warning light SKODA RAPID SPACEBACK 2015 1.G Workshop Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2015, Model line: RAPID SPACEBACK, Model: SKODA RAPID SPACEBACK 2015 1.GPages: 208, PDF Size: 29.2 MB

Page 118 of 208

NoteDuring control, speed can be increased by pressing the accelerator pedal. Re-

leasing the accelerator pedal will cause the speed to drop again to the set

speed.

Front Assist

Introduction

This chapter contains information on the following subjects:

Radar sensor

116

Operation

117

Distance warning (dangerous distance)

117

Warning and automatic braking

117

Disable/enable

118

Information messages

118

The Front Assist (hereinafter referred to as the system) warns you of the dan-

ger of a collision with a vehicle or another obstacle in front of the vehicle, and

tries to avoid a collision or mitigate its consequences by automatically applying

the brakes where necessary.

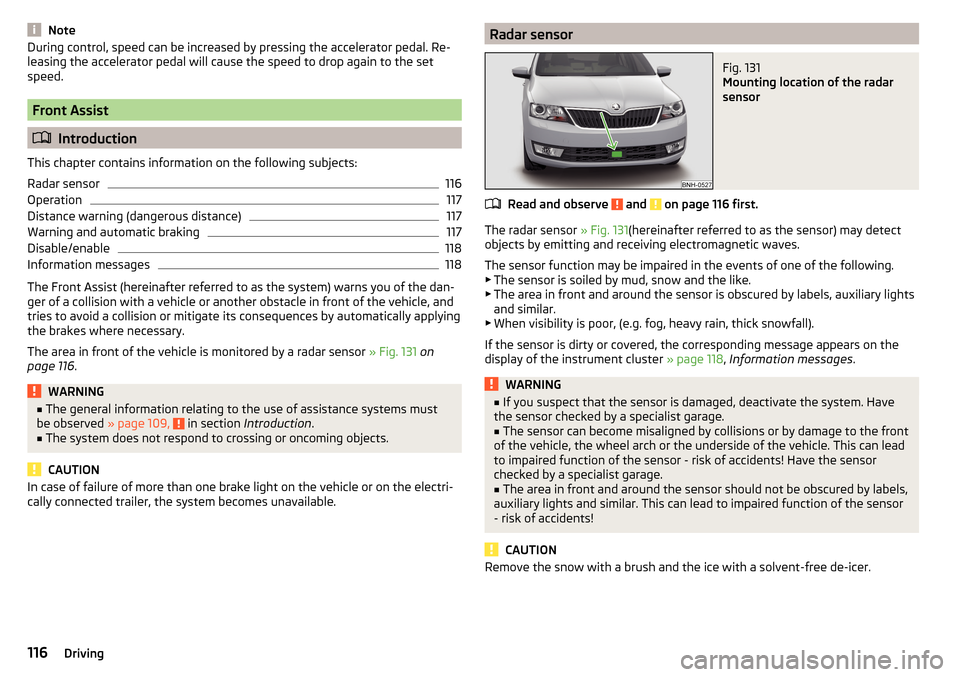

The area in front of the vehicle is monitored by a radar sensor » Fig. 131 on

page 116 .

WARNING■

The general information relating to the use of assistance systems must

be observed » page 109, in section Introduction .■

The system does not respond to crossing or oncoming objects.

CAUTION

In case of failure of more than one brake light on the vehicle or on the electri-

