Engine SKODA ROOMSTER 2012 1.G Repair Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2012, Model line: ROOMSTER, Model: SKODA ROOMSTER 2012 1.GPages: 194, PDF Size: 4.8 MB

Page 159 of 194

›

Replacement bulb set;

› Screwdriver.

Before placing the lifting jack back into its storage area, screw in the arm of the

lifting jack fully. WARNING

■ The factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances attempt to lift heavier vehicles or other loads - risk of

injury!

■ Ensure that the vehicle tool kit is safely secured in the boot. Note

Ensure that the box is always secured with the strap. ÐChanging a wheel

ä

Introduction

This chapter contains information on the following subjects:

Preliminary work 157

Changing a wheel 158

Subsequent steps 158

Loosening and tightening wheel bolts 159

Raising the vehicle 159

Securing wheels against theft 160

WARNING

■ If you are in flowing traffic, switch on the hazard warning light system and

set up the warning triangle at the prescribed distance! The national legal re-

quirements must be observed. In this way you are not only protecting yourself

but other road users as well.

■ If the wheel is damaged or in the event of a puncture, park the vehicle as far

away as possible from the flow of traffic. Park on as flat and firm a surface as

possible. WARNING (Continued)

■ If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpectedly

rolling away.

■ If the vehicle is subsequently fitted with tyres which are different to those it

was fitted with at the works, follow these guidelines »

page 150, New wheels

and tyres.

■ Always raise the vehicle with the doors closed.

■ Never position any body parts, such as arms or legs under the vehicle, while

the vehicle is raised with a lifting jack. ■ Secure the base plate of the lifting jack with suitable means to prevent pos-

sible moving. A soft and slippery ground under the base plate may move the

lifting jack, causing the vehicle to fall down. It is therefore always necessary to

place the lifting jack on a solid surface or use a wide and stable base. Use a

non-slip base (e.g. a rubber foot mat) if the surface is smooth, such as cobbled

stones, tiled floor, etc.

■ Never start the engine with the vehicle sitting on the raised jack - danger of

suffering injury.

■ Only attach the lifting jack to the attachment points provided for this pur-

pose. CAUTION

■ The prescribed tightening torque of the wheel bolts for steel and light alloy

wheels is 120 Nm.

■ If the anti-theft wheel bolt is fastened too tightly, it can cause damage to the

anti-theft wheel bolt and adapter. Note

■ The anti-theft wheel bolt set and adapter can be purchased from a

ŠKODA Serv-

ice Partner. ■ The national legal requirements must be observed when changing a wheel. Ð Preliminary work

First read and observe the introductory information and safety warn-

ings on page 157.

The following steps must be carried out before actually changing the wheel:

£

ä

157

Do-it-yourself

Page 160 of 194

›

In the event of a puncture, park the vehicle as far away as possible from the

flow of traffic. The place you choose should be level.

› Let all of the occupants get out.

While changing a tyre, the occupants of the

vehicle should not stand on the road (instead they should remain behind a crash

barrier).

› Switch off the engine and move the gearshift lever into

Neutral or move the

selector lever for the automatic gearbox into position P .

› Firmly apply the

handbrake.

› If a trailer is connected, remove it.

› Remove the vehicle tool kit

» page 156 and the spare wheel » page 151, Spare

wheel from the boot. ÐChanging a wheel

First read and observe the introductory information and safety warn-

ings on page 157.

Always change a wheel on a level surface as far as possible.

›

Remove the full wheel trim

» page 152 or caps » page 152.

› In the case of light alloy wheel rims remove the wheel trim cap

» page 152.

› First of all slacken the anti-theft wheel bolt and then the other wheel

bolts » page 159.

› Jack up the vehicle until the wheel that needs changing is clear of the

ground » page 159.

› Unscrew the wheel bolts and place them on a clean surface (cloth, paper, etc.).

› Remove the wheel.

› Attach the spare wheel and slightly screw on the wheel bolts.

› Lower the vehicle.

› Alternately tighten the wheel bolts opposite each other using the wheel

wrench (crosswise) and then tighten the anti-theft wheel bolt » page 159.

› Reinstall the wheel trim/wheel trim cap or the caps. Note

■ All bolts must be clean and must turn easily.

■ Under no circumstances grease or oil the wheel bolts!

■ When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect »

page 148 . Ð

ä Subsequent steps

First read and observe the introductory information and safety warn-

ings on page 157.

The following steps must also be performed after changing the wheel.

›

Stow and attach the replaced wheel in the spare wheel well using a special

screw » page 151, Spare wheel.

› Stow the vehicle tool kit in the space provided.

› Check

the tyre pressure

on the installed spare wheel as soon as possible.

› Have the

tightening torque of the wheel bolts checked with a torque wrench

as soon as possible.

