brake light SKODA SUPERB 2008 Owner´s Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2008, Model line: SUPERB, Model: SKODA SUPERB 2008Pages: 252, PDF Size: 16.33 MB

Page 183 of 252

Cavity protectionRead and observe

and on page 177 first.

All the cavities of your vehicle which are at risk from corrosion are protectedfor life by a layer of protective wax applied in the factory.

This wax protection does not need to be inspected or re-applied.

If any small amount of wax flow out of the cavities at high temperatures, these

must be removed with a plastic scraper and the stains cleaned using a petrole-

um cleaner.

WARNINGSafety regulations should be observed when using petroleum cleaner to re-

move wax – risk of fire!

Jack

Read and observe

and on page 177 first.

The jack is maintenance-free.

If necessary, the moving parts of the jack should be lubricated with a suitable lubricant.

Wheels

Read and observe

and on page 177 first.

Wheel rims

Also thoroughly wash the wheel rims when washing the vehicle on a regular basis.

Regularly remove salt and brake abrasion, otherwise the rim material will be

corroded.

Damage to the paint layer on the wheel rims must be touched up immediately.

Light alloy wheels

After washing thoroughly and treat the wheel rims with a protective product

for light alloy wheels. Products which cause abrasion must not be used to

treat the wheel rims.

CAUTIONSevere layers of dirt on the wheels can also result in wheel imbalance. This

may show itself in the form of a wheel vibration which is transmitted to the

steering wheel which, in certain circumstances, can cause premature wear of

the steering. This means it is necessary to remove the dirt.

Towing device and mounting recess

Read and observe

and on page 177 first.

Close the mounting recess with the cap to prevent any ingress of dirt.

If dirt is present, clean the inner surfaces of the mounting recess and treat

with a suitable preservative.

Always check the ball head before hitching a trailer. Apply a suitable grease, if

necessary.

Fit the protective cap when stowing away the ball head to protect the luggage

compartment against dirt.

CAUTION

Apply grease to the inner part of the mounting recess. Make sure you do not

remove any grease.

Underbody protection

Read and observe

and on page 177 first.

The underside of your vehicle is protected for life against chemical and me-

chanical influences.

When driving, it cannot be guaranteed that no damage to the protective layer

will occur.

We recommend having the protective layer underneath the vehicle and the

chassis checked — preferably before the beginning of winter and at the end of

winter.

WARNINGNever use additional underbody protection or anti-corrosion agents for ex-

haust pipes, catalytic converters, diesel particle filters or heat shields.

When the engine reaches its operating temperature, these substances may ignite - risk of fire!180General Maintenance

Page 191 of 252

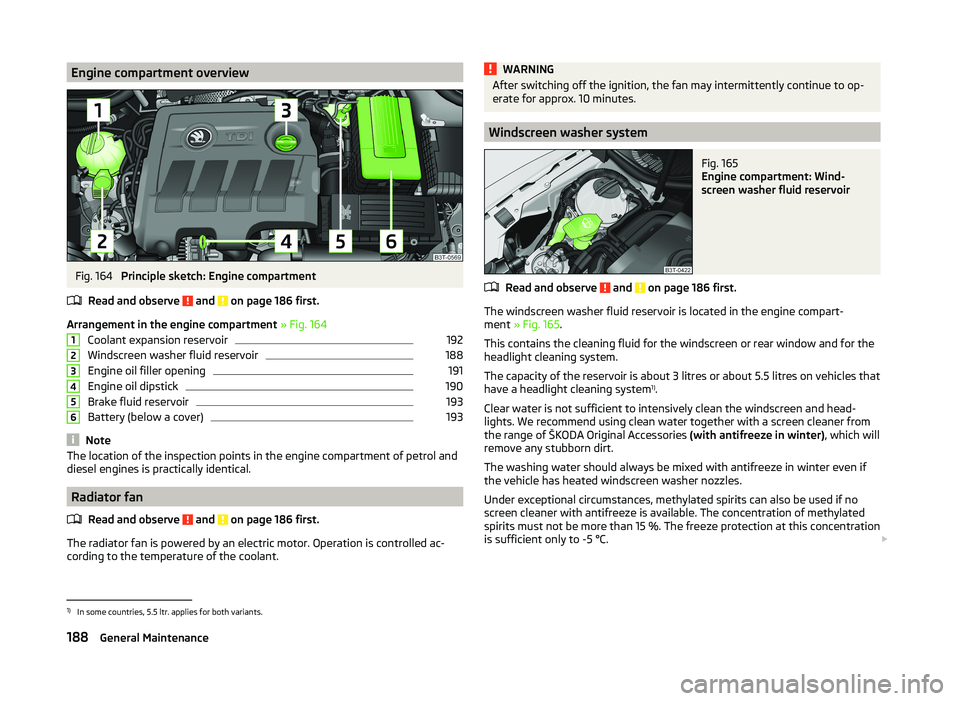

Engine compartment overviewFig. 164

Principle sketch: Engine compartment

Read and observe

and on page 186 first.