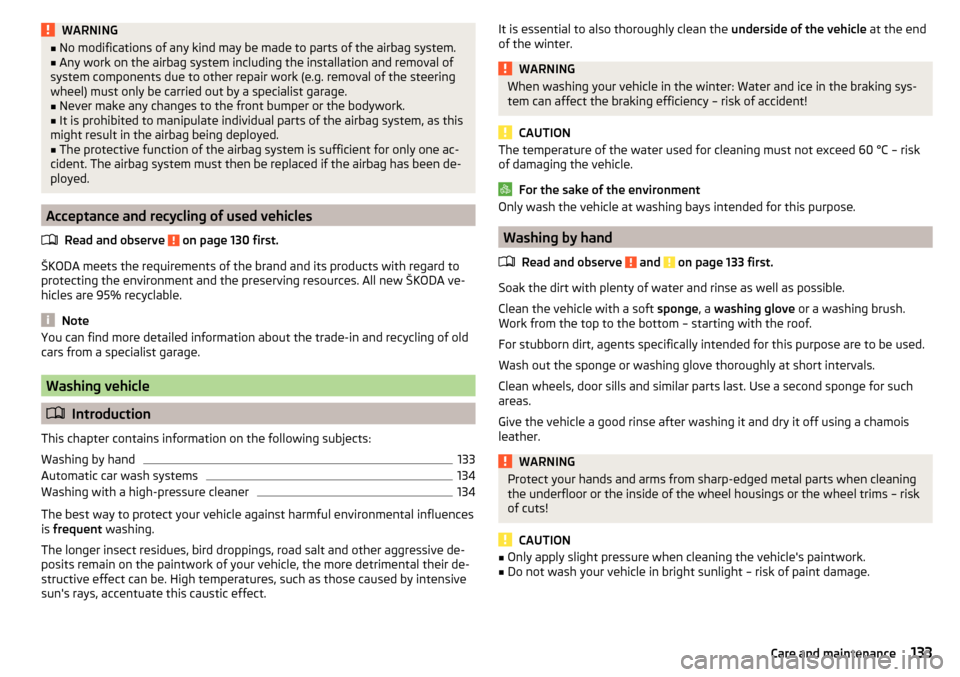

cally connected trailer, the system becomes unavailable.Radar sensorFig. 131

Mounting location of the radar

sensor

Read and observe and on page 116 first.

The radar sensor » Fig. 131(hereinafter referred to as the sensor) may detect

objects by emitting and receiving electromagnetic waves.

The sensor function may be impaired in the events of one of the following. ▶ The sensor is soiled by mud, snow and the like.

▶ The area in front and around the sensor is obscured by labels, auxiliary lights

and similar.

▶ When visibility is poor, (e.g. fog, heavy rain, thick snowfall).

If the sensor is dirty or covered, the corresponding message appears on the

display of the instrument cluster » page 118, Information messages .

WARNING■

If you suspect that the sensor is damaged, deactivate the system. Have

the sensor checked by a specialist garage.■

The sensor can become misaligned by collisions or by damage to the front

of the vehicle, the wheel arch or the underside of the vehicle. This can lead

to impaired function of the sensor - risk of accidents! Have the sensor

checked by a specialist garage.

■

The area in front and around the sensor should not be obscured by labels,

auxiliary lights and similar. This can lead to impaired function of the sensor

- risk of accidents!

CAUTION

Remove the snow with a brush and the ice with a solvent-free de-icer.116Driving

Page 122 of 208

The tyre pressure monitoring function (hereinafter referred to as the system)

monitors the tyre pressure while driving.

When changing the tyre inflation pressure, the warning light illuminates

in

the instrument cluster and an audible signal is heard.

Information on the procedure for the notification of change of tyre inflation pressure » page 34 .

The system can only function properly if the tyres have the prescribed inflation

pressure and this pressure values are stored in the system.WARNING■ The general information relating to the use of assistance systems must

be observed » page 109, in section Introduction .■

Having the correct tyre inflation pressure is always the driver's responsi-

bility. Tyre pressure should be checked regularly » page 155.

■

The system cannot warn in case of very rapid tyre inflation pressure loss,

e.g. in case of sudden tyre damage.

Save tyre pressure values

Read and observe

on page 120 first.

The tyre pressure values are always stored in the system, if one of the follow-

ing events occurs.

▶ Change of tyre inflation pressure.

▶ Change one or more wheels.

▶ Change in position of a wheel on the vehicle.

▶ The warning light in the instrument cluster.

The storage of the tyre pressure values depends on equipment, either in the

infotainment or by pressing a button.

WARNINGBefore storing the pressures, the tyres must be inflated to the specified in-

flation pressure » page 155. When storing incorrect pressure values, the

system could possibly not issue any warnings, even with a too low tyre

pressure.

