warning SKODA SUPERB 2009 2.G / (B6/3T) Owner's Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2009, Model line: SUPERB, Model: SKODA SUPERB 2009 2.G / (B6/3T)Pages: 294, PDF Size: 21.33 MB

Page 242 of 294

Accessories, changes and

replacement of parts

241

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

Accessories, changes and replacement of partsAccessories and replacement partsŠkoda vehicles have been bu

ilt according to the latest discoveries in safety engi-

neering. Thus one should no

t change the condition in which the vehicle was deliv-

ered from the manufacturer without some thought. The following guidelines should be observed when a vehicle is to be retrofitted with accessories, have technical ch

anges made to it or a par t has to be replaced at some

time in the future.•

Advise should always be obtained from an authorised Škoda Service Partner

before

buying any accessories and

before

making any technical changes

⇒

.

•

This is particularly the case when acce

ssories are bought in a foreign country.

•

Škoda Genuine Accessories and Skoda or

iginal parts can be bought from

authorised Škoda Service Partners who also professionally undertake the assembly of parts which were not purchased there.•

All Škoda original accessories which are listed in the catalogue of original acces-

sories such as spoilers, transport systems, child seats, etc., are homologized.•

Radios, aerials and other electrical accessories should only be installed by

authorised Škoda Service Partners.•

The guidelines issued by Škoda Auto must be observed when making technical

changes.•

This is to ensure that no technical damage

occurs to the vehicle, that travelling

and operating safety are maintained and that the chnages are permissible. The authorised Škoda Service Partners undertake this work professionally or refer it to a specialist company in special cases. Any damage which is done caused by technical changes made without consulting a Skoda dealer is

excluded from the guarantee.

WARNING

•

We advise you, in your own interest, to only use Škoda Genuine Accesso-

ries and Škoda original parts which have

been expressly approved for use on

your Škoda. Reliability, safety and su

itabiliity have been established for

these Škoda original parts.•

We cannot guarantee suitability of installation into your vehicle of other

products despite keeping a constant ey

e on market developments (also not

in the case where there is an attestation or permission can be produced).Technical changesInterference on the electronic components and their software can lead to opera-tional faults. This interference can also impair not directly affected systems because of the networking of the electronic co

mponents. This means that the operating

safety of your vehicle can

be considerably jeopardized,

a greater wear of vehicle

parts can occur and finally the vehi

cle registration documents expire.

We trust that you will understand that

Škoda Auto cannot be liable for damage

resulting from unprofessional work. We therefore recommend that you have all work carried out using Škoda original parts at authorised Škoda Service Partners.

WARNING

Work or modifications on your vehicle, which have been carried out unpro-fessionally, can cause operational faults - risk of accident!Vehicles of the group N1The vehicle of the group N1 is a box car wh

ich is designed and manufactured for the

transportation of goods.

WARNING (continued)

