engine oil SKODA SUPERB 2008 Owner´s Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2008, Model line: SUPERB, Model: SKODA SUPERB 2008Pages: 252, PDF Size: 16.33 MB

Page 191 of 252

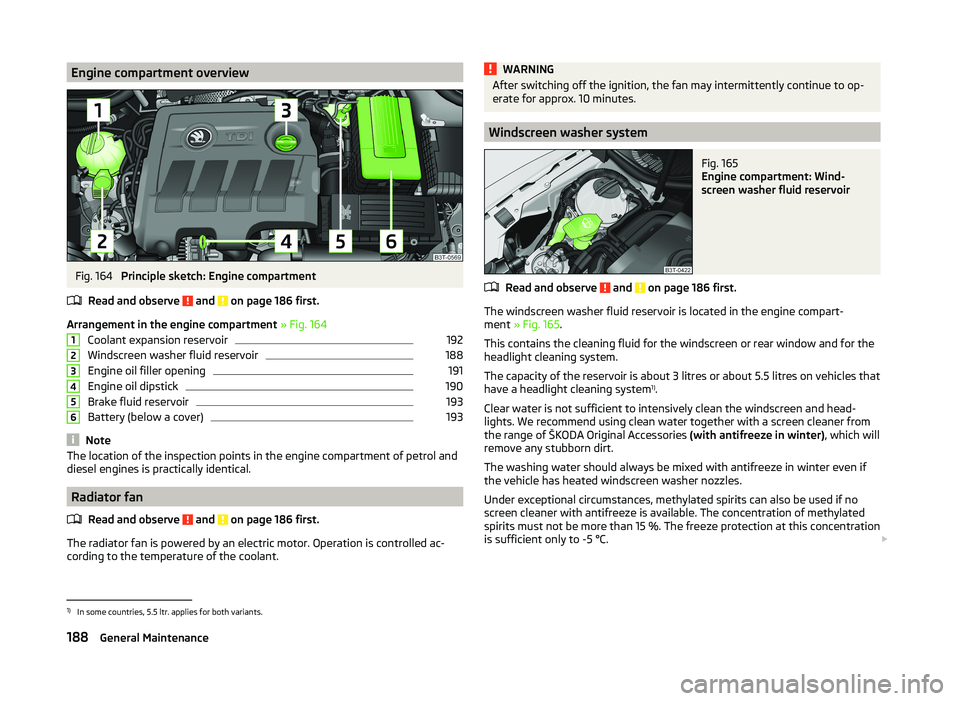

Engine compartment overviewFig. 164

Principle sketch: Engine compartment

Read and observe

and on page 186 first.

Arrangement in the engine compartment » Fig. 164

Coolant expansion reservoir

192

Windscreen washer fluid reservoir

188

Engine oil filler opening

191

Engine oil dipstick

190

Brake fluid reservoir

193

Battery (below a cover)

193

Note

The location of the inspection points in the engine compartment of petrol and

diesel engines is practically identical.

Radiator fan

Read and observe

and on page 186 first.

The radiator fan is powered by an electric motor. Operation is controlled ac-

cording to the temperature of the coolant.

123456WARNINGAfter switching off the ignition, the fan may intermittently continue to op-

erate for approx. 10 minutes.

Windscreen washer system

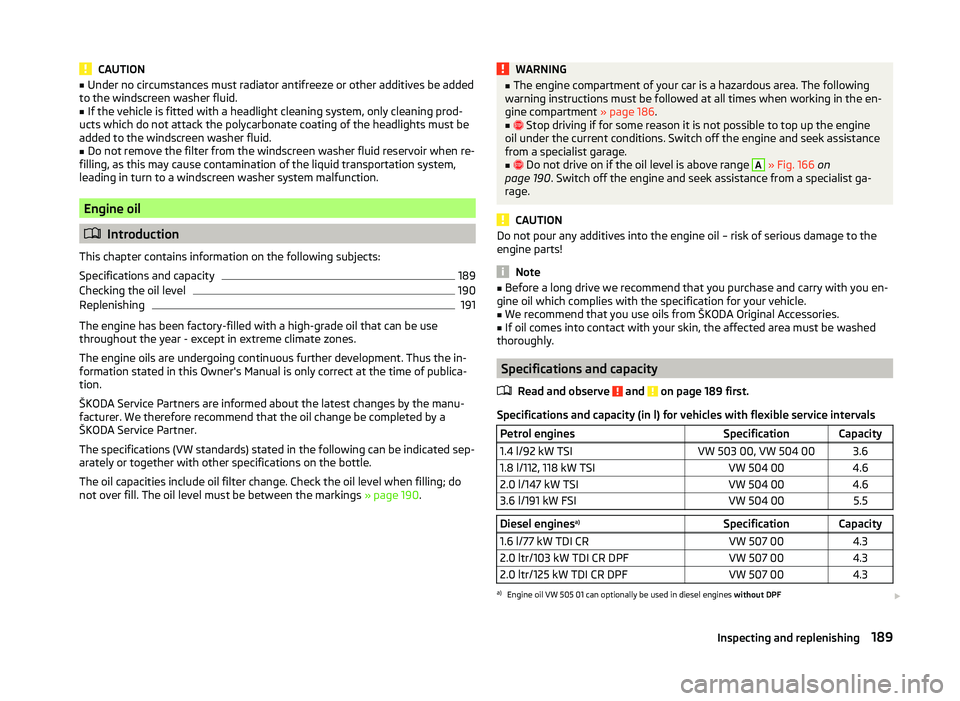

Fig. 165

Engine compartment: Wind-

screen washer fluid reservoir

Read and observe and on page 186 first.

