maintenance SKODA SUPERB 2006 1.G / (B5/3U) Owner's Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2006, Model line: SUPERB, Model: SKODA SUPERB 2006 1.G / (B5/3U)Pages: 281, PDF Size: 12.67 MB

Page 238 of 281

Wheels and Tyres237

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

Wheel alignment errors

Incorrect wheel alignment at the front and rear will not only increase wear-

and-tear on the tyres but will also has an adverse effect on vehicle safety.

Contact your specialist garage if you notice any unusual tyre wear.

WARNING

•If the inflation pressure is too low, the tyre must perform a

greater flexing work. At higher speeds the tyre will warm up as a

result of this. This can result in tread separation and even a tyre

blowout.

•Immediately replace the damaged rims or tyres.

For the sake of the environment

Tyres which are insufficiently inflated increase your fuel consumption.

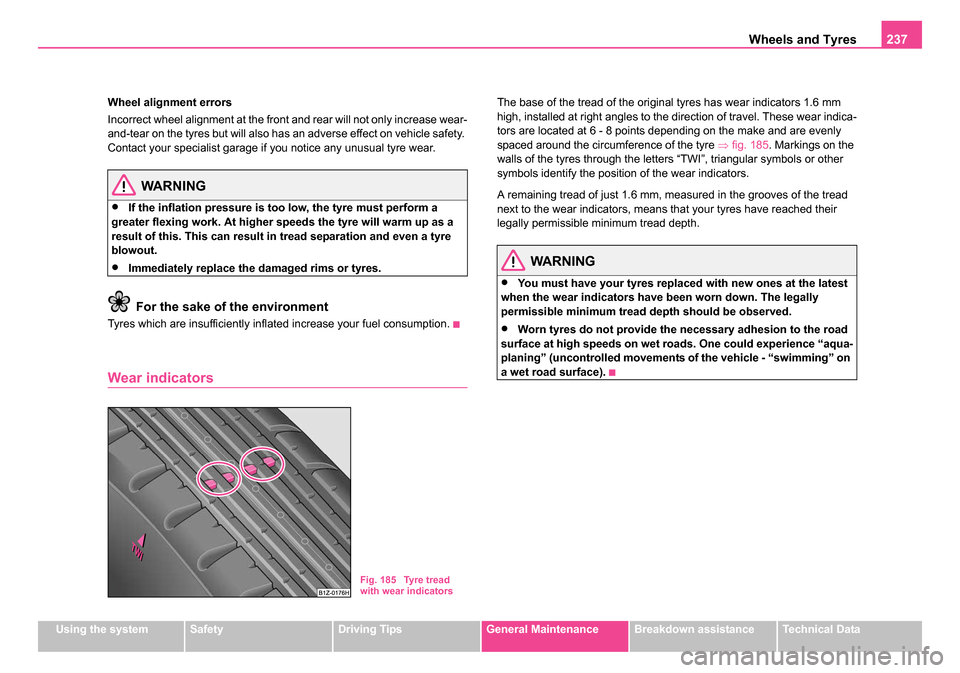

Wear indicators

The base of the tread of the original tyres has wear indicators 1.6 mm

high, installed at right angles to the direction of travel. These wear indica-

tors are located at 6 - 8 points depending on the make and are evenly

spaced around the circumference of the tyre ⇒fig. 185 . Markings on the

walls of the tyres through the letters “TWI”, triangular symbols or other

symbols identify the position of the wear indicators.

A remaining tread of just 1.6 mm, measured in the grooves of the tread

next to the wear indicators, means that your tyres have reached their

legally permissible minimum tread depth.

WARNING

•You must have your tyres replaced with new ones at the latest

when the wear indicators have been worn down. The legally

permissible minimu m tread depth should be observed.

•Worn tyres do not provide the necessary adhesion to the road

surface at high speeds on wet roads. One could experience “aqua-

planing” (uncontrolled movements of the vehicle - “swimming” on

a wet road surface).

