check engine light SKODA ROOMSTER 2011 1.G User Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2011, Model line: ROOMSTER, Model: SKODA ROOMSTER 2011 1.GPages: 212, PDF Size: 3.3 MB

Page 82 of 212

For the sake of the environment

Never warm up the engine when the vehicle is standing. Drive off right away.

When driving the engine reaches its operating temperature more rapidly and the

pollutant emissions are lower.

Petrol engines These engines are fitted with a starter system which selects the correct fuel-air

mixture for every external air temperature.

●

Do not operate accelerator before and when starting engine.

● Interrupt the attempt at starting after 10 seconds if the engine does not start

right away and wait for about 30 seconds before repeating the attempt.

● It is possible that the fuse on the electrical fuel pump is defect if the engine

still does not start. Check the fuse and replace it if necessary ⇒ page 179.

● If the engine does not start, contact the nearest specialist garage to obtain

professional assistance.

It may be necessary, if the engine is very hot, to slightly depress the accelerator

after the engine has started.

Diesel engines Glow plug system

Diesel engines are equipped with a glow plug system, the pre-glow period being

controlled automatically in line with the coolant temperature and outside temper-

ature.

The pre-glow indicator light comes on after the ignition has been switched on.

You should not switch on any major electrical components during the heating

period otherwise the vehicle battery will be drained unnecessarily.

● You should start the engine immediately after the glow plug warning light

has gone out.

● The glow plug warning light will come on for about one second if the engine is

at a normal operating temperature or if the outside temperature is above +5 °C.

This means that you can start the engine right away.

● Interrupt the attempt at starting after 10 seconds if the engine does not start

right away and wait for about 30 seconds before repeating the attempt. ●

It is possible that the fuse on the diesel pre-glow system is defect if the en-

gine still does not start. Check the fuse and replace it if necessary ⇒ page 179.

● Contact the nearest specialist garage to obtain professional assistance.

Starting the engine after fuel tank has run dry

It may take longer than normal to start the engine after refuelling if the fuel tank

has run completely dry - up to one minute. This is because the fuel system must

first of all be filled while the attempting to start the engine.

Switching off the engine –

The engine can be switched off by turning the ignition key into position 1 ⇒

fig. 78 . WARNING

● Never switch off the engine before the vehicle is stationary - risk of acci-

dent!

● The brake booster only operates when the engine is running. Greater

physical effort for braking is required when engine is switched off. Because if

you do not stop as normal, this can cause an accident and severe injuries. CAUTION

you should not switch the engine off right away at the end of your journey after

the engine has been operated for a lengthy period at high loads but should be al-

lowed it to run at idling speed for about 2

minutes. This prevents any accumula-

tion of heat when the engine is switched off. Note

● The radiator fan may continue running for a further 10 minutes or so after the

engine and the ignition have been switched off. The coolant fan may, however, al-

so switch on again after some time if the coolant temperature rises because of an

accumulation of heat in the engine or if the engine is warm and the engine com-

partment is additionally heated by strong sunlight.

● This is why particular care is required when carrying out any work in the en-

gine compartment ⇒

page 150, Working in the engine compartment. 80

Starting-off and Driving

Page 133 of 212

WARNING

● When the warning light lights up, immediately reduce the speed and

avoid sudden steering and brake manoeuvres. Please stop the vehicle without

delay at the nearest possible stop and inspect the tyres and their inflation

pressures.

● The driver is responsible for the correct tyre inflation pressures. For this

reason, the tyre inflation pressures must be checked regularly.

● Under certain circumstances (e.g. sporty style of driving, wintry or unpaved

roads) the warning light can be delayed or does not light up at all.

● The tyre pressure monitoring system does not take away the responsibility

from the driver for the correct tyre inflation pressure. Note

The tyre pressure monitoring system:

● does not replace the regular tyre inflation pressure control, because the sys-

tem cannot detect an even pressure loss,

● cannot warn in case of very rapid tyre inflation pressure loss, e.g. in case of

sudden tyre damage. In this case carefully bring the vehicle to a standstill without

sudden steering movements and without sharp braking.

● In order to ensure a proper functioning of the tyre inflation pressure-control

system, it is necessary to carry out the basic setting again every 10 000 km or 1x a

year.

