warning light SKODA SUPERB 2010 2.G / (B6/3T) Owner's Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2010, Model line: SUPERB, Model: SKODA SUPERB 2010 2.G / (B6/3T)Pages: 287, PDF Size: 16.59 MB

Page 222 of 287

Inspecting and replenishing221

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

If any splashes of coolant get into yo ur eyes, rinse out your eyes immedi-

ately with clear water and contact a doctor as soon as possible.

You should also consult a doctor without delay if you have inadvertently

swallowed coolant.Caution

Do not continue your journey if for some reason it is not possible under the

conditions prevailing to top up with coolant. Switch the engine off and obtain

professional assistance from a specialist garage, otherwise it could lead to severe

engine damage.

For the sake of the environment

Do not re-use coolant if it is necessary to drain the coolant in the system. It should be

collected and disposed of in compliance with environmental protection regulations.Radiator fan

The radiator fan may switch on suddenly.The radiator fan is driven by an electric motor and controlled according to the coolant

temperature.

The radiator fan may continue running for up to 10 minutes after the engine has been

switched off - even if the igni tion is also off. It may also switch on suddenly after a

certain time, if.

the coolant temperature has risen beca use of an accumulation of heat or

the warm engine compartment is heated up additionally by strong sunlight.

WARNING

You must therefore be aware when workin g in the engine compartment that the

fan may switch on suddenly - risk of injury!

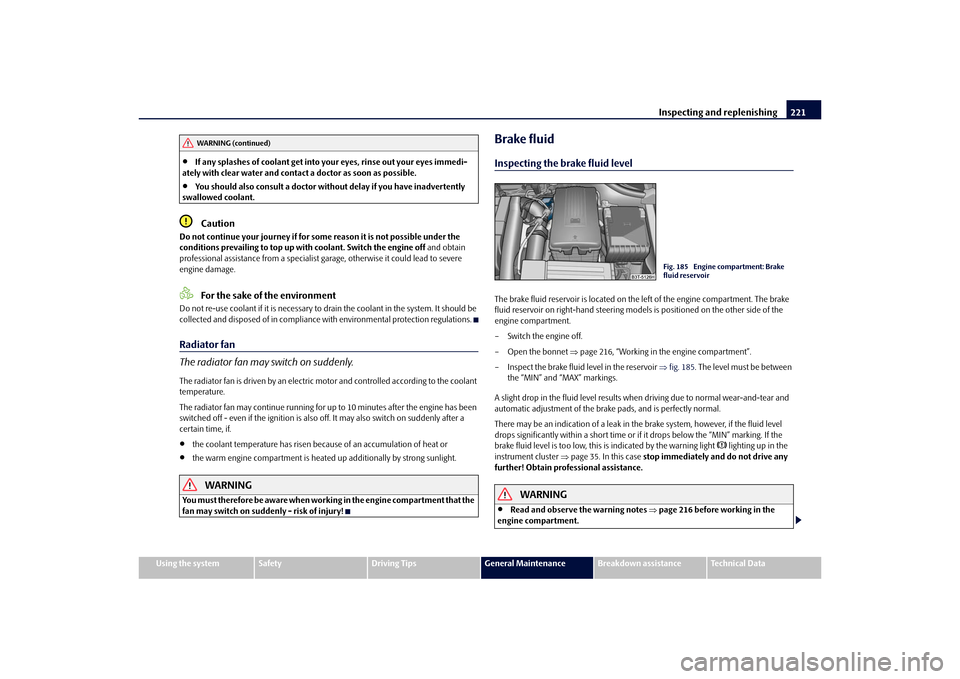

Brake fluidInspecting the brake fluid levelThe brake fluid reservoir is located on the left of the engine compartment. The brake

fluid reservoir on right-hand steering models is positioned on the other side of the

engine compartment.

– Switch the engine off.

– Open the bonnet page 216, “Working in the engine compartment”.

– Inspect the brake fluid level in the reservoir fig. 185 . The level must be between

the “MIN” and “MAX” markings.

A slight drop in the fluid level results when driving due to normal wear-and-tear and

automatic adjustment of the brak e pads, and is perfectly normal.

