heating SKODA RAPID SPACEBACK 2015 1.G Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2015, Model line: RAPID SPACEBACK, Model: SKODA RAPID SPACEBACK 2015 1.GPages: 208, PDF Size: 29.2 MB

Page 138 of 208

Rubber sealsRead and observe

and on page 134 first.

All door seals and window guides are factory-treated with a colourless mattvarnish layer to prevent the freezing of painted body parts and to protect

against driving noise.

CAUTION

■ Do not treat the door seals and window guides with any products whatsoev-

er .■

Applying additional treatments to the seals can corrode the protective coat-

ing, and driving noise may occur.

Chrome and anodized parts

Read and observe

and on page 134 first.

First clean the chrome parts and anodized parts with a damp cloth and thenpolish them with a soft, dry cloth.

If this method does not completely clean the parts, use cleaning products spe-

cially designed for this purpose.

CAUTION

■ Do not polish the chrome parts and anodized parts in a dusty environment -

risk of surface scratches.■

Never use aggressive cleaning agents or chemical solvents for these parts -

there is risk of damage.

Windows and external mirrors

Fig. 149

Fuel filler flap: Remove ice scra-

per

Read and observe and on page 134 first.

Removing snow and ice

Use a plastic ice scraper for removing snow and ice from the windows and mir-

rors.

The ice scraper can be found on the inside of the fuel filler flap.

›

Open the fuel filler flap.

›

Slide out the ice scraper in the direction of the arrow » Fig. 149.

Cleaning windows

Regularly clean windows from the inside with clean water.

Dry the glass surfaces with a clean chamois leather or a cloth intended for this

purpose.

CAUTION

Instructions for removing snow and ice■The ice scraper should not be moved forward and backward but in one direc-

tion to avoid any damage to the surface of the glass.■

Snow or ice that is contaminated with coarse dirt such as fine gravel, sand or

salt must not be removed from the windows and mirrors – there is a risk of

damage to the surface of the windows and mirrors.

■

Do not remove snow or ice from glass parts using warm or hot water – risk of

cracks forming in the glass.

■

Make sure that when removing snow and ice from the windows, the labels

attached to the vehicle by the factory are not damaged.

CAUTION

Information for cleaning windows■Do not clean the inside of the windows with sharp-edged objects or corro-

sive and acidic cleaning agents – there is a risk of damaging the heating ele-

ments or window aerial.■

When drying the windows after washing the vehicle, do not use window

leathers that have been used to polish the bodywork. Residues of preserva-

tives in the window leather can make the window dirty and reduce visibility.

Headlight glasses

Read and observe

and on page 134 first.

Clean plastic front headlight lenses using clean, warm water and soap.

136General Maintenance

Page 142 of 208

Seat coversRead and observe

and on page 138 first.

Electrically heated seats

Use a specific cleaning agent such as dry foam or similar to clean the covers.

»

.

Seats without seat heating

Thoroughly vacuum the seat covers with a vacuum cleaner before cleaning.

Clean the seat covers with a damp cloth or cleaning products specially de-

signed for this purpose.

Indented points arising on the fabrics by everyday use, can be removed by

brushing against the direction of hair with a damp brush.

Always clean all parts of the covers, so that there are no visible edges. Then

allow the seat to dry completely.

CAUTION

■ Do not clean the covers of electrically heated seats either with water or with

other liquids - there is a risk of damaging the seat heating system.■

Regularly remove dust from the seat covers using a vacuum cleaner.

■

Electrically heated seats must not be dried after cleaning by switching on the

heater.

■

Do not sit on wet seats - risk of seat deformation.

■

Always clean the seats “from seam to seam”.

Safety belts

Read and observe

and on page 138 first.

Wash dirty seat belts with mild soapy water.

Remove coarse dirt with a soft brush.

WARNING■ The seat belts must not be removed for cleaning.■Never clean the seat belts chemically as chemical cleaning products could

destroy the fabric.■

The seat belts must not be allowed to come into contact with corrosive

liquids (e.g. acids).