› Change the damaged wheel or consult a ŠKODA specialist garage about repair

possibilities. Note

■ If it is determined that the wheel bolts are corroded and difficult to turn when

changing the wheel, the bolts must be replaced before checking the tightening

torque. ■ Drive cautiously and only at a moderate speed until the tightening torque has

been checked. Ð

ä

158 Do-it-yourself

Page 163 of 194

WARNING (Continued)

■ Do not drive faster than 80 km/h (50 mph).

■ Avoid accelerating at full throttle, sharp braking and fast cornering.

■ Check the tyre inflation pressure after driving for 10 minutes!

■ The sealant is hazardous to heath. Remove immediately if it comes into con-

tact with the skin. For the sake of the environment

Used sealant or sealant whose expiry date has passed must be disposed of in ac-

cordance with environmental protection regulations. Note

■ Observe the manufacturer's usage instructions for the breakdown kit.

■ A new bottle of sealant can be purchased from ŠKODA Original Accessories.

■ Immediately replace the wheel that was repaired using the breakdown kit or

consult a ŠKODA specialist garage about repair possibilities. ÐComponents of the breakdown kit

Fig. 134

Components of the breakdown kit

First read and observe the introductory information and safety warn-

ings on page 160.

ä The breakdown kit contains the following parts:

Valve remover

Sticker with speed designation

“max. 80 km/h”/“max. 50 mph”

Inflation hose with plug

Air compressor

Tyre inflation hose

Tyre inflation pressure indicator

Air release valve

ON and OFF switch

12 volt cable connector

Tyre inflator bottle with sealing agent

Replacement valve core

The valve remover 1

has a slot at its lower end which fits into the valve core.

This is the only way in which you can remove and re-install the valve core from

the tyre valve. The same also applies to the replacement valve core 11

.

Ð Preparing to use the breakdown kit

First read and observe the introductory information and safety warn-

ings on page 160.

The following preparatory work must be carried out before using the breakdown

kit.

›

In the event of a puncture, park the vehicle as far away as possible from the

flow of traffic. Park on as flat and firm a surface as possible.

› Let all of the occupants get out.

While changing a tyre, the occupants of the

vehicle should not stand on the road (instead they should remain behind a crash

barrier).

› Switch off the engine and move the gearshift lever into

Neutral or move the

selector lever

for the automatic gearbox into position P .

› Firmly apply the

handbrake.

› Check that you can carry out the repairs with the breakdown kit

» page 160.

› If a trailer is connected, remove it.

› Remove the breakdown kit

from the boot.

› Stick the sticker 2

»

Fig. 134 on page 161 on the dash panel in view of the driv-

er.

› Do not remove the foreign body, e.g. screw or nail, from the tyre.

› Unscrew the valve cap.

£ 1

2

3

4

5

6

7

8

9

10

11

ä

161

Do-it-yourself

Page 164 of 194

›

Use the valve remover 1

to unscrew the valve core and place it on a clean sur-

face (rag, paper, etc.). ÐSealing and inflating tyres

First read and observe the introductory information and safety warn-

ings on page 160.

Sealing

›

Forcefully shake the tyre inflator bottle 10

» Fig. 134 on page 161 several times.

› Firmly screw the inflation hose 3

onto the tyre inflator bottle 10

in a clockwise

direction. The film on the cap is pierced automatically.

› Remove the plug from the inflation hose 3

and plug the open end fully onto

the tyre valve.

› Hold the bottle 10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

› Remove the empty tyre inflator bottle from the valve.

› Screw the valve core back into the tyre valve using the valve remover 1

.

Inflating

› Screw the tyre inflation hose 5

» Fig. 134 on page 161 of the air compressor

firmly onto the tyre valve.

› Check that the air release valve 7

is closed.

› Start the engine and run it in idle.

› Plug the connector 9

into 12 Volt socket »

page 61, 12-volt power socket.

› Switch on the air compressor with the ON and OFF switch 8

.

› Allow the air compressor to run until a pressure of 2.0 - 2.5 bar is achieved.

Maximum run time of 8 minutes » !

› Switch off the air compressor.

› If you cannot reach an air pressure of 2.0 – 2.5 bar, unscrew the tyre inflation

hose 5

from the tyre valve.

› Drive the vehicle 10 metres forwards or backwards to allow the sealing agent to

“distribute” in the tyre.

› Firmly screw the tyre inflation hose 5

back onto the tyre valve and repeat the

inflation process.

› If you cannot reach the required tyre inflation pressure here either, this means

the tyre has sustained too much damage. You cannot seal with tyre with the

breakdown kit » .

› Switch off the air compressor.

› Remove the tyre inflation hose 5

from the tyre valve.