The windscreen washer fluid reservoir is located in the engine compart-

ment » Fig. 165 .

This contains the cleaning fluid for the windscreen or rear window and for the

headlight cleaning system.

The capacity of the reservoir is about 3 litres or about 5.5 litres on vehicles that

have a headlight cleaning system 1)

.

Clear water is not sufficient to intensively clean the windscreen and head-

lights. We recommend using clean water together with a screen cleaner from

the range of ŠKODA Original Accessories (with antifreeze in winter), which will

remove any stubborn dirt.

The washing water should always be mixed with antifreeze in winter even if

the vehicle has heated windscreen washer nozzles.

Under exceptional circumstances, methylated spirits can also be used if no

screen cleaner with antifreeze is available. The concentration of methylated

spirits must not be more than 15 %. The freeze protection at this concentration

is sufficient only to -5 °C.

1)

In some countries, 5.5 ltr. applies for both variants.

188General Maintenance

Page 192 of 252

CAUTION■Under no circumstances must radiator antifreeze or other additives be added

to the windscreen washer fluid.■

If the vehicle is fitted with a headlight cleaning system, only cleaning prod-

ucts which do not attack the polycarbonate coating of the headlights must be

added to the windscreen washer fluid.

■

Do not remove the filter from the windscreen washer fluid reservoir when re-

filling, as this may cause contamination of the liquid transportation system,

leading in turn to a windscreen washer system malfunction.

Engine oil

Introduction

This chapter contains information on the following subjects:

Specifications and capacity

189

Checking the oil level

190

Replenishing

191

The engine has been factory-filled with a high-grade oil that can be use

throughout the year - except in extreme climate zones.

The engine oils are undergoing continuous further development. Thus the in- formation stated in this Owner's Manual is only correct at the time of publica-

tion.

ŠKODA Service Partners are informed about the latest changes by the manu-

facturer. We therefore recommend that the oil change be completed by a

ŠKODA Service Partner.

The specifications (VW standards) stated in the following can be indicated sep-

arately or together with other specifications on the bottle.

The oil capacities include oil filter change. Check the oil level when filling; do

not over fill. The oil level must be between the markings » page 190.

WARNING■

The engine compartment of your car is a hazardous area. The following

warning instructions must be followed at all times when working in the en-

gine compartment » page 186.■

Stop driving if for some reason it is not possible to top up the engine

oil under the current conditions. Switch off the engine and seek assistance

from a specialist garage.

■

Do not drive on if the oil level is above range

A

» Fig. 166 on

page 190 . Switch off the engine and seek assistance from a specialist ga-

rage.

CAUTION

Do not pour any additives into the engine oil – risk of serious damage to the

engine parts!

Note

■ Before a long drive we recommend that you purchase and carry with you en-

gine oil which complies with the specification for your vehicle.■

We recommend that you use oils from ŠKODA Original Accessories.

■

If oil comes into contact with your skin, the affected area must be washed

thoroughly.

Specifications and capacity

Read and observe

and on page 189 first.

Specifications and capacity (in l) for vehicles with flexible service intervals

Petrol enginesSpecificationCapacity1.4 l/92 kW TSIVW 503 00, VW 504 003.61.8 l/112, 118 kW TSIVW 504 004.62.0 l/147 kW TSIVW 504 004.63.6 l/191 kW FSIVW 504 005.5Diesel engines a)SpecificationCapacity1.6 l/77 kW TDI CRVW 507 004.32.0 ltr/103 kW TDI CR DPFVW 507 004.32.0 ltr/125 kW TDI CR DPFVW 507 004.3a)

Engine oil VW 505 01 can optionally be used in diesel engines

without DPF

189Inspecting and replenishing

Page 193 of 252

Specifications and capacity (in l) for vehicles with fixed service intervalsPetrol enginesSpecificationCapacity1.4 l/92 kW TSIVW 501 01, VW 502 003.6

1.8 l/112, 118 kW TSI

VW 502 00

4.6

applies to RussiaSAE 0W-30

VW 502 00 / 505 00

2.0 l/147 kW TSI

VW 502 00

4.6

applies to Russia SAE 0W-30

VW 502 00 / 505 003.6 l/191 kW FSIVW 502 005.5Diesel engines a)SpecificationCapacity1.6 l/77 kW TDI CRVW 507 004.32.0 ltr/103 kW TDI CR DPFVW 507 004.32.0 ltr/125 kW TDI CR DPFVW 507 004.3a)

Engine oil VW 505 01 can optionally be used in diesel engines

without DPF

CAUTION

■

If the above engine oils are not available, a different engine oil can be used in

an emergency. To prevent damage to the engine, a maximum of 0.5 litres only

of the following engine oils may be used until the next oil change: ■ For petrol engine models: ACEA A3/ACEA B4 or API SN/API SM;

■ For diesel engine models: ACEA C3 or API CJ-4.

