low oil pressure SKODA SUPERB 2006 1.G / (B5/3U) Owner's Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2006, Model line: SUPERB, Model: SKODA SUPERB 2006 1.G / (B5/3U)Pages: 281, PDF Size: 12.67 MB

Page 26 of 281

Instruments and Indicator/Warning Lights25

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

The red symbols indicate

danger (priority 1) while the yellow symbols indi-

cate a warning (priortity 2). Information for the driver may also appear in

addition to the symbols ⇒page 27.

Investigate the displayed faults as soon as possible. If several operational

faults exist at the same time, the symbols will appear one after the other

and are each visible for about 2 seconds.

The error messages are faded out after 10 seconds or by actuating the

rocker switch ⇒page 23, fig. 11 and are stored under the information

CAR STATUS .

There is at least one error message to be read when the term CAR

STATUS is flashing in the main menu. The display will show STATUS 1/2

(for example) if a number of error messages are present. This display indi-

cates that the first of a total of two error messages should be displayed.

Actuate the rocker switch , to call up the individual error messages.

If a fault occurs, a warning signal will also sound in addition to the symbol

and text in the display:

•Priority 1 - three warning signals

•Priority 2 - one warning signal

Operational check of the automatic gearbox

When the ignition is switched on, the Auto Check Control automatically

carries out an operational check. The following text will appear first if the

selector lever is the position P or N:

"APPLY FOOT BRAKE WHEN SELECTING GEAR WITH VEHICLE

STATIONARY." (Apply foot brake when selecting a gear while the

vehicle is stationary).

You must depress the brake pedal first and press the Shiftlock button at

the same time in order to move the selector lever out of these positions. The text will disappear once you select a drive position (

R, D etc.), and the

Auto Check Control function is displayed.

If the Auto Check Control detects faults, these will be displayed about 15

seconds after starting the engine in place of the text shown above. A

warning signal sounds at the same time.

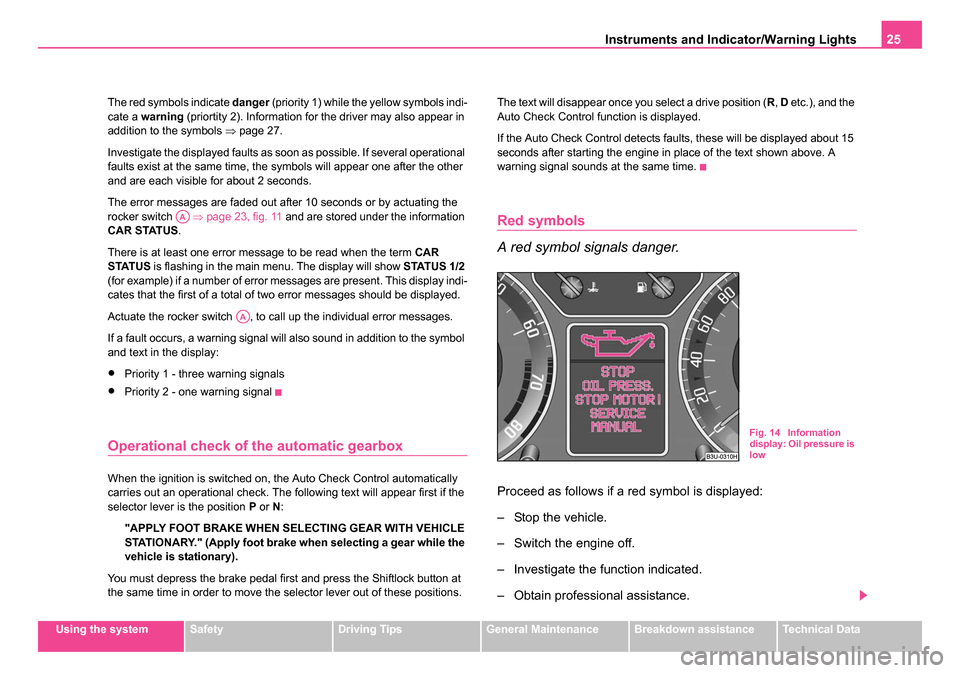

Red symbols

A red symbol signals danger.

Proceed as follows if a red symbol is displayed:

– Stop the vehicle.

– Switch the engine off.

– Investigate the function indicated.

– Obtain professional assistance.

AA

AA

Fig. 14 Information

display: Oil pressure is

low

NKO B5 20.book Page 25 Monday, July 3, 2006 2:09 PM

Page 27 of 281

Instruments and Indicator/Warning Lights

26

Meaning of the red symbols:

Three successive warning signals will sound if a red symbol appears. The

symbol continues flashing until the fault is rectified.