Fig. 185 Tyre tread

with wear indicators

NKO B5 20.book Page 237 Monday, July 3, 2006 2:09 PM

Page 240 of 281

Wheels and Tyres239

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

The following

speed restrictions apply to tyres.

The date of manufacture is also stated on the tyre wall (possibly only on

the inside of wheel):

DOT ... 20 04...

means, for example, that the tyre was manufactured in the 20th week of

the year 2004.

Any spare wheel which differs from the tyres fitted to the vehicle (e.g.

winter tyres or low-profile tyres) should only be used only for a short time

in the event of a puncture and when adopting an appropriately cautious

style of driving. It should be replaced as quickly as possible by a normal

wheel.

WARNING

•Only use those tyres or wheel rims which have been approved

for your model of Škoda Auto a.s. vehicle. Failure to observe this

instruction will adversely affect the road safety of your vehicle -

risk of accident! Approval and li cencing of your vehicle on public

roads may also become void as a result.

•You must on no account drive at a higher speed than is permis-

sible for your tyres - risk of an accident resulting from tyre damage

and loss of control over your vehicle.

•Tyres which are 6 years old or more should only be fitted in

exceptional cases and when adopting an appropriately cautious

style of driving.

•Never fit tyres which have already been used without having

adequate knowledge of their previous history. Tyres age even if

they have not been used at all or only very little. A spare tyre must

only be used in exceptional cases and only then when adopting an

appropriately cautious style of driving.

•Do not, where possible, replac e individual tyres but at least

replace them on both wheels of a given axle at the same time.

Always fit the tyres with the deeper tread depth to the front wheels.

For the sake of the environment

Old tyres must be disposed of in conformity with the appropriate regula-

tions.

Note

It is not normally possible to fit wheels from other models of cars for tech-

nical reasons. This may also apply in certain circumstances to the wheels

of the same type of vehicle.

Wheel bolts

Wheels and wheel bolts are matched to each other in terms of design.

Each time you fit other wheels - e.g. light alloy wheels or wheels with

winter tyres - you must therefore also use the matching wheel bolts of the

correct length and shape of spherical cap. This is essential to ensure that

the wheels are tightly fitted and that the brake system operates properly.

Speed symbolPermissible maximum speed

S180 km/h

T190 km/h

H210 km/h

V240 km/h

W270 km/h

Y300 km/h

WARNING (continued)

NKO B5 20.book Page 239 Monday, July 3, 2006 2:09 PM

Page 242 of 281

Wheels and Tyres241

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

WARNING

You must on no account drive your car at more than the permis-

sible maximum speed for your winter tyres - risk of an accident

resulting from tyre damage and loss of control over your car.

For the sake of the environment

Fit your summer tyres on again in good time since summer tyres offer you

better grip and handling on roads which are free of snow and ice as well

as ar temperatures below 7 °C - the braking distance is shorter, there is

less tyre noise, tyre wear is reduced and fuel consumption is reduced.

Note

Please observe the various differing legal requirements regarding tyres.

Unidirectional tyres*

The direction of rotation of the tyres is marked by arrows on the wall of

the tyre . This indicates the direction of rotation of the tyre, and it is essen-

tial that the tyres are fitted on to run in this direction. Only then are the

tyres able to provide the optimal properties in terms of grip, low noise,

wear-and-tear and aquaplaning.

Should it be necessary to fit on a spare wheel in exceptional cases with a

tyre not dedicated to the running direction or in opposite running direction,

please adopt a cautious style of driving as the tyre is no longer able to

provide optimal grip and handling in such a situation. This particularly

important on wet roads. Please refer to the notes ⇒page 247, “Spare

wheel”.

You should have the defective tyre replaced as soon as possible and

restore the correct direction of rotation on all tyres

Snow chains

Snow chains can be used only for wheel sizes 6J x 16 ET 40 or 6J x 16

ET 37. Your Škoda Service Partner can provide you with more detailed

information.

Snow chains must only be mounted on the front wheels.

When driving on wintry roads, snow chains improve not only traction, but

also the braking performance.

Only use fine-link snow chains . They must not project more than 15 mm

- including the chain lock.