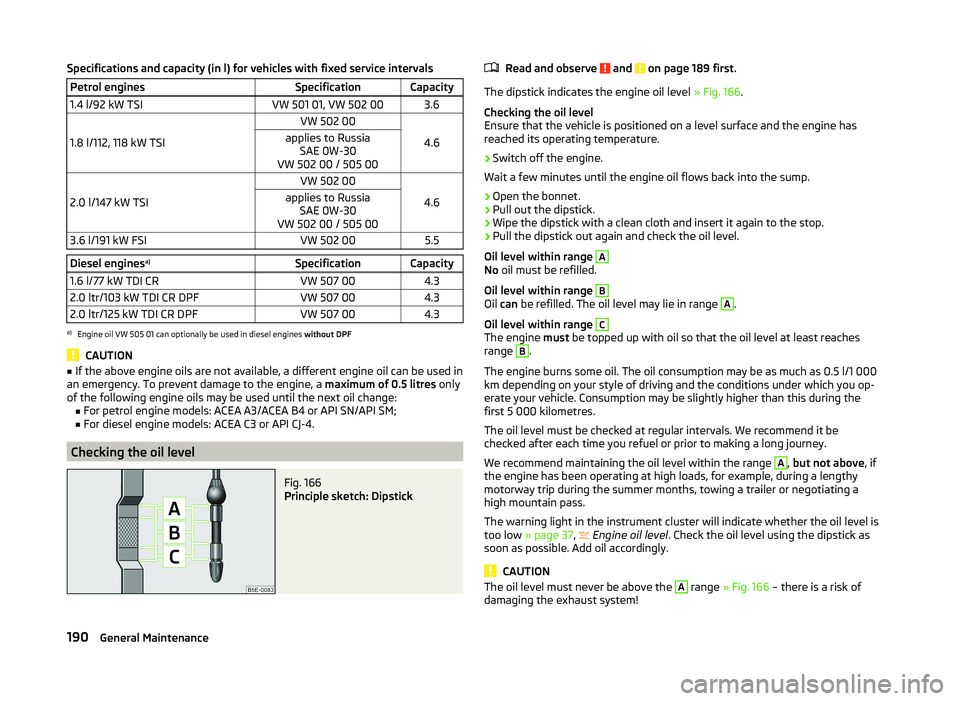

Checking the oil level

Fig. 166

Principle sketch: Dipstick

Read and observe and on page 189 first.

The dipstick indicates the engine oil level » Fig. 166.

Checking the oil level

Ensure that the vehicle is positioned on a level surface and the engine has

reached its operating temperature.

›

Switch off the engine.

Wait a few minutes until the engine oil flows back into the sump.

›

Open the bonnet.

›

Pull out the dipstick.

›

Wipe the dipstick with a clean cloth and insert it again to the stop.

›

Pull the dipstick out again and check the oil level.

Oil level within range

A

No oil must be refilled.

Oil level within range

B

Oil can be refilled. The oil level may lie in range

A

.

Oil level within range

C

The engine must be topped up with oil so that the oil level at least reaches

range

B

.

The engine burns some oil. The oil consumption may be as much as 0.5 l/1 000

km depending on your style of driving and the conditions under which you op-

erate your vehicle. Consumption may be slightly higher than this during the

first 5 000 kilometres.

The oil level must be checked at regular intervals. We recommend it be

checked after each time you refuel or prior to making a long journey.

We recommend maintaining the oil level within the range

A

, but not above , if

the engine has been operating at high loads, for example, during a lengthy

motorway trip during the summer months, towing a trailer or negotiating a

high mountain pass.

The warning light in the instrument cluster will indicate whether the oil level is

too low » page 37 ,

Engine oil level

. Check the oil level using the dipstick as

soon as possible. Add oil accordingly.

CAUTION

The oil level must never be above the A range » Fig. 166 – there is a risk of

damaging the exhaust system!190General Maintenance

Page 194 of 252

ReplenishingRead and observe

and on page 189 first.

›

Check the oil level » page 190.

›

Unscrew the cap of the engine oil filler opening » Fig. 164 on page 188 .

›

Replenish the oil in portions of 0.5 litres in accordance with the correct speci-

fications » page 189 .

›

Check the oil level » page 190.

›

Carefully screw on the oil filler opening cap and push the dipstick in fully.

Coolant

Introduction

This chapter contains information on the following subjects:

Capacity

191

Checking the coolant level

192

Replenishing

192

The coolant consists of water with coolant additive. This mixture guarantees

antifreeze protection, protects the cooling/heater system against corrosion

and prevents lime formation.

Vehicles exported to countries with a mild climate are already factory-filled

with a coolant which offers antifreeze protection down to about -25 ℃. In

these countries, the concentration of coolant additive should be at least 40%.

Vehicles exported to countries with a cold climate are already factory-filled

with a coolant which offers antifreeze protection down to about -35 °C. In

these countries, the concentration of coolant additive should be at least 50%.

If a higher concentration of antifreeze is required for climatic reasons, the con-

centration of coolant additive can be increased up to a maximum of 60% (anti-

freeze protection down to approx. -40 °C).

When refilling, only use the same antifreeze identified on the coolant expan-

sion vessel » Fig. 167 on page 192 .

WARNINGThe engine compartment of your car is a hazardous area. The following

warning instructions must be followed at all times when working in the en- gine compartment » page 186.