Arrangement in the engine compartment » Fig. 164

Coolant expansion reservoir

192

Windscreen washer fluid reservoir

188

Engine oil filler opening

191

Engine oil dipstick

190

Brake fluid reservoir

193

Battery (below a cover)

193

Note

The location of the inspection points in the engine compartment of petrol and

diesel engines is practically identical.

Radiator fan

Read and observe

and on page 186 first.

The radiator fan is powered by an electric motor. Operation is controlled ac-

cording to the temperature of the coolant.

123456WARNINGAfter switching off the ignition, the fan may intermittently continue to op-

erate for approx. 10 minutes.

Windscreen washer system

Fig. 165

Engine compartment: Wind-

screen washer fluid reservoir

Read and observe and on page 186 first.

The windscreen washer fluid reservoir is located in the engine compart-

ment » Fig. 165 .

This contains the cleaning fluid for the windscreen or rear window and for the

headlight cleaning system.

The capacity of the reservoir is about 3 litres or about 5.5 litres on vehicles that

have a headlight cleaning system 1)

.

Clear water is not sufficient to intensively clean the windscreen and head-

lights. We recommend using clean water together with a screen cleaner from

the range of ŠKODA Original Accessories (with antifreeze in winter), which will

remove any stubborn dirt.

The washing water should always be mixed with antifreeze in winter even if

the vehicle has heated windscreen washer nozzles.

Under exceptional circumstances, methylated spirits can also be used if no

screen cleaner with antifreeze is available. The concentration of methylated

spirits must not be more than 15 %. The freeze protection at this concentration

is sufficient only to -5 °C.

1)

In some countries, 5.5 ltr. applies for both variants.

188General Maintenance

Page 195 of 252

Petrol enginesCapacity2.0 l/147 kW TSI8.63.6 l/191 kW FSI9.0Diesel enginesCapacity1.6 l/77 kW TDI CR8.42.0 l/103 kW TDI CR8.42.0 l/125 kW TDI CR8.4

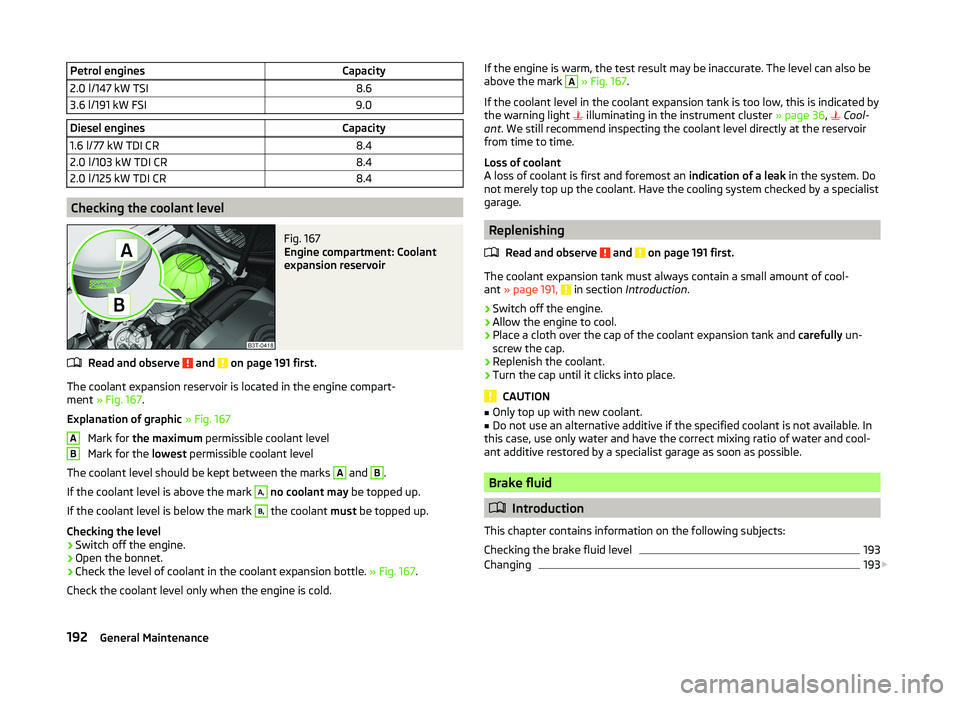

Checking the coolant level

Fig. 167

Engine compartment: Coolant

expansion reservoir

Read and observe and on page 191 first.