s2dk.1.book Page 241 Wednesday, April 8, 2009 12:23 PM

Page 244 of 294

Breakdown assistance

243

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

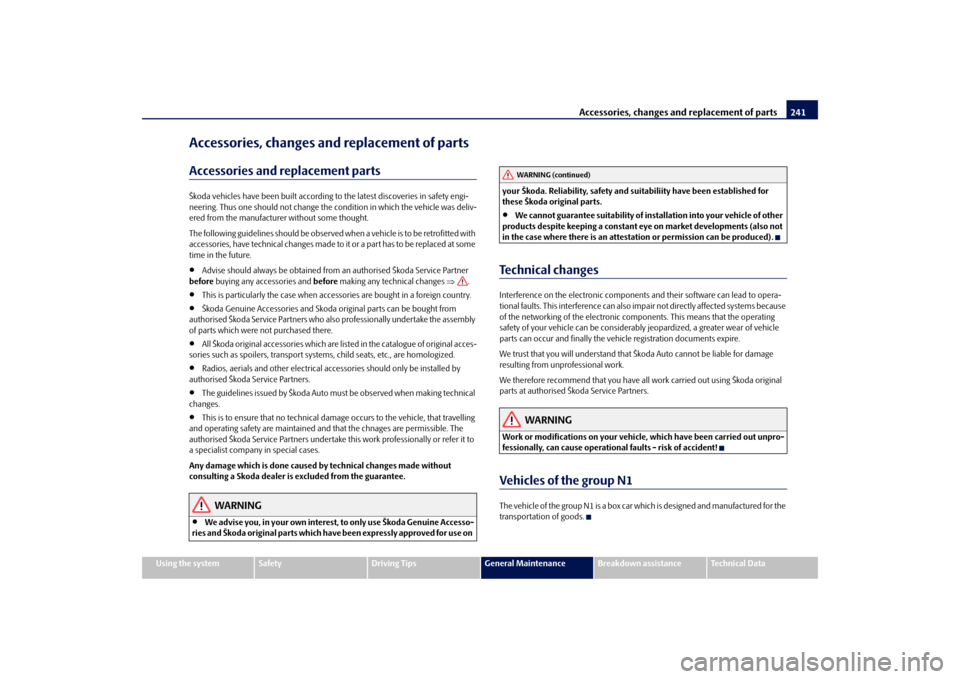

Breakdown assistanceBreakdown assistanceFirst-aid box*First-aid box The compartment for stowing the first-aid bo

x is located in the right of the luggage

compartment

⇒fig. 213

.

Note

Pay attention to the use-by-date of the contents of the first-aid box.

Warning triangleThe warning triangle can be attached to the

trim panel of the rear wall with rubber

straps

⇒fig. 214

.

Fire extinguisher*The fire extinguisher is attached with straps in a holder under the driver seat. Please read carefully the

instructions which are atta

ched to the fire extin-

guisher. The fire extinguisher must be checked by an authorised person or company annu- ally (please observe the differing legal requirements).

Fig. 213 Compartment for stowing first-aid box

Fig. 214 Placing of the warning triangle

s2dk.1.book Page 243 Wednesday, April 8, 2009 12:23 PM

Page 245 of 294

Breakdown assistance

244

WARNING

If the fire extinguisher is not correc

tly attached, in case of sudden manoeu-

vres or an accident it can be “thrown” through the interior compartment and cause injuries.

Note

•

The fire extinguisher must comply with

the relevant and valid legal require-

ments.•

Pay attention to the expiration date of the fire extinguisher. If the fire extin-

guisher is used after the expiration date,

its proper function is

no longer assured.