CAUTION

■

Do not continue if for some reason it is not possible to fill with coolant un-

der the current circumstances! Switch off the engine and seek assistance from

a specialist garage.■

If the expansion tank is empty, do not top up with coolant. The system could

ventilate - there is a risk of engine damage,

do not continue driving! Switch

off the engine and seek assistance from a specialist garage.

■

The concentration of coolant additive in the coolant must never be under

40%.

■

Over 60% of coolant additive in the coolant reduces the antifreeze protec-

tion and cooling effect.

■

A coolant additive that does not comply with the correct specifications can

significantly reduce the corrosion protection.

■

Any faults resulting from corrosion may cause a loss of coolant and can con-

sequently result in major engine damage!

■

Do not fill the coolant above the mark

A

» Fig. 167 on page 192 .

■

If a fault causes the engine to overheat, we recommend visiting a specialist

garage, as otherwise serious engine damage may occur.

■

Additional headlights and other attached components in front of the air inlet

impair the cooling efficiency of the coolant.

■

Never cover the radiator - there is a risk of the engine overheating.

Capacity

Read and observe

and on page 191 first.

Coolant capacity (in litres) 1)

Petrol enginesCapacity1.4 l/92 kW TSI7.71.8 l/112 kW TSI

1.8 l/118 kW TSI8.6 1)

The coolant capacity is approximately 1 Litre greater on vehicles that are fitted with an auxiliary heater

(auxiliary heating and ventilation).

191Inspecting and replenishing

Page 196 of 252

WARNING■The engine compartment of your car is a hazardous area. The following

warning instructions must be followed at all times when working in the en-

gine compartment » page 186.■

Do not continue your journey if the fluid level has fallen below the MIN

marking » Fig. 168 on page 193 - there is a risk of an accident. Seek help

from a specialist garage.

■

Do not use used brake fluid - the function of the brake system may be im-

paired – risk of accident!

CAUTION

Brake fluid damages the paintwork of the vehicle.

Note

■ The brake fluid is changed as part of a compulsory inspection service.■We recommend using brake fluids from the ŠKODA Original Accessories

range.

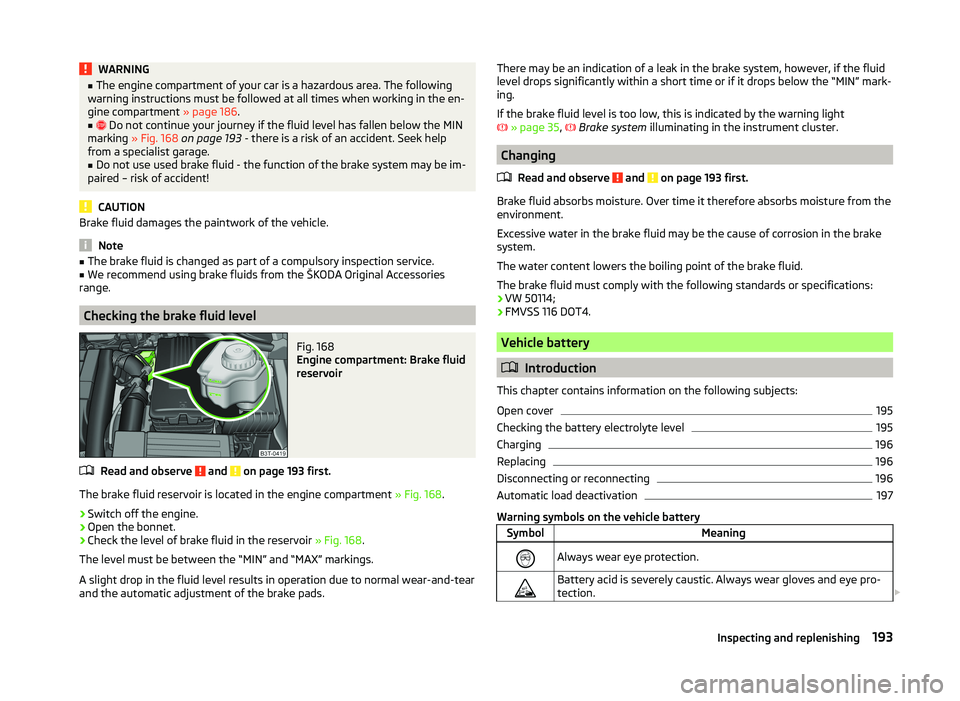

Checking the brake fluid level

Fig. 168

Engine compartment: Brake fluid

reservoir

Read and observe and on page 193 first.

The brake fluid reservoir is located in the engine compartment » Fig. 168.

›

Switch off the engine.

›

Open the bonnet.

›

Check the level of brake fluid in the reservoir » Fig. 168.

The level must be between the “MIN” and “MAX” markings.

A slight drop in the fluid level results in operation due to normal wear-and-tear

and the automatic adjustment of the brake pads.

There may be an indication of a leak in the brake system, however, if the fluid

level drops significantly within a short time or if it drops below the “MIN” mark- ing.

If the brake fluid level is too low, this is indicated by the warning light

» page 35 ,

Brake system illuminating in the instrument cluster.

Changing

Read and observe

and on page 193 first.

Brake fluid absorbs moisture. Over time it therefore absorbs moisture from the

environment.

Excessive water in the brake fluid may be the cause of corrosion in the brake

system.