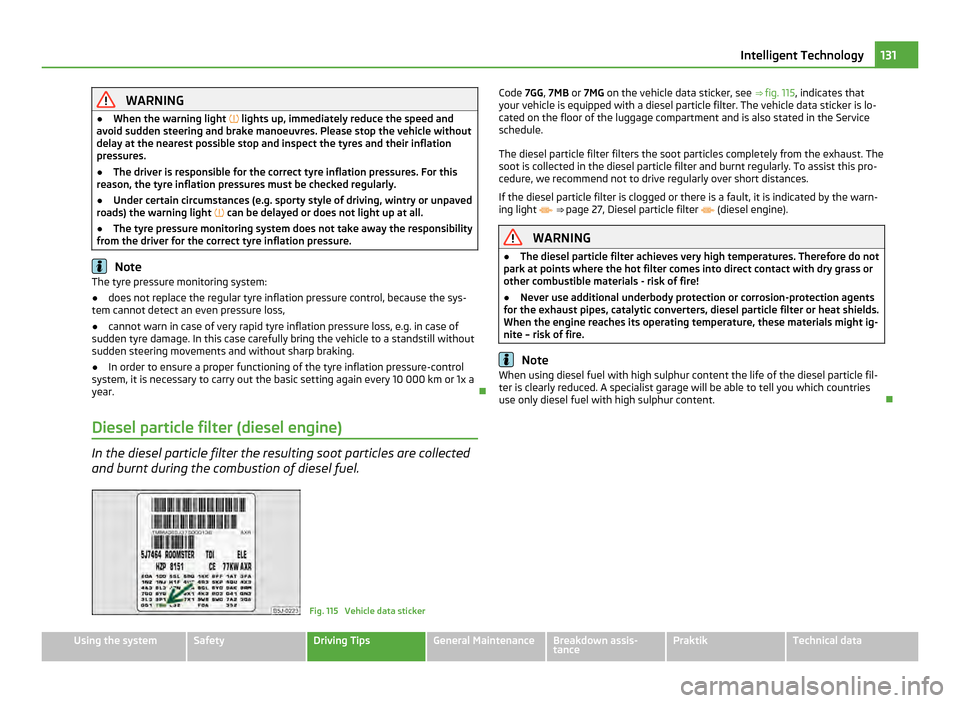

Diesel particle filter (diesel engine) In the diesel particle filter the resulting soot particles are collected

and burnt during the combustion of diesel fuel. Fig. 115 Vehicle data stickerCode 7GG

, 7MB or 7MG on the vehicle data sticker, see ⇒ fig. 115, indicates that

your vehicle is equipped with a diesel particle filter. The vehicle data sticker is lo-

cated on the floor of the luggage compartment and is also stated in the Service

schedule.

The diesel particle filter filters the soot particles completely from the exhaust. The

soot is collected in the diesel particle filter and burnt regularly. To assist this pro-

cedure, we recommend not to drive regularly over short distances.

If the diesel particle filter is clogged or there is a fault, it is indicated by the warn-

ing light ⇒

page 27, Diesel particle filter (diesel engine). WARNING

● The diesel particle filter achieves very high temperatures. Therefore do not

park at points where the hot filter comes into direct contact with dry grass or

other combustible materials - risk of fire!

● Never use additional underbody protection or corrosion-protection agents

for the exhaust pipes, catalytic converters, diesel particle filter or heat shields.

When the engine reaches its operating temperature, these materials might ig-

nite – risk of fire. Note

When using diesel fuel with high sulphur content the life of the diesel particle fil-

ter is clearly reduced. A specialist garage will be able to tell you which countries

use only diesel fuel with high sulphur content. 131

Intelligent Technology Using the system Safety Driving Tips General Maintenance Breakdown assis-

tance Praktik Technical data

Page 141 of 212

Towing a trailer

Towing a trailer

Technical requirements Your vehicle is designed primarily for transporting persons and luggage. It can,

however, also be used for towing a trailer - provided certain technical equipment

is fitted.

If your vehicle has been

factory-fitted with a towing device or has a towing device

from

ŠKODA Original Accessories, the towing device satisfies all technical and le-

gal requirements.

Your vehicle is fitted with a 13-pin power socket for the electrical connection be-

tween the vehicle and trailer. If the trailer which you wish to tow has a 7-pin con-

nector , you can use a suitable adapter from ŠKODA Original Accessories.

This work must be carried out in accordance with the manufacturer's specifica-

tions if a towing device is retrofitted.

Authorised ŠKODA Service Partners can provide detailed information about retro-

fitting a towing device and for any necessary modifications to the cooling system. WARNING

We recommend that you have the towing device from ŠKODA Original Acces-

sories installed by an authorised

ŠKODA Service Partner. He is familiar with all

the relevant details relating to retrofitting such equipment. There is a risk of

an accident if the towing device is not properly fitted!