There may be an indication of a leak in the brake system, however, if the fluid level

drops significantly within a short time or if it drops below the “MIN” marking. If the

brake fluid level is too low, this is indicated by the warning light

lighting up in the

instrument cluster page 35. In this case stop immediately and do not drive any

further! Obtain professional assistance.

WARNING

Read and observe the warning notes page 216 before working in the

engine compartment.

WARNING (continued)

Fig. 185 Engine compartment: Brake

fluid reservoir

s3fg.2.book Page 221 Friday, April 30, 2010 12:17 PM

Page 224 of 287

Inspecting and replenishing223

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

There is a risk of injuries, scalding, accidents and burns when carrying out any work on

the battery and on the electrical system. For

this reason, it is essential to comply with

the warning instructions stated below and with the general applicable rules of

safety.

WARNING

The battery acid is strongly corrosive and must, therefore, be handled with

the greatest of care. Always wear prot ective gloves, eye and skin protection

when handling batteries. Corrosive fumes in the air irritate the air passages and

lead to conjunctivitis and inflammation of the air passages in the lungs. Battery

acid corrodes dental enamel and create s deep wounds after contact with the

skin which take a long time to heal. Repeated contact with diluted acids causes

skin diseases (inflammations, ulcers, slin cracks). Acids coming into contact

with water are diluted accompanied by significant development of heat.

Do not tilt the battery otherwise battery electrolyte may flow out of the

battery vent openings. Protect the eyes with safety glas ses or a shield! There is

the danger of suffering blindness! If an y battery electrolyte gets into your eye,

rinse out your eye immediately with cl ear water for several minutes. Contact a

doctor without delay.

Splashes of acid on your skin or clothes should be neutralised as soon as

possible using soap suds and then rinsed with plenty of water. Contact a doctor

immediately if you swal low battery electrolyte.

Keep batteries out of the reach of children.

Hydrogen is released when you charge a battery and a highly explosive gas

mixture is produced. An explosion can be caused through sparkling over during

unclamping or loosening of the cabl e plug while the ignition is on.

Bridging of the poles will create a short circuit (e.g. through metal objects,

cables). Possible consequences of a short circuit: Melting of lead struts, explo-

sion and burning of the battery, jets of acid spurting out.

It is prohibited to work with a naked flame and light, to smoke or to carry out

any activities which produce sparks. Avoi d creating sparks when working with

cables and electrical devices. Strong sparking represents a risk of injury.

Before carrying out any work on the el ectrical system, switch off the engine,

the ignition as well as all electrical components and disconnect the negative cable (-) on the battery. If you wish to replace a bulb it is sufficient to switch off

the appropriate light.

Never charge a frozen or thawed battery - risk of explosion and caustic

burns! Replace a frozen battery.

Never jump-start the batteries which ha ve a too low electrolyte level - risk

of explosion and caustic burns.

Never use a battery which is damaged - risk of explosion! Immediately

replace a damaged battery.Caution

You must only disconnect the battery if th e ignition is switched off, otherwise the

electrical system (electronic components ) of the vehicle may be damaged. When

disconnecting the battery from the electrical system of the vehicle, first disconnect the

negative terminal (-) of the battery. Then disconnect the positive terminal (+).

When reconnecting the battery, first connect the positive terminal (+) and only

then the negative terminal (-) of the battery. You must on no account connect the

cables wrongly - risk of a cable fire.

Ensure that battery acid does not come into contact with the vehicle body other-

wise damage could occur to the paintwork.

Do not place the battery in direct daylight in order to protect the battery housing

from the effects of ultra-violet light.For the sake of the environment

A removed battery is a special type of wa ste which is harmful to the environment -

contact your specialist garage regarding disposing of the battery.

Note

Please also refer to the guidelines page 226, also after connecting the battery.

WARNING (continued)

s3fg.2.book Page 223 Friday, April 30, 2010 12:17 PM

Page 227 of 287

Inspecting and replenishing

226

Disconnecting and reconnecting the batteryOn disconnecting and reconnecting the batt ery the following functions are initially

deactivated or are no longer able to operate fault-free:

We recommend having the vehi cle checked by an authorised Škoda Service Partner to

ensure full functionality of all electrical systems.Replacing the batteryYou should only replace a battery with a ne w battery of the same capacity, voltage (12

V), amperage and of the same size. The auth orised Škoda Service Partners have a range

of suitable batteries available.