•

The fire extinguisher is only supplied in

certain countries within the scope of

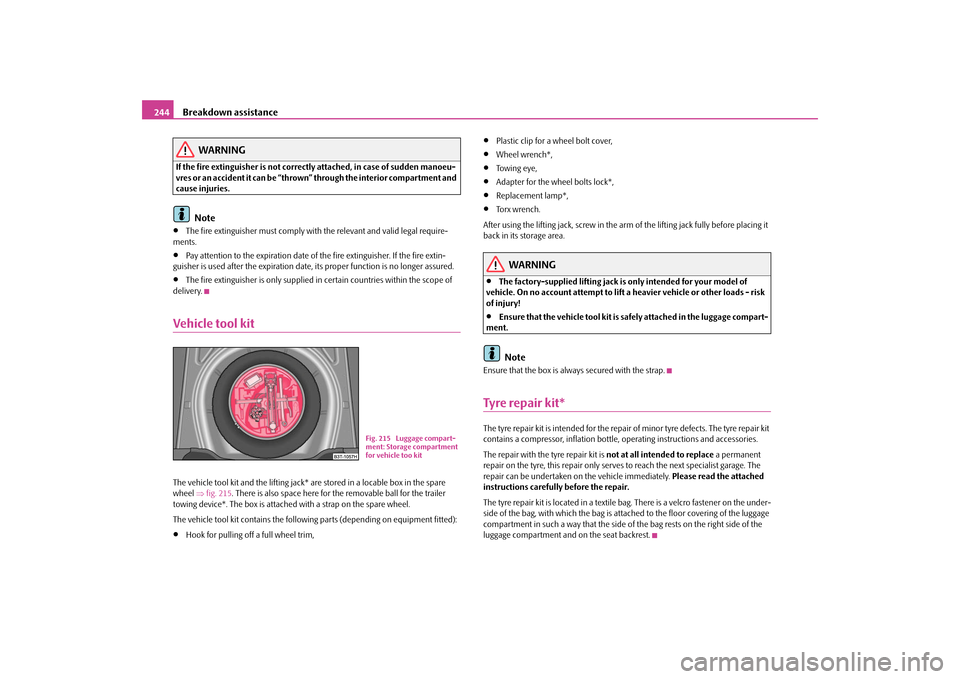

delivery.Vehicle tool kitThe vehicle tool kit and the lifting jack*

are stored in a locable box in the spare

wheel

⇒fig. 215

. There is also space here for the removable ball for the trailer

towing device*. The box is attached

with a strap on the spare wheel.

The vehicle tool kit contains the following parts (depending on equipment fitted):•

Hook for pulling off a full wheel trim,

•

Plastic clip for a wheel bolt cover,

•

Wheel wrench*,

•

To w i n g e y e ,

•

Adapter for the wheel bolts lock*,

•

Replacement lamp*,

•

Torx wrench.

After using the lifting jack, screw in the arm

of the lifting jack fully before placing it

back in its storage area.

WARNING

•

The factory-supplied lifting jack is only intended for your model of

vehicle. On no account attempt to lift a heavier vehicle or other loads - risk of injury!•

Ensure that the vehicle tool kit is

safely attached in the luggage compart-

ment.

Note

Ensure that the box is alwa

ys secured with the strap.

Tyre repair kit*The tyre repair kit is intended for the repair of minor tyre defects. The tyre repair kit contains a compressor, inflation bottle, operating instructions and accessories. The repair with the

tyre repair kit is

not at all intended to replace

a permanent

repair on the tyre, this repair only serves

to reach the next specialist garage. The

repair can be undertaken on

the vehicle immediately.

Please read the attached

instructions carefully before the repair. The tyre repair kit is located in a textile bag. There is a velcro fastener on the under- side of the bag, with which the bag is atta

ched to the floor covering of the luggage

compartment in such a way that the side of the bag rests on the right side of the luggage compartment and on the seat backrest.

Fig. 215 Luggage compart- ment: Storage compartment for vehicle too kit

s2dk.1.book Page 244 Wednesday, April 8, 2009 12:23 PM

Page 246 of 294

Breakdown assistance

245

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

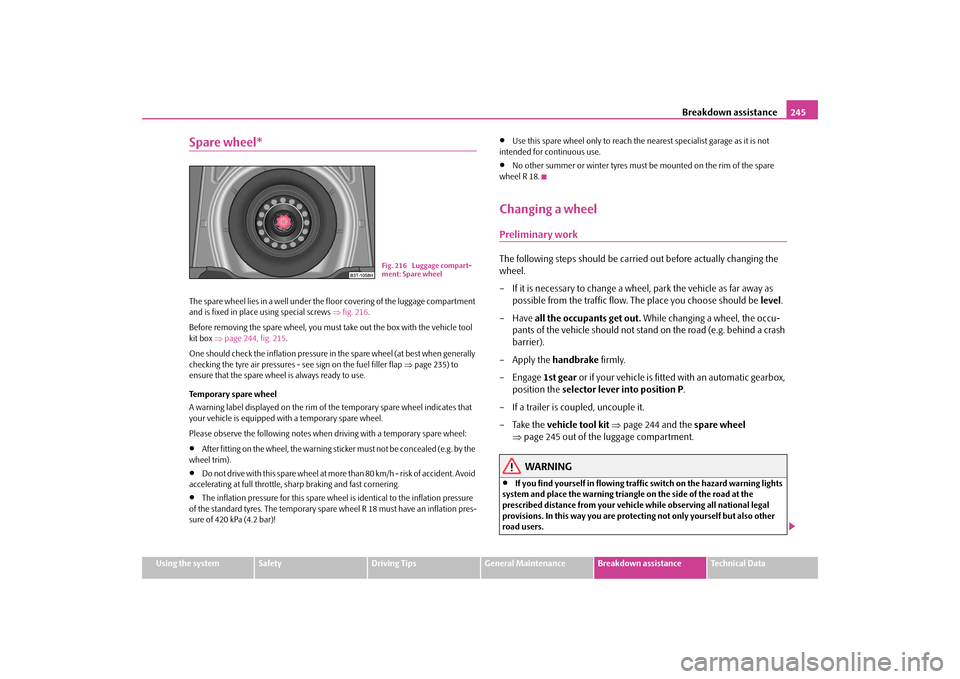

Spare wheel*The spare wheel lies in a well under the floor covering of the luggage compartment and is fixed in place using special screws

⇒fig. 216

.