General Maintenance Trailer load

The permissible trailer load must on no account be exceeded.

You can negotiate appropriately steeper inclines and descents if you do not make

full use of the permissible trailer load.

The trailer loads specified only apply for

altitudes up to 1000 metres above mean

sea level. The fact that the engine power output drops with increasing height due

to a lowering of air pressure and thus the ability to climb, means that the towed

weight must be reduced by 10 % for every further increase of 1 000 metres in height above sea level. The towed weight is the weight of the (laden) vehicle and

the (laden) trailer together. One should take this into account before driving up to

higher altitudes.

The trailer and drawbar load information on the type plate of the towing device

are merely test data for the towing device The data relating to your vehicle,

which is often less than this test data, can be found in your vehicle registration

documents.

Distribution of the load

Distribute the load in the trailer in such a way that any heavy items are located as

close as possible to the axle. Secure the items to prevent them slipping.

Tyre pressure

Correct the tyre inflation pressure on your vehicle for that of

“fully laden”

⇒ page 161. The inflation pressure of the tyres fitted to the trailer adjust in ac-

cordance with the manufacturer's recommendation.

Exterior mirrors

You have to have additional exterior mirrors fitted if you are not able to see the

traffic behind the trailer with the standard rear-view mirrors. Both exterior mirrors

should be attached to folding arms. Adjust the mirrors so that they provide you

with an adequate field of view to the rear.

Headlights

Before starting off with a hitched trailer, also check the setting of the headlights.

Alter the setting as necessary with the aid of the headlight beam adjuster

⇒ page 42.

Detachable ball head

The ball head is detachable on vehicles with towing device and can be obtained

from ŠKODA Original Accessories. It is stowed together with separate fitting in-

structions in the spare wheel well in the luggage compartment of the vehicle. Note

● We recommend that you also have your vehicle inspected between service in-

tervals if you tow a trailer frequently.

● The handbrake on the towing vehicle must be put on when coupling and de-

coupling the trailer. 139

Towing a trailer Using the system Safety Driving Tips General Maintenance Breakdown assis-

tance Praktik Technical data

Page 142 of 212

Driving Tips

–

Do not, as far as possible, drive with your vehicle unladen and the trailer laden.

– Do not make full use of the legal maximum speeds. This applies in particular to

downhill sections.

– Apply the brakes in good time.

– Keep a check on the coolant temperature gauge if the outside temperature is

high.

Distribution of weight

The distribution of the weight is very poor if your vehicle is unladen and the trailer

is laden. Maintain a particularly low speed if you cannot avoid driving with this

combination.

Driving speed

Do not drive faster than 80

km/h for safety reasons. This also applies for countries

in which higher speeds are allowed.

The fact that the driving stability of the vehicle + trailer combination reduces with

increasing speed means that the legally allowed speed should not be used when

there are unfavourable road, weather or wind conditions, particularly near acci-

dent black spots.

You must always reduce your speed immediately as soon as you detect even just

the slightest swaying of the trailer. On no account attempt to stop the trailer

from “swaying” by accelerating.

Apply the brakes in good time! If the trailer is fitted with a trailer brake, apply the

brakes gently at first and then brake firmly. This will avoid brake jolts resulting

from the trailer wheels locking. Shift down gears in good time before negotiating

a downhill section to allow the engine to also act as a brake.

Engine overheating

Please keep a check on the coolant temperature gauge if you have to negotiate a

lengthy slope in a low gear at a high engine speed when the outside temperature

is very high ⇒ page 11.

If the needle of the coolant temperature gauge moves into the right-hand area or

even the red area of the scale, reduce your speed immediately. Stop and switch

off the engine if the warning light in the instrument cluster begins flashing.

Wait a few minutes and check the level of coolant in the coolant expansion bottle

⇒ page 154, Inspecting the coolant level. Please refer to the following guidelines

⇒

page 23, Coolant temperature/ Coolant

quantity .

The coolant temperature can be reduced by switching on the heating.

