warning light SKODA SUPERB 2010 2.G / (B6/3T) Owners Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2010, Model line: SUPERB, Model: SKODA SUPERB 2010 2.G / (B6/3T)Pages: 287, PDF Size: 16.59 MB

Page 191 of 287

Intelligent Technology

190

been washed in an automatic vehicle wash , since the brake discs and brake pads may

be moist or even have a coatin g of ice on them in winter. Yo u s h o u l d d r y t h e b r a k e s a s

soon as possible by applying and releasing the brakes several times.

There also may be a certain delay before the full braking efficiency is available when

driving on roads which have been treated with road salt if you have not used the brakes

for some considerable time beforehand. The layer of salt on the brake discs and brake

pads must first be rubbed off when you apply the brakes.

Corrosion

Corrosion on the brake discs and dirt on th e bake pads occur if the vehicle has been

parked for a long period an d if you do not make much use of the braking system.

We recommend cleaning the brak e discs by firmly applying the brakes at a fairly high

speed if you do not make much use of the braking system or if surface corrosion is

present .

Faults in the brake surface

If you notice that the braking distance ha s suddenly become longer and that the brake

pedal can be depressed further, it is possible that a brake circuit of the dual-circuit

brake system has failed. Drive, in such cases, to the nearest specialist garage without

delay in order to have the problem rectified. Drive at a reduced speed while on your

way to the dealer and adapt your style of driving to the higher brake pedal pressure

required.

Low brake fluid level

An insufficient level of brake fluid may result in problems in the brake system. The level

of the brake fluid is monitored electronically page 35, “Brake system ”.

WARNING

Only apply the brakes for the purpose of drying and cleaning the brake discs

if the traffic conditions permit this. Do not place any other road users in jeop-

ardy.

When retrospectively mounting a front spoiler, solid wheel hubs etc. one

must ensure that the air supply to the front wheel brakes is not reduced other-

wise the braking system could run too hot.

Allow for the fact that new brake pads do not achieve their full braking effi-

ciency until approximately 200 kilometres. New brake pads must be first “run in” before they develop their optimal fric

tion force. You can, however, compen-

sate for this slightly reduced braking fo rce by increasing the pressure on the

brake pedal. This guideline also applie s to any new brake pads installed at a

future date.

Caution

Never allow the brakes to rub by applying sl ight pressure if you do not wish to brake

the vehicle. This causes the br akes to overheat and can also result in a longer braking

distance and excessive wear.

Before negotiating a steep downhill section, please reduce your speed, shift down

into the next lower gear (manual gearbox) or select a lower driving stage (automatic

gearbox). This enables you to make full us e of the braking power of the vehicle and

reduces the strain on the brakes. Any additional braking should be done intermittently,

not continuously.Note

The brake light flashes automatically in case of an emergency braking at speeds greater

than 60 km/h or with the intervention of th e ABS, which lasts longer than 1.5 seconds.

After the speed was reduced below 10 km/h or the vehicle was stopped, the brake light

stops flashing and the hazard warning light system switches on. The hazard warning

light system is switched of f automatically after accelerating or driving off again.Brake boosterThe brake booster boosts the pressure whic h you generate with the brake pedal. The

necessary pressure is only genera ted when the engine is running.

WARNING

Never switch off the engine befo re the vehicle is stationary.

The brake booster only operates when the engine is running. Greater phys-

ical effort for braking is required when en gine is switched off. Because if you do

not stop as normal, this can cause an accident and severe injuries.WARNING (continued)

s3fg.2.book Page 190 Friday, April 30, 2010 12:17 PM

Page 192 of 287

Intelligent Technology191

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

Antilock brake system (ABS)ABS prevents the wheels locking when braking.General

The ABS contributes significantly to enhanc ing the active safety of your vehicle.

Compared to a vehicle not fitted with the ABS brake system, you are able to retain

optimal steering ability even during a full br ake application on a slippery road surface

because the wheels do not lock up.

In general you must not expect that the braking distance will be shorter under all

circumstances as a result of the ABS. The braking distance for example on gravel and

fresh snow, when you should anyway be driving slowly and cautiously, will be longer.

Operating principle

The brake pressure will be reduced on a wheel which is rotating at a speed which is too

low for the speed of the vehicle and tending to lock. This control cycle is noticeable

from a pulsating movement of the brake pedal which is accompanied by noises.

