jack points SKODA ROOMSTER 2006 1.G Owner's Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2006, Model line: ROOMSTER, Model: SKODA ROOMSTER 2006 1.GPages: 274, PDF Size: 48.64 MB

Page 150 of 274

Seat belts149

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

Important safety information regarding

the use of seat belts

The correct use of the seat belts considerably reduces the

risk of injury!

WARNING

•The belt webbing must not be jammed in-between at any point

or twisted, or chafe against any sharp edges.

•It is important that the belt webb ing is properly routed if the seat

belts are to offer their maximum protection ⇒page 150, “How are

seat belts correctly fastened?”.

•No two persons (also not children) should ever use a single seat

belt together.

•The maximum protection which seat belts can offer is only

achieved if you are correctly seated ⇒page 143, “Correct seated

position”.

•The belt webbing must not run across solid or fragile objects

(e.g. spectacles, ball-point pens, keys etc.) as this may be a cause

of injuries.

•Bulky, loose clothing (e.g. a winter coat over a jacket) does not

allow you to be correctly seated and impairs proper operation of

the seat belts.

•It is prohibited to use clamps or other objects to adjust seat

belts (e.g. for shortening the belts for smaller persons).

•The lock tongue should only be inserted into the lock which is

the correct one for your seat. Wrong use of the safety belt will

reduce its capacity to protect and the risk of injury increases.

•The backrests must not be tilted too far to the rear otherwise the

seatbelts can lose their effectiveness.

•The belt webbing must always be kept clean. Soiled belt

webbing may impair proper operation of the inertia reel

⇒ page 204, “Seat belts”.

•The slot of the belt tongue must not be blocked by paper or

similar objects otherwise the belt tongue will not lock in place prop-

erly.

•Inspect the seat belts regularly to ensure they are in good condi-

tion. If you find seat belts which have damage to the seat belt

webbing, seat belt connections, to the inertia reels or to the lock,

the relevant safety belt must be replaced by a specialist garage.

•The seat belts must not be removed or changed in any way. Do

not make an attempt to repair the seat belts yourself.

•Damaged seat belts which have been subjected to stress in an

accident and were therefore stretched, must be replaced - this is

best done by a specialist garage. The anchorage points of the belts

must also be inspected. The anchorage points for the belts should

also be checked.

•In certain countries it is possible to use seat belts which differ

in terms of their operation from the seat belts which are described

on the pages which follow.

WARNING (continued)

NKO 20 A05.book Page 149 Wednesday, June 21, 2006 1:42 PM

Page 242 of 274

Breakdown assistance241

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

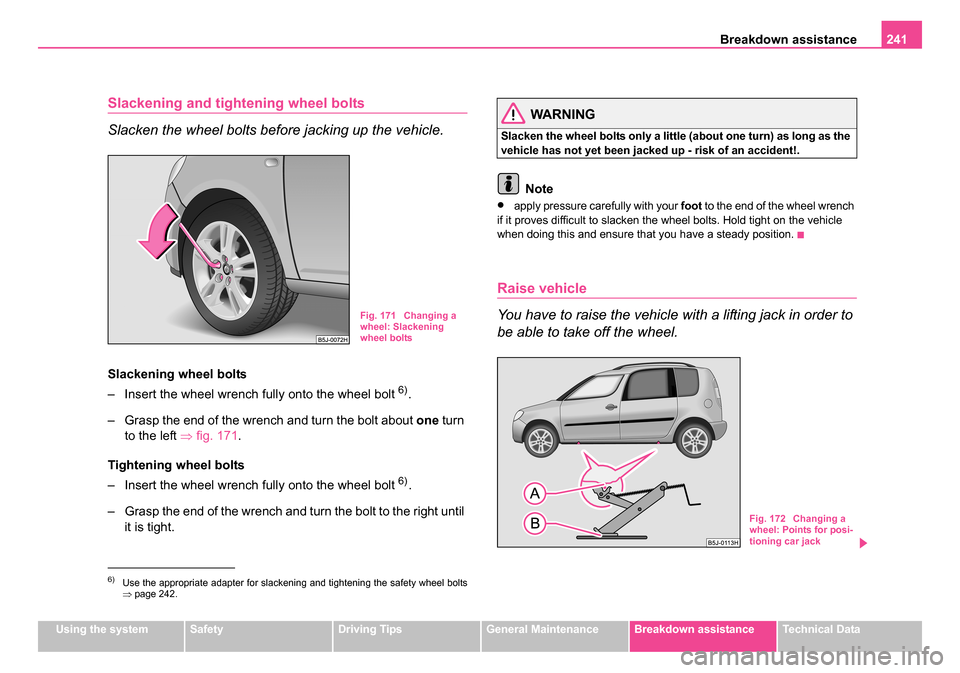

Slackening and tightening wheel bolts

Slacken the wheel bolts before jacking up the vehicle.