The water content lowers the boiling point of the brake fluid.

The brake fluid must comply with the following standards or specifications: › VW 50114;

› FMVSS 116 DOT4.

Vehicle battery

Introduction

This chapter contains information on the following subjects:

Open cover

195

Checking the battery electrolyte level

195

Charging

196

Replacing

196

Disconnecting or reconnecting

196

Automatic load deactivation

197

Warning symbols on the vehicle battery

SymbolMeaningAlways wear eye protection.Battery acid is severely caustic. Always wear gloves and eye pro-

tection. 193Inspecting and replenishing

Page 209 of 252

WARNING■If you are in flowing traffic, switch on the hazard warning light system

and set up the warning triangle at the prescribed distance! The national le-

gal requirements must be observed.■

Park the vehicle as far away as possible from the flow of traffic. Park on

as flat and firm a surface as possible.

■

The following instructions must be followed if the vehicle is subsequently

fitted with tyres or rims that differ from the factory fitted ones » page 201,

Explanation of the tyre labelling .

WARNINGInformation on the wheel bolts■The wheel bolts must be clean and must turn easily. Never treat them

with grease or oil.■

The prescribed tightening torque of the wheel bolts for steel and light al-

loy wheels is 120 Nm.

■

If the wheel bolts are tightened to a too low tightening torque, the rim

can come loose when the car is moving. A tightening torque which is too

high can damage the bolts and threads and this can result in permanent

deformation of the contact surfaces on the rim.

■

In case of incorrect treatment of the wheel bolts, the wheel can loosen

when the car is moving.

Note

The national legal requirements must be observed when changing a wheel.

Preliminary work

Read and observe

on page 206 first.

Before changing the wheel, the following work must be carried out.

›

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

›

Switch off the engine.

›

Select the 1st gear or place the selector lever of the automatic transmission

in the P-position .

›

Apply the handbrake firmly.

›

Uncouple a trailer.

›Remove the

vehicle tool kit » page 205 and the spare wheel » page 200 from

the boot.

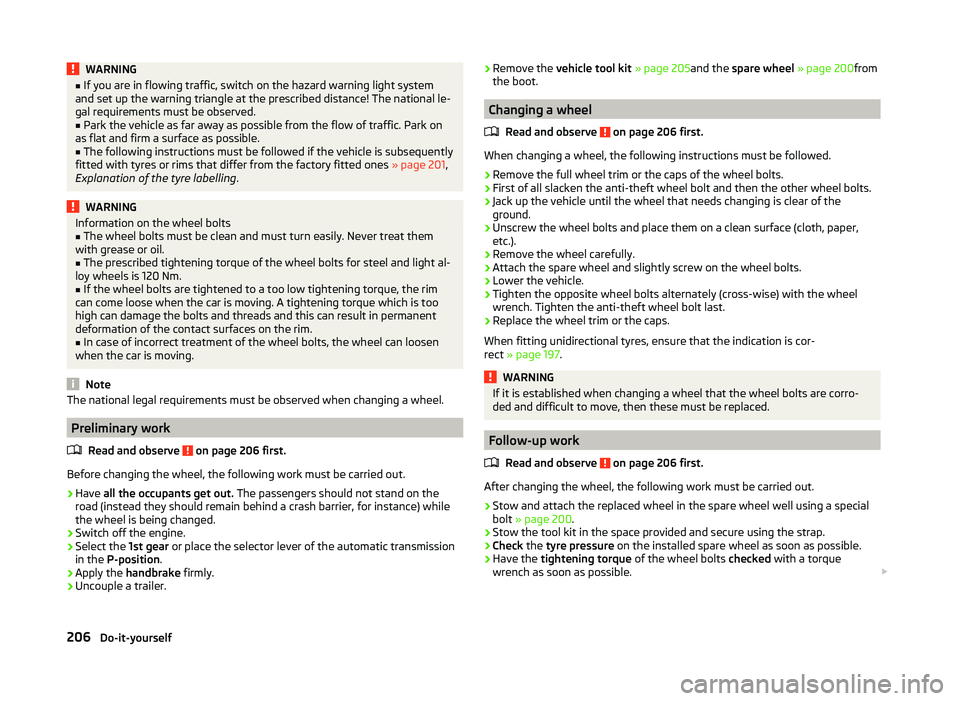

Changing a wheel

Read and observe

on page 206 first.

When changing a wheel, the following instructions must be followed.

›

Remove the full wheel trim or the caps of the wheel bolts.

›

First of all slacken the anti-theft wheel bolt and then the other wheel bolts.

›

Jack up the vehicle until the wheel that needs changing is clear of the

ground.

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper, etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Tighten the opposite wheel bolts alternately (cross-wise) with the wheelwrench. Tighten the anti-theft wheel bolt last.

›

Replace the wheel trim or the caps.

When fitting unidirectional tyres, ensure that the indication is cor-

rect » page 197 .

WARNINGIf it is established when changing a wheel that the wheel bolts are corro-

ded and difficult to move, then these must be replaced.

Follow-up work

Read and observe

on page 206 first.

After changing the wheel, the following work must be carried out.

›

Stow and attach the replaced wheel in the spare wheel well using a special

bolt » page 200 .

›

Stow the tool kit in the space provided and secure using the strap.

›

Check the tyre pressure on the installed spare wheel as soon as possible.