■

The seat belts must be fully dried before being rolled up.

Inspecting and replenishing

Fuel

Introduction

This chapter contains information on the following subjects:

Petrol and diesel refuelling

141

Lead-free petrol

141

Diesel fuel

142

The correct fuel grades for your vehicle are specified on the inside of the fuel

filler flap » Fig. 150 on page 141 .

WARNING■

The operating instructions of the refuelling system must always be fol-

lowed.■

Do not smoke when refuelling and do not use a mobile phone.

■

The fuel and fuel vapours are explosive - it can be fatal!

CAUTION

■ Never drive until the fuel tank is completely empty! The irregular supply of

fuel can cause misfiring, which can result in damage to parts of the engine and

the exhaust system.■

Immediately remove any fuel that has spilled onto the vehicle's paintwork –

risk of paint damage.

■

If the vehicle was not purchased in the country where it was intended to be

operated, you should check whether the fuel specified by the manufacturer is

offered in the country where the vehicle will be operated. You should also per-

haps check whether the manufacturer has recommended a different fuel for

operation of the vehicle in the corresponding country. If no prescribed fuel is

available, then you must check whether it is permitted by the manufacturer to

operate the vehicle with another fuel type.

140General Maintenance

Page 150 of 208

Coolant

Introduction

This chapter contains information on the following subjects:

Checking the coolant level

148

Replenishing

149

The coolant provides cooling for the motor.

It consists of water and coolant additive with additives that protect the cooling

system against corrosion and prevents furring.

The coolant additive in the coolant must be at least 40%.

The coolant additive may be increased to a maximum of 60%.

The correct mixing ratio of water and coolant additive is to be checked if nec-

essary by a specialist garage or is to be restored if necessary.

The description of the coolant is shown in the coolant expansion reservoir

» Fig. 155 on page 148 .

WARNINGThe engine compartment of your car is a hazardous area. The following

warning instructions must be followed at all times when working in the en- gine compartment » page 143.■

The coolant is harmful to health.

■

Avoid contact with the coolant.

■

Coolant vapours are harmful to health.

■

Never open the end cover of the coolant expansion reservoir while the

engine is still warm. The cooling system is pressurised!

■

When opening the end cover of the coolant expansion reservoir, cover it

with a cloth to protect your face, hands and arms from hot steam or hot

coolant.

■

If any coolant splashes into your eyes, immediately rinse out your eyes

with clear water and contact a doctor as soon as possible.

■

Always keep the coolant in the original container, safe from people who

are not completely independent, especially children - there is a danger of

poisoning!

■

If coolant is swallowed, consult a doctor immediately.

■

Never spill operating fluids over the hot engine - risk of fire.

CAUTION■ Do not continue if for some reason it is not possible to fill with coolant un-

der the current circumstances! Switch off the engine and seek assistance from

a specialist garage.■

If the expansion tank is empty, do not top up with coolant. The system could

ventilate - there is a risk of engine damage,

do not continue driving! Switch

off the engine and seek assistance from a specialist garage.

■

The concentration of coolant additive in the coolant must never be under

40%.

■

Over 60% of coolant additive in the coolant reduces the antifreeze protec-

tion and cooling effect.

■

A coolant additive that does not comply with the correct specification can

significantly reduce the corrosion protection of the cooling system.

■

Any faults resulting from corrosion may cause a loss of coolant and can con-

sequently result in major engine damage.

■

Do not fill the coolant above the mark

A

. » Fig. 155 on page 148

■

If an error occurs, leading to the engine overheating, the help of a professio-

nal garage is to be sought - there is a risk of serious engine damage occurring.

■

Additional headlights and other attached components in front of the air inlet

impair the cooling efficiency of the coolant.

■

Never cover the radiator - there is a risk of the engine overheating.