Slackening wheel bolts

– Insert the wheel wrench fully onto the wheel bolt

6).

– Grasp the end of the wrench and turn the bolt about one turn

to the left ⇒fig. 171 .

Tightening wheel bolts

– Insert the wheel wrench fully onto the wheel bolt

6).

– Grasp the end of the wrench and turn the bolt to the right until it is tight.

WARNING

Slacken the wheel bolts only a little (about one turn) as long as the

vehicle has not yet been jacked up - risk of an accident!.

Note

•apply pressure carefully with your foot to the end of the wheel wrench

if it proves difficult to slacken the wheel bolts. Hold tight on the vehicle

when doing this and ensure that you have a steady position.

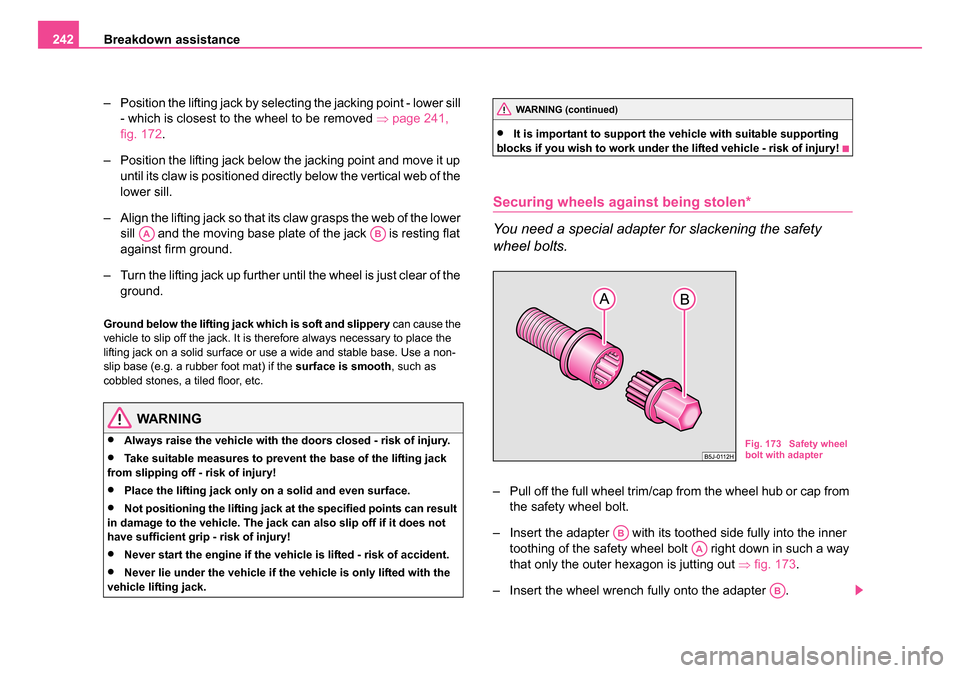

Raise vehicle

You have to raise the vehicle with a lifting jack in order to

be able to take off the wheel.

6)Use the appropriate adapter for slackening and tightening the safety wheel bolts

⇒ page 242.

Fig. 171 Changing a

wheel: Slackening

wheel bolts

Fig. 172 Changing a

wheel: Points for posi-

tioning car jack

NKO 20 A05.book Page 241 Wednesday, June 21, 2006 1:42 PM

Page 243 of 274

Breakdown assistance

242

– Position the lifting jack by selecting the jacking point - lower sill - which is closest to the wheel to be removed ⇒page 241,

fig. 172 .

– Position the lifting jack below the jacking point and move it up until its claw is positioned directly below the vertical web of the

lower sill.

– Align the lifting jack so that its claw grasps the web of the lower sill and the moving base plate of the jack is resting flat

against firm ground.

– Turn the lifting jack up further until the wheel is just clear of the ground.

Ground below the lifting jack which is soft and slippery can cause the

vehicle to slip off the jack. It is therefore always necessary to place the

lifting jack on a solid surface or use a wide and stable base. Use a non-

slip base (e.g. a rubber foot mat) if the surface is smooth, such as

cobbled stones, a tiled floor, etc.

WARNING

•Always raise the vehicle with the doors closed - risk of injury.

•Take suitable measures to prevent the base of the lifting jack

from slipping off - risk of injury!

•Place the lifting jack only on a solid and even surface.

•Not positioning the lifting jack at the specified points can result

in damage to the vehicle. The jack can also slip off if it does not

have sufficient grip - risk of injury!

•Never start the engine if the vehicle is lifted - risk of accident.