CAUTION

The tyre pressure values are to be saved every 10,000 km or once annually to

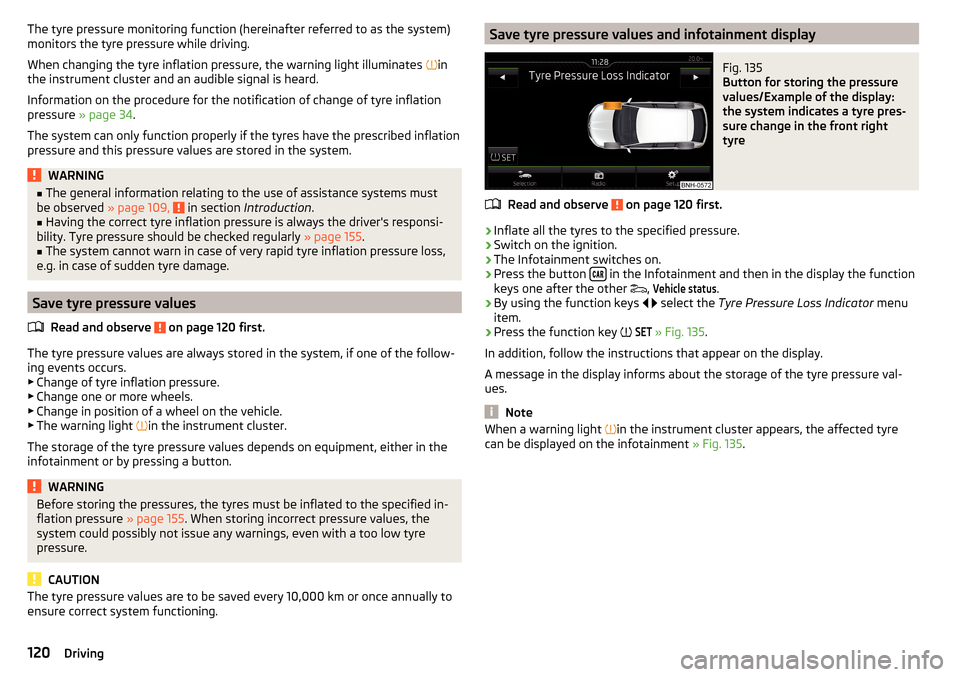

ensure correct system functioning.Save tyre pressure values and infotainment displayFig. 135

Button for storing the pressure

values/Example of the display:

the system indicates a tyre pres-

sure change in the front right

tyre

Read and observe on page 120 first.

›

Inflate all the tyres to the specified pressure.

›

Switch on the ignition.

›

The Infotainment switches on.

›

Press the button in the Infotainment and then in the display the function

keys one after the other ,

Vehicle status

.

›

By using the function keys

select the

Tyre Pressure Loss Indicator menu

item.

›

Press the function key

SET

» Fig. 135

.

In addition, follow the instructions that appear on the display.

A message in the display informs about the storage of the tyre pressure val-

ues.

Note

When a warning light in the instrument cluster appears, the affected tyre

can be displayed on the infotainment » Fig. 135.120Driving

Page 123 of 208

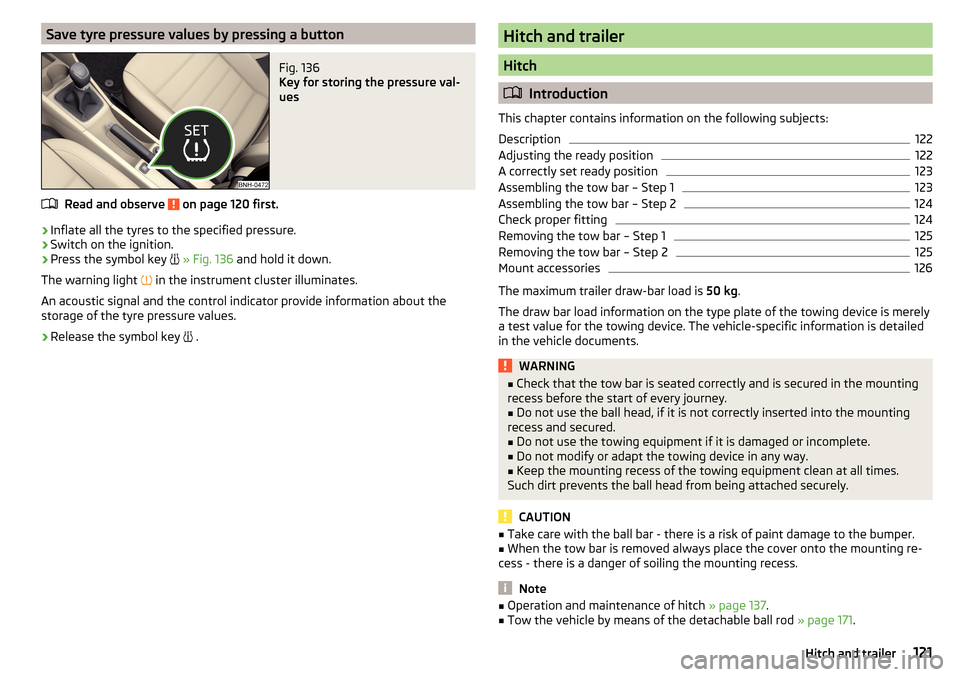

Save tyre pressure values by pressing a buttonFig. 136

Key for storing the pressure val-

ues

Read and observe on page 120 first.

›

Inflate all the tyres to the specified pressure.

›

Switch on the ignition.

›

Press the symbol key

» Fig. 136 and hold it down.

The warning light in the instrument cluster illuminates.

An acoustic signal and the control indicator provide information about the

storage of the tyre pressure values.

›

Release the symbol key .

Hitch and trailer

Hitch

Introduction

This chapter contains information on the following subjects:

Description

122

Adjusting the ready position

122

A correctly set ready position

123

Assembling the tow bar – Step 1

123

Assembling the tow bar – Step 2

124

Check proper fitting

124

Removing the tow bar – Step 1

125

Removing the tow bar – Step 2

125

Mount accessories

126

The maximum trailer draw-bar load is 50 kg.

The draw bar load information on the type plate of the towing device is merely

a test value for the towing device. The vehicle-specific information is detailed

in the vehicle documents.