For the sake of the environment

Batteries contain poisonous substances such as sulphuric acid and lead. They must be

disposed of in accordance with local environmental protection regulations and on no

account as domestic waste!

In view of the problems involved with it s proper disposal, we recommend having

the battery replaced by a specialist garage.

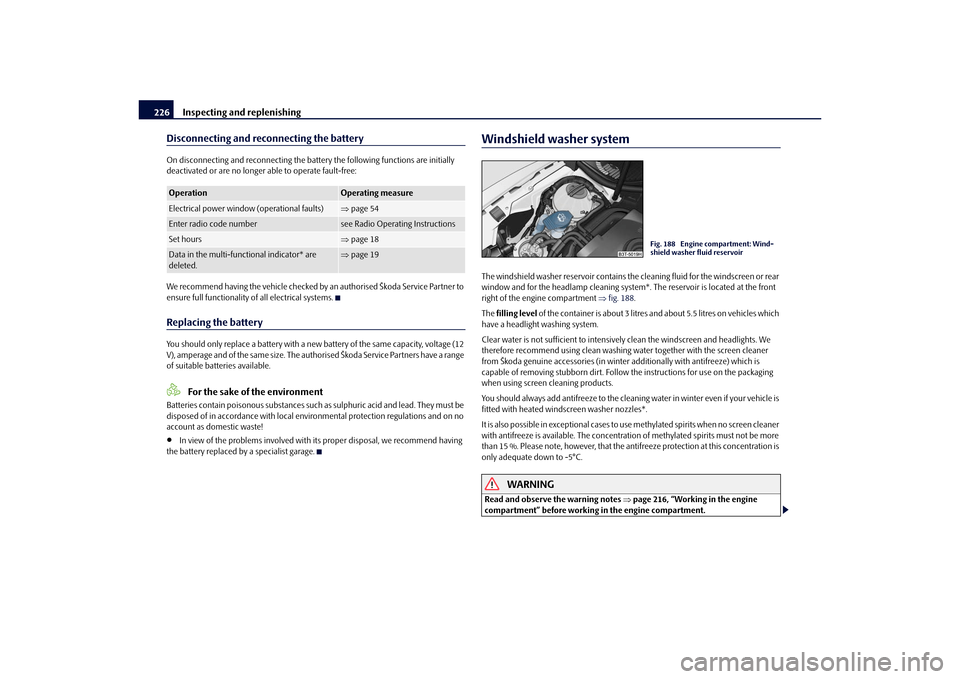

Windshield washer systemThe windshield washer reservoir contains the cleaning fluid for the windscreen or rear

window and for the headlamp cleaning system *. The reservoir is located at the front

right of the engine compartment fig. 188 .

The filling level of the container is about 3 litres and about 5.5 litres on vehicles which

have a headlight washing system.

Clear water is not sufficient to intensively clean the windscreen and headlights. We

therefore recommend using clean washing water together with the screen cleaner

from Škoda genuine accessories (in winter additionally with antifreeze) which is

capable of removing stubborn dirt. Follow the instructions for use on the packaging

when using screen cleaning products.

You should always add antifreeze to the cleaning water in winter even if your vehicle is

fitted with heated wind screen washer nozzles*.

It is also possible in exceptional cases to use methylated spirits when no screen cleaner

with antifreeze is available. The concentration of methylated spirits must not be more

than 15 %. Please note, however, that the anti freeze protection at this concentration is

only adequate down to -5°C.

WARNING

Read and observe the warning notes page 216, “Working in the engine

compartment” before working in the engine compartment.

Operation

Operating measure

Electrical power window (operational faults)

page 54

Enter radio code number

see Radio Operat ing Instructions

Set hours

page 18

Data in the multi-functional indicator* are

deleted.

page 19

Fig. 188 Engine compartment: Wind-

shield washer fluid reservoir

s3fg.2.book Page 226 Friday, April 30, 2010 12:17 PM

Page 232 of 287

Wheels and Tyres231

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

The date of manufacture

is also stated on the tyre wall (possibly only on the inside of

wheel).

