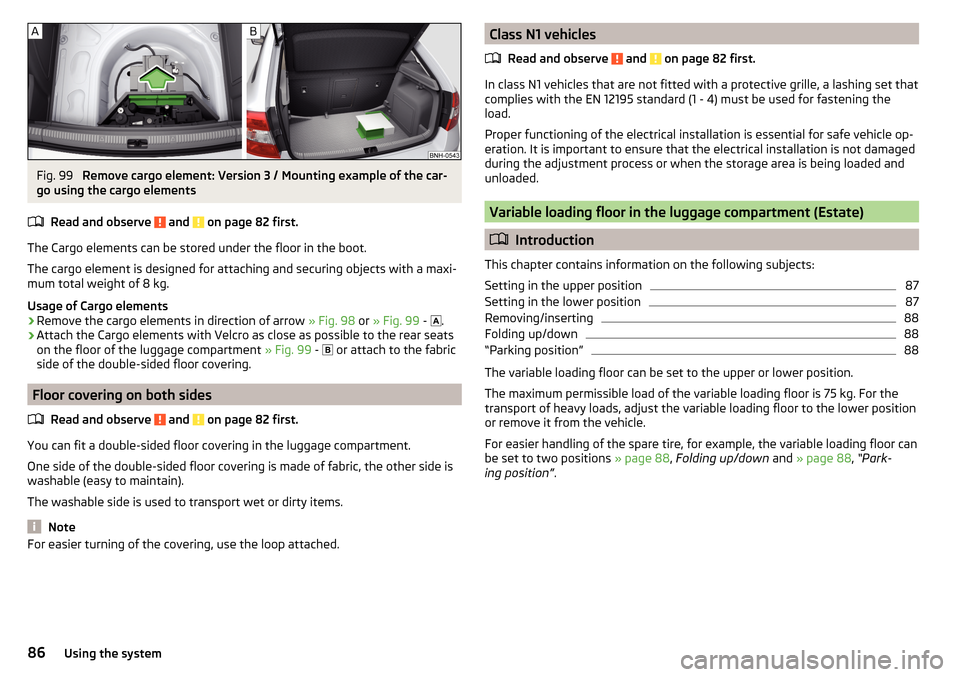

Cargo elements

Fig. 98

Remove cargo element: Version 1/version 2

85Transporting and practical equipment

Page 88 of 208

Fig. 99

Remove cargo element: Version 3 / Mounting example of the car-

go using the cargo elements

Read and observe

and on page 82 first.

The Cargo elements can be stored under the floor in the boot.

The cargo element is designed for attaching and securing objects with a maxi-

mum total weight of 8 kg.

Usage of Cargo elements

›

Remove the cargo elements in direction of arrow » Fig. 98 or » Fig. 99 -

.

›

Attach the Cargo elements with Velcro as close as possible to the rear seats

on the floor of the luggage compartment » Fig. 99 -

or attach to the fabric

side of the double-sided floor covering.

Floor covering on both sides

Read and observe

and on page 82 first.

You can fit a double-sided floor covering in the luggage compartment.

One side of the double-sided floor covering is made of fabric, the other side is washable (easy to maintain).

The washable side is used to transport wet or dirty items.

Note

For easier turning of the covering, use the loop attached.Class N1 vehicles

Read and observe

and on page 82 first.

In class N1 vehicles that are not fitted with a protective grille, a lashing set that

complies with the EN 12195 standard (1 - 4) must be used for fastening the

load.

Proper functioning of the electrical installation is essential for safe vehicle op-

eration. It is important to ensure that the electrical installation is not damaged

during the adjustment process or when the storage area is being loaded and

unloaded.

Variable loading floor in the luggage compartment (Estate)

Introduction

This chapter contains information on the following subjects:

Setting in the upper position

87

Setting in the lower position

87

Removing/inserting

88

Folding up/down

88

“Parking position”

88

The variable loading floor can be set to the upper or lower position.

The maximum permissible load of the variable loading floor is 75 kg. For the

transport of heavy loads, adjust the variable loading floor to the lower position

or remove it from the vehicle.

For easier handling of the spare tire, for example, the variable loading floor can

be set to two positions » page 88, Folding up/down and » page 88 , “Park-

ing position” .

86Using the system

Page 90 of 208

Removing/insertingFig. 102

Remove variable loading floor

Removing

›

Grasp the variable loading floor at handle

A

» Fig. 102 .

›

Lift the variable loading floor in the direction of arrow

1

until its rear area is

about 15 cm

B

below the luggage compartment cover » .

›

Remove the variable loading floor from the vehicle by moving it in the direc-

tion of arrow

2

.

Inserting

›

Grasp the variable loading floor at handle

A

» Fig. 102 .

›

Insert variable loading floor into the vehicle with the front portion tilted

about 15 cm

B

beneath the luggage compartment cover » .

›

Then follow the same steps as when setting the upper position » page 87 or

the lower position » page 87 .