WARNING■ Check that the tow bar is seated correctly and is secured in the mounting

recess before the start of every journey.■

Do not use the ball head, if it is not correctly inserted into the mounting

recess and secured.

■

Do not use the towing equipment if it is damaged or incomplete.

■

Do not modify or adapt the towing device in any way.

■

Keep the mounting recess of the towing equipment clean at all times.

Such dirt prevents the ball head from being attached securely.

CAUTION

■ Take care with the ball bar - there is a risk of paint damage to the bumper.■When the tow bar is removed always place the cover onto the mounting re-

cess - there is a danger of soiling the mounting recess.

Note

■ Operation and maintenance of hitch » page 137.■Tow the vehicle by means of the detachable ball rod » page 171.121Hitch and trailer

Page 129 of 208

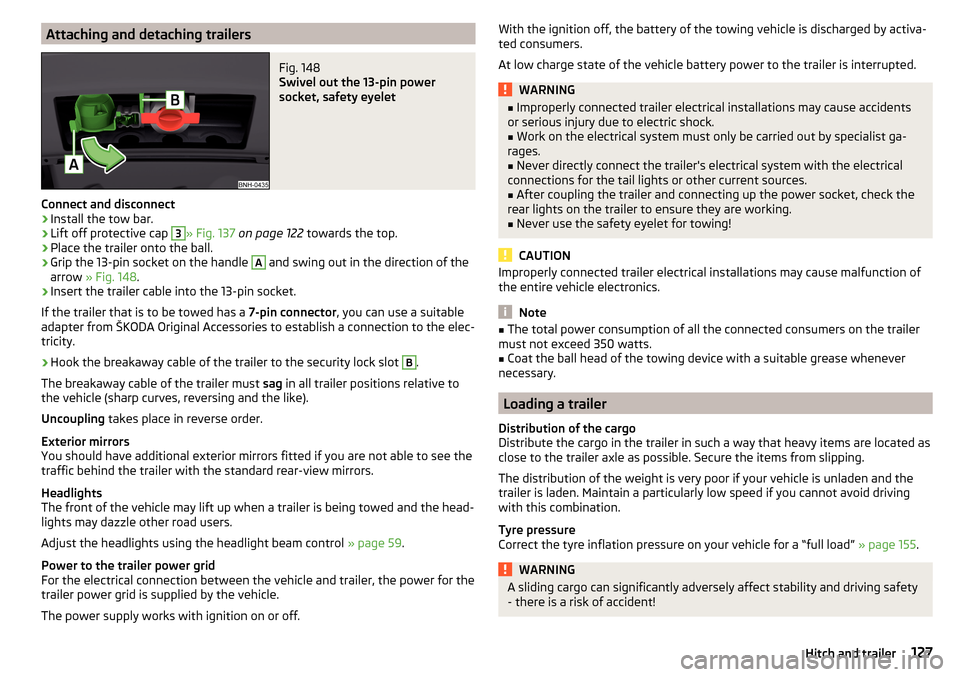

Attaching and detaching trailersFig. 148

Swivel out the 13-pin power

socket, safety eyelet

Connect and disconnect

›

Install the tow bar.

›

Lift off protective cap

3

» Fig. 137 on page 122 towards the top.

›

Place the trailer onto the ball.

›

Grip the 13-pin socket on the handle

A

and swing out in the direction of the

arrow » Fig. 148 .

›

Insert the trailer cable into the 13-pin socket.

If the trailer that is to be towed has a 7-pin connector, you can use a suitable

adapter from ŠKODA Original Accessories to establish a connection to the elec-

tricity.

›

Hook the breakaway cable of the trailer to the security lock slot

B

.

The breakaway cable of the trailer must sag in all trailer positions relative to

the vehicle (sharp curves, reversing and the like).

Uncoupling takes place in reverse order.

Exterior mirrors

You should have additional exterior mirrors fitted if you are not able to see the

traffic behind the trailer with the standard rear-view mirrors.

Headlights

The front of the vehicle may lift up when a trailer is being towed and the head-

lights may dazzle other road users.

Adjust the headlights using the headlight beam control » page 59.

Power to the trailer power grid

For the electrical connection between the vehicle and trailer, the power for the

trailer power grid is supplied by the vehicle.

The power supply works with ignition on or off.

With the ignition off, the battery of the towing vehicle is discharged by activa- ted consumers.

At low charge state of the vehicle battery power to the trailer is interrupted.WARNING■ Improperly connected trailer electrical installations may cause accidents

or serious injury due to electric shock.■

Work on the electrical system must only be carried out by specialist ga-

rages.

■

Never directly connect the trailer's electrical system with the electrical

connections for the tail lights or other current sources.

■

After coupling the trailer and connecting up the power socket, check the

rear lights on the trailer to ensure they are working.