DOT ... 20 09...

means, for example, that the tyre was ma nufactured in the 20th week of the year 2009.

Any spare wheel which differs from the tyres fitted to the vehicle (e.g. winter tyres or

low-profile tyres) should only be used for a short time in the event of a puncture and

when adopting an appropriately cautious styl e of driving. It should be replaced as

quickly as possible by a normal wheel.

WARNING

Only use those tyres or wheel rims which have been approved for your

model of Škoda Auto vehicle. Failure to observe this instruction will adversely

affect the road safety of your vehicle - risk of accident! Approval and licencing

of your vehicle on public roads may also become void as a result.

You must on no account drive at a high er speed than is permissible for your

tyres - risk of an accident resulting from tyre damage and loss of control over

your vehicle.

Tyres which are 6 years old or more should only be fitted in exceptional

cases and when adopting an approp riately cautious style of driving.

Never fit tyres which have already been used without having adequate

knowledge of their previous history. Tyre s age even if they have not been used

at all or only very little. A spare tyre must only be used in exceptional cases and

only then when adopting an appropriately cautious style of driving.

Do not, where possible, replace individu al tyres but at least replace them on

both wheels of a given axle at the same time. Always fit the tyres with the

deeper tread depth to the front wheels.For the sake of the environment

Old tyres must be disposed of in conf ormity with the appropriate regulations.

Note

It is not normally possible to fit wheels from other models of cars for technical reasons.

This may also apply in certain circumstances to the wheels of the same type of

vehicle.Wheel boltsWheels and wheel bolts are matched to each other in terms of design. Each time you

fit other wheels - e.g. light alloy wheels or wheels with winter tyres - you must therefore

also use the matching wheel bolts of the corr ect length and shape of spherical cap. This

is essential to ensure that the wheels are tightly fitted and that the brake system oper-

ates properly.

If you retrofit wheel trims (or have this done), please also ensure that an adequate

flow of air remains assured for cooling the brake system.

The authorised Škoda Service Partners are instructed in the technical possibilities

which exist regarding converting or retrofitting tyres, wheels and wheel trims.

WARNING

In case of incorrect treatment of the wheel bolts, the wheel can loosen when

the car is moving - risk of accident!

The wheel bolts must be clean and must turn easily. However, they must

never be treated with grease or oil.

If the wheel bolts are tightened to a too low tightening torque, the rim can

lossen when the car is moving - risk of accident! A tightening torque which is

too high can damage the bolts and threads and this can result in permanent

deformation of the contac t surfaces on the rims.Caution

The prescribed tightening torque of the wh eel bolts for steel and light alloy wheels is

120 Nm.

s3fg.2.book Page 231 Friday, April 30, 2010 12:17 PM

Page 238 of 287

Breakdown assistance237

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

The spare wheel lies in a well under the floor covering of the luggage compartment and

is fixed in place using special screws

page 236, fig. 195 .

Before removing the spare wheel, you must take out the box with the vehicle tool kit

box page 236, fig. 194.

One should check the inflation pressure in the spare wheel (at best when generally

checking the tyre air pressures - see sign on the fuel filler flap page 228) to ensure

that the spare wheel is always ready to use.

Temporary spare wheel

A warning label displayed on the rim of the temporary spare wheel indicates that your

vehicle is equippe d with a temporary spare wheel.

Please observe the following notes when driving with a temporary spare wheel:

The warning label must not be covered after installing the wheel.

Do not drive faster than 80 km/h with this spare wheel and pay particular attention

while driving. Avoid accelerating at full throttle, sharp braking and fast cornering.

The inflation pressure for this spare wheel is identical to the inflation pressure of

the standard tyres. The temporary spare wheel R 18 must have an inflation pressure of

420 kPa (4.2 bar)!

Use this spare wheel only to reach the nearest specialist garage as it is not intended

for continuous use.

No other summer or winter tyres must be mounted on the rim of the spare wheel

R 18.