This is consciously intended to provide the driver with the information that the wheels

are tending to lock (ABS control range) . You must always keep the brake pedal

depressed to enable the ABS to optimally control the brake application in this braking

range. Never interrupt the application of the brakes!

WARNING

The ABS can also not overcome the physical limits of your vehicle. Please do

not forget this, particularly when driving on icy or wet road surfaces. If the ABS

is operating within the control range, adapt your speed immediately to the

conditions of the road surface and the traffic situation. The increased safety

offered by the ABS must not tempt you to take greater risks than otherwise -

risk of an accident!

The normal braking system is still fully functional if there is an ABS fault.

Visit a specialist garage as quickly as poss ible and adjust your style of driving to

take account of the ABS fault in the meantime since you will not know the extent

of the fault and in how far the braking efficiency is affected.Note

A warning light comes on if a fault occurs in the ABS system

page 34.

Changes to vehicle (e.g. on engine, on the brakes, on chassis or another combina-

tion of tyres and wheels) can in fluence the function of the ABS page 234, “Accesso-

ries, changes and replacement of parts”.

Brake Assist*During a severe brake application (e.g. if a hazard exists), the Brake Assist increases the

braking force and thus makes it possible to rapidly produce the pressure required in

the brake system.

The majority of drivers do a pply the brakes in good time in dangerous situations, but

do not depress the brake pedal with sufficient pressure. Consequently, it is not possible

for the vehicle to achieve its maximum deceleration and the vehicle covers a greater

distance than necessary.

The Brake Assist is activated by the very qu ick operation of the brake pedal. In such

cases, a much greater braking pressure exists than during a normal brake application.

This makes it possible, even with a relatively low resistance of the brake pedal, to

produce an adequate pressure in the brake system in the shortest possible time, which

is required for maximum dece leration of the vehicle. You must apply the brake pedal

firmly and hold it in this position in or der to achieve the shortest possible braking

distance.

The Brake Assist is able to help you achi eve a shorter braking distance in emergency

situations by rapidly producing the pressure required in the brake system. It fully

exploits the attributes of the ABS. After you release the brake pedal, the function of the

Brake Assist is automatically switched off and the brakes operate in the normal way.

The Brake Assist is part of the ESP system. If a fault occurs in the ESP, the Brake Assist

function is also not available. Further information on the ESP page 187.

WARNING

The Brake Assist is also not able to overcome the physical limits of your

vehicle in terms of the braking distance required.

Adapt your speed to the conditions of the road surface and to the traffic situ-

ation.

The increased safety offered by the Brake Assist must not tempt you to take

a greater safety risk than otherwise.

s3fg.2.book Page 191 Friday, April 30, 2010 12:17 PM

Page 193 of 287

Intelligent Technology

192

Uphill Start Assist*The uphill start assist makes it easier to start off on steep hills. The system assists a start

off by holding the brake pressure produced by the brake pedal actuation for approx. 2

seconds after releasing the brake pedal. The driver can therefore move his foot from

the brake pedal to the accelerator pedal and start off on the slope, without having to

actuate the handbrake. The brake pressure drops gradually the more you operate the

accelerator pedal. If the vehicle does not start off within 2 seconds, it starts to roll back.

The uphill start assist is active as of a 5 % slope, if the driver door is closed. It is always

active on slopes when in forward or reverse start off. When driving downhill, it is

inactive.Electromechanical power steeringThe power steering enables you to steer the vehicle with le ss physical force.

With the electromechanical power steering , the steering assist is automatically

adapted to the speed and to the steering angle.

It is still possible to fully steer the vehicle if the power steering fails or if the engine is

not running (vehicle being towed in). The only difference is that greater physical effort

is required.

If there is a fault in the power steering, the warning light

or lights up in the instru-

ment cluster page 31.

WARNING

Contact your specialist garage if the power steering is defective.

Tyre pressure monitoring system*The tyre pressure monitoring system compares with the aid of the ABS sensors the

speed and also the rolling circumference of the individual wheels. If the rolling circum-

ference of a wheel is changed, the warning light

lights up in the instrument cluster

page 34 and an audible signal sounds. The rolling circumference of the tyre can

change if:

the tyre inflation pressure is too low,

the structure of the tyre is damaged,

the vehicle is loaded on one side,

the wheels of an axle are loaded heavily (e.g. when towing a trailer or when driving

uphill or downhill),

snow chains are mounted,

the temporary spare wheel is mounted,

one wheel per axle was changed.