■

Never use the safety eyelet for towing!

CAUTION

Improperly connected trailer electrical installations may cause malfunction of

the entire vehicle electronics.

Note

■ The total power consumption of all the connected consumers on the trailer

must not exceed 350 watts.■

Coat the ball head of the towing device with a suitable grease whenever

necessary.

Loading a trailer

Distribution of the cargo

Distribute the cargo in the trailer in such a way that heavy items are located as

close to the trailer axle as possible. Secure the items from slipping.

The distribution of the weight is very poor if your vehicle is unladen and the

trailer is laden. Maintain a particularly low speed if you cannot avoid driving

with this combination.

Tyre pressure

Correct the tyre inflation pressure on your vehicle for a “full load” » page 155.

WARNINGA sliding cargo can significantly adversely affect stability and driving safety

- there is a risk of accident!127Hitch and trailer

Page 130 of 208

Trailer loadThe permissible trailer load must not be exceeded under any circumstances.Permissible trailer loadEngineGearboxPermissible trailer load, braked (kg)Permissible trailer load, unbraked (kg)Gradients of up to 12 %Gradients of up to 8 %1.2 l/66 kW TSIMG9001000580DSG90010005901.2 l/81 kW TSIMG110012005901.4 l/92 kW TSIDSG12001200600DSG (Green tec)120012006101.6 l./81 kW MPIMG10001100580AG100011006001.4 l/66 kW TDI CRMG10001100610DSG100011006201.6 l/85 kW TDI CRMG12001200630WARNINGThe maximum permissible axle and draw-bar load and the permissible

weight of the trailer must not exceed - this could cause an accident!

Towing a trailer

Driving speed

For safety reasons, do not drive faster than 80 km/h when towing a trailer.

Immediately reduce your speed as soon as even the slightest swaying of the

trailer is detected. Never attempt to stop the trailer from “swaying” by acceler-

ating.

Brakes

Apply the brakes in good time! If the trailer is fitted with a trailer brake, apply

the brakes gently at first, then brake firmly. This will avoid brake jolts resulting

from the trailer wheels locking.

On downhill sections shift down a gear in good time to also use the engine as

a brake.

WARNINGAlways drive particularly carefully with the trailer.

CAUTION

If you tow a trailer frequently, you should also have your vehicle inspected be-

tween service intervals.

Anti-theft alarm system

When the vehicle is locked, the alarm is activated when the electrical connec-

tion to the trailer is interrupted.

Always switch off the anti-theft alarm system before a trailer is coupled or un-

coupled » page 54 .

Conditions for including a trailer in the anti-theft alarm system. The vehicle is factory-fitted with an anti-theft alarm system and towing

device.

The trailer is electrically connected to the towing vehicle by means of the

trailer socket.

128Driving

Page 135 of 208

WARNING■No modifications of any kind may be made to parts of the airbag system.■Any work on the airbag system including the installation and removal of

system components due to other repair work (e.g. removal of the steering

wheel) must only be carried out by a specialist garage.■

Never make any changes to the front bumper or the bodywork.

■

It is prohibited to manipulate individual parts of the airbag system, as this

might result in the airbag being deployed.

■

The protective function of the airbag system is sufficient for only one ac-

cident. The airbag system must then be replaced if the airbag has been de-

ployed.

Acceptance and recycling of used vehicles

Read and observe

on page 130 first.

ŠKODA meets the requirements of the brand and its products with regard to

protecting the environment and the preserving resources. All new ŠKODA ve-

hicles are 95% recyclable.

Note

You can find more detailed information about the trade-in and recycling of old

cars from a specialist garage.

Washing vehicle

Introduction

This chapter contains information on the following subjects:

Washing by hand

133

Automatic car wash systems

134

Washing with a high-pressure cleaner

134

The best way to protect your vehicle against harmful environmental influences

is frequent washing.

The longer insect residues, bird droppings, road salt and other aggressive de-

posits remain on the paintwork of your vehicle, the more detrimental their de-

structive effect can be. High temperatures, such as those caused by intensive

sun's rays, accentuate this caustic effect.

It is essential to also thoroughly clean the underside of the vehicle at the end

of the winter.WARNINGWhen washing your vehicle in the winter: Water and ice in the braking sys-

tem can affect the braking efficiency – risk of accident!

CAUTION

The temperature of the water used for cleaning must not exceed 60 °C – risk

of damaging the vehicle.

For the sake of the environment

Only wash the vehicle at washing bays intended for this purpose.

Washing by hand

Read and observe

and on page 133 first.

Soak the dirt with plenty of water and rinse as well as possible.

Clean the vehicle with a soft sponge, a washing glove or a washing brush.

Work from the top to the bottom – starting with the roof.