If several operational faults of priority 1 exist, the symbols appear one after

the other and are each illuminated for about 2 seconds.

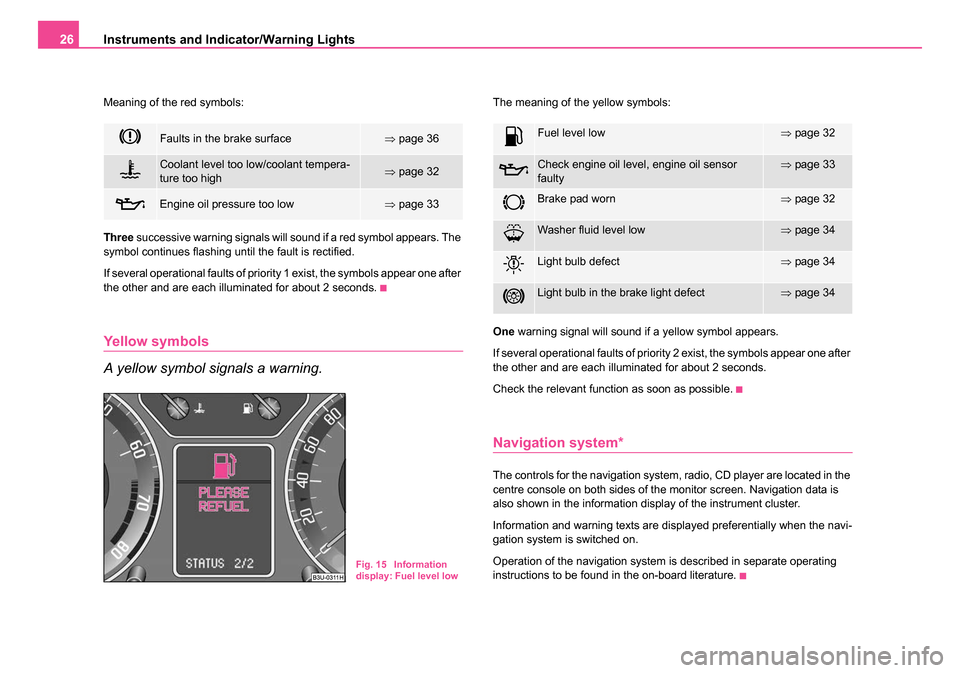

Yellow symbols

A yellow symbol signals a warning.

The meaning of the yellow symbols:

One warning signal will sound if a yellow symbol appears.

If several operational faults of priority 2 exist, the symbols appear one after

the other and are each illuminated for about 2 seconds.

Check the relevant function as soon as possible.

Navigation system*

The controls for the navigation system, radio, CD player are located in the

centre console on both sides of the monitor screen. Navigation data is

also shown in the information display of the instrument cluster.

Information and warning texts are displayed preferentially when the navi-

gation system is switched on.

Operation of the navigation system is described in separate operating

instructions to be found in the on-board literature.

Faults in the brake surface⇒ page 36

Coolant level too low/coolant tempera-

ture too high⇒page 32

Engine oil pressure too low⇒page 33

Fig. 15 Information

display: Fuel level low

Fuel level low⇒page 32

Check engine oil level, engine oil sensor

faulty⇒page 33

Brake pad worn⇒page 32

Washer fluid level low⇒page 34

Light bulb defect⇒page 34

Light bulb in the brake light defect⇒page 34

NKO B5 20.book Page 26 Monday, July 3, 2006 2:09 PM

Page 34 of 281

Instruments and Indicator/Warning Lights33

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

A peep sounds as an additional warning signal.

The following text will be displayed in the information display*:

PLEASE REFUEL

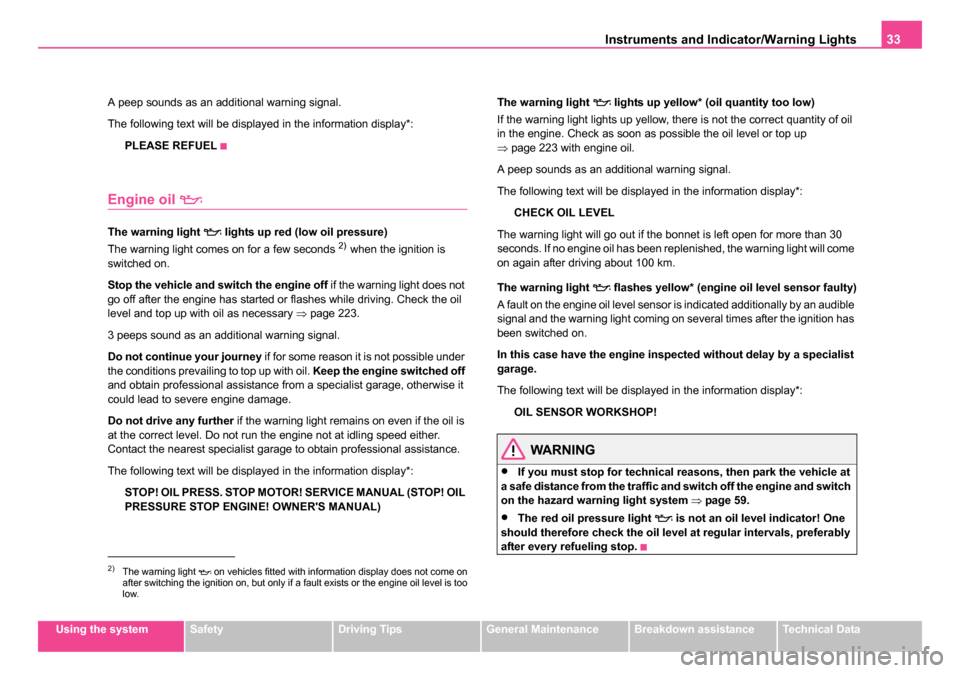

Engine oil

The warning light lights up red (low oil pressure)

The warning light comes on for a few seconds 2) when the ignition is

switched on.

Stop the vehicle and switch the engine off if the warning light does not

go off after the engine has started or flashes while driving. Check the oil

level and top up with oil as necessary ⇒ page 223.

3 peeps sound as an additional warning signal.

Do not continue your journey if for some reason it is not possible under

the conditions prevailing to top up with oil. Keep the engine switched off

and obtain professional assistance from a specialist garage, otherwise it

could lead to severe engine damage.

Do not drive any further if the warning light remains on even if the oil is

at the correct level. Do not run the engine not at idling speed either.

Contact the nearest specialist garage to obtain professional assistance.

The following text will be displayed in the information display*:

STOP! OIL PRESS. STOP MOTOR! SERVICE MANUAL (STOP! OIL

PRESSURE STOP ENGINE! OWNER'S MANUAL) The warning light

lights up yellow* (oil quantity too low)

If the warning light lights up yellow, there is not the correct quantity of oil

in the engine. Check as soon as possible the oil level or top up

⇒ page 223 with engine oil.

A peep sounds as an additional warning signal.

The following text will be displayed in the information display*:

CHECK OIL LEVEL

The warning light will go out if the bonnet is left open for more than 30

seconds. If no engine oil has been replenished, the warning light will come

on again after driving about 100 km.

The warning light

flashes yellow* (engine oil level sensor faulty)

A fault on the engine oil level sensor is indicated additionally by an audible

signal and the warning light coming on several times after the ignition has

been switched on.

In this case have the engine inspected without delay by a specialist

garage.

The following text will be displayed in the information display*:

OIL SENSOR WORKSHOP!

WARNING

•If you must stop for technical reasons, then park the vehicle at

a safe distance from the traffic and switch off the engine and switch

on the hazard warning light system ⇒page 59.

•The red oil pressure light is not an oil le vel indicator! One

should therefore check the oil level at regular intervals, preferably

after every refueling stop.

2)The warning light on vehicles fitted with information display does not come on

after switching the ignition on, but only if a fault exists or the engine oil level is too

low.

NKO B5 20.book Page 33 Monday, July 3, 2006 2:09 PM

Page 190 of 281

Intelligent Technology189

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

Low brake fluid level

An insufficient level of brake fluid may result in problems in the brake

system. The level of the brake fluid is monitored electronically

⇒page 36,

“Brake system ”.

WARNING

•Only apply the brakes for the purpose of drying and cleaning the

brake discs if the traffic conditions permit this. Do not place any

other road users in jeopardy.

•When retrospectively mounting a front spoiler, solid wheel hubs

etc. one must ensure that the air supply to the front wheel brakes

is not reduced otherwise the braking system could run too hot.

•Allow for the fact that new brake pads do not achieve their full

braking efficiency until approximately 200 kilometres. New brake

pads must be first “run in” before they develop their optimal fric-

tion force. You can, however, compensate for this slightly reduced

braking force by increasing the pressure on the brake pedal. This

guideline also applies to any new brake pads installed at a future

date.

Caution

•Never allow the brakes to rub by applying slight pressure if you do not

wish to brake the vehicle. This causes the brakes to overheat and can also

result in a longer braking distance and excessive wear.