Basic setting of the system

After changing the tyre inflation pressures, after changing one or several wheels, the

position of a wheel on the vehicle (e.g. ex changing the wheels between the axles) or

when the warning light lights up while drivin g, a basic setting of the system must be

carried out as follows.

Inflate all tyres to the specified inflation pressure page 228.

Switch on the ignition.

Fig. 172 Button for setting the tyre

inflation pressure control value

s3fg.2.book Page 192 Friday, April 30, 2010 12:17 PM

Page 194 of 287

Intelligent Technology193

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

Press button page 192, fig. 172 for more than 2 seconds. While pressing

the button, the warning light

lights up. At the same time the memory of the system

is erased and the new calibration is started, which is confirmed with an audible signal

and then the warning light

goes out.

If the warning light

does not go out after the basic setting, there is a fault in the

system. Have the vehicle inspected by your nearest specialist garage.

Warning light

lights up

If the tyre inflation pressure of at least one wheel is insufficiently inflated in comparison

to the stored basic value, the warning light

lights up.

Warning light

flashes

If the warning light flashes, there is a system fault. Have the vehicle inspected by your

nearest specialist garage.

WARNING

When the warning light

lights up, immediately reduce the speed and

avoid sudden steering and brake manoeuvr es. Please stop the vehicle without

delay at the nearest possible stop and in spect the tyres and their inflation pres-

sures.

The driver is responsible for the correct tyre inflation pressures. For this

reason, the tyre inflation pressu res must be checked regularly.

Under certain circumstances (e.g. sporty style of driving, wintry or unpaved

roads) the warning light

can be delayed or does not light up at all.

The tyre pressure monitoring system does not take away the responsibility

from the driver for the correct tyre inflation pressure.Note

The tyre pressure monitoring system:

does not replace the regular tyre inflatio n pressure control, because the system

cannot detect an even pressure loss;

cannot warn in case of very rapid tyre inflation pressure loss, e.g. in case of sudden

tyre damage. In this case carefully bring the vehicle to a standstill without sudden

steering movements and without sharp braking.

In order to ensure a proper functioning of the tyre inflation pressure-control

system, it is necessary to carry out the ba sic setting again every 10 000 km or 1x a

year.

Diesel particle filter* (diesel engine)In the diesel particle filter the resu lting soot particles are collected and