For stubborn dirt, agents specifically intended for this purpose are to be used. Wash out the sponge or washing glove thoroughly at short intervals.

Clean wheels, door sills and similar parts last. Use a second sponge for such areas.

Give the vehicle a good rinse after washing it and dry it off using a chamois

leather.

WARNINGProtect your hands and arms from sharp-edged metal parts when cleaning

the underfloor or the inside of the wheel housings or the wheel trims – risk

of cuts!

CAUTION

■ Only apply slight pressure when cleaning the vehicle's paintwork.■Do not wash your vehicle in bright sunlight – risk of paint damage.133Care and maintenance

Page 136 of 208

Automatic car wash systemsRead and observe

and on page 133 first.

The usual precautionary measures must be taken before washing the vehicle

in an automatic car wash system (e.g. closing the windows and the sliding/tilt-

ing roof etc.).

If your vehicle is fitted with any particular attached parts, such as a spoiler,

roof rack system etc., it is best to consult the operator of the car wash system

beforehand.

After an automatic wash with wax treatment, the lips of the wipers should be

cleaned with cleaning agents specially designed for the purpose, and then de-

greased.

CAUTION

■ Before driving through a car wash fold in the exterior mirrors - there is a risk

of damage.■

For vehicles with roof antenna the antenna rod should be unscrewed before

driving through a car wash - there is a risk of damage.

Washing with a high-pressure cleaner

Read and observe

and on page 133 first.

When washing the vehicle with a high-pressure cleaner, the instructions for

use of the equipment must be observed. This applies in particular to the pres-

sure used and to the spraying distance .

Maintain a sufficiently large distance to the parking aid sensors and soft mate-

rials such as rubber hoses or insulation material.

CAUTION

■ The films should not be washed with any high-pressure cleaners - risk of

damage » page 135 .■

Do not aim the water jet directly at the lock cylinders or the door or opening

joints when washing the vehicle in the winter – there is a risk of freezing.

■

The sensors of the parking aid can be sprayed only for a short time and there

must be a minimum distance of 10 cm - there is a risk of damage.

Cleaning vehicle exterior

Introduction

This chapter contains information on the following subjects:

Vehicle paint work

135

Films

135

Plastic parts

135

Rubber seals

136

Chrome and anodized parts

136

Windows and external mirrors

136

Headlight glasses

136

Door closing cylinder

137

Cavity protection

137

Jack

137

Wheels

137

Towing device and mounting recess

137

Under-body protection

138

Wiper blades

138

We recommend using vehicle care products from ŠKODA Original Accessories.

These are available from ŠKODA Partners. The usage instructions on the pack-

age must be observed.

WARNING■ Vehicle care products may be harmful to your health if not used according

to the instructions.■

Always keep the vehicle care products safe from people who are not com-

pletely independent, e.g. children - there is a danger of poisoning!

■

Protect your hands and arms from sharp-edged metal parts when clean-

ing the underfloor, the inside of the wheel housings or the wheel trims –

risk of cuts!

CAUTION

■ Do not use any insect sponges, rough kitchen sponges or similar cleaning

products – risk of damaging the paintwork surface.■

Cleaners that contain solvents can damage the material being cleaned.

134General Maintenance

Page 139 of 208

CAUTION■The headlights are never to be wiped dry - there is a risk of damaging the

protective lacquer and the headlight glass subsequently developing cracks.■

Do not use sharp objects to clean the glasses - there is a risk of damaging

the protective lacquer and the headlight glasses subsequently developing

cracks.

■

Do not use any aggressive cleaning or chemical solvent products to clean the

headlights – risk of damaging the headlight lenses.

Door closing cylinder

Read and observe

and on page 134 first.

Specific products must be used for de-icing door lock cylinders.

CAUTION

Make sure that as little water as possible gets into the locking cylinder when

washing the vehicle - there is a risk of freezing the lock cylinder!

Cavity protection

Read and observe

and on page 134 first.

All the cavities of your vehicle which are at risk from corrosion are protectedfor life by a layer of protective wax applied in the factory.

This wax protection does not need to be inspected or re-applied.

If any small amount of wax flow out of the cavities at high temperatures, these

must be removed with a plastic scraper and the stains cleaned using a petrole-

um cleaner.

WARNINGSafety regulations should be observed when using petroleum cleaner to re-

move wax – risk of fire!

Jack

Read and observe

and on page 134 first.

The jack is maintenance-free.

If necessary, the moving parts of the jack should be lubricated with a suitable lubricant.

Wheels

Read and observe

and on page 134 first.

Wheel rims

Also thoroughly wash the wheel rims when washing the vehicle on a regular basis.

Regularly remove salt and brake abrasion, otherwise the rim material will be

corroded.

Light alloy wheels

After washing thoroughly, treat the wheel rims with a protective product for

light alloy wheels.