Before removing the spare wheel, you must take out the box with the vehicle tool kit box

⇒page 244, fig. 215

.

One should check the inflation pressure in the spare wheel (at best when generally checking the tyre air pressures - see sign on the fuel filler flap

⇒page 235) to

ensure that the spare wheel is always ready to use. Temporary spare wheel A warning label displayed on the rim of the temporary spare wheel indicates that your vehicle is equipped with a temporary spare wheel. Please observe the following notes when driving with a temporary spare wheel:•

After fitting on the wheel, the warning stic

ker must not be concealed (e.g. by the

wheel trim).•

Do not drive with this spare wheel at more than 80 km/h - risk of accident. Avoid

accelerating at full throttle, sharp braking and fast cornering.•

The inflation pressure for this spare wheel is identical to the inflation pressure

of the standard tyres. The temporary spare wheel R 18 must have an inflation pres-sure of 420 kPa (4.2 bar)!

•

Use this spare wheel only to reach the nearest specialist garage as it is not

intended for continuous use.•

No other summer or winter tyres must

be mounted on the rim of the spare

wheel R 18.Changing a wheelPreliminary workThe following steps should be carried out before actually changing the wheel. – If it is necessary to change a wheel, park the vehicle as far away as

possible from the traffic flow. The place you choose should be

level

.

–Have

all the occupants get out.

While changing a wheel, the occu-

pants of the vehicle should not stan

d on the road (e.g. behind a crash

barrier).

– Apply the

handbrake

firmly.

–Engage

1st gear

or if your vehicle is fitted with an automatic gearbox,

position the

selector lever into position P

.

– If a trailer is coupled, uncouple it. – Take the

vehicle tool kit

⇒

page 244 and the

spare wheel

⇒

page 245 out of the luggage compartment.WARNING

•

If you find yourself in flowing traffic switch on the hazard warning lights

system and place the warning triangle

on the side of the road at the

prescribed distance from

your vehicle while obse

rving all national legal

provisions. In this way you are protecting not only yourself but also other road users.

Fig. 216 Luggage compart- ment: Spare wheel

s2dk.1.book Page 245 Wednesday, April 8, 2009 12:23 PM

Page 247 of 294

Breakdown assistance

246

•

Never start the engine with the vehicle

sitting on the raised jack - danger

of suffering injury!

Caution

If you have to change a wheel on a slope

first block the opposite wheel with a stone

or similar object in order to secure th

e vehicle from unexpectedly rolling away.

Note

Comply with the national legal regulations.Changing a wheelAlways change a wheel on a level surface as far as possible. – Take off the full wheel trim*

⇒

page 247 or the caps

⇒

page 247.

– In the case of light alloy wheels remove the wheel trim cap

⇒

page 248.

– First of all slacken the safety wh

eel bolt * and afterwards the other

wheel bolts

⇒

page 248.

– Jack up the vehicle until the wheel to

be changed is clear of the ground

⇒

page 249.

– Unscrew the wheel bolts and place them on a clean surface (cloth,

paper etc.).

– Take off the wheel. – Fit on the spare wheel and tighten the wheel bolts slightly. –Lower the car.

– Tighten the wheel bolts firmly, al

ternately and diagonally using the

wheel wrench (crosswise) and last the safety wheel bolt*

⇒

page 248.

– Mount the full wheel trim/w

heel trim cap or the caps.

Note

•

All bolts must be clean

and must turn easily.

•

You must never grease or oil the wheel bolts!

•

When fitting on unidirectional tyres, ensure that the tyres rotate in the correct

direction

⇒page 235.

Subsequent stepsAfter changing the wheel, you must perform the following steps. – Stow and attach the replaced wheel in the spare wheel well using a

special screw

⇒

page 245, fig. 216

.