Remove the full wheel trims if you wish to fit snow chains to the wheels.

Observe the national legal requirements relating to the maximum vehicle

speed with snow chains.

WARNING

Please pay attention to the information in the supplied fitting

instructions of the snow chain manufacturer.

Caution

You must take the chains off as soon as you drive on roads which are free

of snow. They adversely affect the handling of your vehicle, damage the

tyres and are rapidly destroyed.

Note

We recommend that you use snow chains from the Škoda genuine

accessories.

NKO B5 20.book Page 241 Monday, July 3, 2006 2:09 PM

Page 244 of 281

Accessories, changes and replacement of parts243

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

WARNING

Work or modifications on your vehicle, which have been carried out

unprofessionally, can cause operation al faults - risk of accident!

NKO B5 20.book Page 243 Monday, July 3, 2006 2:09 PM

Page 246 of 281

Breakdown assistance245

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

Breakdown assistance

Breakdown assistance

First-aid box*

First-aid box

The compartment for stowing the first-aid box is located in the left of the

luggage compartment ⇒fig. 187 .

Note

Pay attention to the use-by-date of the contents of the first-aid box.

Warning triangle

– To remove the warning triangle, turn the rotary lock in direction

of arrow ⇒fig. 188 and fold the fixture down.

Fig. 187 Compartment

for stowing first-aid

boxFig. 188 Warning

triangle fitted inside

boot lid

NKO B5 20.book Page 245 Monday, July 3, 2006 2:09 PM

Page 248 of 281

Breakdown assistance247

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

•Hook for pulling off a full wheel trim,

•Plastic clip for a wheel bolt cover,

•Wheel wrench,

•Assembly pin for changing wheel,

•Screwdriver with reversible blade,

•Adapter for the wheel bolts lock.

After using the lifting jack, screw in the arm of the lifting jack fully before

placing it back in its stowage area.

WARNING

•The hexagon socket in the handle of the screwdriver should

only be used to fit on the wheel bolts. Never use the hexagon

socket of the screwdriver for tightening the wheel bolts because

you will not be able to achieve the necessary tightening torque with

the hexagon socket - risk of accident!

•The factory-supplied lifting jack is only intended for your model

of vehicle. On no account attempt to lift a heavier vehicle or other

loads - risk of injury!

•Ensure that the vehicle tool kit is safely attached in the luggage

compartment.