Once a tyre inflation pressure of 2.0

– 2.5 bar is achieved, continue the journey at

a maximum speed of 80 km/h (50 mph). ä

Check the tyre inflation pressure after driving for 10 minutes

» page 162. WARNING

■ During inflation, the tyre inflation hose and air compressor may get hot- risk

of injury! ■ Do not place the hot tyre inflation hose or hot air compressor on flammable

materials - risk of fire!

■ If you cannot inflate the tyre to at least 2.0 bar, this means the damage sus-

tained was too serious. The sealing agent cannot be used to seal the tyre. Do

not drive the vehicle. Get professional assistance! CAUTION

Switch off the air compressor after running 8 minutes at the latest - danger of

overheating! Allow the air compressor to cool a few minutes before switching it

on again. Ð Check after driving for 10 minutes

First read and observe the introductory information and safety warn-

ings on page 160.

Check the tyre inflation pressure after driving for 10 minutes!

If the tyre inflation pressure is 1.3 bar or less:

›

Do not drive the vehicle! You cannot properly seal with tyre with the break-

down kit.

› Get professional assistance.

If the tyre inflation pressure is 1.3 bar or more:

› Adjust the tyre inflation pressure to the correct value (see inside of fuel filler

cap).

› Continue driving carefully to the nearest ŠKODA specialist garage at a maxi-

mum speed of 80 km/h (50 mph). Ð

ä

162 Do-it-yourself

Page 165 of 194

Jump-starting

ä

Introduction

This chapter contains information on the following subjects:

Jump-starting 163

Jump-starting in vehicles with the START-STOP system 164

The battery of another vehicle can be used to jump-start your vehicle if the en-

gine will not start because the battery is flat. Jump-start cables are required for

this purpose.

Both batteries must have a rated voltage of 12 V. The capacity (Ah) of the battery

supplying the power must not be significantly less than the capacity of the dis-

charged battery in your vehicle.

Jump-start cables

Only use jump-start cables which have an adequately large cross-section and in-

sulated terminal clamps. Observe the manufacturer's instructions.

Positive cable - colour coding in the majority of cases is red.

Negative cable - colour coding in the majority of cases is black. WARNING

■ A discharged vehicle battery may already freeze at temperatures just below

0 °C. In case of frozen battery carry out no jump-starting - risk of explosion! ■ Pay attention to the warning instructions relating to working in the engine

compartment »

page 136, Engine compartment .

■ The non-insulated parts of the terminal clamps must never make contact

with each other. In addition, the jump-start cable connected to the positive

terminal of the battery must not come into contact with electrically conduct-

ing parts of the vehicle - risk of short circuit!

■ Do not clamp the jump-start cable to the negative terminal of the dis-

charged battery. There is the risk of detonating gas seeping out the battery

being ignited by the strong spark which results from the engine being started.

■ Route the jump-start cables so that they cannot be caught by any rotating

parts in the engine compartment.

■ Do not bend over the battery - risk of caustic burns!

■ The vent screws of the battery cells must be tightened firmly. WARNING (Continued)

■ Keep any sources of ignition (naked flame, smouldering cigarettes, etc.)

away from the battery - risk of an explosion! ■ Never jump-start vehicle batteries with an electrolyte level that is too low -

risk of explosion and caustic burns. Note

■ There must not be any contact between the two vehicles otherwise current

may flow as soon as the negative terminals are connected. ■ The discharged battery must be properly connected to the system of the vehi-

cle. ■ We recommend you buy jump-start cables from a car battery specialist. Ð Jump-starting