– Stow the vehicle tool kit in the space provided.–

Check

the

tyre pressure

on the spare wheel just mounted as soon as

possible.

– Have the

tightening torque

of the wheel bolts

checked

with a torque

wrench as soon as possible. Steel and light alloy wheels must be tight-ened to a tightening torque of

120 Nm

.

– Have the defective tyre repaired as soon as possible.

WARNING

It is necessary to observe the guidelines given on

⇒page 237 if the vehicle is

subsequently fitted with tyres which are

different to those it was fitted with

at the works.

WARNING (continued)

s2dk.1.book Page 246 Wednesday, April 8, 2009 12:23 PM

Page 249 of 294

Breakdown assistance

248

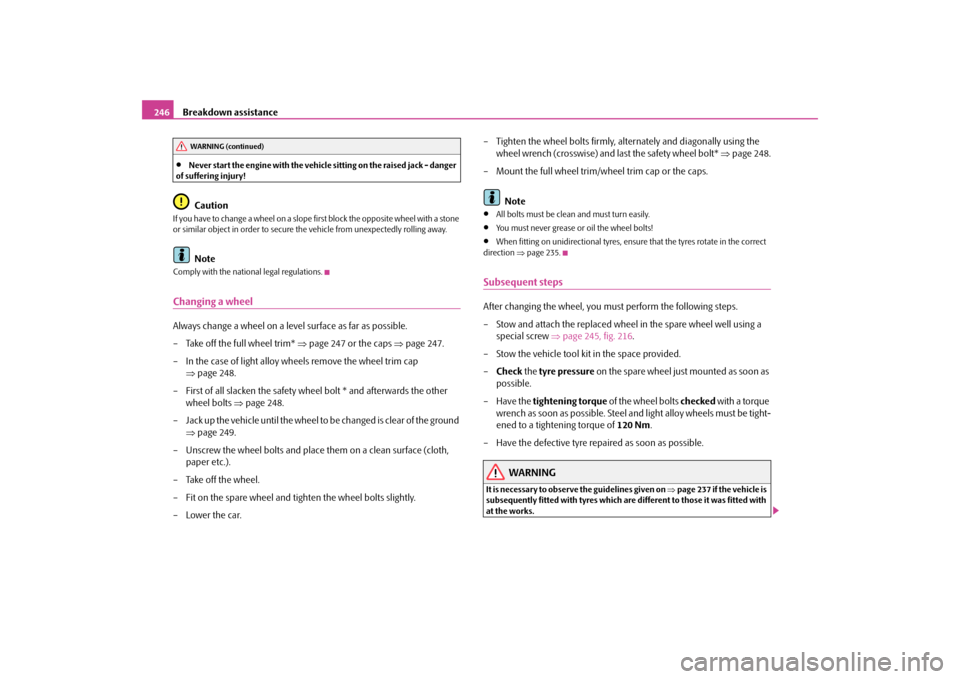

Wheel trim caps*Pulling off – Carefully remove the wheel tr

im cap using the wire clamp

⇒

fig. 218

.