The coolant expansion reservoir is located in the engine compart-

ment » Fig. 167 .

Explanation of graphic » Fig. 167

Mark for the maximum permissible coolant level

Mark for the lowest permissible coolant level

The coolant level should be kept between the marks

A

and

B

.

If the coolant level is above the mark

A,

no coolant may be topped up.

If the coolant level is below the mark

B,

the coolant must be topped up.

Checking the level

›

Switch off the engine.

›

Open the bonnet.

›

Check the level of coolant in the coolant expansion bottle. » Fig. 167.

Check the coolant level only when the engine is cold.

ABIf the engine is warm, the test result may be inaccurate. The level can also be

above the mark A » Fig. 167 .

If the coolant level in the coolant expansion tank is too low, this is indicated by

the warning light

illuminating in the instrument cluster » page 36,

Cool-

ant . We still recommend inspecting the coolant level directly at the reservoir

from time to time.

Loss of coolant

A loss of coolant is first and foremost an indication of a leak in the system. Do

not merely top up the coolant. Have the cooling system checked by a specialist

garage.

Replenishing

Read and observe

and on page 191 first.

The coolant expansion tank must always contain a small amount of cool-

ant » page 191, in section Introduction .

›

Switch off the engine.

›

Allow the engine to cool.

›

Place a cloth over the cap of the coolant expansion tank and carefully un-

screw the cap.

›

Replenish the coolant.

›

Turn the cap until it clicks into place.

CAUTION

■ Only top up with new coolant.■Do not use an alternative additive if the specified coolant is not available. In

this case, use only water and have the correct mixing ratio of water and cool-

ant additive restored by a specialist garage as soon as possible.

Brake fluid

Introduction

This chapter contains information on the following subjects:

Checking the brake fluid level

193

Changing

193

192General Maintenance

Page 196 of 252

WARNING■The engine compartment of your car is a hazardous area. The following

warning instructions must be followed at all times when working in the en-

gine compartment » page 186.■

Do not continue your journey if the fluid level has fallen below the MIN

marking » Fig. 168 on page 193 - there is a risk of an accident. Seek help

from a specialist garage.

■

Do not use used brake fluid - the function of the brake system may be im-

paired – risk of accident!

CAUTION

Brake fluid damages the paintwork of the vehicle.

Note

■ The brake fluid is changed as part of a compulsory inspection service.■We recommend using brake fluids from the ŠKODA Original Accessories

range.

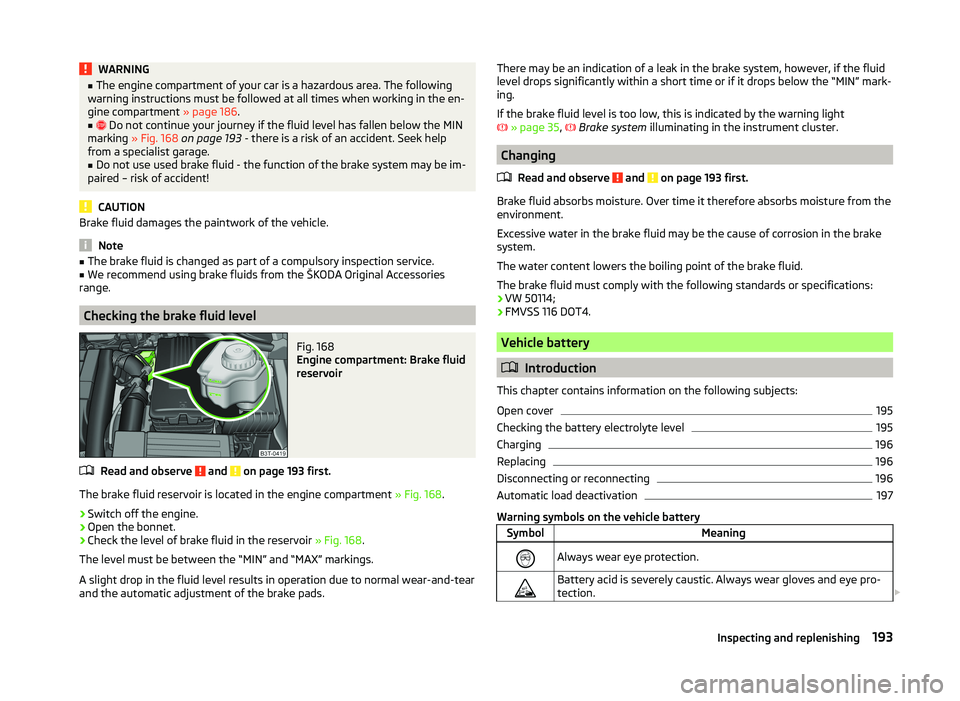

Checking the brake fluid level

Fig. 168

Engine compartment: Brake fluid

reservoir

Read and observe and on page 193 first.