•Before negotiating a steep downhill section, please reduce your

speed, shift down into the next lower gear (manual gearbox) or select a

lower driving stage (automatic gearbox). This enables you to make full use

of the braking power of the vehicle and reduces the strain on the brakes.

Any additional braking should be done intermittently, not continuously.

Brake booster

The brake booster boosts the pressure which you generate with the brake

pedal. The necessary pressure is only generated when the engine is

running.

WARNING

•Never switch off the engine before the vehicle is stationary.

•The brake booster only operates when the engine is running.

Greater physical effort for braking is required when engine is

switched off. Because if you do not stop as normal, this can cause

an accident and severe injuries.

Antilock brake system (ABS)

ABS prevents the wheels locking when braking.

General

The ABS contributes significantly to enhancing the active safety of your

vehicle. Compared to a car not fitted with the ABS brake system, you are

able to retain optimal steering ability even during a full brake application

on a slippery road surface because the wheels do not lock up.

You must not expect, however, that the braking distance will be shorter

under all circumstances as a result of the ABS. The braking distance for

example on gravel and fresh snow, when you should anyway be driving

slowly and cautiously, will be longer.

NKO B5 20.book Page 189 Monday, July 3, 2006 2:09 PM

Page 208 of 281

Taking care of your vehicle and cleaning the vehicle 207

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

For the sake of the environment

Only wash your vehicle at washing bays specifically reserved for this

purpose. This ensures that no water which may be contaminated by oil

flows into the sewage system. It is not even permitted to wash your vehicle

in certain areas except at such specific washing bays.

Washing with a high-pressure cleaner

When you wash your vehicle with a high-pressure cleaner, it is essential

to comply with the instructions for use of the cleaning equipment. This

applies in particular to the pressure used and to the spraying distance .

Maintain a sufficiently large distance to soft materials such as rubber

hoses or insulation material.

On no account use circular spray nozzles or so-called dirt cutters!

WARNING

It is particularly important that you do not clean tyres with circular

spray jets. Visible but also invisible damage to tyres may occur

even at a relatively large spraying distance and if sprayed only for

a short time - risk of accident!

Caution

The water containing wax must be no hotter than 60°C, otherwise the

vehicle can be damaged.

Wax treatment

Good wax treatment is an effective way of protecting the paintwork from

harmful environmental influences and minor mechanical damage.

The vehicle must be treated with a high-quality hard wax polish at the

latest, when no more drops form on the clean paintwork.

A new layer of a high-quality hard wax polish can be applied to the clean

bodywork after it has dried thoroughly. Even if you use a wax preserver

regularly we still recommend that you treat the paintwork of the vehicle at

least twice a year with hard wax.

Caution

Never apply wax to the windows.

Polishing

Polishing is only necessary if the paintwork of your vehicle has become

unattractive and if it is no longer possible to achieve a gloss with wax

preservers.

You must treat the paintwork with a wax preserver if the polish you use

does not contain any preserving elements ⇒page 207, “Wax treatment”.

We recommend using a preservative from Škoda genuine accessories

offered by your Škoda dealer.

Caution

•You must not treat mat painted parts or plastic with polishing products

or hard wax.

•Do not polish the paintwork of the vehicle in a dusty environment,

otherwise the paintwork can be scratched.

NKO B5 20.book Page 207 Monday, July 3, 2006 2:09 PM

Page 226 of 281

Inspecting and Replenishing225

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

Your Škoda Service Partner can also supply you with the correct coolant

additives.

Caution

•Other coolant additives may cause operational problems which,

in particular, involves significantly reducing the anticorrosion effect.

•Any faults or problems resulting from corrosion may cause a loss

of coolant and, as a consequence of this, result in major engine

damage.