CAUTION

■

When removing or inserting the variable loading floor, a distance of 15 cm B» Fig. 102 underneath the boot cover must be adhered to - risk of damaging

the boot lid seal.■

The variable loading floor cannot be placed in the vehicle when the luggage

compartment cover is in the “park position” » page 84.

■

After removing the variable cargo floor, place it down in such a way that it

cannot be damaged or soiled.

Folding up/downFig. 103

Fold up/fold down variable loading floor

The variable loading floor can be folded up in both positions (upper and lower).

Folding up

›

Grasp the variable loading floor at handle

A

» Fig. 103 .

›

Lift the variable loading floor in the direction of the arrow

1

until the folding

corners

B

lock into place in area

C

.

Folding down

›

Grasp the variable loading floor in the middle or at handle

A

» Fig. 103 .

›

Unlock the variable loading floor by pulling it in the direction of the arrow

2

.

“Parking position”

Fig. 104

Set parking position / fold down from the parking position

The variable loading floor can only be in set to the “parking position” when it is

in the lower position » page 87 and the luggage compartment cover has been

taken out » page 84.

88Using the system

Page 91 of 208

Folding up›Remove the luggage compartment cover from the vehicle » page 84.›

Grasp the variable loading floor at handle

A

» Fig. 104 .

›

Lift the variable loading floor in the direction of the arrow

1

until the folding

corners

B

lock into place in area

C

.

Folding down

›

Push the folding corners

B

» Fig. 104 on both sides of the variable loading

floor in the direction of the arrow

2

and release these from positions

C

.

›

Grasp the variable loading floor in the middle or at handle

A

.

›

Fold down the variable loading floor in the direction of arrow

3

.

WARNINGThe variable loading floor in the “parking position” restricts the driver's

view at the back.

CAUTION

■ The variable loading floor can only be in set to the “parking position” when it

is in the lower position and the luggage compartment cover has been taken

out.■

If the variable loading floor is in the “parking position”, the “parking position”

on the luggage compartment cover cannot be set » page 84.

Roof rack

Introduction

This chapter contains information on the following subjects:

fixing points for base support

89

Roof load

90WARNINGWhen transporting cargo the following the instructions must be adhered

to.■

The items being transported on the roof rack must always be securely at-

tached – risk of accident!

■

Always secure the load with appropriate and undamaged lashing straps

or tensioning straps.

■

Distribute the load evenly over the roof rack system.

WARNING (Continued)■ When transporting heavy objects or objects which take up a large area on

the roof rack system, handling of the car may change as a result of the dis-

placement of the centre of gravity. The style of driving and speed must

therefore be adapted to the current circumstances.■

Avoid abrupt and sudden driving/braking manoeuvres.

■

The permissible roof load, permissible axle loads and permissible total ve-

hicle weight must not be exceeded under any circumstance – risk of acci-

dent!

CAUTION

■ On models fitted with an electrical sliding/tilting roof, ensure that the slid-

ing/tilting roof does not strike any items of luggage transported on the roof

when tilting.■

Ensure that the boot lid does not hit the roof load when opened.

■

The height of the vehicle changes after mounting a roof luggage rack system

including the load that is being transported. Compare the vehicle height with

available clearances, such as underpasses and garage doors.

■

Ensure the roof aerial is not impaired by the load being transported.

Note

We recommend that you use a roof rack from ŠKODA Original Accessories.

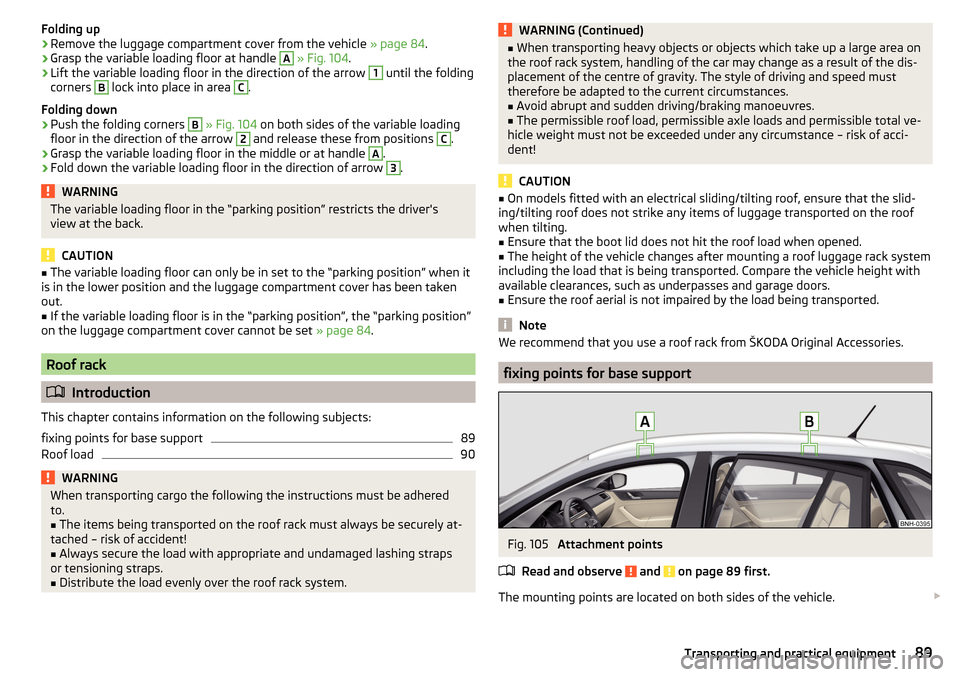

fixing points for base support

Fig. 105

Attachment points

Read and observe

and on page 89 first.