›

Have the tightening torque of the wheel bolts checked with a torque

wrench as soon as possible.

206Do-it-yourself

Page 216 of 252

›After starting the engine, close the protective cap of the jump-starting point.

Towing the vehicle

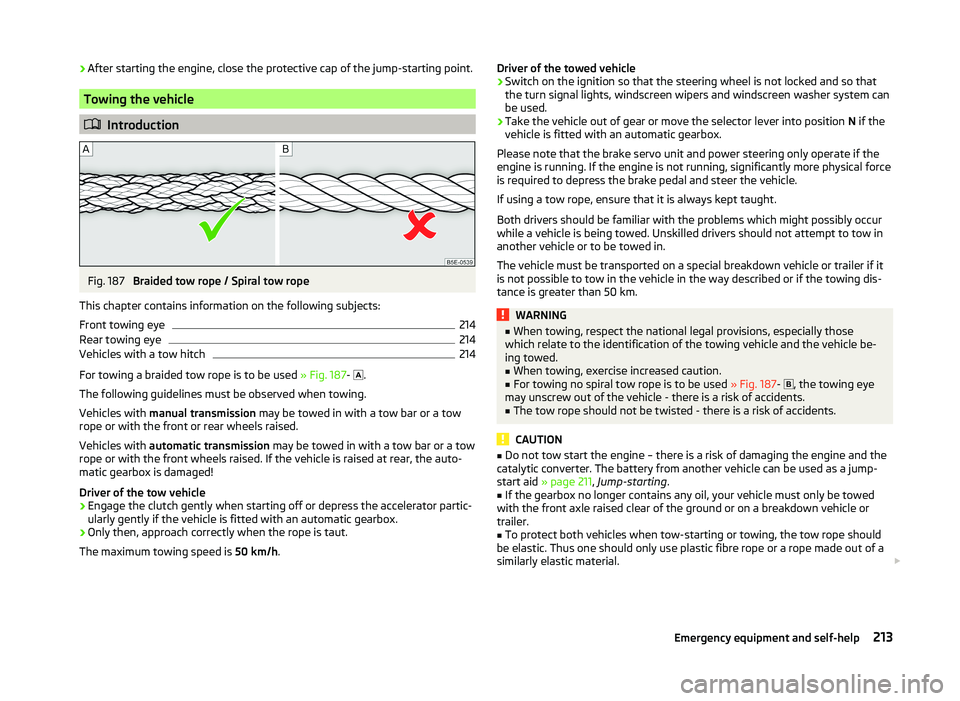

Introduction

Fig. 187

Braided tow rope / Spiral tow rope

This chapter contains information on the following subjects:

Front towing eye

214

Rear towing eye

214

Vehicles with a tow hitch

214

For towing a braided tow rope is to be used » Fig. 187-

.

The following guidelines must be observed when towing.

Vehicles with manual transmission may be towed in with a tow bar or a tow

rope or with the front or rear wheels raised.

Vehicles with automatic transmission may be towed in with a tow bar or a tow

rope or with the front wheels raised. If the vehicle is raised at rear, the auto-

matic gearbox is damaged!

Driver of the tow vehicle

›

Engage the clutch gently when starting off or depress the accelerator partic-

ularly gently if the vehicle is fitted with an automatic gearbox.

›

Only then, approach correctly when the rope is taut.

The maximum towing speed is 50 km/h.

Driver of the towed vehicle›Switch on the ignition so that the steering wheel is not locked and so that

the turn signal lights, windscreen wipers and windscreen washer system can

be used.›

Take the vehicle out of gear or move the selector lever into position N if the

vehicle is fitted with an automatic gearbox.

Please note that the brake servo unit and power steering only operate if the

engine is running. If the engine is not running, significantly more physical force

is required to depress the brake pedal and steer the vehicle.

If using a tow rope, ensure that it is always kept taught.

Both drivers should be familiar with the problems which might possibly occur while a vehicle is being towed. Unskilled drivers should not attempt to tow in

another vehicle or to be towed in.

The vehicle must be transported on a special breakdown vehicle or trailer if it

is not possible to tow in the vehicle in the way described or if the towing dis-

tance is greater than 50 km.

WARNING■ When towing, respect the national legal provisions, especially those

which relate to the identification of the towing vehicle and the vehicle be-

ing towed.■

When towing, exercise increased caution.

■

For towing no spiral tow rope is to be used » Fig. 187-

, the towing eye

may unscrew out of the vehicle - there is a risk of accidents.

■

The tow rope should not be twisted - there is a risk of accidents.

CAUTION

■ Do not tow start the engine – there is a risk of damaging the engine and the

catalytic converter. The battery from another vehicle can be used as a jump-

start aid » page 211 , Jump-starting .■

If the gearbox no longer contains any oil, your vehicle must only be towed

with the front axle raised clear of the ground or on a breakdown vehicle or

trailer.

■

To protect both vehicles when tow-starting or towing, the tow rope should

be elastic. Thus one should only use plastic fibre rope or a rope made out of a

similarly elastic material.