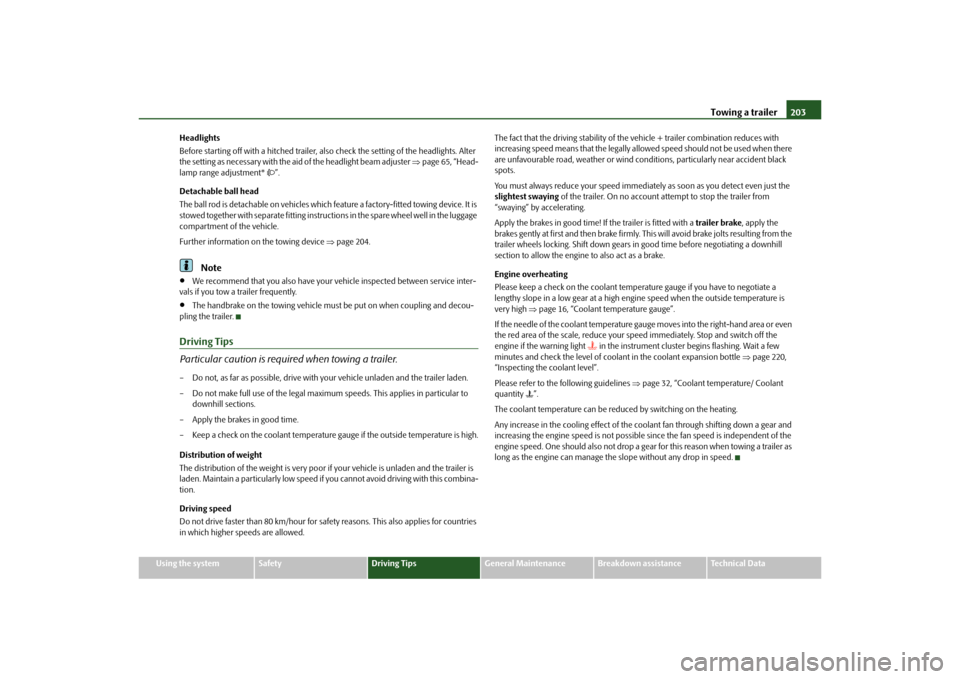

burnt during the combustion of diesel fuel.Code 7GG, 7MB or 7MG on the vehicle data sticker, see fig. 173 , indicates that your

vehicle is equipped with a diesel particle fi lter. The vehicle data sticker is located on

the floor of the luggage compartment and is also stated in the Service schedule.

The diesel particle filter filters the soot particles completely from the exhaust. The soot

is collected in the diesel particle filter and burnt regularly. To assist this procedure, we

recommend not to drive regu larly over short distances.

If the diesel particle filter is clogged or there is a fault, it is indicated by the warning light

.

WARNING

The diesel particle filter achieves very high temp eratures. Therefore do not

park at points where the hot filter comes into direct contact with dry grass or

other combustible materials - risk of fire!

Never use additional underbody protection or corrosion-protection agents

for the exhaust pipes, catalytic converters, diesel particle filter or heat shields.

Fig. 173 Vehicle data sticker

s3fg.2.book Page 193 Friday, April 30, 2010 12:17 PM

Page 204 of 287

Towing a trailer203

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

Headlights

Before starting off with a hitched trailer, also check the setting of the headlights. Alter

the setting as necessary with the aid of the headlight beam adjuster

page 65, “Head-

lamp range adjustment* ”.

Detachable ball head

The ball rod is detachable on vehicles which feature a factory-fitted towing device. It is

stowed together with separate fitting instru ctions in the spare wheel well in the luggage

compartment of the vehicle.

Further information on the towing device page 204.

Note

We recommend that you also have your vehicle inspected between service inter-

vals if you tow a trailer frequently.

The handbrake on the towing vehicle must be put on when coupling and decou-

pling the trailer.

Driving Tips

Particular caution is required when towing a trailer.– Do not, as far as possible, drive with your vehicle unladen and the trailer laden.

– Do not make full use of the legal maximum speeds. This applies in particular to downhill sections.

– Apply the brakes in good time.

– Keep a check on the coolant temperature gauge if the outside temperature is high.

Distribution of weight

The distribution of the weight is very poor if your vehicle is unladen and the trailer is

laden. Maintain a particularly low speed if you cannot avoid driving with this combina-

tion.

Driving speed

Do not drive faster than 80 km/hour for safety reasons. This also applies for countries

in which higher speeds are allowed. The fact that the driving stability of the vehicle + trailer combination reduces with

increasing speed means that the legally allowed speed should not be used when there

are unfavourable road, weather or wind cond

itions, particularly near accident black

spots.

You must always reduce your speed immediat ely as soon as you detect even just the

slightest swaying of the trailer. On no account attempt to stop the trailer from

“swaying” by accelerating.

Apply the brakes in good time! If the trailer is fitted with a trailer brake, apply the

brakes gently at first and then brake firmly. This will avoid brake jolts resulting from the

trailer wheels locking. Shift down gears in good time before negotiating a downhill

section to allow the engine to also act as a brake.

Engine overheating

Please keep a check on the coolant temperature gauge if you have to negotiate a

lengthy slope in a low gear at a high engi ne speed when the outside temperature is

very high page 16, “Coolant temperature gauge”.

If the needle of the coolant temperature gauge moves into the right-hand area or even

the red area of the scale, reduce your speed immediately. Stop and switch off the

engine if the warning light

in the instrument cluster begins flashing. Wait a few

minutes and check the level of coolant in the coolant expansion bottle page 220,

“Inspecting the coolant level”.

Please refer to the following guidelines page 32, “Coolant temperature/ Coolant

quantity ”.

The coolant temperature can be reduced by switching on the heating.