•Never lie under the vehicle if the vehicle is only lifted with the

vehicle lifting jack.

•It is important to support the ve hicle with suitable supporting

blocks if you wish to work under the lifted vehicle - risk of injury!

Securing wheels against being stolen*

You need a special adapter for slackening the safety

wheel bolts.

– Pull off the full wheel trim/cap from the wheel hub or cap from the safety wheel bolt.

– Insert the adapter with its toothed side fully into the inner toothing of the safety wheel bolt right down in such a way

that only the outer hexagon is jutting out ⇒fig. 173 .

– Insert the wheel wrench fully onto the adapter .

AAAB

WARNING (continued)

Fig. 173 Safety wheel

bolt with adapter

AB

AA

AB

NKO 20 A05.book Page 242 Wednesday, June 21, 2006 1:42 PM

Page 268 of 274

Index267

Environmental compatibility . . . . . . . . . 187, 191

ESP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Warning light . . . . . . . . . . . . . . . . . . . . . . 35

Exhaust gas Warning light . . . . . . . . . . . . . . . . . . . . . . 33

Exhaust gas inspection Warning light . . . . . . . . . . . . . . . . . . . . . . 33

Explanations . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Exterior mirror . . . . . . . . . . . . . . . . . . . . . . . . 66

Exterior mirror heater . . . . . . . . . . . . . . . . . . 66

F

Fastening elements . . . . . . . . . . . . . . . . . . . . 78

First-aid box . . . . . . . . . . . . . . . . . . . . . . . . . 235

Fixing net . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Fog lights . . . . . . . . . . . . . . . . . . . . . . . . 57, 257 Warning light . . . . . . . . . . . . . . . . . . . . . . 29

Fog lights with integrated turning light . . . . . . 57

Folding seats forwards . . . . . . . . . . . . . . . . . 73

Force limiter of the power windows . . . . . . . . 53

Front airbag . . . . . . . . . . . . . . . . . . . . . . . . . 156

Front armrest . . . . . . . . . . . . . . . . . . . . . . . . . 93

Front headlight . . . . . . . . . . . . . . . . . . . . . . 255

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205 Diesel . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Fuel gauge . . . . . . . . . . . . . . . . . . . . . . . . 14

Petrol . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Warning light . . . . . . . . . . . . . . . . . . . . . . 32

Fuel consumption . . . . . . . . . . . . . . . . . 20, 187 Saving energy . . . . . . . . . . . . . . . . . . . . 187 Fuel gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Fuel reserve

Warning light . . . . . . . . . . . . . . . . . . . . . . 32

Full wheel trim . . . . . . . . . . . . . . . . . . . . . . . 239

Fuse Assignment . . . . . . . . . . . . . . . . . . . . . . 250

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

G

Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Gearbox mechanical . . . . . . . . . . . . . . . . . . . . . . . 113

General view Cockpit . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Glow plug system . . . . . . . . . . . . . . . . . . . . 112 Warning light . . . . . . . . . . . . . . . . . . . . . . 30

H

Handbrake . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Hazard warning light system . . . . . . . . . . . . . 59Warning light . . . . . . . . . . . . . . . . . . . . . . 29

Head airbag . . . . . . . . . . . . . . . . . . . . . . . . . 161

Head restraint . . . . . . . . . . . . . . . . . . . . . . . . 70

Headlight cleaning system . . . . . . . . . . . . . . . 65

Headlight flasher . . . . . . . . . . . . . . . . . . . . . . 60

Headlights Fog lights . . . . . . . . . . . . . . . . . . . . . . . . . 57

Headlight cleaning system . . . . . . . . . . . . 65

Heated windscreen washer nozzles . . . . . . . 63 Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Heating the front seats . . . . . . . . . . . . . . . . . . 71

Horn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

I

Ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Ignition lock . . . . . . . . . . . . . . . . . . . . . . . . . 110

Immobiliser . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Warning light . . . . . . . . . . . . . . . . . . . . . . . 32

Information display . . . . . . . . . . . . . . . . . . . . . 22

Instrument cluster . . . . . . . . . . . . . . . . . . . . . 13

Interior light Luggage compartment . . . . . . . . . . . . . . . 62

Interior lighting front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Interior monitor . . . . . . . . . . . . . . . . . . . . . . . . 50

Intermittent wiping . . . . . . . . . . . . . . . . . . . . . 63

ISOFIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

ISOFIX system . . . . . . . . . . . . . . . . . . . . . . . 174

J

Jacking points . . . . . . . . . . . . . . . . . . . . . . . 241

Jump-starting . . . . . . . . . . . . . . . . . . . . 243, 244

K

Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

NKO 20 A05.book Page 267 Wednesday, June 21, 2006 1:42 PM