Any increase in the cooling effect of the coolant fan through shifting down a gear

and increasing the engine speed is not possible since the fan speed is independ-

ent of the engine speed. One should also not drop a gear for this reason when

towing a trailer as long as the engine can manage the slope without any drop in

speed. 140

Towing a trailer

Page 152 of 212

Inspecting and Replenishing

Engine compartment

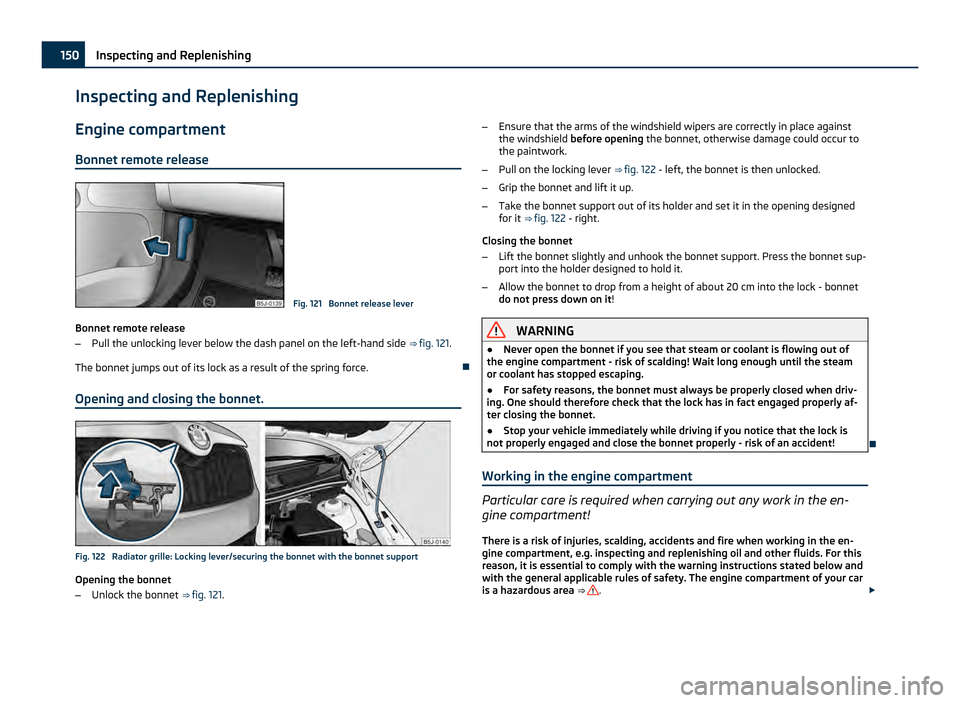

Bonnet remote release Fig. 121 Bonnet release lever

Bonnet remote release

– Pull the unlocking lever below the dash panel on the left-hand side ⇒ fig. 121.

The bonnet jumps out of its lock as a result of the spring force.

Opening and closing the bonnet. Fig. 122 Radiator grille: Locking lever/securing the bonnet with the bonnet support

Opening the bonnet

–

Unlock the bonnet ⇒

fig. 121. –

Ensure that the arms of the windshield wipers are correctly in place against

the windshield before opening the bonnet, otherwise damage could occur to

the paintwork.

– Pull on the locking lever ⇒ fig. 122 - left, the bonnet is then unlocked.

– Grip the bonnet and lift it up.

– Take the bonnet support out of its holder and set it in the opening designed

for it ⇒ fig. 122 - right.

Closing the bonnet

– Lift the bonnet slightly and unhook the bonnet support. Press the bonnet sup-

port into the holder designed to hold it.

– Allow the bonnet to drop from a height of about 20 cm into the lock - bonnet

do not press down on it! WARNING

● Never open the bonnet if you see that steam or coolant is flowing out of

the engine compartment - risk of scalding! Wait long enough until the steam

or coolant has stopped escaping.

● For safety reasons, the bonnet must always be properly closed when driv-

ing. One should therefore check that the lock has in fact engaged properly af-

ter closing the bonnet.

● Stop your vehicle immediately while driving if you notice that the lock is

not properly engaged and close the bonnet properly - risk of an accident!

Working in the engine compartment Particular care is required when carrying out any work in the en-

gine compartment!

There is a risk of injuries, scalding, accidents and fire when working in the en-

gine compartment, e.g. inspecting and replenishing oil and other fluids. For this

reason, it is essential to comply with the warning instructions stated below and

with the general applicable rules of safety. The engine compartment of your car

is a hazardous area ⇒

.

£150

Inspecting and Replenishing

Page 154 of 212

Engine coolant expansion reservoir

Windshield washer fluid reservoir

Engine oil filler opening

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Engine oil dipstick . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Brake fluid reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Battery (below a cover) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156Note

The location of the inspection points in the engine compartment of petrol and die-

sel engines is practically identical.