Any increase in the cooling effect of the coolant fan through shifting down a gear and

increasing the engine speed is not possible since the fan speed is independent of the

engine speed. One should also not drop a gear for this reason when towing a trailer as

long as the engine can manage th e slope without any drop in speed.

s3fg.2.book Page 203 Friday, April 30, 2010 12:17 PM

Page 205 of 287

Towing a trailer

204

Detachable towing device*The detachable ball head of the towing device is stowed in a box for the car tool kit in

the spare wheel well in the luggage compartment.

An instruction for correct installation and remo val of the ball head of the towing device

is supplied with the ball head

Inspect the ball head to ensure that it is prop erly locked each time before setting off.

The inspection is performed by turning th e closed locking lever downwards. If the

locking lever can only be turned around a small angle (approx. 5°), the locking mecha-

nism is O.K. After the inspection pull the locking lever back again to its stop. The towing

device must not be used, if it does not wish to close or the locking lever turns slightly

in the closed position.

WARNING

Do not use any aids or tools for installing or removing the ball head. This might

result in damage to the locking mechanism to the extent that the safety of the

towing device is no longer assured - risk of an accident!

Note

Do not carry out any modifications or repairs to the ball head or to any other

components on the towing device.

Contact a specialist garage if you en counter any problems using the device.

Never unlock the ball head with a trailer coupled to it.

You should take off the ball head if yo u drive without towing a trailer. Inspect

whether the end cover properly seals off the mounting shaft.

Remove the ball head beforehand if you wish to clean your vehicle using a steam

jet. Ensure that the end cover properly seals the mounting shaft.

It is recommended to wear gloves when installing and removing.

Fig. 178 Detachable ball head

s3fg.2.book Page 204 Friday, April 30, 2010 12:17 PM

Page 207 of 287

Taking care of your vehicle and cleaning the vehicle

206

There are no particular points to note be fore washing your vehicle in an automatic

vehicle wash system other than the usua l precautionary measures (closing the

windows and the sliding/tilting roof etc.).

If you have any particular attached parts fitted to your car - such as spoiler, roof rack

system, two-way radio aerial - it is best to first of all consult the operator of the car

wash plant.

It is important to degrease the lips of the windscreen wiper rubbers after passing

through the automatic vehicle wash system.Washing vehicle by handIt is important to first soften the dirt with plenty of water and rinse it off as thoroughly

as possible before washin g your vehicle by hand.

One should then clean the vehicle using a soft washing sponge, washing glove or a

washing brush and only slight pressure. Work from the top to the bottom - beginning

with the roof. Only place slight pressure on the vehicle paintwork during cleaning Only

use a car shampoo for stubborn dirt.

Wash out the sponge or washing glove thoroughly at short intervals.

Clean wheels, door sills and similar parts last. Use a second sponge for such areas.

Rinse off the vehicle well after giving it a wash and dry it off using a chamois leather.

WARNING

The ignition should always be switched off when you wash your vehicle -

risk of accident!

Protect your hands and arms from sharp-edged metal parts when you are

cleaning the underfloor, the inside of the wheel housings or the wheel trims -

risk of cuts!Caution

Do not wash your vehicle in bright sunlight - risk of paint damage.

Ensure that the jet of water is not aimed di rectly at the locking cylinders or at the

door and panel joints if you spray your vehi cle in winter down with a hose - risk of

freezing.

Do not use any insect sponges, rough kitc hen sponges or similar cleaning products

- risk of damage to the surface of paintwork.For the sake of the environment

Only wash your vehicle at wa shing bays specifically reserved for this purpose. This

ensures that no water which may be contaminated by oil flows into the sewage system.

It is not even permitted to wash your vehicl e in certain areas except at such specific

washing bays.Washing with a high-pressure cleanerWhen you wash your vehicle with a high-press ure cleaner, it is essential to comply with

the instructions for use of the cleaning equi pment. This applies in particular to the

pressure used and to the spraying distance . Maintain a sufficiently large distance to

soft materials such as rubber hoses or insulation material.

On no account use circular spray nozzles or so-called dirt cutters!

WARNING

It is particularly important that you do not clean tyres with circular spray jets.

Visible but also invisible damage to tyres may occur even at a relatively large

spraying distance and if sprayed only for a short time - risk of accident!

Caution

The water containing wax must be no hotter than 60°C, otherwise the vehicle can be

damaged.Wax treatmentGood wax treatment is an effective way of protecting the paintwork from harmful envi-

ronmental influences and minor mechanical damage.