The brake fluid reservoir is located in the engine compartment » Fig. 168.

›

Switch off the engine.

›

Open the bonnet.

›

Check the level of brake fluid in the reservoir » Fig. 168.

The level must be between the “MIN” and “MAX” markings.

A slight drop in the fluid level results in operation due to normal wear-and-tear

and the automatic adjustment of the brake pads.

There may be an indication of a leak in the brake system, however, if the fluid

level drops significantly within a short time or if it drops below the “MIN” mark- ing.

If the brake fluid level is too low, this is indicated by the warning light

» page 35 ,

Brake system illuminating in the instrument cluster.

Changing

Read and observe

and on page 193 first.

Brake fluid absorbs moisture. Over time it therefore absorbs moisture from the

environment.

Excessive water in the brake fluid may be the cause of corrosion in the brake

system.

The water content lowers the boiling point of the brake fluid.

The brake fluid must comply with the following standards or specifications: › VW 50114;

› FMVSS 116 DOT4.

Vehicle battery

Introduction

This chapter contains information on the following subjects:

Open cover

195

Checking the battery electrolyte level

195

Charging

196

Replacing

196

Disconnecting or reconnecting

196

Automatic load deactivation

197

Warning symbols on the vehicle battery

SymbolMeaningAlways wear eye protection.Battery acid is severely caustic. Always wear gloves and eye pro-

tection. 193Inspecting and replenishing

Page 209 of 252

WARNING■If you are in flowing traffic, switch on the hazard warning light system

and set up the warning triangle at the prescribed distance! The national le-

gal requirements must be observed.■

Park the vehicle as far away as possible from the flow of traffic. Park on

as flat and firm a surface as possible.

■

The following instructions must be followed if the vehicle is subsequently

fitted with tyres or rims that differ from the factory fitted ones » page 201,

Explanation of the tyre labelling .

WARNINGInformation on the wheel bolts■The wheel bolts must be clean and must turn easily. Never treat them

with grease or oil.■

The prescribed tightening torque of the wheel bolts for steel and light al-

loy wheels is 120 Nm.

■

If the wheel bolts are tightened to a too low tightening torque, the rim

can come loose when the car is moving. A tightening torque which is too

high can damage the bolts and threads and this can result in permanent

deformation of the contact surfaces on the rim.

■

In case of incorrect treatment of the wheel bolts, the wheel can loosen

when the car is moving.

Note

The national legal requirements must be observed when changing a wheel.

Preliminary work

Read and observe

on page 206 first.

Before changing the wheel, the following work must be carried out.

›

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

›

Switch off the engine.

›

Select the 1st gear or place the selector lever of the automatic transmission

in the P-position .

›

Apply the handbrake firmly.

›

Uncouple a trailer.

›Remove the

vehicle tool kit » page 205 and the spare wheel » page 200 from

the boot.

Changing a wheel

Read and observe

on page 206 first.

When changing a wheel, the following instructions must be followed.

›

Remove the full wheel trim or the caps of the wheel bolts.

›

First of all slacken the anti-theft wheel bolt and then the other wheel bolts.

›

Jack up the vehicle until the wheel that needs changing is clear of the

ground.

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper, etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Tighten the opposite wheel bolts alternately (cross-wise) with the wheelwrench. Tighten the anti-theft wheel bolt last.

›

Replace the wheel trim or the caps.

When fitting unidirectional tyres, ensure that the indication is cor-

rect » page 197 .

WARNINGIf it is established when changing a wheel that the wheel bolts are corro-

ded and difficult to move, then these must be replaced.

Follow-up work

Read and observe

on page 206 first.

After changing the wheel, the following work must be carried out.

›

Stow and attach the replaced wheel in the spare wheel well using a special

bolt » page 200 .

›

Stow the tool kit in the space provided and secure using the strap.

›

Check the tyre pressure on the installed spare wheel as soon as possible.

›

Have the tightening torque of the wheel bolts checked with a torque

wrench as soon as possible.

206Do-it-yourself

Page 213 of 252

Tyre inflation pressure indicator

Air release valve

ON and OFF switch

12 volt cable connector

Tyre inflator bottle with sealing agent

Replacement valve core

The valve remover 1

has a slot at its lower end which fits into the valve core.