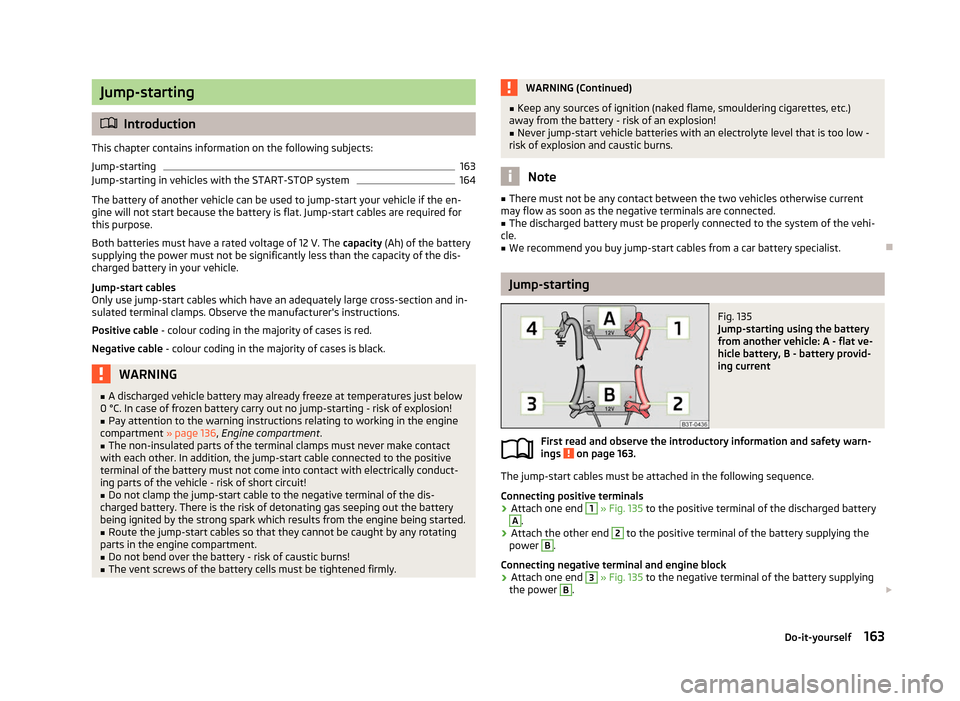

Fig. 135

Jump-starting using the battery

from another vehicle: A - flat ve-

hicle battery, B - battery provid-

ing current

First read and observe the introductory information and safety warn-

ings on page 163.

The jump-start cables must be attached in the following sequence.

Connecting positive terminals

› Attach one end 1

»

Fig. 135

to the positive terminal of the discharged battery A

.

› Attach the other end 2

to the positive terminal of the battery supplying the

power B

.

Connecting negative terminal and engine block

› Attach one end 3

»

Fig. 135

to the negative terminal of the battery supplying

the power B

.

£

ä

163

Do-it-yourself

Page 166 of 194

›

Attach the other end 4

to a solid metal part which is connected firmly to the

engine block, or to the engine block itself.

Starting engine

› Start the engine on the vehicle providing the power and allow it to idle.

› Now start the engine of the vehicle with the discharged battery.

› If the engine does not start, terminate the attempt to start the engine after

10 seconds and wait for about 30 seconds before repeating the process.

› Disconnect the cables in exactly the

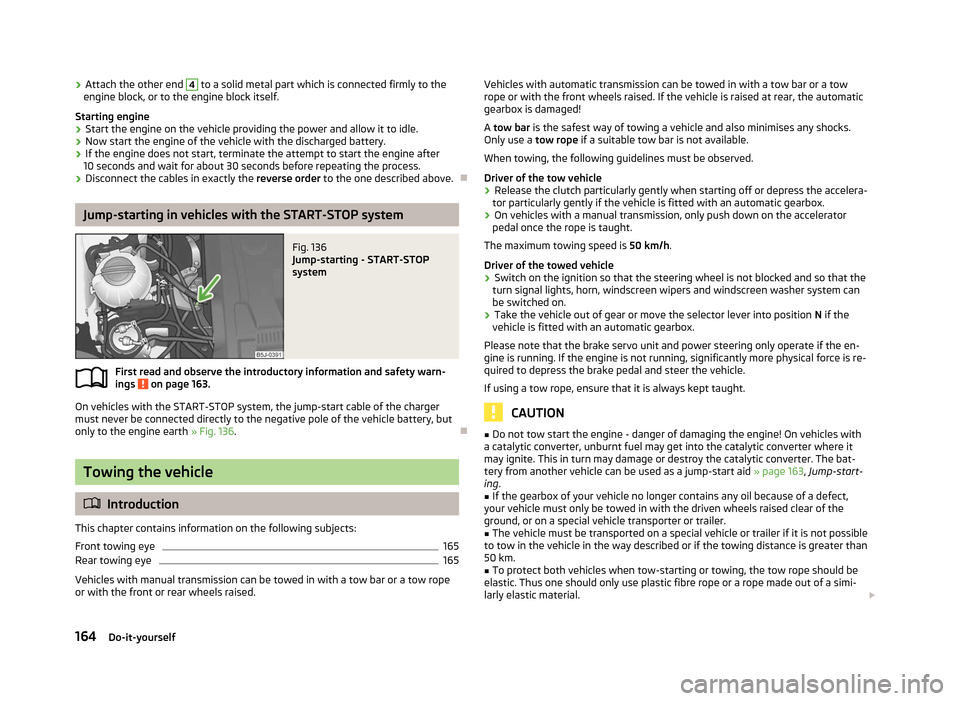

reverse order to the one described above. ÐJump-starting in vehicles with the START-STOP system

Fig. 136

Jump-starting - START-STOP

system

First read and observe the introductory information and safety warn-

ings on page 163.

On vehicles with the START-STOP system, the jump-start cable of the charger

must never be connected directly to the negative pole of the vehicle battery, but

only to the engine earth » Fig. 136. ÐTowing the vehicle

ä

Introduction

This chapter contains information on the following subjects:

Front towing eye 165

Rear towing eye 165

Vehicles with manual transmission can be towed in with a tow bar or a tow rope

or with the front or rear wheels raised.