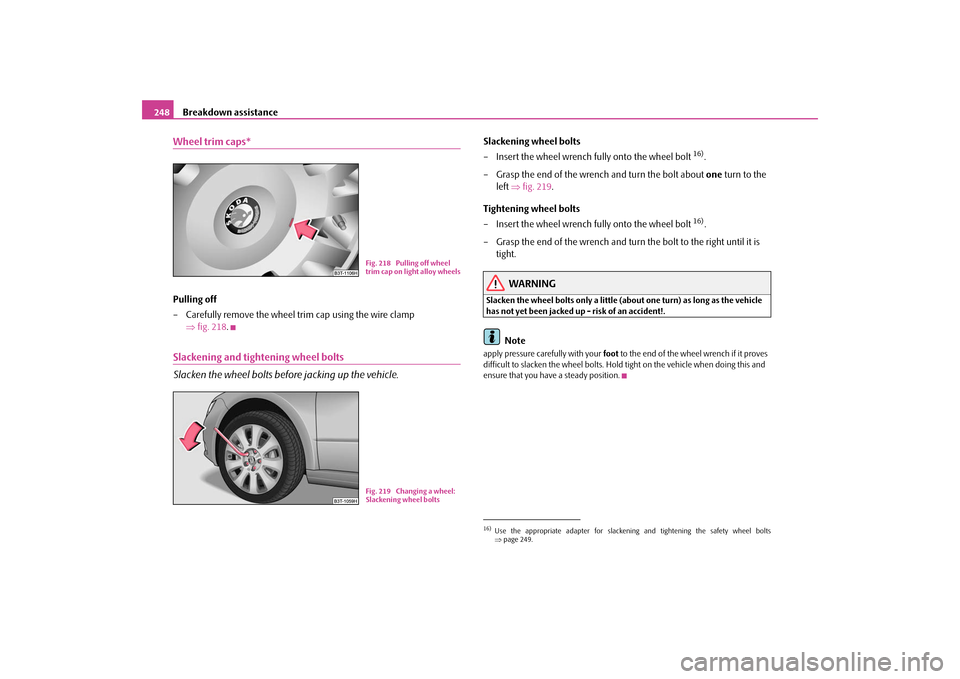

Slackening and tightening wheel bolts Slacken the wheel bolts before jacking up the vehicle.

Slackening wheel bolts – Insert the wheel wrench fully onto the wheel bolt

16).

– Grasp the end of the wrench and turn the bolt about

one

turn to the

left

⇒

fig. 219

.

Tightening wheel bolts – Insert the wheel wrench fully onto the wheel bolt

16).

– Grasp the end of the wrench and turn the bolt to the right until it is

tight.

WARNING

Slacken the wheel bolts only a little (a

bout one turn) as long as the vehicle

has not yet been jacked up - risk of an accident!.

Note

apply pressure carefully with your

foot

to the end of the wheel wrench if it proves

difficult to slacken the wheel bolts. Hold tight on the vehicle when doing this and ensure that you have a steady position.

Fig. 218 Pulling off wheel trim cap on light alloy wheelsFig. 219 Changing a wheel: Slackening wheel bolts

16)Use the appropriate adapter for slackening

and tightening the safety wheel bolts

⇒ page 249.

s2dk.1.book Page 248 Wednesday, April 8, 2009 12:23 PM

Page 250 of 294

Breakdown assistance

249

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

Raise vehicle You have to raise the vehicle with a lifting jack in order to be able to take off the wheel. Position the lifting jack by selecting

the jacking point which is closest to

the wheel to be removed

⇒

fig. 220

. The jacking point is located directly

below the engraving in the lower sill. – Position the lifting jack below the jacking point and move it up until its

claw is positioned directly below the vertical web of the lower sill.

– Align the car jack so that its claw grasps the web of the lower sill

and the base plate is resting flat on the floor.

– Turn the lifting jack up further until the wheel is just clear of the

ground.

Ground below the lifting jack which is soft and slippery

can cause the vehicle to

slip off the jack. It is therefore always ne

cessary to place the lifting jack on a solid

surface or use a wide and stable base. Use

a non-slip base (e.g. a rubber foot mat)

if the

surface is smooth

, such as cobbled stones, a tiled floor, etc.

WARNING

•

Always raise the vehicle with the doors closed - risk of injury!

•

Take suitable measures to prevent the base of the lifting jack from slip-

ping off - risk of injury!•

Not positioning the lifting jack at

the specified points can result in

damage to the vehicle. The jack can also sl

ip off if it does not have sufficient

grip - risk of injury!•

It is important to support the vehicle with suitable supporting blocks if

you wish to work under the lifted vehicle - risk of injury!Securing wheels against being stolen* You need a special adapter for slackening the safety wheel bolts.– Pull off the full wheel trim/cap from the wheel hub or cap from the

safety wheel bolt.

– Insert the adapter with its toothed side fully into the inner toothing

of the safety wheel bolt right down in such a way that only the outer hexagon is jutting out

⇒

fig. 221

.

– Insert the wheel wrench fully onto the adapter .– Slacken the wheel bolt, or tighten it firmly

⇒

page 248.