Changing a wheelPreliminary workThe following steps should be carried ou t before actually changing the wheel.

– If it is necessary to change a wheel, park the vehicle as far away as possible from

the traffic flow. The place you choose should be level.

–Have all the occupants get out. While changing a wheel, the occupants of the

vehicle should not stand on the road (e.g. behind a crash barrier).

– Apply the handbrake firmly. –Engage

1st gear or if your vehicle is fitted with an automatic gearbox, position the

selector lever into position P .

– If a trailer is coupled, uncouple it.

–Take the vehicle tool kit page 236 and the spare wheel* page 236 out of the

luggage compartment.

WARNING

If you find yourself in flowing traffic switch on the hazard warning lights

system and place the warning triangle on the side of the road at the prescribed

distance from your vehicle while observin g all national legal provisions. In this

way you are protecting not only yourself but also other road users.

Never start the engine with the vehicle si tting on the raised jack - danger of

suffering injury.Caution

If you have to change a wheel on a slope fi rst block the opposite wheel with a stone or

similar object in order to secure the vehicle from unexpectedly rolling away.

Note

Comply with the national legal regulations.Changing a wheelAlways change a wheel on a level surface as far as possible.

– Take off the full wheel trim* page 238 or the wheel trim cap page 239 or the

caps page 239.

– In the case of light alloy wheels remove the wheel trim cap page 239.

– First of all slacken the safety wheel bolt * and afterwards the other wheel bolts page 239.

– Jack up the vehicle until the wheel to be changed is clear of the ground

page 240.

– Unscrew the wheel bolts and place them on a clean surface (cloth, paper etc.).

s3fg.2.book Page 237 Friday, April 30, 2010 12:17 PM

Page 239 of 287

Breakdown assistance

238

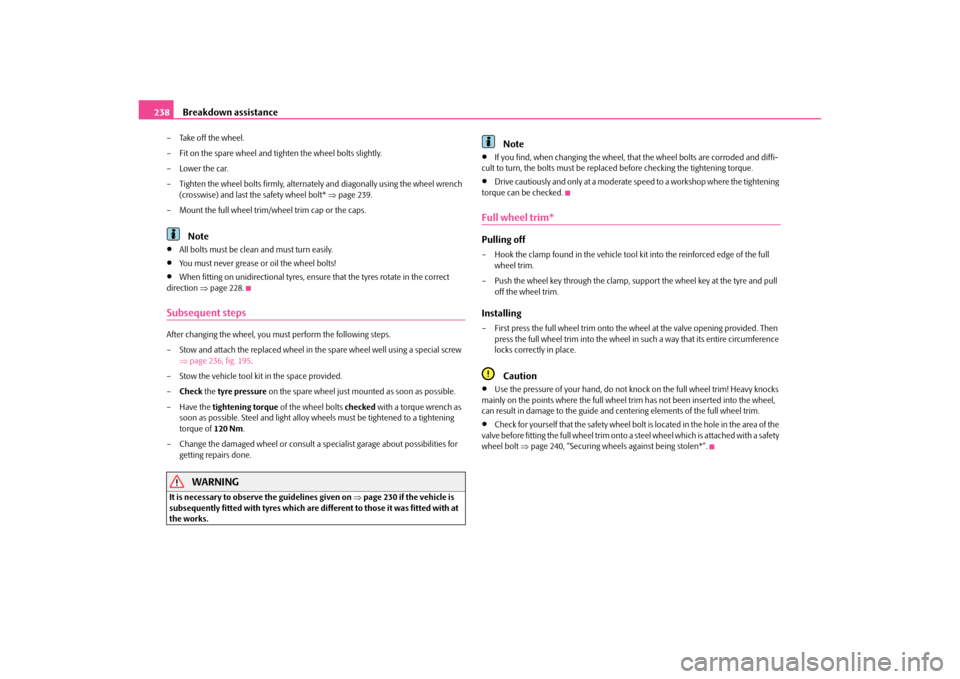

– Take off the wheel.

– Fit on the spare wheel and ti ghten the wheel bolts slightly.

–Lower the car.

– Tighten the wheel bolts firmly, alternately and diagonally using the wheel wrench (crosswise) and last the safety wheel bolt* page 239.