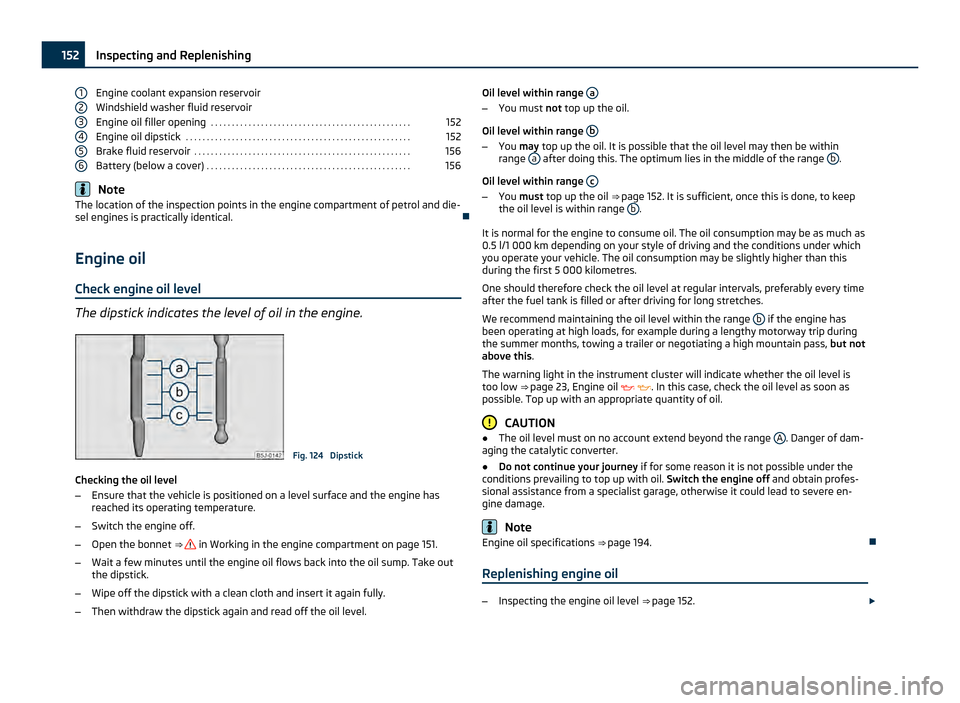

Engine oil Check engine oil level The dipstick indicates the level of oil in the engine.

Fig. 124 Dipstick

Checking the oil level

– Ensure that the vehicle is positioned on a level surface and the engine has

reached its operating temperature.

– Switch the engine off.

– Open the bonnet ⇒ in Working in the engine compartment on page 151.

– Wait a few minutes until the engine oil flows back into the oil sump. Take out

the dipstick.

– Wipe off the dipstick with a clean cloth and insert it again fully.

– Then withdraw the dipstick again and read off the oil level.

1 2

3

4

5

6 Oil level within range

a –

You must not top up the oil.

Oil level within range b –

You may top up the oil. It is possible that the oil level may then be within

range a after doing this. The optimum lies in the middle of the range

b .

Oil level within range c –

You must top up the oil ⇒ page 152. It is sufficient, once this is done, to keep

the oil level is within range b .

It is normal for the engine to consume oil. The oil consumption may be as much as

0.5 l/1 000 km depending on your style of driving and the conditions under which

you operate your vehicle. The oil consumption may be slightly higher than this

during the first 5 000 kilometres.

One should therefore check the oil level at regular intervals, preferably every time

after the fuel tank is filled or after driving for long stretches.

We recommend maintaining the oil level within the range b if the engine has

been operating at high loads, for example during a lengthy motorway trip during

the summer months, towing a trailer or negotiating a high mountain pass, but not

above this .

The warning light in the instrument cluster will indicate whether the oil level is

too low ⇒ page 23,

Engine oil . In this case, check the oil level as soon as

possible. Top up with an appropriate quantity of oil. CAUTION

● The oil level must on no account extend beyond the range A . Danger of dam-

aging the catalytic converter.

● Do not continue your journey if for some reason it is not possible under the

conditions prevailing to top up with oil. Switch the engine off and obtain profes-

sional assistance from a specialist garage, otherwise it could lead to severe en-

gine damage. Note

Engine oil specifications ⇒

page 194.

Replenishing engine oil –

Inspecting the engine oil level ⇒

page 152. £152

Inspecting and Replenishing

Page 156 of 212

When refilling, we only recommend you use the same antifreeze described on the

antifreeze expansion tank.

Please contact an authorised

ŠKODA Service Partner if you have any questions re-

garding the coolant or if you wish to fill up with a different coolant.

An authorised ŠKODA Service Partner can also supply you with the correct coolant

additives.