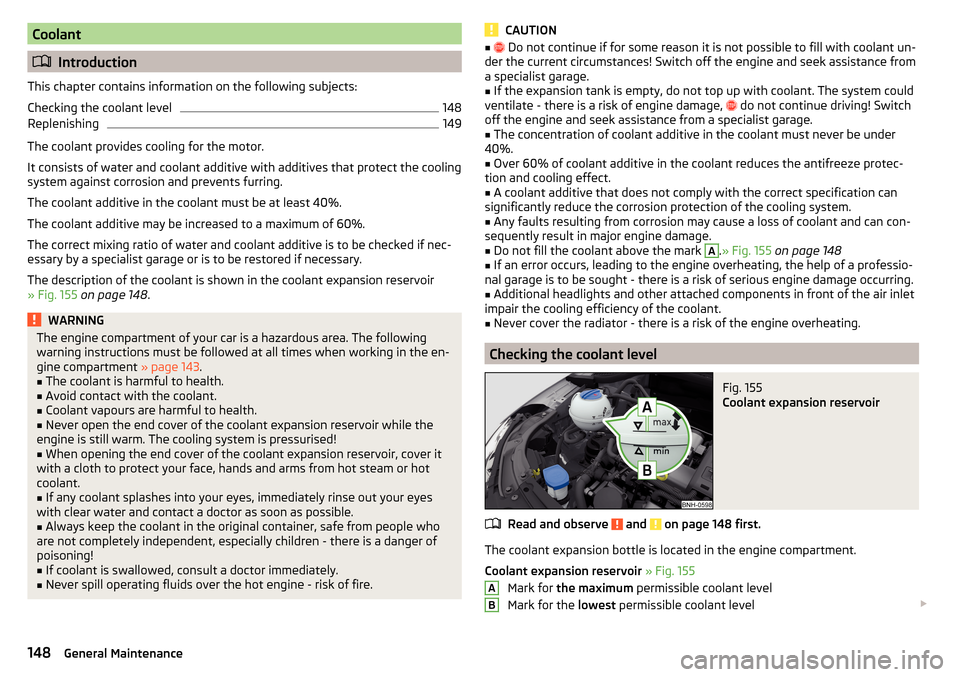

Checking the coolant level

Fig. 155

Coolant expansion reservoir

Read and observe and on page 148 first.

The coolant expansion bottle is located in the engine compartment.

Coolant expansion reservoir » Fig. 155

Mark for the maximum permissible coolant level

Mark for the lowest permissible coolant level

AB148General Maintenance

Page 169 of 208

Preparations for using the breakdown kitRead and observe

on page 166 first.

The following preparatory work must be carried out before using the puncture

repair kit.

›

Switch off the engine.

›

For vehicles with manual transmission select gear 1.

›

On vehicles with automatic transmission , place the selector lever in the P

position.

›

Firmly apply the handbrake.

›

Check that you can carry out the repairs with the breakdown kit » page 166,

General information .

›

Uncouple trailer, if attached.

›

Remove the breakdown kit from the boot.

›

Stick the sticker

1

» Fig. 171 on page 166 on the dashboard in the driver's

field of view.

›

Unscrew the valve cap.

›

Use the valve remover

2

to unscrew the valve core and place it on a clean

surface (rag, paper, etc.).

Sealing and inflating the tyre

Read and observe

on page 166 first.

Sealing

›

Forcefully shake the tyre inflater bottle

10

» Fig. 171 on page 166 back and

forth several times.

›

Firmly screw the inflation hose

3

onto the tyre inflater bottle

10

. The film on

the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and plug the open end fully onto

the tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflater bottle into the tyre.

›

Remove the filler plug from the tyre valve.

›

Screw the valve core back into the tyre valve using the valve remover

2

.

Inflating

›

Screw the tyre inflation hose

7

» Fig. 171 on page 166 of the air compressor

firmly onto the tyre valve.

›

For vehicles with manual transmission the lever into the neutral position.

›On vehicles with

automatic transmission , place the selector lever in the P

position.›

Start the engine and run it in idle.