Fig. 220 Changing a wheel: Points for positioning car jac

k

AA

AB

WARNING (continued)

Fig. 221 Safety wheel bolt with adapter

AB

AA

AB

s2dk.1.book Page 249 Wednesday, April 8, 2009 12:23 PM

Page 251 of 294

Breakdown assistance

250

– Reinstall the full wheel trim/wheel cap after removing the adapter or

place the cap onto the safety wheel bolt.

– Have the

tightening torque

checked

w i t h a t o rq u e w re n c h a s s o o n a s

possible. Steel and light alloy wheels must be tightened to a tightening torque of

120 Nm

.

The safety wheel bolts on vehicles fitted with them (one safety wheel bolt per wheel) can only be loosened or tigh

ten up by using the adapter provided.

It is meaningful to note the code numbe

r hammered into the rear side of the

adapter or the rear side of the safety wheel bolts. You can obtain a replacement adapter from an authorised Škoda Service Partner, if necessary, by quoting this number. We recommend that you always carry the

adapter for the wheel bolts with you in

the vehicle. It should be st

owed in the vehicle tool kit.

Caution

Damage can occur to the adapter and safety

wheel bolt if the safety wheel bolt is

tightened up too much.

Note

The set of safety wheel bolts can be obta

ined from an authorised Škoda Service

Par tner.Jump-startingInitial stepsYou can use the battery of another vehicl

e for jump-starting yours if the engine

does not start because the battery on your

vehicle is flat. You will require jump-start

cables for this purpose.

Both batteries must have a rated voltage of 12 V. The

capacity

(Ah) of the battery

supplying the power must not be signific

antly less than the capacity of the

discharged battery

in your vehicle.

Jump-start cables Only use jump-start cables which have an

adequately large cross-section and insu-

lated terminal clamps. Please pay attent

ion to the manufacturer's instructions.

Positive cable -

colour coding in the

majority of cases red.

Negative cable -

colour coding in the majority of cases black.

WARNING

•

A discharged battery may already freeze

at temperatures just below 0°C.

In case of frozen battery carry out no jump-starting - risk of explosion!•

Please pay attention to the warning instructions relating to working in

the engine compartment

⇒page 223, “Working in the engine compart-

ment”.

Note

•

There must not be any contact between the two vehicles otherwise current may

flow as soon as the negative terminals are connected.•

The discharged battery must be proper

ly connected to the system of the

vehicle.•

Switch off any mobile phone, pay attent

ion to the instructions for use of the

mobile phone in such a situation.•

We recommend purchasing jump-start cabl

es from Škoda Service Partners as a

Škoda original accessory or from retailers who sell branded batteries.