The mounting points are located on both sides of the vehicle.

89Transporting and practical equipment

Page 127 of 208

Removing the tow bar – Step 1Fig. 144

Remove cap from the lock / insert key into the lock

Fig. 145

Unlock lock

Read and observe and on page 121 first.

›

Remove the cover

A

from the lock in the direction of the arrow

1

» Fig. 144 .

›

Insert the key into the lock

B

in the direction of arrow

2,

so that the arrow

on the key symbol shows.

›

Turn the key

B

in the direction of arrow

3,

so that the arrow on the key

symbol

» Fig. 145 shows.

WARNINGNever remove the tow bar while the trailer is still coupled.

Note

We recommend putting the protective cover onto the ball head before remov-

ing the tow bar.Removing the tow bar – Step 2Fig. 146

Release tow bar

Read and observe and on page 121 first.

Removing

›

To begin with, follow the first step for the ball rod assembly » page 125.

›

Grasp the ball bar from below » Fig. 146 .

›

Pull the hand wheel

A

in the direction of the arrow

1

.

›

Turn the hand wheel in the direction of the arrow

2

to the stop, and hold in

this position.

›

Remove the tow bar from the mounting recess downwards and in the direc-

tion of the arrow

3

.

At the same time, the ball head latches into the ready position and is thus

ready to be re-inserted into the mounting recess »

.

Subsequent steps

After removing the tow bar the following work must be carried out.

›

Fit the cover for the mounting recess

A

in the opposite direction to arrow

1

» Fig. 141 on page 123 .

WARNINGNever allow the tow bar to remain unsecured in the boot. This could cause

damage on sudden braking and could put the safety of the occupants at

risk! 125Hitch and trailer

Page 139 of 208

CAUTION■The headlights are never to be wiped dry - there is a risk of damaging the

protective lacquer and the headlight glass subsequently developing cracks.■

Do not use sharp objects to clean the glasses - there is a risk of damaging

the protective lacquer and the headlight glasses subsequently developing

cracks.

■

Do not use any aggressive cleaning or chemical solvent products to clean the

headlights – risk of damaging the headlight lenses.

Door closing cylinder

Read and observe

and on page 134 first.

Specific products must be used for de-icing door lock cylinders.

CAUTION

Make sure that as little water as possible gets into the locking cylinder when

washing the vehicle - there is a risk of freezing the lock cylinder!

Cavity protection

Read and observe

and on page 134 first.

All the cavities of your vehicle which are at risk from corrosion are protectedfor life by a layer of protective wax applied in the factory.

This wax protection does not need to be inspected or re-applied.

If any small amount of wax flow out of the cavities at high temperatures, these

must be removed with a plastic scraper and the stains cleaned using a petrole-

um cleaner.

WARNINGSafety regulations should be observed when using petroleum cleaner to re-

move wax – risk of fire!

Jack

Read and observe

and on page 134 first.

The jack is maintenance-free.

If necessary, the moving parts of the jack should be lubricated with a suitable lubricant.

Wheels

Read and observe

and on page 134 first.

Wheel rims

Also thoroughly wash the wheel rims when washing the vehicle on a regular basis.

Regularly remove salt and brake abrasion, otherwise the rim material will be

corroded.

Light alloy wheels

After washing thoroughly, treat the wheel rims with a protective product for

light alloy wheels.

For the treatment of wheel rims do not use products which may cause damage

to the paint on the rims.

CAUTION

■ Damage to the paint layer on the wheel rims must be touched up immediate-

ly.■

Severe layers of dirt on the wheels can also result in wheel imbalance. This

may show itself in the form of a wheel vibration which is transmitted to the

steering wheel which, in certain circumstances, can cause premature wear of

the steering. This means it is necessary to remove the dirt.

Towing device and mounting recess

Read and observe

and on page 134 first.

Close the mounting recess with the cover to prevent any dirt from getting in.

If dirt is present, clean the inner surfaces of the mounting recess and treat

with a suitable preservative.

Always check the ball head before hitching a trailer. Apply a suitable grease, if

necessary.

Use the protective cover when stowing away the tow bar, in order to stop the

boot from getting dirty.

CAUTION

Apply grease to the inner part of the mounting recess. Make sure you do not

remove any grease.137Care and maintenance