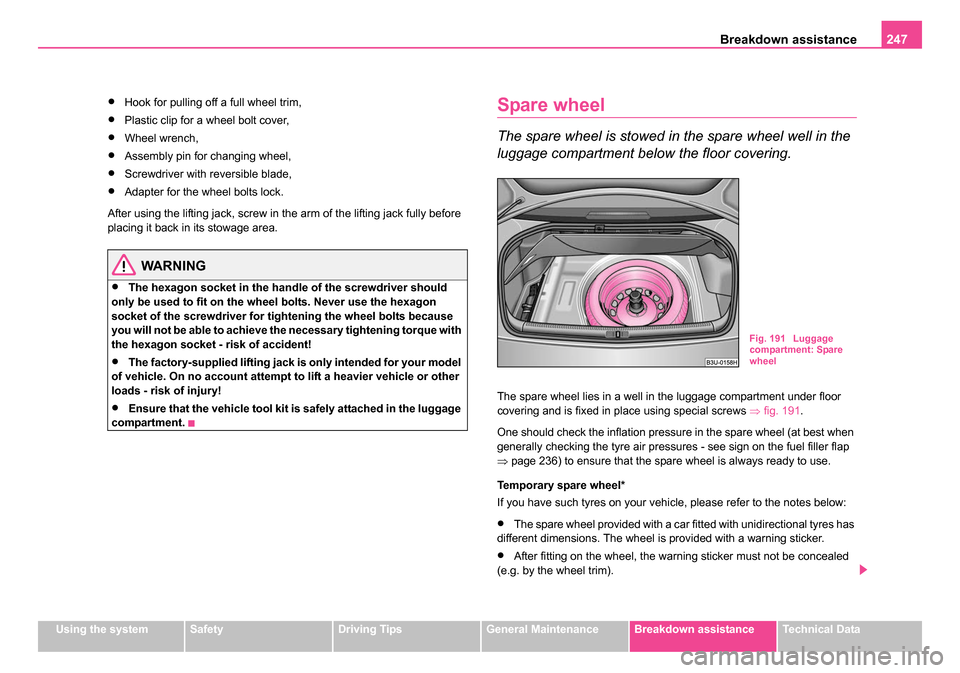

Spare wheel

The spare wheel is stowed in the spare wheel well in the

luggage compartment below the floor covering.

The spare wheel lies in a well in the luggage compartment under floor

covering and is fixed in place using special screws ⇒fig. 191 .

One should check the inflation pressure in the spare wheel (at best when

generally checking the tyre air pressures - see sign on the fuel filler flap

⇒ page 236) to ensure that the spare wheel is always ready to use.

Temporary spare wheel*

If you have such tyres on your vehicle, please refer to the notes below:

•The spare wheel provided with a car fitted with unidirectional tyres has

different dimensions. The wheel is provided with a warning sticker.

•After fitting on the wheel, the warning sticker must not be concealed

(e.g. by the wheel trim).

Fig. 191 Luggage

compartment: Spare

wheel

NKO B5 20.book Page 247 Monday, July 3, 2006 2:09 PM

Page 250 of 281

Breakdown assistance249

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

– Jack up the vehicle until the wheel to be changed is clear of

the ground ⇒page 252.

– Unscrew the wheel bolts and place them on a clean surface (cloth, paper etc.).

– Take off the wheel.

– Fit on the spare wheel and tighten the wheel bolts slightly.

– Lower the car.

– Tighten the wheel bolts firmly, alternately and diagonally using the wheel wrench ⇒page 251.

– Mount the full wheel trim/wheel trim cap or the caps.

Note

•All bolts must be clean and must turn easily.

•You must never grease or oil the wheel bolts!

•When fitting on unidirectional tyres, ensure that the tyres rotate in the

correct direction ⇒page 235.

Subsequent steps

After changing the wheel, you must perform the following steps.

– Stow and attach the replaced wheel in the spare wheel well.

– Stow the vehicle tool kit in the space provided. –

Check the tyre pressure on the spare wheel just mounted as

soon as possible.

– Have the tightening torque of the wheel bolts checked with

a torque wrench as soon as possible. The tightening torque for

steel and light alloy wheels must be 120 Nm.

– Have the defective tyre repaired as soon as possible.

WARNING

It is necessary to observe the guidelines given on ⇒ page 238,

“New tyres and wheels” if the vehicle is subsequently fitted with

tyres which are different to those it was fitted with at the works.

Note

•If you find, when changing the wheel, that the wheel bolts are corroded

and difficult to turn, the bolts must be replaced before checking the tight-

ening torque.

•Drive cautiously and only at a moderate speed to a workshop where

the tightening torque can be checked.

Full wheel trim*

Pulling off

– Hook the clamp (found in the vehicle toolkit) into the reinforced edge of the full wheel trim.

– Push the wheel key through the clamp, support the wheel key at the tyre and pull off the wheel trim.