The kit is located in a box under the floor covering in the luggage compart-

ment. This contains a sealing means and an air compressor.

Note

The declaration of conformity is included with the air compressor or the log

folder.

Preparations for using the breakdown kit

Read and observe

on page 209 first.

The following preparatory work must be carried out before using the puncturerepair kit.

›

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

›

Switch off the engine.

›

Select the 1st gear or place the selector lever of the automatic transmission

in the P-position .

›

Apply the handbrake firmly.

›

Check that you can carry out the repairs with the breakdown kit

» page 209.

›

Uncouple a trailer.

›

Remove the breakdown kit from the boot.

›

Stick the appropriate sticker

2

» Fig. 183 on page 209 onto the dashboard in

the driver's field of view.

›

Unscrew the valve cap.

›

Use the valve remover

1

to unscrew the valve core and place it on a clean

surface (rag, paper, etc.).

67891011Sealing and inflating the tyre

Read and observe

on page 209 first.

Sealing

›

Shake the tyre inflator bottle

10

» Fig. 183 on page 209 vigorously several

times.

›

Firmly screw the inflation hose

3

onto the tyre inflator bottle

10

in a clock-

wise direction. The film on the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and plug the open end fully onto

the tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

›

Remove the empty tyre inflator bottle from the valve.

›

Screw the valve core back into the tyre valve using the valve remover

1

.

Inflating

›

Screw the air compressor tyre inflation hose

5

» Fig. 183 on page 209 firmly

onto the tyre valve.

›

Check that the air release valve

7

is closed.

›

Start the engine and run it in idle.

›

Plug the connector

9

into 12 Volt socket » page 91, Cigarette lighter .

›

Switch on the air compressor with the ON and OFF switch

8

.

›

Allow the air compressor to run until a pressure of 2.0 - 2.5 bar is achieved.

Maximum run time of 8 minutes » .

›

Switch off the air compressor.

›

If you cannot reach an air pressure of 2.0 - 2.5 bar, unscrew the tyre inflation

hose

5

from the tyre valve.

›

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent

to “distribute” in the tyre.

›

Firmly screw the tyre inflation hose

5

back onto the tyre valve and repeat

the inflation process.

›

If you cannot reach the required tyre inflation pressure here either, this

means the tyre has sustained too much damage. You cannot seal with tyre with the breakdown kit »

.

›

Switch off the air compressor.

›

Remove the tyre inflation hose

5

from the tyre valve.

Once a tyre pressure of 2.0 - 2.5 bar is reached, the journey may be continued

at a maximum speed of 80 km/h (50 mph).

210Do-it-yourself

Page 216 of 252

›After starting the engine, close the protective cap of the jump-starting point.

Towing the vehicle

Introduction

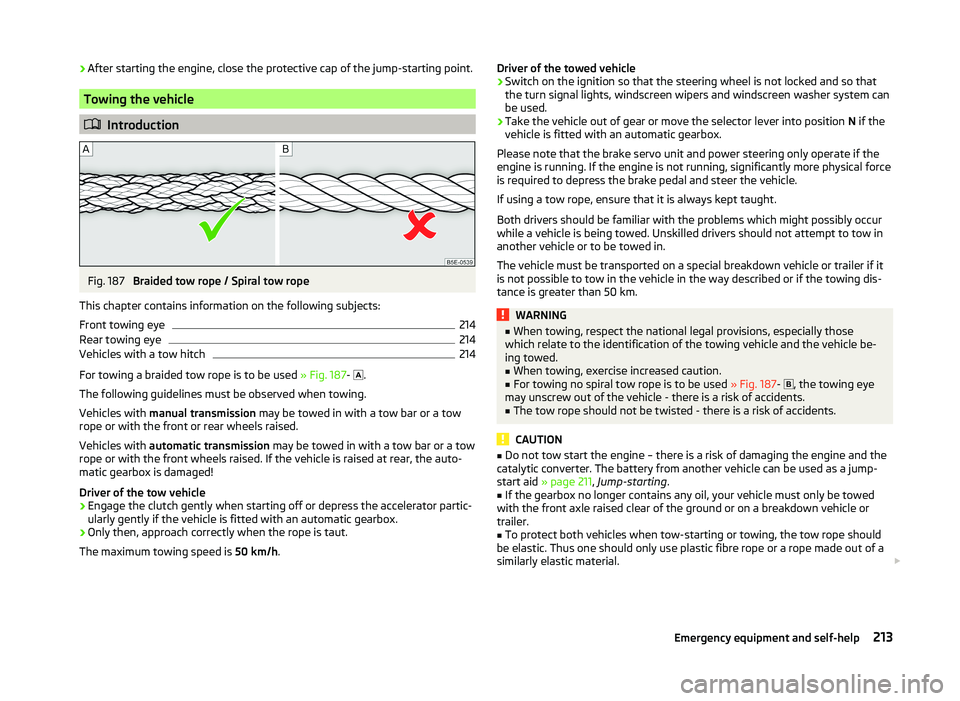

Fig. 187

Braided tow rope / Spiral tow rope

This chapter contains information on the following subjects:

Front towing eye

214

Rear towing eye

214

Vehicles with a tow hitch

214

For towing a braided tow rope is to be used » Fig. 187-

.

The following guidelines must be observed when towing.

Vehicles with manual transmission may be towed in with a tow bar or a tow

rope or with the front or rear wheels raised.

Vehicles with automatic transmission may be towed in with a tow bar or a tow

rope or with the front wheels raised. If the vehicle is raised at rear, the auto-

matic gearbox is damaged!

Driver of the tow vehicle

›

Engage the clutch gently when starting off or depress the accelerator partic-

ularly gently if the vehicle is fitted with an automatic gearbox.

›

Only then, approach correctly when the rope is taut.

The maximum towing speed is 50 km/h.

Driver of the towed vehicle›Switch on the ignition so that the steering wheel is not locked and so that

the turn signal lights, windscreen wipers and windscreen washer system can

be used.›

Take the vehicle out of gear or move the selector lever into position N if the

vehicle is fitted with an automatic gearbox.

Please note that the brake servo unit and power steering only operate if the

engine is running. If the engine is not running, significantly more physical force

is required to depress the brake pedal and steer the vehicle.

If using a tow rope, ensure that it is always kept taught.

Both drivers should be familiar with the problems which might possibly occur while a vehicle is being towed. Unskilled drivers should not attempt to tow in

another vehicle or to be towed in.

The vehicle must be transported on a special breakdown vehicle or trailer if it

is not possible to tow in the vehicle in the way described or if the towing dis-

tance is greater than 50 km.

WARNING■ When towing, respect the national legal provisions, especially those

which relate to the identification of the towing vehicle and the vehicle be-

ing towed.■

When towing, exercise increased caution.

■

For towing no spiral tow rope is to be used » Fig. 187-

, the towing eye

may unscrew out of the vehicle - there is a risk of accidents.

■

The tow rope should not be twisted - there is a risk of accidents.

CAUTION

■ Do not tow start the engine – there is a risk of damaging the engine and the

catalytic converter. The battery from another vehicle can be used as a jump-

start aid » page 211 , Jump-starting .■

If the gearbox no longer contains any oil, your vehicle must only be towed

with the front axle raised clear of the ground or on a breakdown vehicle or

trailer.

■

To protect both vehicles when tow-starting or towing, the tow rope should

be elastic. Thus one should only use plastic fibre rope or a rope made out of a

similarly elastic material.