ä Vehicles with automatic transmission can be towed in with a tow bar or a tow

rope or with the front wheels raised. If the vehicle is raised at rear, the automatic

gearbox is damaged!

A tow bar

is the safest way of towing a vehicle and also minimises any shocks.

Only use a tow rope if a suitable tow bar is not available.

When towing, the following guidelines must be observed.

Driver of the tow vehicle

› Release the clutch particularly gently when starting off or depress the accelera-

tor particularly gently if the vehicle is fitted with an automatic gearbox.

› On vehicles with a manual transmission, only push down on the accelerator

pedal once the rope is taught.

The maximum towing speed is 50 km/h.

Driver of the towed vehicle

› Switch on the ignition so that the steering wheel is not blocked and so that the

turn signal lights, horn, windscreen wipers and windscreen washer system can

be switched on.

› Take the vehicle out of gear or move the selector lever into position

N if the

vehicle is fitted with an automatic gearbox.

Please note that the brake servo unit and power steering only operate if the en-

gine is running. If the engine is not running, significantly more physical force is re-

quired to depress the brake pedal and steer the vehicle.

If using a tow rope, ensure that it is always kept taught. CAUTION

■ Do not tow start the engine - danger of damaging the engine! On vehicles with

a catalytic converter, unburnt fuel may get into the catalytic converter where it

may ignite. This in turn may damage or destroy the catalytic converter. The bat-

tery from another vehicle can be used as a jump-start aid » page 163, Jump-start-

ing .

■ If the gearbox of your vehicle no longer contains any oil because of a defect,

your vehicle must only be towed in with the driven wheels raised clear of the

ground, or on a special vehicle transporter or trailer.

■ The vehicle must be transported on a special vehicle or trailer if it is not possible

to tow in the vehicle in the way described or if the towing distance is greater than

50 km. ■ To protect both vehicles when tow-starting or towing, the tow rope should be

elastic. Thus one should only use plastic fibre rope or a rope made out of a simi-

larly elastic material. £

164 Do-it-yourself

Page 168 of 194

Fuses and light bulbs

Fuses

ä

Introduction

This chapter contains information on the following subjects:

Fuses in the dash panel 167

Fuses in the engine compartment 168

Individual electrical circuits are protected by fuses.

› Before replacing a fuse, switch off the ignition and the appropriate consumer

› Find out which fuse belongs to the component that is not operat-

ing » page 167, Fuses in the dash panel

or » page 168, Fuses in the engine

compartment .

› Take the plastic clip out of its fixture in the cover of the fuse box, place it on the

relevant fuse and pull it out.

› A blown fuses is recognisable by the molten metal strip. Replace the faulty fuse

with a new one of the

same amperage.

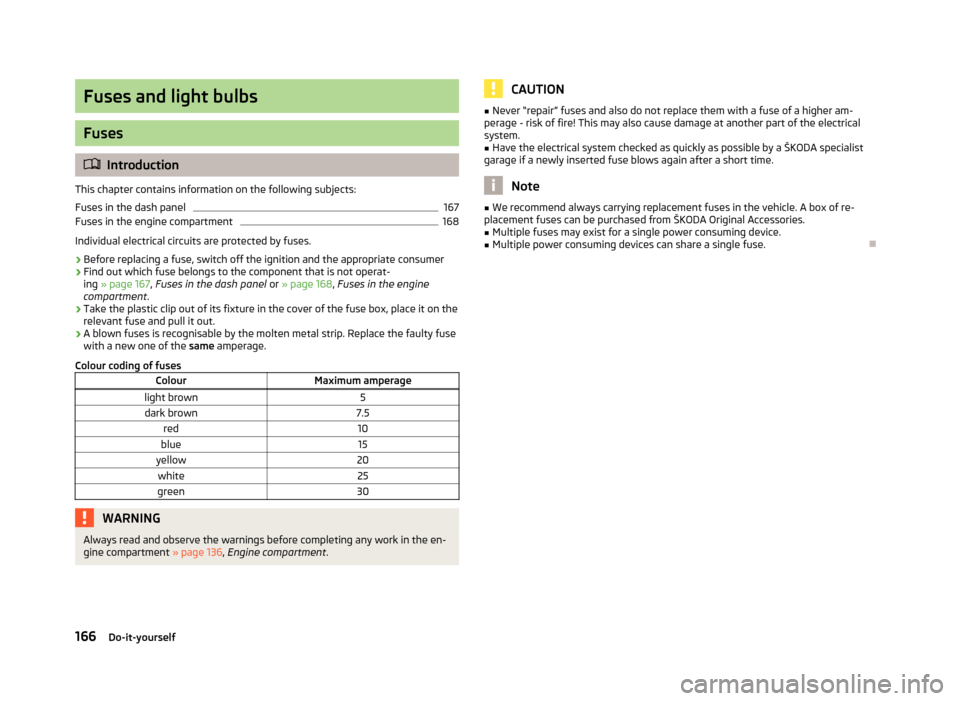

Colour coding of fuses Colour Maximum amperage

light brown 5

dark brown 7.5

red 10

blue 15

yellow 20

white 25

green 30WARNING

Always read and observe the warnings before completing any work in the en-

gine compartment » page 136, Engine compartment . CAUTION

■ Never “repair” fuses and also do not replace them with a fuse of a higher am-

perage - risk of fire! This may also cause damage at another part of the electrical

system.