›

Plug the connector

6

into the 12-volt socket » page 75.

›

Switch on the air compressor with the ON and OFF switch

9

.

›

Allow the air compressor to run until a pressure of 2.0 - 2.5 bar is achieved.

Maximum run time of 8 minutes » .

›

Switch off the air compressor.

›

If you cannot reach an air pressure of 2.0 - 2.5 bar, unscrew the tyre inflation

hose

7

from the tyre valve.

›

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent

to “distribute” in the tyre.

›

Firmly screw the tyre inflation hose

7

back onto the tyre valve and repeat

the inflation process.

›

Switch off the air compressor.

›

Remove the tyre inflation hose

7

from the tyre valve.

Once a tyre inflation pressure of 2.0 - 2.5 bar is achieved, you can continue the journey.

WARNING■ If the tyre cannot be inflated to at least. 2.0 bar, the damage is too great.

The sealing agent cannot be used to seal the tyre. Do not continue to

drive! Seek help from a specialist garage.■

The tyre inflation hose and air compressor may get hot as the tyre is be-

ing inflated – there is a risk of burning.

CAUTION

Switch off the air compressor after running 8 minutes at the latest – there is a

risk of overheating! Allow the air compressor to cool a few minutes before

switching it on again.

Notes for driving with tyre repaired

Read and observe

on page 166 first.

The inflation pressure of the repaired tyre must be checked after driving for 10

minutes.

If the tyre pressure is 1.3 bar or less

›

Do not continue to drive! The tyre cannot be properly sealed with the

breakdown kit.

167Emergency equipment and self-help

Page 178 of 208

No.Power consumer15Air conditioning system, selector lever of the automatic gearbox, di-

agnosis terminal16Instrument cluster17Alarm system, horn18Not assigned19Not assigned20Not assigned21Not assigned22Front- and rear windscreen wiper system23Heated front seats24Blower fan for air conditioning system, heating, air conditioning,

heating25Not assigned26Switch for front seat heating27Rear window wiper28Not assigned29airbag30Electric power windows, light switches, reverse light switches, air

conditioning system, Park Assist, exterior mirror, power feed for cen-

tre button strip, power feed for side button strip, interior mirror31Fuel pump, radiator fan, cruise control, coil of the relay for the front

and rear windscreen wipers32Diagnostic terminal, headlight range control, operating lever under

the steering wheel, interior lighting33Coil on starter relay, clutch pedal switch34Heated windscreen washer jets35Not assigned36Not assigned37Radar38Not assigned39Electrical auxiliary heating system40Not assigned41Rear window heaterNo.Power consumer42Power windows - front passenger43Towing hitch - contact in the socket44Cigarette lighter, 12-volt power socket45Power windows - rear right46Front and rear window washer, operating lever under the steering

wheel47Towing hitch - contact in the socket48Towing hitch - right light49Fuel pump50Radio51Heating of the external mirror52KESSY53Steering lock (KESSY)54ABS or ESC55Not assigned56Not assigned57Not assigned58Not assigned59Not assigned