– Mount the full wheel trim/wheel trim cap or the caps.

Note

All bolts must be clean and must turn easily.

You must never grease or oil the wheel bolts!

When fitting on unidirectional tyres, ensu re that the tyres rotate in the correct

direction page 228.

Subsequent stepsAfter changing the wheel, you must perform the following steps.

– Stow and attach the replaced wheel in the spare wheel well using a special screw

page 236, fig. 195 .

– Stow the vehicle tool kit in the space provided.

– Check the tyre pressure on the spare wheel just mounted as soon as possible.

– Have the tightening torque of the wheel bolts checked with a torque wrench as

soon as possible. Steel and light alloy wh eels must be tightened to a tightening

torque of 120 Nm .

– Change the damaged wheel or consult a specialist garage about possibilities for getting repairs done.

WARNING

It is necessary to observe the guidelines given on page 230 if the vehicle is

subsequently fitted with tyres which are different to those it was fitted with at

the works.

Note

If you find, when changing the wheel, that the wheel bolts are corroded and diffi-

cult to turn, the bolts must be replaced before checking the tightening torque.

Drive cautiously and only at a moderate speed to a workshop where the tightening

torque can be checked.

Full wheel trim*Pulling off– Hook the clamp found in the vehicle tool ki t into the reinforced edge of the full

wheel trim.

– Push the wheel key through the clamp, support the wheel key at the tyre and pull off the wheel trim.Installing– First press the full wheel trim onto the wheel at the valve opening provided. Then

press the full wheel trim into the wheel in such a way that its entire circumference

locks correctly in place.

Caution

Use the pressure of your hand, do not knock on the full wheel trim! Heavy knocks

mainly on the points where the full wheel trim has not been inserted into the wheel,

can result in damage to the guide and centering elements of the full wheel trim.

Check for yourself that the safety wheel bolt is located in the hole in the area of the

valve before fitting the full wheel trim onto a steel wheel which is attached with a safety

wheel bolt page 240, “Securing wheels against being stolen*”.

s3fg.2.book Page 238 Friday, April 30, 2010 12:17 PM

Page 240 of 287

Breakdown assistance239

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

Wheel bolts with caps*Pulling off– Push the plastic clip sufficiently far onto the cap until the inner catches of the clip

are positioned at the collar of the cap and detach the cap fig. 196 .Installing– Push the caps fully onto the wheel bolts.

The caps are located in the well of the luggage compartment.Wheel trim caps*Pulling off– Carefully remove the wheel tr im cap using the wire clamp fig. 197 .

Slackening and tightening wheel bolts

Slacken the wheel bolts before jacking up the vehicle.Slackening wheel bolts– Push the wheel wrench* fully onto the wheel bolt

16).

– Grasp the end of the wrench* and turn the bolt about one turn to the left

fig. 198 .

Tightening wheel bolts– Push the wheel wrench* fully onto the wheel bolt

16).

– Grasp the end of the wrench* and turn the bolt to the right until it is tight.

WARNING

Slacken the wheel bolts only a little (about one turn) as long as the vehicle has

not yet been jacked up - risk of an accident!.

Note

Apply pressure carefully with your foot to the end of the wrench* if it proves difficult

to slacken the bolts. Hold tight on the vehicl e when doing this and ensure that you have

a steady position.

Fig. 196 Removing the cap.Fig. 197 Pulling off wheel trim cap on

light alloy wheels

16)Use the appropriate adapter for slackening and tightening the safety wheel bolts page 240.