For the treatment of wheel rims do not use products which may cause damage

to the paint on the rims.

CAUTION

■ Damage to the paint layer on the wheel rims must be touched up immediate-

ly.■

Severe layers of dirt on the wheels can also result in wheel imbalance. This

may show itself in the form of a wheel vibration which is transmitted to the

steering wheel which, in certain circumstances, can cause premature wear of

the steering. This means it is necessary to remove the dirt.

Towing device and mounting recess

Read and observe

and on page 134 first.

Close the mounting recess with the cover to prevent any dirt from getting in.

If dirt is present, clean the inner surfaces of the mounting recess and treat

with a suitable preservative.

Always check the ball head before hitching a trailer. Apply a suitable grease, if

necessary.

Use the protective cover when stowing away the tow bar, in order to stop the

boot from getting dirty.

CAUTION

Apply grease to the inner part of the mounting recess. Make sure you do not

remove any grease.137Care and maintenance

Page 143 of 208

Petrol and diesel refuellingFig. 150

Open fuel filler flap / unscrew tank cap / place the tank cap on

the fuel filler flap

Read and observe

and on page 140 first.

Refuelling can be done if the following conditions are met. The vehicle is unlocked.

The engine and the ignition are switched off.

›

Press on the fuel filler flap in the direction of the arrow

1

» Fig. 150 .

›

Open the flap in the direction of the arrow

2

.

›

Unscrew the tank cap in the direction of the arrow

3

.

›

Remove the tank cap and place on top of the fuel filler flap in direction of ar-

row

4

.

›

Insert the pump nozzle into the fuel filler tube as far as it will go.

The fuel tank is full just as soon as the pump nozzle switches off for the first

time »

.

›

Remove the pump nozzle from the fuel filler neck and put it back in the

pump.

›

Screw in the tank cap in the opposite direction of the arrow

3

until it audibly

clicks into place.

›

Close the fuel filler flap until it clicks into place.

Check that the fuel filler flap is closed properly.

WARNINGInstructions for filling the reserve canister■Never fill the reserve can inside the vehicle.■

Never place the reserve can on the vehicle.

■

Always place the reserve can on the floor.

■

We do not recommend carrying any fuel canisters in your vehicle for safe-

ty reasons. In the event of an accident, these canisters can become dam-

aged and fuel may escape – risk of fire!

CAUTION

■ The fuel tank is full as soon as the pump nozzle switches off for the first

time, provided the nozzle has been operated properly. Do not continue refuel-

ling.■

Be careful when filling diesel fuel from the spare canister and then do this

slowly and cautiously – danger of contaminating the body.

Note

The fuel tank has a capacity of about 55 litres, containing a reserve of approx.

7 litres .

Lead-free petrol

The correct fuel grades for your vehicle are specified on the inside of the fuel

filler flap.

Read and observe

and on page 140 first.

The vehicle can only be operated with unleaded petrol that meets the EN 2281)

standard.

All petrol engines can be operated using petrol that contains at most 10% bio-

ethanol (E10).

Unleaded petrol 95/min. 92 and 93 RON/ROZ

We recommend using unleaded fuel with an octane rating of 95 RON. Unlea-

ded petrol with the octane ratings 92 or 93 RON can also be used, but may re-

sult in a slight loss in performance and slightly increased fuel consumption.

Unleaded petrol min. 95 RON / ROZ

Use unleaded fuel with the octane rating 95 RON or higher.

1)

In Germany also DIN 51626-1 or E10 for unleaded petrol with octane number 91 or 95 or DIN 51626-2 or E5

for unleaded petrol with octane number 95 and 98.

141Inspecting and replenishing

Page 147 of 208

Close the flap›Lift the bonnet.›

Decouple the bonnet support and press into the holder designed to hold it.

›

Let the bonnet drop into the lock carrier lock from a height of around 20 cm –

do not push it in !

Check that the bonnet is closed properly.

WARNING■ If you notice that the lock is not properly engaged while driving, stop the

vehicle immediately and close the bonnet – risk of accident!■

Make sure that when closing the bonnet, no body parts are crushed -

there is danger of injury!

CAUTION

Never open the bonnet by the locking lever » Fig. 151.