213Emergency equipment and self-help

Page 224 of 252

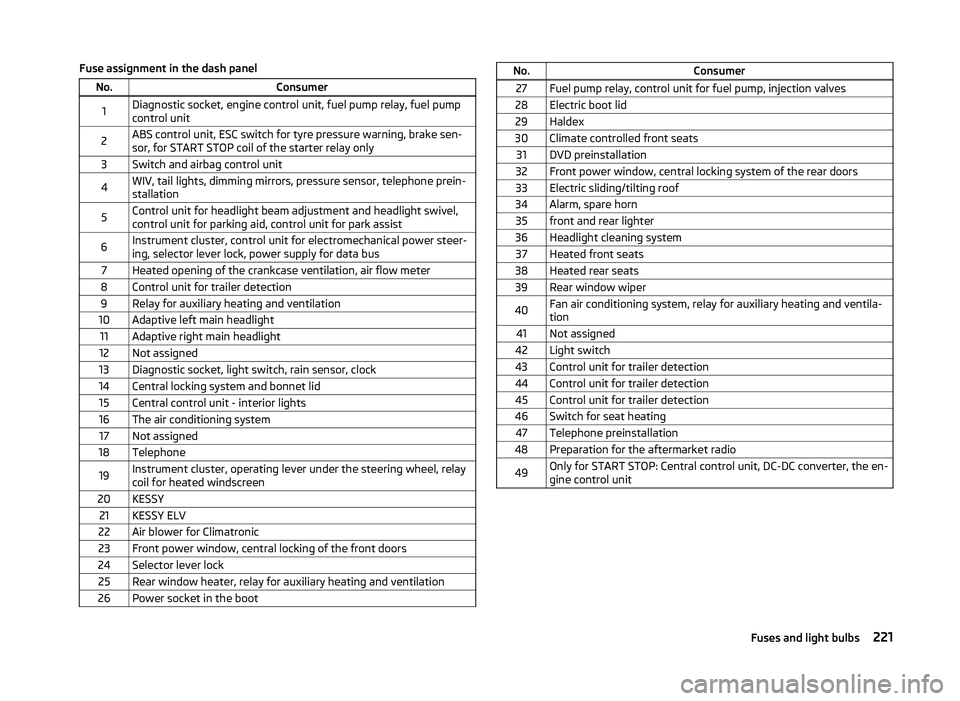

Fuse assignment in the dash panelNo.Consumer1Diagnostic socket, engine control unit, fuel pump relay, fuel pump

control unit2ABS control unit, ESC switch for tyre pressure warning, brake sen-

sor, for START STOP coil of the starter relay only3Switch and airbag control unit4WIV, tail lights, dimming mirrors, pressure sensor, telephone prein-

stallation5Control unit for headlight beam adjustment and headlight swivel,

control unit for parking aid, control unit for park assist6Instrument cluster, control unit for electromechanical power steer-

ing, selector lever lock, power supply for data bus7Heated opening of the crankcase ventilation, air flow meter8Control unit for trailer detection9Relay for auxiliary heating and ventilation10Adaptive left main headlight11Adaptive right main headlight12Not assigned13Diagnostic socket, light switch, rain sensor, clock14Central locking system and bonnet lid15Central control unit - interior lights16The air conditioning system17Not assigned18Telephone19Instrument cluster, operating lever under the steering wheel, relay

coil for heated windscreen20KESSY21KESSY ELV22Air blower for Climatronic23Front power window, central locking of the front doors24Selector lever lock25Rear window heater, relay for auxiliary heating and ventilation26Power socket in the bootNo.Consumer27Fuel pump relay, control unit for fuel pump, injection valves28Electric boot lid29Haldex30Climate controlled front seats31DVD preinstallation32Front power window, central locking system of the rear doors33Electric sliding/tilting roof34Alarm, spare horn35front and rear lighter36Headlight cleaning system37Heated front seats38Heated rear seats39Rear window wiper40Fan air conditioning system, relay for auxiliary heating and ventila-

tion41Not assigned42Light switch43Control unit for trailer detection44Control unit for trailer detection45Control unit for trailer detection46Switch for seat heating47Telephone preinstallation48Preparation for the aftermarket radio49Only for START STOP: Central control unit, DC-DC converter, the en-