Coolant capacity Petrol engines Capacities (in litres)

1.2 l/51 kW - EU5/EU2 DDK 5,5

1.2 l/63 kW TSI - EU5 7,7

1.2 l/77 kW TSI - EU5 7,7

1.4 l/63 kW - EU5 5,5

1.6 l/77 kW - EU4/EU2 DDK 5,5

Diesel engines Capacities (in litres)

1.2 l/55 kW TDI CR DPF - EU5 6,6

1.6 l/66 kW TDI CR DPF - EU5 8,4

1.6 l/77 kW TDI CR DPF - EU5 8,4

CAUTION

● Other coolant additives may cause operational problems which, in particular,

involves significantly reducing the anticorrosion effect.

● Any faults or problems resulting from corrosion may cause a loss of coolant

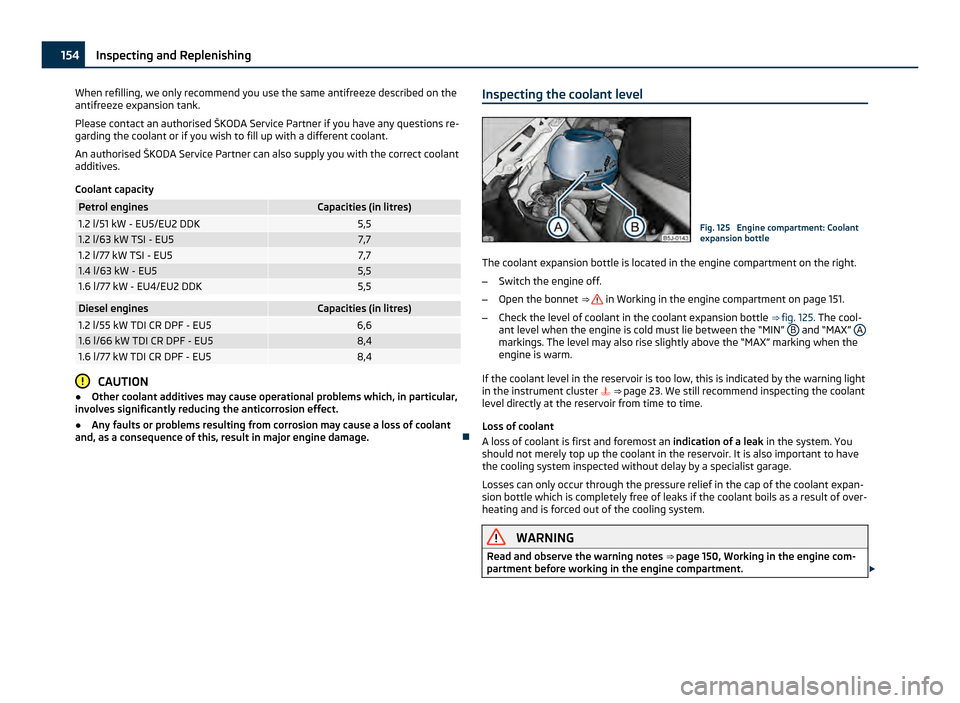

and, as a consequence of this, result in major engine damage. Inspecting the coolant level Fig. 125 Engine compartment: Coolant

expansion bottle

The coolant expansion bottle is located in the engine compartment on the right.

– Switch the engine off.

– Open the bonnet ⇒ in Working in the engine compartment on page 151.

– Check the level of coolant in the coolant expansion bottle ⇒ fig. 125 . The cool-

ant level when the engine is cold must lie between the

“MIN” B and “MAX”

A markings. The level may also rise slightly above the “MAX” marking when the

engine is warm.

If the coolant level in the reservoir is too low, this is indicated by the warning light

in the instrument cluster

⇒ page 23. We still recommend inspecting the coolant

level directly at the reservoir from time to time.

Loss of coolant

A loss of coolant is first and foremost an indication of a leak in the system. You

should not merely top up the coolant in the reservoir. It is also important to have

the cooling system inspected without delay by a specialist garage.

Losses can only occur through the pressure relief in the cap of the coolant expan-

sion bottle which is completely free of leaks if the coolant boils as a result of over-