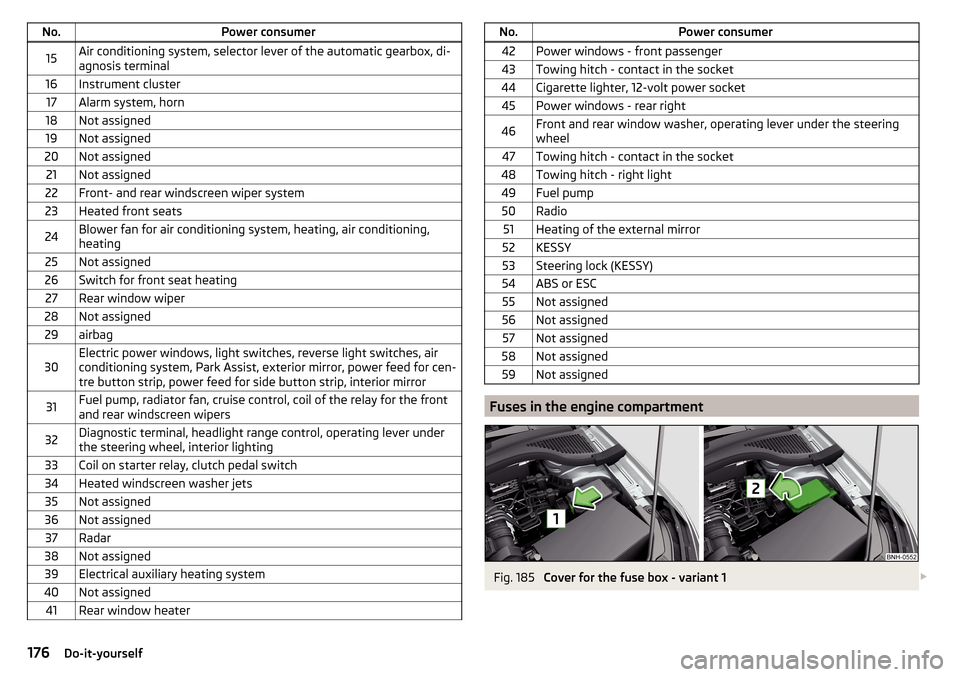

Fuses in the engine compartment

Fig. 185

Cover for the fuse box - variant 1

176Do-it-yourself

Page 179 of 208

Fig. 186

Cover for the fuse box - variant 2

Read and observe

and on page 174 first.

Replacing fuses

›

Press the lock button on the cover in direction of arrow

1

» Fig. 185 or

» Fig. 186 .

›

Raise the cover and remove in the direction of the arrow

2

.

›

Remove the plastic clip from the holder in the fuse box cover.

›

Replace the appropriate fuse.

›

Replace the bracket at the original position.

›

Place the cover on top of the fuse box.

›

Push in the locking button on the cover and lock.

The cover must engage securely.

CAUTION

The cover for the fuse box in the engine compartment must always be re-

placed correctly. Water may get into the fuse box if the cover is not replaced

properly - there is a risk of damage to the vehicle!