s2dk.1.book Page 250 Wednesday, April 8, 2009 12:23 PM

Page 252 of 294

Breakdown assistance

251

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

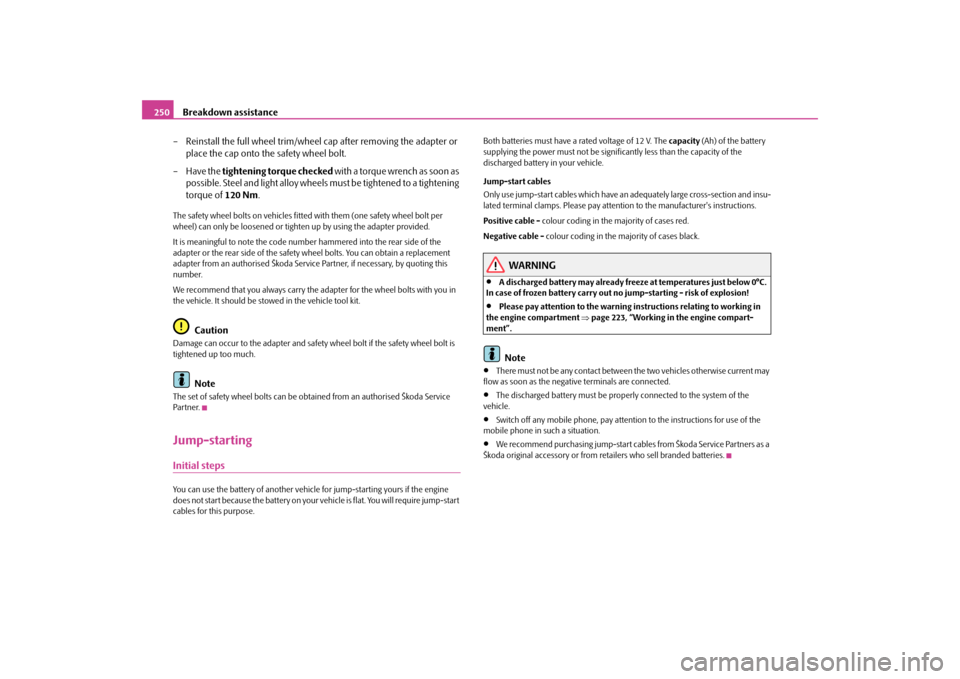

Start engineIt is important to connect the jump

-start cables in the correct order.

Connecting positive terminals – Attach one end to the positive terminal

⇒

fig. 222

of the

discharged battery .

– Attach the other end to the positive terminal of the battery

supplying the power .

Connecting negative term

inal and engine block

– Attach one end to the negative

terminal of the battery supplying

the power .

– Attach the other end to a solid metal part which is connected

firmly to the engine block, or

to the engine block itself.

Starting engine – Start the engine of the vehicle providing current and run the engine at

idling speed.

– Now start the engine of the vehicle with the discharged battery.

– Interrupt the attempt at starting an engine after 10 seconds if it does

not start right away and wait for about 30 seconds before repeating the attempt.

– Disconnect the cables on the engine in exactly the

reverse order

they

were connected up.

WARNING

•

The non-insulated parts of the terminal clamps must never make contact

with each other. Furthermore, the cable connected to the positive terminal of the battery must not come into contact with electrically conducting parts of the vehicle - risk of a short circuit!•

Do not affix the jump starting cables to the negative terminal of the

discharged battery. There is the risk

of detonating gas seeping out the

battery being ignited by the strong

spark which results from the engine

being started.•

Run the jump-start cables so that th

ey cannot be caught

by any rotating

parts in the engine compartment.•

Do not bend over the batteries - risk of caustic burns!

•

The vent screws of the battery cells must be tightened firmly.

•

Keep any sources of ignition (naked

flame, smouldering cigarettes etc.)

away from the battery - risk of an explosion!•

Never jump-start the batteries which have a too low electrolyte level -

risk of explosion and caustic burns!

Fig. 222 Jump-starting using the battery from another vehicle: A - flat vehicle battery, B - battery providing current

A1AAA2AB

A3

AB

A4

s2dk.1.book Page 251 Wednesday, April 8, 2009 12:23 PM

Page 255 of 294

Breakdown assistance

254

Rear towing eye– Press onto the bottom part of the cover in the rear bumper

⇒

fig. 226

and take it out.

– Screw in the towing eye anti

clockwise down to the stop

⇒

fig. 227

and

tighten up using the wheel wrench (push the wheel wrench through eye).

– Put the cover in place after screwing out the towing eye again and

press into place. The co

ver must engage firmly.

Tow-starting a vehicleIf the engine does not start, we generally do

not

recommend

to tow-start

your vehicle. One should attempt to start the engine using jump start cables

⇒

page 250 or call on the services of the SERVICE mobile.

If your vehicle has to be towed – Engage 2nd or 3rd gear wi

th the vehicle stationary.

– Depress the clutch pedal fully and keep it depressed. – Switch on the ignition.– Wait until both vehicles are movi

ng then release the clutch pedal

slowly.

– Depress the clutch pedal fully when the engine fires and take the

vehicle out of gear.

For technical reasons it is not possib

le to tow-start a car fitted with an

automatic

gearbox

.WARNING

There is high risk of having an accident when tow-starting a vehicle, when for example the towed vehicle runs into the towing vehicle.

Caution

Vehicles which are fitted with a catalytic

converter should not be tow-started over

a d i s t a n c e o f m o re t h a n 5 0 m e t re s . U n b u r n

t fuel may get into the catalytic converter

and damage it.Towing in a vehicle fitted with a manual gearboxPlease refer to the notes

⇒page 252.

Fig. 226 Rear bumper: Removing coverFig. 227 Rear bumper: Installing the towing eye

s2dk.1.book Page 254 Wednesday, April 8, 2009 12:23 PM