gine control unit221Fuses and light bulbs

Page 226 of 252

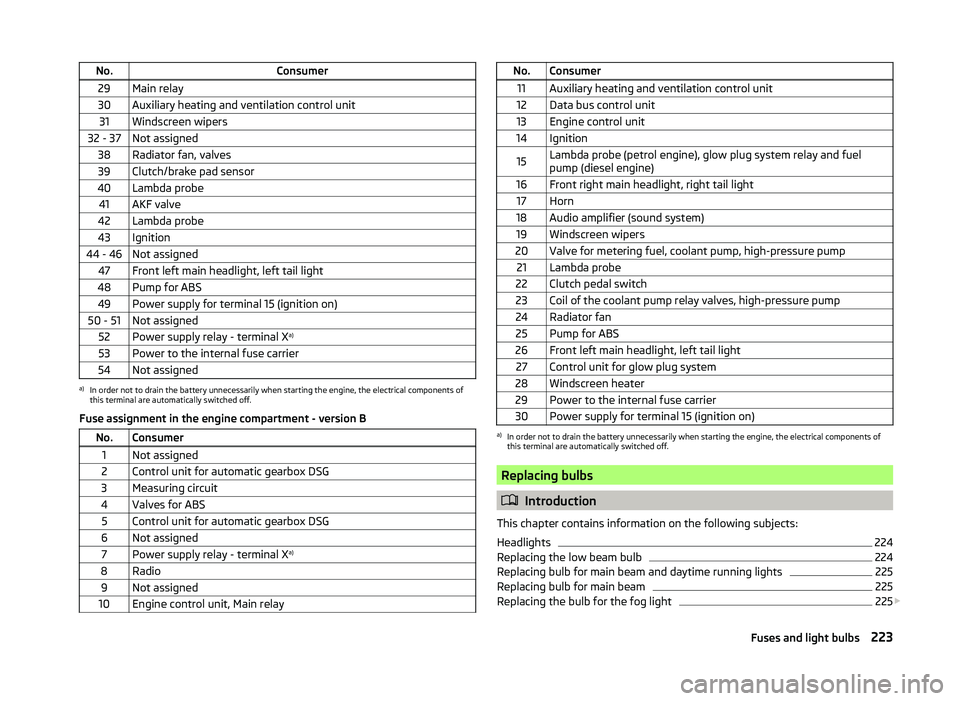

No.Consumer29Main relay30Auxiliary heating and ventilation control unit31Windscreen wipers32 - 37Not assigned38Radiator fan, valves39Clutch/brake pad sensor40Lambda probe41AKF valve42Lambda probe43Ignition44 - 46Not assigned47Front left main headlight, left tail light48Pump for ABS49Power supply for terminal 15 (ignition on)50 - 51Not assigned52Power supply relay - terminal Xa)53Power to the internal fuse carrier54Not assigneda)

In order not to drain the battery unnecessarily when starting the engine, the electrical components of

this terminal are automatically switched off.

Fuse assignment in the engine compartment - version B

No.Consumer1Not assigned2Control unit for automatic gearbox DSG3Measuring circuit4Valves for ABS5Control unit for automatic gearbox DSG6Not assigned7Power supply relay - terminal X a)8Radio9Not assigned10Engine control unit, Main relayNo.Consumer11Auxiliary heating and ventilation control unit12Data bus control unit13Engine control unit14Ignition15Lambda probe (petrol engine), glow plug system relay and fuel

pump (diesel engine)16Front right main headlight, right tail light17Horn18Audio amplifier (sound system)19Windscreen wipers20Valve for metering fuel, coolant pump, high-pressure pump21Lambda probe22Clutch pedal switch23Coil of the coolant pump relay valves, high-pressure pump24Radiator fan25Pump for ABS26Front left main headlight, left tail light27Control unit for glow plug system28Windscreen heater29Power to the internal fuse carrier30Power supply for terminal 15 (ignition on)a)

In order not to drain the battery unnecessarily when starting the engine, the electrical components of

this terminal are automatically switched off.

Replacing bulbs

Introduction

This chapter contains information on the following subjects:

Headlights

224

Replacing the low beam bulb

224

Replacing bulb for main beam and daytime running lights

225

Replacing bulb for main beam

225

Replacing the bulb for the fog light

225

223Fuses and light bulbs

Page 239 of 252

Index

A

Abroad Driving abroad

153

Unleaded petrol153

ABS Operation

155

Warning light38

Accessories173

Adaptive headlights (AHL)70

Adjust Auxiliary heating (auxiliary heating and ventila- tion)

119

Head restraints83

Adjusting Belt height

15

Exterior mirrors80

Interior mirror79

Manual air conditioning114

Seats81, 82

Steering wheel10

Adjusting the seats9, 81

Adjustment Range of light

68

Aerial177

See windows179

AHL70

Warning light38

Airbag16

Deactivating21

Deactivating the front passenger airbag21

Deployment16

Front airbag17

Head airbag20

Indicator light40

Knee airbag18

Modifications and damage to the airbag system 175

Side airbag

19

Airbag system16

Air conditioning system110

Air outlets110

Climatronic115

Manual air conditioning system112

Air outlets110

Air recirculation Climatronic

117

Alarm Switching off

55

Triggering55

Anti-theft alarm system Activating/deactivating

56

Trailer172

Anti-theft wheel bolts208

Antilock brake system (ABS)155

Armrest Front

87

rear96

Rear87

Ashtray91

ASR Operation

155

warning light37

Assist systems154

ABS38, 155

ASR37, 155

Cruise Control System161

DSR155

EDL155

ESC37, 154

HBA155

HHC156

Park assist157

Parking aid156

START STOP162

Audio see radio / navigation system

4

Auto Check Control33

Automatic driving lamp control70

Automatic gearbox Selector lever-emergency unlocking217

Starting off and driving147

Tiptronic146

Using the selector lever145

Automatic gearbox modes145

Automatic load deactivation197

Automatic retractable cargo cover (Superb Combi))

101

Automatic transmission145

Kickdown147

Malfunction148

Selector lever lock146

AUX Installation in the storage compartment

92

Auxiliary heating (auxiliary heating and ventila- tion)

118

Adjust119

Radio remote control120

Switching on/off119

Avoiding damage to the vehicle Driving through water

152

Avoiding damage to your vehicle152

B

Ball head Check fitting

168

Fitting168

Ready position167

Removing169

Battery In the remote control key

215

Replace the remote control of the auxiliary heater (parking heater)

216

Belts12

Belt tensioners15

Bonnet Closing

187

Opening187

Warning light36

236Index