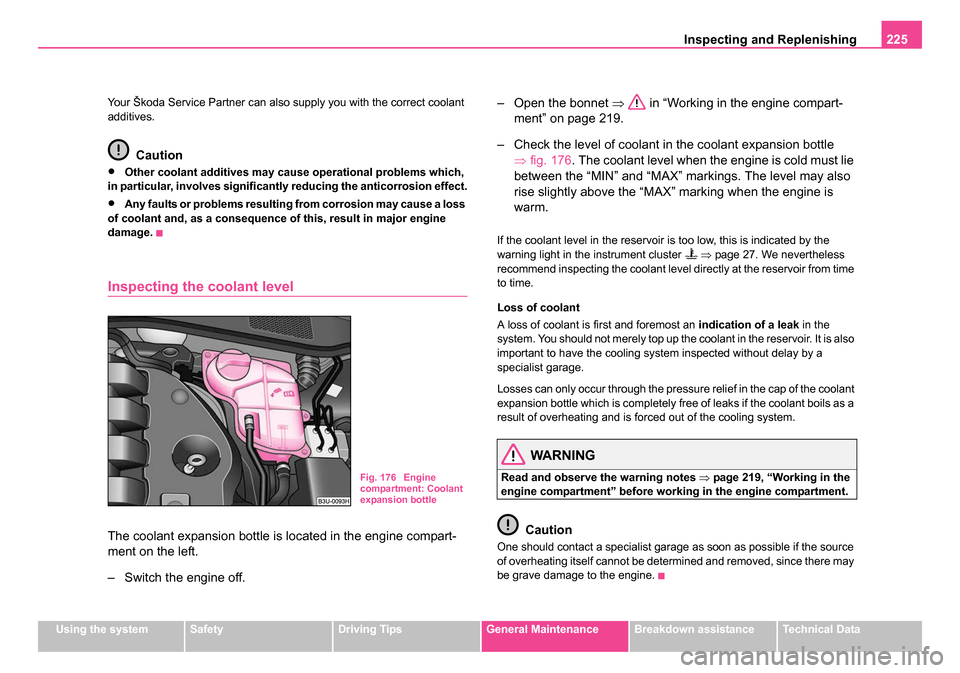

Inspecting the coolant level

The coolant expansion bottle is located in the engine compart-

ment on the left.

– Switch the engine off. – Open the bonnet

⇒ in “Working in the engine compart-

ment” on page 219.

– Check the level of coolant in the coolant expansion bottle ⇒fig. 176. The coolant level when the engine is cold must lie

between the “MIN” and “MAX” markings. The level may also

rise slightly above the “MAX” marking when the engine is

warm.

If the coolant level in the reservoir is too low, this is indicated by the

warning light in the instrument cluster ⇒ page 27. We nevertheless

recommend inspecting the coolant level directly at the reservoir from time

to time.

Loss of coolant

A loss of coolant is first and foremost an indication of a leak in the

system. You should not merely top up the coolant in the reservoir. It is also

important to have the cooling system inspected without delay by a

specialist garage.

Losses can only occur through the pressure relief in the cap of the coolant

expansion bottle which is completely free of leaks if the coolant boils as a

result of overheating and is forced out of the cooling system.

WARNING

Read and observe the warning notes ⇒page 219, “Working in the

engine compartment” before working in the engine compartment.

Caution

One should contact a specialist garage as soon as possible if the source

of overheating itself cannot be determined and removed, since there may

be grave damage to the engine.

Fig. 176 Engine

compartment: Coolant

expansion bottle

NKO B5 20.book Page 225 Monday, July 3, 2006 2:09 PM

Page 250 of 281

Breakdown assistance249

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

– Jack up the vehicle until the wheel to be changed is clear of

the ground ⇒page 252.

– Unscrew the wheel bolts and place them on a clean surface (cloth, paper etc.).

– Take off the wheel.

– Fit on the spare wheel and tighten the wheel bolts slightly.

– Lower the car.

– Tighten the wheel bolts firmly, alternately and diagonally using the wheel wrench ⇒page 251.

– Mount the full wheel trim/wheel trim cap or the caps.

Note

•All bolts must be clean and must turn easily.

•You must never grease or oil the wheel bolts!

•When fitting on unidirectional tyres, ensure that the tyres rotate in the

correct direction ⇒page 235.

Subsequent steps

After changing the wheel, you must perform the following steps.

– Stow and attach the replaced wheel in the spare wheel well.

– Stow the vehicle tool kit in the space provided. –

Check the tyre pressure on the spare wheel just mounted as

soon as possible.

– Have the tightening torque of the wheel bolts checked with

a torque wrench as soon as possible. The tightening torque for

steel and light alloy wheels must be 120 Nm.

– Have the defective tyre repaired as soon as possible.

WARNING

It is necessary to observe the guidelines given on ⇒ page 238,

“New tyres and wheels” if the vehicle is subsequently fitted with

tyres which are different to those it was fitted with at the works.

Note

•If you find, when changing the wheel, that the wheel bolts are corroded

and difficult to turn, the bolts must be replaced before checking the tight-

ening torque.

•Drive cautiously and only at a moderate speed to a workshop where

the tightening torque can be checked.

Full wheel trim*

Pulling off

– Hook the clamp (found in the vehicle toolkit) into the reinforced edge of the full wheel trim.

– Push the wheel key through the clamp, support the wheel key at the tyre and pull off the wheel trim.

NKO B5 20.book Page 249 Monday, July 3, 2006 2:09 PM