213Emergency equipment and self-help

Page 224 of 252

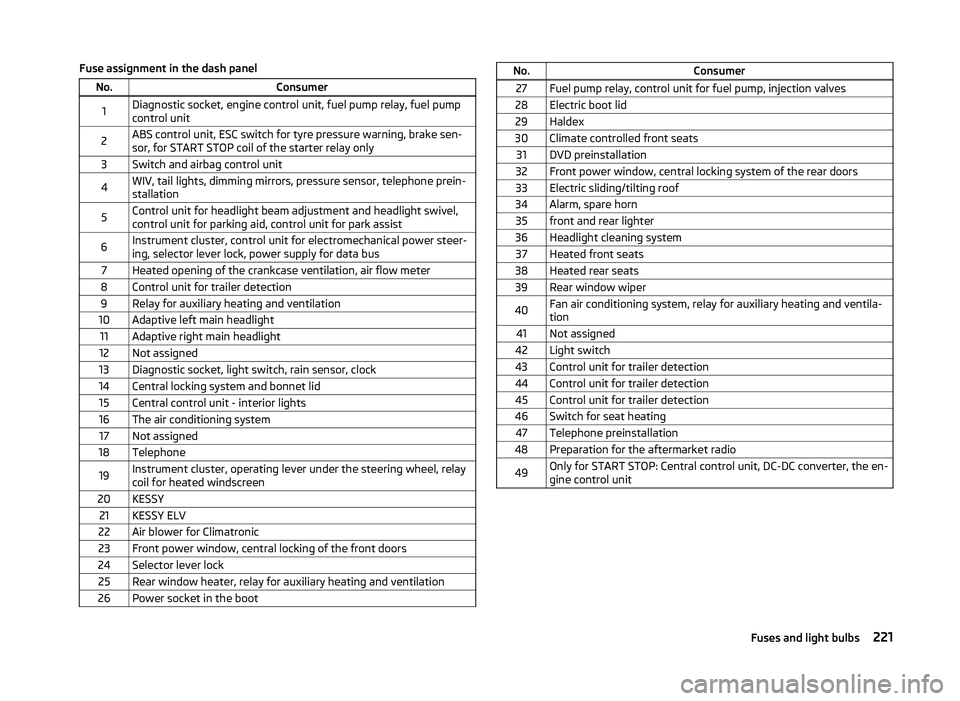

Fuse assignment in the dash panelNo.Consumer1Diagnostic socket, engine control unit, fuel pump relay, fuel pump

control unit2ABS control unit, ESC switch for tyre pressure warning, brake sen-

sor, for START STOP coil of the starter relay only3Switch and airbag control unit4WIV, tail lights, dimming mirrors, pressure sensor, telephone prein-

stallation5Control unit for headlight beam adjustment and headlight swivel,

control unit for parking aid, control unit for park assist6Instrument cluster, control unit for electromechanical power steer-

ing, selector lever lock, power supply for data bus7Heated opening of the crankcase ventilation, air flow meter8Control unit for trailer detection9Relay for auxiliary heating and ventilation10Adaptive left main headlight11Adaptive right main headlight12Not assigned13Diagnostic socket, light switch, rain sensor, clock14Central locking system and bonnet lid15Central control unit - interior lights16The air conditioning system17Not assigned18Telephone19Instrument cluster, operating lever under the steering wheel, relay

coil for heated windscreen20KESSY21KESSY ELV22Air blower for Climatronic23Front power window, central locking of the front doors24Selector lever lock25Rear window heater, relay for auxiliary heating and ventilation26Power socket in the bootNo.Consumer27Fuel pump relay, control unit for fuel pump, injection valves28Electric boot lid29Haldex30Climate controlled front seats31DVD preinstallation32Front power window, central locking system of the rear doors33Electric sliding/tilting roof34Alarm, spare horn35front and rear lighter36Headlight cleaning system37Heated front seats38Heated rear seats39Rear window wiper40Fan air conditioning system, relay for auxiliary heating and ventila-

tion41Not assigned42Light switch43Control unit for trailer detection44Control unit for trailer detection45Control unit for trailer detection46Switch for seat heating47Telephone preinstallation48Preparation for the aftermarket radio49Only for START STOP: Central control unit, DC-DC converter, the en-