The vehicle must be treated with a high-quali ty hard wax polish at the latest, when no

more drops form on the clean paintwork.

s3fg.2.book Page 206 Friday, April 30, 2010 12:17 PM

Page 209 of 287

Taking care of your vehicle and cleaning the vehicle

208

Do not use window leathers which you have us ed to polish the vehicle body to dry off

the windows. Residues of preservatives in the window leather can dirty the window

and reduce visibility.

Do not affix any stickers over the inside of the rear window to avoid damage to the

heating elements of the rear window heater .

We recommend using a preserva tive from Škoda genuine accessories offered by your

Škoda dealer.

Caution

Never remove snow or ice from the glass parts with warm or hot water - risk of forma-

tion of cracks in the glass.The headlight lensesPlease do not use any aggressi ve cleaning or chemical solvent products for cleaning

the front headlights - risk of damage to the plastic lenses. Please use soap and clean

warm water.

Caution

Never wipe the headlights dry and do not use any sharp objects for cleaning the plastic

lenses, this may result in damage to the protective paintwork and consequently in

formation of cracks on the headlight lenses, e.g through effect of chemical products.Door and window sealsThe rubber seals on the doors, boot lid, bonnet and windows remain supple and last

longer if you treat them from time to time with a rubber care product (e.g. with a spray

with silicone-free oil). You also avoid premature wear of the seals and prevent leakages

in this way. It is also easier to open the doors. Rubber seals which are well cared for also

do not stick together in cold winter weather.Locking cylinderWe recommend that you use the spray from Škoda original accessories with regreasing

and anticorrosive effect for de-icing locking cylinders.

Note

When washing your vehicle, ensure that as little water as possible gets into the locking

cylinders.WheelsSteel wheels

You should also thoroughly wash the wheels and wheel trims when giving your vehicle

its regular wash. This prevents any brake dust, dirt and road salt from sticking to the

wheel hubs. You can remove stubborn brake abrasion adhering to the wheels with an

industrial cleaner. Touch up any damage to the paintwork on the wheels before rust is

able to form.

Light alloy wheels

Regular care of light alloy wh eels is necessary in order to retain their decorative

appearance over long periods. It is particul arly important to remove any road salt and

brake abrasion from light alloy wheels every two weeks, otherwise the light metal will

suffer. Wash thoroughly and then treat the wheels with a protective product for light

alloy wheels which does not contain any acidic componen ts. You should provide the

wheel hubs with a hard wax layer every thre e months. You must not use any products

which cause abrasion when treating the wheel hubs. Any damage to the paint layer on

the wheel hubs must be touched up immediately.

We recommend using a preservative from Šk oda genuine accessories offered by your

Škoda dealer.

WARNING

One should remember when cleaning th e wheels that moisture, ice and road

salt may adversely affect braking ef ficiency - risk of an accident!

Note

Severe layers of dirt on the wheels can also result in wheel imbalance. This may show

itself in the form of a wheel vibration which is transmitted to the steering wheel which,

in certain circumstances, can cause premature wear of the steering. This means it is

necessary to remove the dirt.

s3fg.2.book Page 208 Friday, April 30, 2010 12:17 PM

Page 219 of 287

Inspecting and replenishing

218

It is normal for the engine to consume oil. The oil consumption may be as much as 0.5

l/1 000 km depending on your style of driving and the conditions under which you

operate your vehicle. The oil consumption may be slightly hi gher than this during the

first 5 000 kilometres.

One should therefore check the oil level at regular intervals, preferably every time after

the fuel tank is filled or after driving for long stretches.

We recommend maintaining the oil level within the range - but not above this, if

the engine has been operating at high load s, for example during a lengthy motorway

trip during the summer months, towing a tr ailer or negotiating a high mountain pass.

The warning light in the instrument cluster* will indicate page 31 whether the oil

level is too low. In this case, check the oil level as soon as possible. Top up with an

appropriate quantity of oil.

Caution

The oil level must on no account extend beyond the range . Danger of damaging

the catalytic converter.