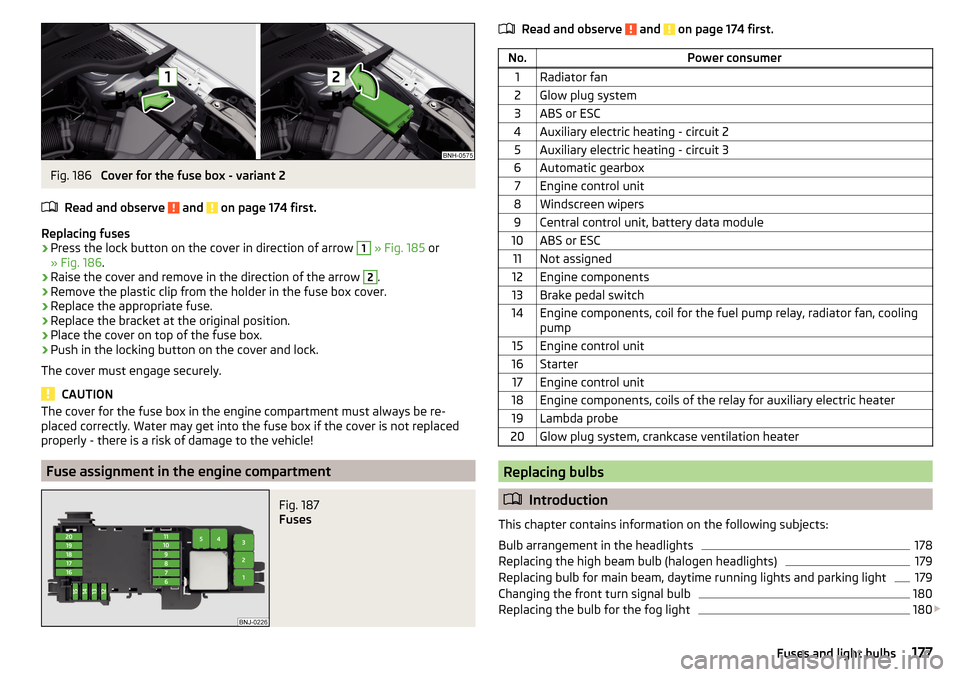

Fuse assignment in the engine compartment

Fig. 187

Fuses

Read and observe and on page 174 first.No.Power consumer1Radiator fan2Glow plug system3ABS or ESC4Auxiliary electric heating - circuit 25Auxiliary electric heating - circuit 36Automatic gearbox7Engine control unit8Windscreen wipers9Central control unit, battery data module10ABS or ESC11Not assigned12Engine components13Brake pedal switch14Engine components, coil for the fuel pump relay, radiator fan, cooling

pump15Engine control unit16Starter17Engine control unit18Engine components, coils of the relay for auxiliary electric heater19Lambda probe20Glow plug system, crankcase ventilation heater

Replacing bulbs

Introduction

This chapter contains information on the following subjects:

Bulb arrangement in the headlights

178

Replacing the high beam bulb (halogen headlights)