Engine compartment overview

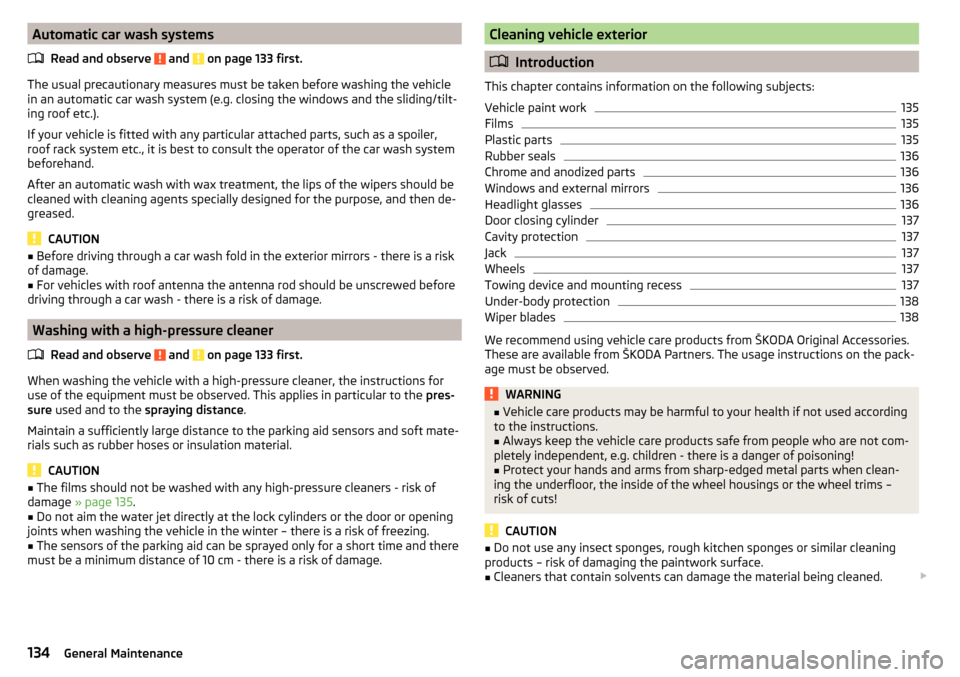

Fig. 152

Principle sketch: Engine compartment

Read and observe

and on page 143 first.

Layout of the engine compartment » Fig. 152

Coolant expansion reservoir

148

Windscreen washer fluid reservoir

145

Engine oil dipstick

147

Engine oil filler opening

147ABCDBrake fluid reservoir150

Vehicle battery

150

Note

The location of the inspection points in the engine compartment of petrol and

diesel engines is practically identical.

Radiator fan

Read and observe

and on page 143 first.

The radiator fan is powered by an electric motor. Operation is controlled ac-

cording to the temperature of the coolant.

WARNINGAfter switching off the ignition, the fan may intermittently continue to op-

erate for approx. 10 minutes.

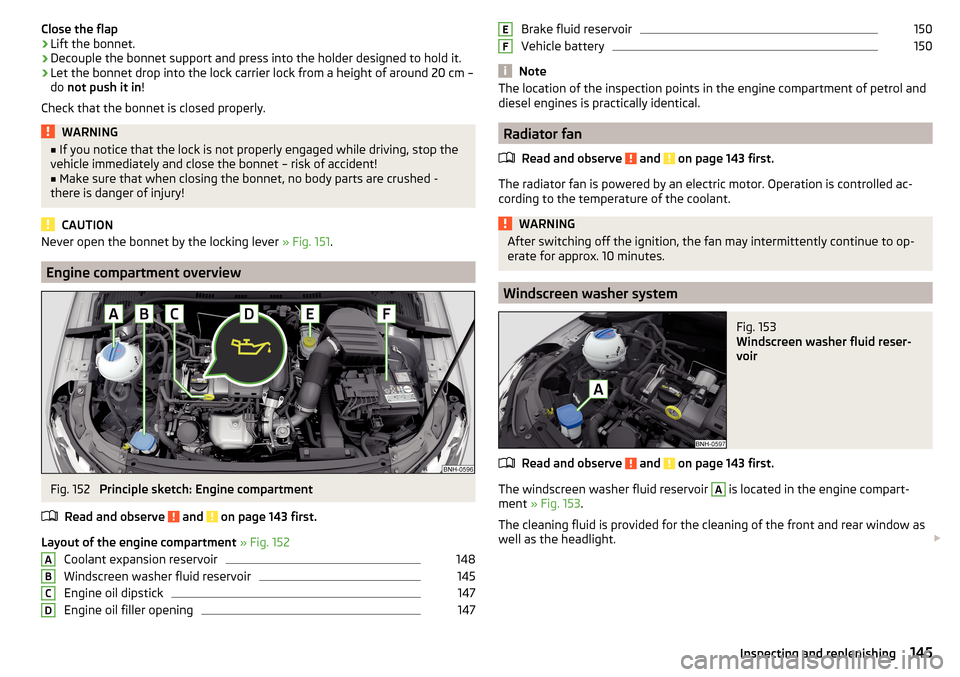

Windscreen washer system

Fig. 153

Windscreen washer fluid reser-

voir

Read and observe and on page 143 first.

The windscreen washer fluid reservoir

A

is located in the engine compart-

ment » Fig. 153 .

The cleaning fluid is provided for the cleaning of the front and rear window as

well as the headlight.

EF145Inspecting and replenishing