Do not continue your journey if for some reason it is not possible under the

conditions prevailing to top up with oil. Switch the engine off and obtain professional

assistance from a specialist garage, otherwise it could lead to severe engine damage.Note

Engine oil specifications page 260.Replenishing engine oil– Inspecting the engine oil level page 217.

– Unscrew the cap of the engine oil filler opening.

– Pour in a suitable grade of oil in portions of 0.5 litres page 260.

– Inspect the oil level page 217, “Check engine oil level”.

– Carefully screw on the cap of the filler opening and push the dipstick in fully.

WARNING

Avoid dripping oil onto hot parts of the engine when topping up will oil - a

risk of fire!

Read and observe the warning notes page 216, “Working in the engine

compartment” before working in the engine compartment.For the sake of the environment

The oil level must on no acco unt extend beyond the range page 217. Oil will

otherwise be drawn in through the crankc ase ventilation and may pass through the

exhaust system to atmosphere. The oil ma y combust in the catalytic converter and

damage it.Changing engine oilThe engine oil must be changed at the intervals stated in the Service schedule or

according to the service interval indicator page 17.

WARNING

Only carry out the engine oil change, if you have the required professional

knowledge!

Read and observe the warning notes page 216 before working in the

engine compartment.

First of all, let the engine cool down, we ar an eye protection and gloves - risk

of caustic burns due to hot oil.Caution

You must not pour any additives into the engine oil - risk of engine damage! Damage,

which results from such product, are excluded from the warranty.

For the sake of the environment

You must on no account pour oil into the ground or into the sewage system.

AAAA

AA

s3fg.2.book Page 218 Friday, April 30, 2010 12:17 PM

Page 221 of 287

Inspecting and replenishing

220

Inspecting the coolant levelThe coolant expansion bottle is located in the engine compartment on the right.

– Switch the engine off.

– Open the bonnet page 216, “Working in the engine compartment”.

– Check the level of coolant in the coolant expansion bottle fig. 184 . The coolant

level when the engine is cold must lie between the (MIN) and (MAX) mark-

ings. The level may also rise slightly ab ove the (MAX) marking when the engine

is warm.

If the coolant level in the reservoir is too lo w, this is indicated by the warning light in

the instrument cluster

page 32. We nevertheless recommend inspecting the

coolant level directly at the reservoir from time to time.

Loss of coolant

A loss of coolant is first and foremost an indication of a leak in the system. You should

not merely top up the coolant in the reservoir. It is also important to have the cooling

system inspected without delay by a specialist garage.

Losses can only occur through the pressure relief in the cap of the coolant expansion

bottle which is completely free of leaks if the coolant boils as a result of overheating

and is forced out of the cooling system.

WARNING

Read and observe the warning notes page 216, “Working in the engine

compartment” before working in the engine compartment.

Caution

One should contact a specialist garage as s oon as possible if the source of overheating

itself cannot be determined and removed, since there may be grave damage to the

engine.Replenishing the coolant– Switch the engine off.

– Allow the engine to cool down.

– Place a cloth over the cap of the coolant expansion reservoir fig. 184 and

unscrew the cap carefully by turning it to the left .

–Top up the coolant.

– Screw the cap tight until it is heard to lock.

The coolant which you use for replenishing the system, must comply with one specific

specification page 219, “Coolant”. Do not use an al ternative additive if the coolant

additive G13 is not available in exceptional cases. Just top up the system with water

and as soon as possible arrange adjustment to correct the mixing ratio of water and

coolant additive again by a specialist garage.

Only use fresh coolant for topping up the system.

Do not fill up over the “MAX” marking! Excess coolant which is heated up is forced out

of the cooling system through the pressure relief valve in the cap of the coolant

compensation bottle.

Wait until the engine has cooled down for a system which has suffered a major loss of

coolant before pouring in coolant. This is necessary to avoid engine damage.

WARNING

The cooling system is pressurized! Do not open the cap of the coolant

expansion bottle if the engine is still hot - risk of scalding!

The coolant additive and thus all of the coolant is harmful to your health.

Avoid contact with the coolant. Coolant vapours are also harmful to the health.

It is important, therefore, to always safely store any coolant additive in its orig-

inal container out of the reach of children - risk of poisoning!

Fig. 184 Engine compartment: Coolant

expansion bottle

Ab

Aa

Aa

s3fg.2.book Page 220 Friday, April 30, 2010 12:17 PM