gine control unit221Fuses and light bulbs

Page 226 of 252

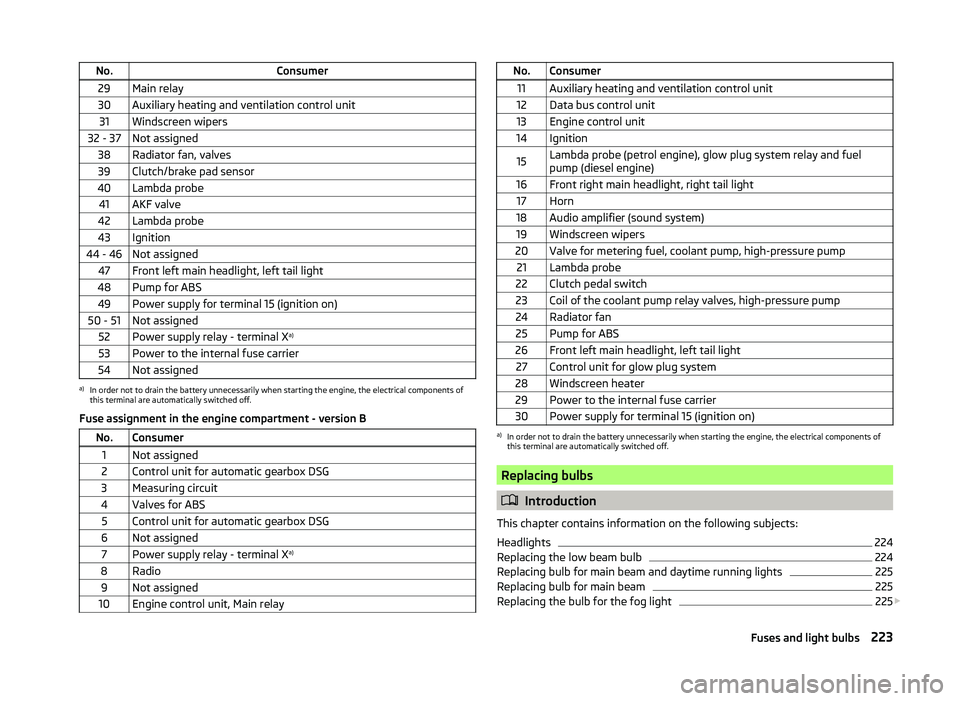

No.Consumer29Main relay30Auxiliary heating and ventilation control unit31Windscreen wipers32 - 37Not assigned38Radiator fan, valves39Clutch/brake pad sensor40Lambda probe41AKF valve42Lambda probe43Ignition44 - 46Not assigned47Front left main headlight, left tail light48Pump for ABS49Power supply for terminal 15 (ignition on)50 - 51Not assigned52Power supply relay - terminal Xa)53Power to the internal fuse carrier54Not assigneda)

In order not to drain the battery unnecessarily when starting the engine, the electrical components of

this terminal are automatically switched off.

Fuse assignment in the engine compartment - version B

No.Consumer1Not assigned2Control unit for automatic gearbox DSG3Measuring circuit4Valves for ABS5Control unit for automatic gearbox DSG6Not assigned7Power supply relay - terminal X a)8Radio9Not assigned10Engine control unit, Main relayNo.Consumer11Auxiliary heating and ventilation control unit12Data bus control unit13Engine control unit14Ignition15Lambda probe (petrol engine), glow plug system relay and fuel

pump (diesel engine)16Front right main headlight, right tail light17Horn18Audio amplifier (sound system)19Windscreen wipers20Valve for metering fuel, coolant pump, high-pressure pump21Lambda probe22Clutch pedal switch23Coil of the coolant pump relay valves, high-pressure pump24Radiator fan25Pump for ABS26Front left main headlight, left tail light27Control unit for glow plug system28Windscreen heater29Power to the internal fuse carrier30Power supply for terminal 15 (ignition on)a)

In order not to drain the battery unnecessarily when starting the engine, the electrical components of

this terminal are automatically switched off.

Replacing bulbs

Introduction

This chapter contains information on the following subjects:

Headlights

224

Replacing the low beam bulb

224

Replacing bulb for main beam and daytime running lights

225

Replacing bulb for main beam

225

Replacing the bulb for the fog light

225

223Fuses and light bulbs

Page 240 of 252

BootAutomatic retraction (Superb Combi)101

Extending variable loading floor105

Folding hook99

Non-closable side pocket (Superb Combi)102

Removable Light (Superb Combi)103

Roll up boot cover (Superb Combi)101

Side compartment with battery102

Boot cover (Superb Combi)101

Boot lid57

automatic locking58

Warning light36

(Superb Combi)58

Brake booster144

Brake fluid192

Checking193

Information messages35

specification193

Brake linings warning light

41

Brakes Brake assist systems

154

Brake booster144

Brake fluid193

Handbrake144

Information messages35

Running in149

Warning light35

Braking Information on braking

143

Break recommendation See Fatigue detection

165

Button in the driver's door Electrical power windows

61

C

Car care

173

Jack180

Car computer See multifunction display

44

Car park ticket holder89

Carrier Roof rack

108

Cavity protection180

CD changer136

Central locking50

Central locking button55

Changing brake fluid

193

bulbs223

Wheels205

Changing a wheel Follow-up work

206

Preliminary work206

Remove and attaching a wheel206

Changing brake fluid

193

Charging a vehicle battery196

Check Fit ball head properly

168

Checking Battery electrolyte level

195

Brake fluid193

Coolant192

Engine oil190

Oil level190

Windscreen washer fluid188

Checks Statutory checks

173

Children and safety22

Child safety Side airbag

24

Child safety lock55

Child seat Classification

25

ISOFIX25

on the front passenger seat23

TOP TETHER27

Use of child seats25

Use of ISOFIX child seats26

Chrome parts refer to Taking care of your vehicle178

Cigarette lighter91

Cleaning Alcantara

182

Covers of electrically heated seats182

Fabrics182

Headlight lenses179

Natural leather181

Plastic parts178

Synthetic leather182

Wheels180

Cleaning the vehicle Towing device

180

Cleaning vehicle176

Climatronic115

Air recirculation117

automatic mode116

Control elements115

Controlling blower118

Cooling system116

Defrosting windscreen118

Setting the temperature116

Clothes hook94

Cockpit 12-Volt power outlet

92

Ashtray91

Cigarette lighter91

General view29

Lighting73

Practical features88

Storage compartments88

Comfort control window

63

COMING HOME72

Compartments88

Components of the puncture repair kits209

Computer See multifunction display

44

237Index