heating and is forced out of the cooling system. WARNING

Read and observe the warning notes ⇒ page 150

, Working in the engine com-

partment before working in the engine compartment. £154

Inspecting and Replenishing

Page 160 of 212

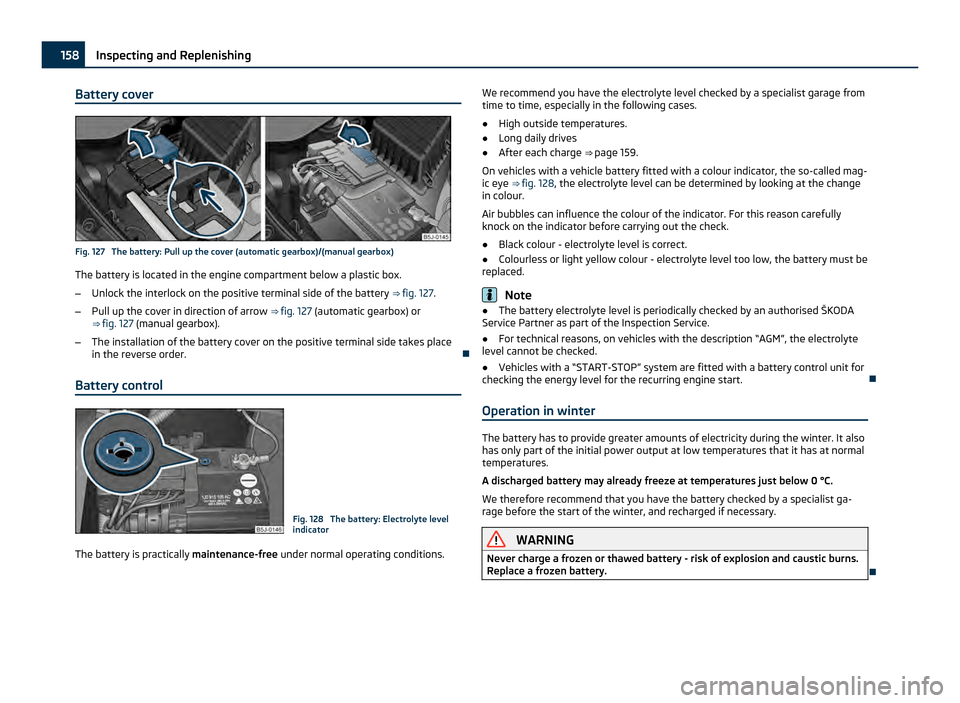

Battery cover

Fig. 127 The battery: Pull up the cover (automatic gearbox)/(manual gearbox)

The battery is located in the engine compartment below a plastic box.

– Unlock the interlock on the positive terminal side of the battery ⇒ fig. 127.

– Pull up the cover in direction of arrow ⇒ fig. 127 (automatic gearbox) or

⇒ fig. 127 (manual gearbox).

– The installation of the battery cover on the positive terminal side takes place

in the reverse order.

Battery control Fig. 128 The battery: Electrolyte level

indicator

The battery is practically maintenance-free under normal operating conditions. We recommend you have the electrolyte level checked by a specialist garage from

time to time, especially in the following cases.

● High outside temperatures.

● Long daily drives

● After each charge ⇒

page 159.

On vehicles with a vehicle battery fitted with a colour indicator, the so-called mag-

ic eye ⇒ fig. 128 , the electrolyte level can be determined by looking at the change

in colour.

Air bubbles can influence the colour of the indicator. For this reason carefully

knock on the indicator before carrying out the check.

● Black colour - electrolyte level is correct.

● Colourless or light yellow colour - electrolyte level too low, the battery must be

replaced. Note

● The battery electrolyte level is periodically checked by an authorised

ŠKODA

Service Partner as part of the Inspection Service.

● For technical reasons, on vehicles with the description “AGM”, the electrolyte

level cannot be checked.

● Vehicles with a “START-STOP” system are fitted with a battery control unit for

checking the energy level for the recurring engine start.

Operation in winter The battery has to provide greater amounts of electricity during the winter. It also

has only part of the initial power output at low temperatures that it has at normal

temperatures.

A discharged battery may already freeze at temperatures just below 0 °C.

We therefore recommend that you have the battery checked by a specialist ga-

rage before the start of the winter, and recharged if necessary. WARNING

Never charge a frozen or thawed battery - risk of explosion and caustic burns.

Replace a frozen battery. 158

Inspecting and Replenishing

Page 162 of 212

CAUTION

Vehicles with a “START-STOP” system are fitted with a special battery type which

allows the battery control unit to check the energy level for recurring engine start.

This battery must only be replaced by a battery of the same type. For the sake of the environment

Batteries contain poisonous substances such as sulphuric acid and lead. For this

reason, it must be disposed of properly. Under no circumstances must it be dis-

posed of in the communal rubbish.

Automatic consumer shut-off Under heavy load on the vehicle battery, the vehicle electrical system manage-

ment automatically takes various measures to avoid draining the vehicle battery.

●

The idling speed is raised to allow the generator to deliver more electricity to

the electrical system.