179

Replacing bulb for main beam, daytime running lights and parking light

179

Changing the front turn signal bulb

180

Replacing the bulb for the fog light

180

177Fuses and light bulbs

Page 195 of 208

Emergency equipmentFire extinguisher160

First aid kit160

Jack161

Vehicle tool kit161

Warning triangle160

Emergency wheel Stow

162

Emission control system Warning light

34

Emissions184

Engine Running-in

106

Starting the engine98

Warning messages36

Engine compartment143

Brake fluid150

Overview145

Vehicle battery150

Engine number183

engine oil specification

146

Engine oil146

change146

Checking147

Replenishing147

Warning light37

EPC Warning light

34

ESC Operation

110

Warning light33

F

Fastening elements

82

Fatigue detection119

Function119

Information messages119

Films135

Fire extinguisher160

First aid kit160

Flashing60

Floor covering in the luggage compartment

86

Fog lights Warning light

35

Fog Lights61

Footmats103

refer to footmats103

Force limit Power windows

58

Front airbag15

Front Assist116

Disable/enable118

Distance warning117

Information messages118

Operation117

Radar sensor116

Warning and automatic braking117

Warning light38

fuel lead-free petrol

141

Fuel140

Diesel142

Fuel gauge30

refer to Fuel140

Refuelling141

Warning light35

Fuel consumption184

Fuel reserve Warning light

35

Fuses Assignment

174

Assignment of fuses in the dash panel175

Colour coding174

Fuse assignment in the engine compartment177

Replacing174

Fuses in the engine compartment Assignment

177

G

Gear change Gear recommendation

39

Information on the selected gear39

Gear changing Gear stick

103

General view Cockpit

27

Genuine parts131

Glasses compartment78

Glow plug system Warning light

34

H

Handbrake

102

Warning light32

Hazard warning light system62

HBA111

Head airbag17

Headlight cleaning system Headlight cleaning system

67

Headlights Bulb arrangement

178

Driving abroad63

Headlight cleaning system67

Headlights with CORNER function62

Head restraints69

Adjust height69

Headrest, removing and installing

70

Heating90

Air distribution control93

Controls91

Exterior mirror68

Rear window64

Seats70

Heating rear window64

HHC111

193Index

Page 198 of 208

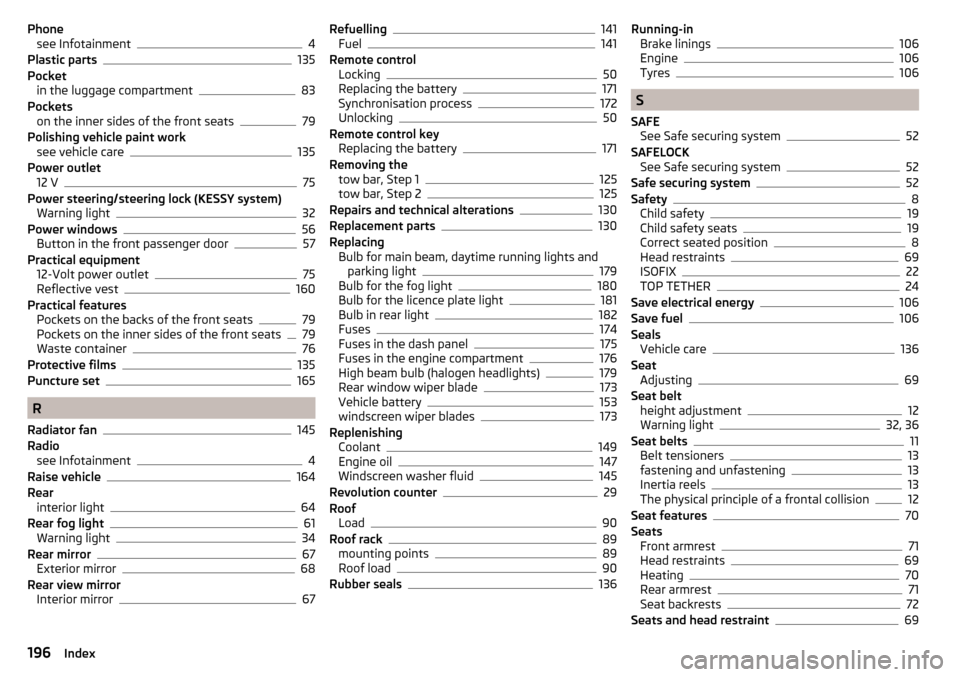

Phonesee Infotainment4

Plastic parts135

Pocket in the luggage compartment

83

Pockets on the inner sides of the front seats

79

Polishing vehicle paint work see vehicle care

135

Power outlet 12 V

75

Power steering/steering lock (KESSY system) Warning light

32

Power windows56

Button in the front passenger door57

Practical equipment 12-Volt power outlet

75

Reflective vest160

Practical features Pockets on the backs of the front seats

79

Pockets on the inner sides of the front seats79

Waste container76

Protective films135

Puncture set165

R

Radiator fan

145

Radio see Infotainment

4

Raise vehicle164

Rear interior light

64

Rear fog light61

Warning light34

Rear mirror67

Exterior mirror68

Rear view mirror Interior mirror

67

Refuelling141

Fuel141

Remote control Locking

50

Replacing the battery171

Synchronisation process172

Unlocking50

Remote control key Replacing the battery

171

Removing the tow bar, Step 1

125

tow bar, Step 2125

Repairs and technical alterations130

Replacement parts130

Replacing Bulb for main beam, daytime running lights andparking light

179

Bulb for the fog light180

Bulb for the licence plate light181

Bulb in rear light182

Fuses174

Fuses in the dash panel175

Fuses in the engine compartment176

High beam bulb (halogen headlights)179

Rear window wiper blade173

Vehicle battery153

windscreen wiper blades173

Replenishing Coolant

149

Engine oil147

Windscreen washer fluid145

Revolution counter29

Roof Load

90

Roof rack89

mounting points89

Roof load90

Rubber seals136

Running-in Brake linings106

Engine106

Tyres106

S

SAFE See Safe securing system

52

SAFELOCK See Safe securing system

52

Safe securing system52

Safety8

Child safety19

Child safety seats19

Correct seated position8

Head restraints69

ISOFIX22

TOP TETHER24

Save electrical energy106

Save fuel106

Seals Vehicle care

136

Seat Adjusting

69

Seat belt height adjustment

12

Warning light32, 36

Seat belts11

Belt tensioners13

fastening and unfastening13

Inertia reels13

The physical principle of a frontal collision12

Seat features70

Seats Front armrest

71

Head restraints69

Heating70

Rear armrest71

Seat backrests72

Seats and head restraint69

196Index