NKO B5 20.book Page 249 Monday, July 3, 2006 2:09 PM

Page 252 of 281

Breakdown assistance251

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

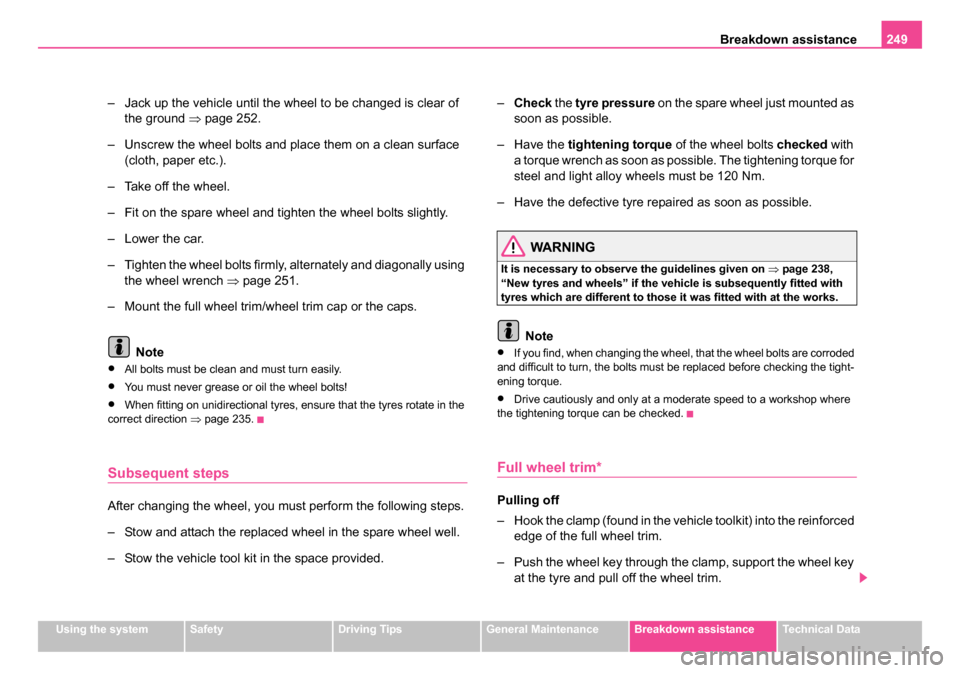

Wheel bolts with caps*

The caps are designed to protect the wheel bolts.

Pulling off

– Insert the plastic clip (in the car tool kit) sufficiently far onto

the cap until the inner catches of the clip are positioned at the

collar of the cap.

– Pull the cap off with the plastic clip ⇒ fig. 193 .

Installing

– Insert the caps onto the bolts.

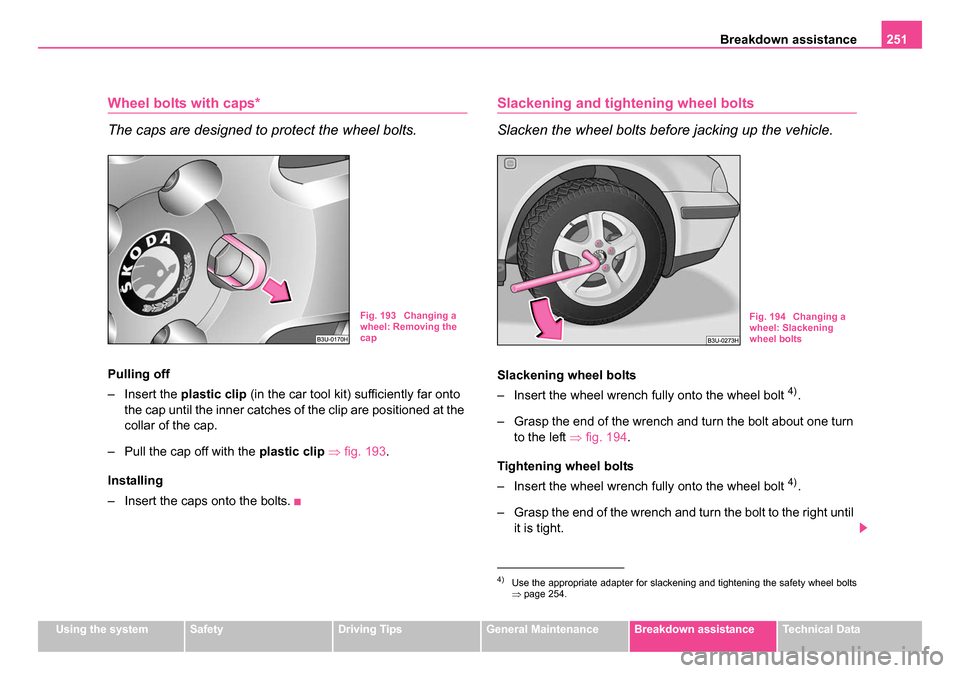

Slackening and tightening wheel bolts

Slacken the wheel bolts before jacking up the vehicle.