■ Have the electrical system checked as quickly as possible by a ŠKODA specialist

garage if a newly inserted fuse blows again after a short time. Note

■ We recommend always carrying replacement fuses in the vehicle. A box of re-

placement fuses can be purchased from

ŠKODA Original Accessories.

■ Multiple fuses may exist for a single power consuming device.

■ Multiple power consuming devices can share a single fuse. Ð

166 Do-it-yourself

Page 169 of 194

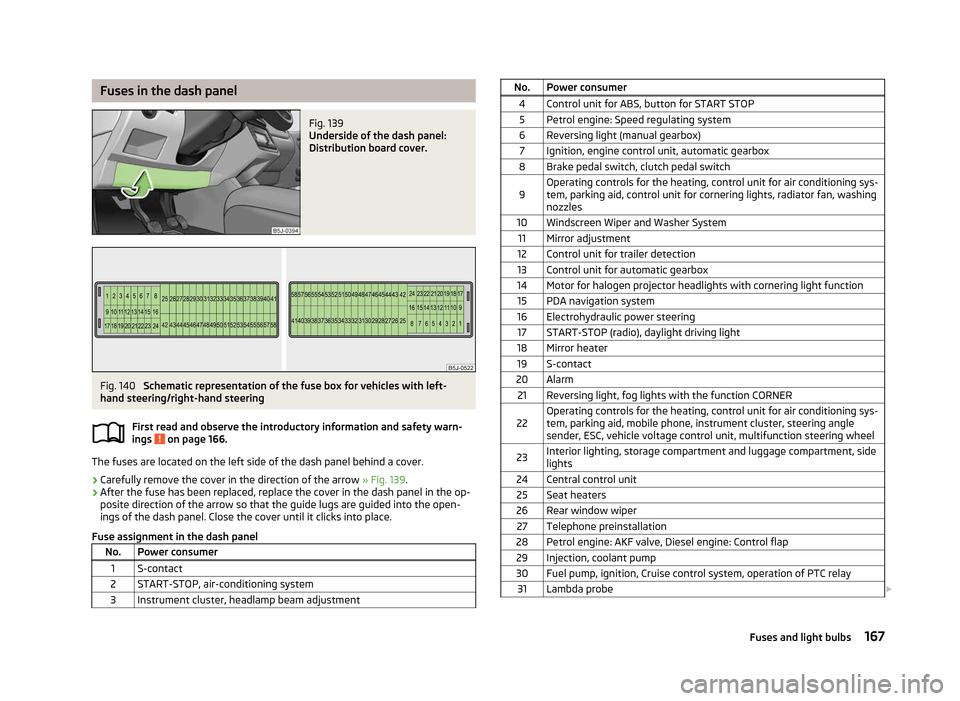

Fuses in the dash panel

Fig. 139

Underside of the dash panel:

Distribution board cover. Fig. 140

Schematic representation of the fuse box for vehicles with left-

hand steering/right-hand steering

First read and observe the introductory information and safety warn-

ings on page 166.

The fuses are located on the left side of the dash panel behind a cover.

›

Carefully remove the cover in the direction of the arrow

» Fig. 139.

› After the fuse has been replaced, replace the cover in the dash panel in the op-

posite direction of the arrow so that the guide lugs are guided into the open-

ings of the dash panel. Close the cover until it clicks into place.