● If necessary, some electrical consumers are limited in their performance or are

temporarily switched off completely. Note

Despite such intervention by the vehicle electric system management, the vehicle

battery may be drained. For example, when the ignition is switched on a long time

with the engine turned off or the side or parking lights are turned on during lon-

ger parking.

Windshield washer system Fig. 129 Engine compartment: Wind-

shield washer fluid reservoir The windshield washer fluid reservoir contains the cleaning fluid for the wind-

shield or rear window and for the headlamp cleaning system. The reservoir is loca-

ted in the front of the engine compartment on the right side of the vehicle

⇒ fig. 129

. On some vehicles, the reservoir is located on the left side of the vehicle

next to the battery.

The filling level of the container is about 3.5 litres and about 5.4 litres on vehicles

which have a headlight washing system.

Clear water is not sufficient to intensively clean the windshield and headlights.

We therefore recommend using clean washing water together with the screen

cleaner from

ŠKODA Original Accessories (in winter additionally with antifreeze)

which is capable of removing stubborn dirt. Follow the instructions for use on the

packaging when using screen cleaning products.

You should always add antifreeze to the cleaning water in winter even if your ve-

hicle is fitted with heated windshield washer nozzles.

It is also possible in exceptional cases to use methylated spirits when no screen

cleaner with antifreeze is available. The concentration of methylated spirits must

not be more than 15 %. Please note, however, that the antifreeze protection at

this concentration is only adequate down to -5 °C. WARNING

Read and observe the warning notes ⇒ page 150

, Working in the engine com-

partment before working in the engine compartment. CAUTION

● On no account should you add radiator antifreeze or other additives to the

windshield washer fluid.

● If the vehicle is fitted with a headlight cleaning system, you should only add

cleaning products which do not attack the polycarbonate glass of the headlights

to the windshield washer fluid. Please contact an authorised

ŠKODA Service Part-

ner who will help you select a suitable cleaning agent. Note

Do not take the filter out of the windshield wash container when filling it up again

with liquid otherwise dirt can get into the liquid transportation system and can

lead to faults in operation of the windshield wash system. 160

Inspecting and Replenishing

Page 171 of 212

WARNING

● If you find yourself in flowing traffic switch on the hazard warning lights

system and place the warning triangle on the side of the road at the prescri-

bed distance from your vehicle. Comply with the national legal regulations. In

this way you are protecting not only yourself but also other road users.

● Never start the engine with the vehicle sitting on the raised jack - danger

of suffering injury. CAUTION

If you have to change a wheel on a slope first block the opposite wheel with a

stone or similar object in order to secure the vehicle from unexpectedly rolling

away. Note

Comply with the national legal regulations.

Changing a wheel Always change a wheel on a level surface as far as possible.

–

Take off the full wheel trim ⇒ page 170 or the caps ⇒ page 170.

– Slacken the wheel bolts ⇒ page 170.

– Jack up the vehicle until the wheel to be changed is clear of the ground

⇒ page 171.

– Unscrew the wheel bolts and place them on a clean surface (cloth, paper, etc.).

– Take off the wheel.

– Fit on the spare wheel and tighten the wheel bolts slightly.

– Lower the car.

– Tighten the wheel bolts firmly, alternately and diagonally using the wrench

(crosswise) ⇒ page 170.

– Mount the full wheel trim/wheel trim cap or the caps. Note

● All bolts must be clean and must turn easily.

● You must never grease or oil the wheel bolts!

● When fitting on unidirectional tyres, ensure that the tyres rotate in the correct

direction ⇒ page 161

.

Subsequent steps After changing the wheel, you must perform the following steps.

–

Stow the vehicle tool kit in the space provided.

– Stow the replaced wheel in the luggage compartment.

– Check the tyre pressure on the spare wheel just mounted as soon as possible.

– Have the tightening torque of the wheel bolts checked with a torque wrench

as soon as possible. Steel and light alloy wheels must be tightened to a tight-

ening torque of 120

Nm.

– Change the damaged wheel or consult a specialist garage about possibilities

for getting repairs done. WARNING

It is necessary to observe the guidelines given on ⇒

page 163, New tyres and

wheels if the vehicle is subsequently fitted with tyres which are different to

those it was fitted with at the works. Note

● If you find, when changing the wheel, that the wheel bolts are corroded and

difficult to turn, the bolts must be replaced before checking the tightening torque.

● Drive cautiously and only at a moderate speed to a workshop where the tight-

ening torque can be checked. 169

Breakdown assistance Using the system Safety Driving Tips General Maintenance Breakdown assis-

tance Praktik Technical data