Slackening wheel bolts

– Insert the wheel wrench fully onto the wheel bolt

4).

– Grasp the end of the wrench and turn the bolt about one turn to the left ⇒fig. 194.

Tightening wheel bolts

– Insert the wheel wrench fully onto the wheel bolt

4).

– Grasp the end of the wrench and turn the bolt to the right until it is tight.

Fig. 193 Changing a

wheel: Removing the

cap

4)Use the appropriate adapter for slackening and tightening the safety wheel bolts

⇒page 254.

Fig. 194 Changing a

wheel: Slackening

wheel bolts

NKO B5 20.book Page 251 Monday, July 3, 2006 2:09 PM

Page 254 of 281

Breakdown assistance253

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

•It is important to support the vehicle with suitable supporting

blocks if you wish to work under the lifted vehicle - risk of injury!

Taking off and fitting on wheel

After you have slackened the wheel bolts and have raised the car

with the car jack, replace the wheel as follows:

Changing a wheel

– Turn the wheel bolt which is farthest to the top fully out with

the hexagon socket in the screwdriver handle (car tool kit)

and place the bolt down on a clean surface ⇒fig. 196 .

– Screw the assembly pin (car tool kit) into the vacant hole ⇒fig. 197.

– Unscrew the remaining wheel bolts as described above.

– Take off the wheel.

Fitting on wheel

– Push the spare wheel over the assembly pin.

WARNING (continued)

Fig. 196 Changing a

wheel: Remove bolts

with hexagon in screw-

driver

Fig. 197 Changing a

wheel: assembly pin

NKO B5 20.book Page 253 Monday, July 3, 2006 2:09 PM

Page 256 of 281

Breakdown assistance255

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

– Have the tightening torque checked with a torque wrench as

soon as possible. The tightening torque must be 120 Nm.

The safety wheel bolts on vehicles fitted with them (one safety wheel bolt

per wheel) can only be loosened or tighten up by using the adapter

provided.

It is meaningful to note the code number hammered into the rear side of

the adapter or the rear side of the safety wheel bolts. You can obtain a

replacement adapter from a Škoda Service Partner, if necessary, by

quoting this number.

We recommend that you always carry the adapter for the wheel bolts with

you in the vehicle. It should be stowed in the vehicle tool kit.

Caution

•Damage can occur to the adapter and safety wheel bolt if the safety

wheel bolt is tightened up too much.

•On steel wheels, the theft-deterrent wheel bolt must always be

installed in the hole, which is close to the valve. Otherwise the full wheel

trim cannot be mounted and the full wheel trim can be damaged during the

assembly.

Note

The set of safety wheel bolts can be obtained from a Škoda Service

Partner.

Jump-starting

Initial steps

You can use the battery of another vehicle for jump-starting yours if the

engine does not start because the battery on your vehicle is flat. You will

require jump-start cables for this purpose.

Both batteries must have a rated voltage of 12 V. The capacity (Ah) of the

battery supplying the power must not be significantly less than the

capacity of the discharged battery in your vehicle.

Jump-start cables

Only use jump-start cables which have an adequately large cross-section

and insulated terminal clamps. Please pay attention to the manufacturer's

instructions.

Positive cable - colour coding in the majority of cases red.

Negative cable - colour coding in the majority of cases black.

WARNING

•A discharged battery may already freeze at temperatures just

below 0°C. In case of frozen battery carry out no jump-starting - risk

of explosion! Also after thawing of the battery there is a risk of

caustic burns due to leaking acid. Replace the frozen battery.

•Please pay attention to the warning instructions relating to

working in the engine compartment ⇒page 219.

Note

•There must not be any contact between the two vehicles otherwise

current may flow as soon as the negative terminals are connected.

NKO B5 20.book Page 255 Monday, July 3, 2006 2:09 PM