Fuse assignment in the dash panel No. Power consumer

1 S-contact

2 START-STOP, air-conditioning system

3 Instrument cluster, headlamp beam adjustment ä No. Power consumer

4 Control unit for ABS, button for START STOP5 Petrol engine: Speed regulating system

6 Reversing light (manual gearbox) 7 Ignition, engine control unit, automatic gearbox

8 Brake pedal switch, clutch pedal switch

9 Operating controls for the heating, control unit for air conditioning sys-

tem, parking aid, control unit for cornering lights, radiator fan, washing

nozzles

10 Windscreen Wiper and Washer System 11 Mirror adjustment

12 Control unit for trailer detection

13 Control unit for automatic gearbox

14 Motor for halogen projector headlights with cornering light function 15 PDA navigation system

16 Electrohydraulic power steering 17 START-STOP (radio), daylight driving light

18 Mirror heater 19 S-contact

20 Alarm 21 Reversing light, fog lights with the function CORNER

22 Operating controls for the heating, control unit for air conditioning sys-

tem, parking aid, mobile phone, instrument cluster, steering angle

sender, ESC, vehicle voltage control unit, multifunction steering wheel

23 Interior lighting, storage compartment and luggage compartment, side

lights

24 Central control unit 25 Seat heaters

26 Rear window wiper 27 Telephone preinstallation

28 Petrol engine: AKF valve, Diesel engine: Control flap 29 Injection, coolant pump

30 Fuel pump, ignition, Cruise control system, operation of PTC relay 31 Lambda probe £ 167

Fuses and light bulbs

Page 170 of 194

No. Power consumer

32 High pressure fuel pump, pressure valve

33 Engine control unit

34 Engine control unit, vacuum pump 35 Power supply of ignition lock

36 Main beam 37 Rear fog light, DC/DC converter START-STOP

38 Fog lights 39 Air blower for heating

40-41 Not assigned 42 Rear window heater

43 Horn

44 Windscreen wipers 45 Central control unit for convenience system

46 Engine control unit, fuel pump 47 Cigarette lighter, power socket in the luggage compartment

48 ABS, START-STOP (DC/DC) converter ESP 49 Turn signal lights, brake lights50 START-STOP (DC/DC) converter infotainment, radio 51 Electrical power window (front and rear) - left side

52 Electrical power window (front and rear) - right side

53 Parking light = left side, electrical sliding/tilting roof

54 START-STOP (instrument cluster), alarm 55 Control unit for automatic gearbox

56 Headlight cleaning system, parking light - right side 57 Left low beam, headlight range adjustment

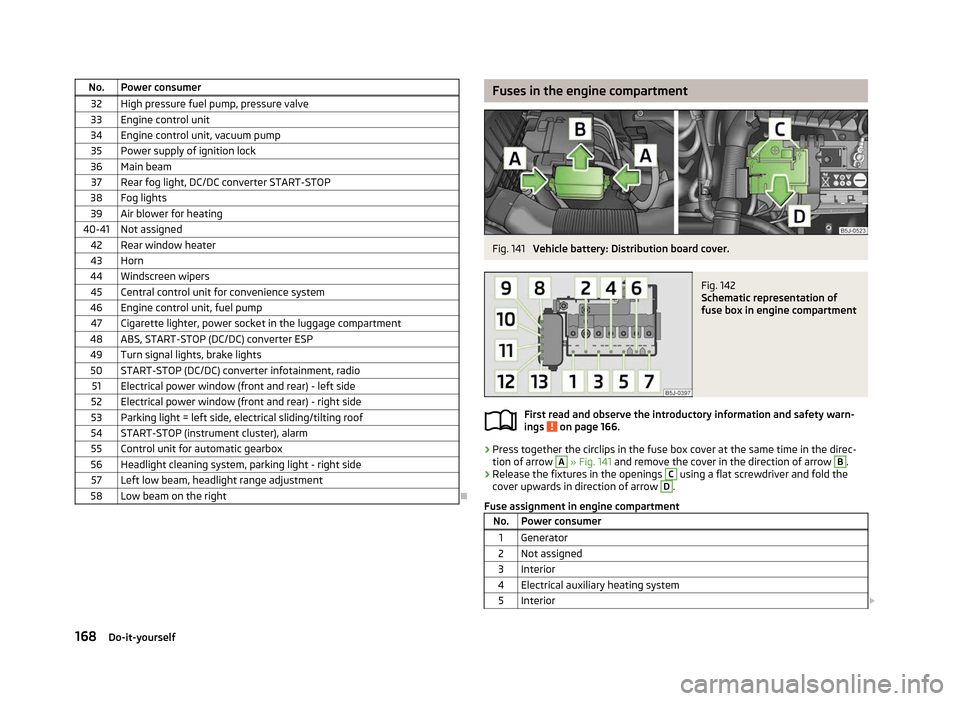

58 Low beam on the right Ð Fuses in the engine compartment

Fig. 141

Vehicle battery: Distribution board cover. Fig. 142

Schematic representation of

fuse box in engine compartment

First read and observe the introductory information and safety warn-

ings on page 166.

›

Press together the circlips in the fuse box cover at the same time in the direc-

tion of arrow A

» Fig. 141

and remove the cover in the direction of arrow B

.

› Release the fixtures in the openings C

using a flat screwdriver and fold the

cover upwards in direction of arrow D

.

Fuse assignment in engine compartment No. Power consumer

1 Generator

2 Not assigned

3 Interior

4 Electrical auxiliary heating system 5 Interior £ ä

168 Do-it-yourself

Page 171 of 194

No. Power consumer

6 Glow plugs, radiator fan7 Electrohydraulic power steering

8 ABS or TCS or ESC 9 Radiator fan

10 Automatic gearbox 11 ABS or TCS or ESC

12 Central control unit

13 Electrical auxiliary heating system Note

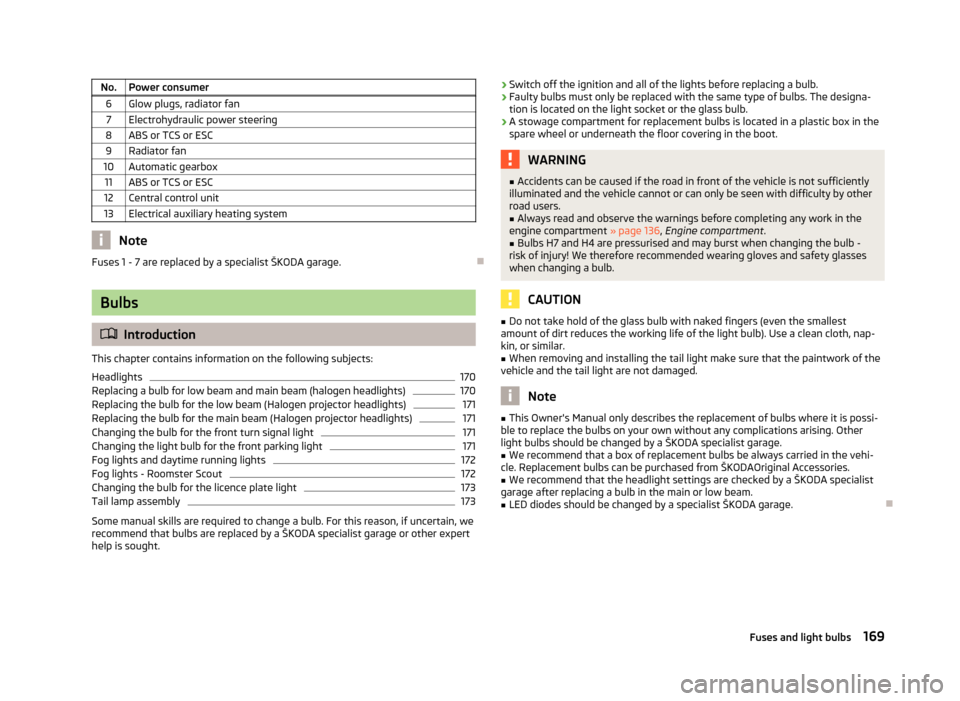

Fuses 1 - 7 are replaced by a specialist ŠKODA garage. ÐBulbs

ä

Introduction

This chapter contains information on the following subjects:

Headlights 170

Replacing a bulb for low beam and main beam (halogen headlights) 170

Replacing the bulb for the low beam (Halogen projector headlights) 171

Replacing the bulb for the main beam (Halogen projector headlights) 171

Changing the bulb for the front turn signal light 171

Changing the light bulb for the front parking light 171

Fog lights and daytime running lights 172

Fog lights - Roomster Scout 172

Changing the bulb for the licence plate light 173

Tail lamp assembly 173

Some manual skills are required to change a bulb. For this reason, if uncertain, we

recommend that bulbs are replaced by a ŠKODA specialist garage or other expert

help is sought. ›

Switch off the ignition and all of the lights before replacing a bulb.

› Faulty bulbs must only be replaced with the same type of bulbs. The designa-

tion is located on the light socket or the glass bulb.

› A stowage compartment for replacement bulbs is located in a plastic box in the

spare wheel or underneath the floor covering in the boot. WARNING

■ Accidents can be caused if the road in front of the vehicle is not sufficiently

illuminated and the vehicle cannot or can only be seen with difficulty by other

road users.

■ Always read and observe the warnings before completing any work in the

engine compartment » page 136, Engine compartment .

■ Bulbs H7 and H4 are pressurised and may burst when changing the bulb -

risk of injury! We therefore recommended wearing gloves and safety glasses

when changing a bulb. CAUTION

■ Do not take hold of the glass bulb with naked fingers (even the smallest

amount of dirt reduces the working life of the light bulb). Use a clean cloth, nap-

kin, or similar. ■ When removing and installing the tail light make sure that the paintwork of the

vehicle and the tail light are not damaged. Note

■ This Owner's Manual only describes the replacement of bulbs where it is possi-

ble to replace the bulbs on your own without any complications arising. Other

light bulbs should be changed by a

ŠKODA specialist garage.

■ We recommend that a box of replacement bulbs be always carried in the vehi-

cle. Replacement bulbs can be purchased from

ŠKODAOriginal Accessories.

■ We recommend that the headlight settings are checked by a ŠKODA specialist

garage after replacing a bulb in the main or low beam.

■ LED diodes should be changed by a specialist ŠKODA garage. Ð

169

Fuses and light bulbs