Fig. 198 Changing a wheel: Slackening

wheel bolts

s3fg.2.book Page 239 Friday, April 30, 2010 12:17 PM

Page 241 of 287

Breakdown assistance

240

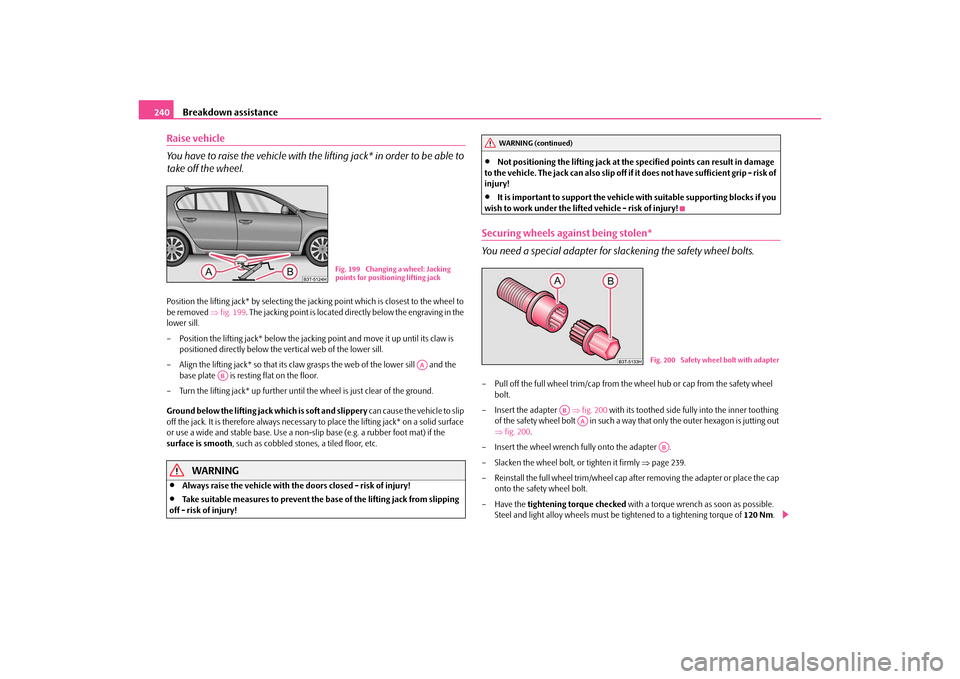

Raise vehicle

You have to raise the vehicle with the lifting jack* in order to be able to

take off the wheel.Position the lifting jack* by selecting the ja cking point which is closest to the wheel to

be removed fig. 199 . The jacking point is located directly below the engraving in the

lower sill.

– Position the lifting jack* below the jacking point and move it up until its claw is positioned directly below the vertical web of the lower sill.

– Align the lifting jack* so that its claw grasps the web of the lower sill and the

base plate is resting flat on the floor.

– Turn the lifting jack* up further until the wheel is just clear of the ground.

Ground below the lifting jack which is soft and slippery can cause the vehicle to slip

off the jack. It is therefore always necessary to place the lifting jack* on a solid surface

or use a wide and stable base. Use a non-sl ip base (e.g. a rubber foot mat) if the

surface is smooth , such as cobbled stones, a tiled floor, etc.

WARNING

Always raise the vehicle with the doors closed - risk of injury!

Take suitable measures to prevent the base of the lifting jack from slipping

off - risk of injury!

Not positioning the lifting jack at the specified points can result in damage

to the vehicle. The jack can al so slip off if it does not have sufficient grip - risk of

injury!

It is important to support the vehicle with suitable supporting blocks if you

wish to work under the lifted vehicle - risk of injury!

Securing wheels against being stolen*

You need a special adapter for sl ackening the safety wheel bolts.– Pull off the full wheel trim/cap from the wheel hub or cap from the safety wheel

bolt.

– Insert the adapter fig. 200 with its toothed side full y into the inner toothing

of the safety wheel bolt in such a way that only the outer hexagon is jutting out

fig. 200 .

– Insert the wheel wrench fully onto the adapter .

– Slacken the wheel bolt, or tighten it firmly page 239.

– Reinstall the full wheel trim/wheel cap after removing the adapter or place the cap onto the safety wheel bolt.

– Have the tightening torque checked with a torque wrench as soon as possible.

Steel and light alloy wheels must be tightened to a tightening torque of 120 Nm.

Fig. 199 Changing a wheel: Jacking

points for positioning lifting jack

AA

AB

WARNING (continued)

Fig. 200 Safety wheel bolt with adapter

AB

AA

AB

s3fg.2.book Page 240 Friday, April 30, 2010 12:17 PM

Page 253 of 287

Fuses and light bulbs

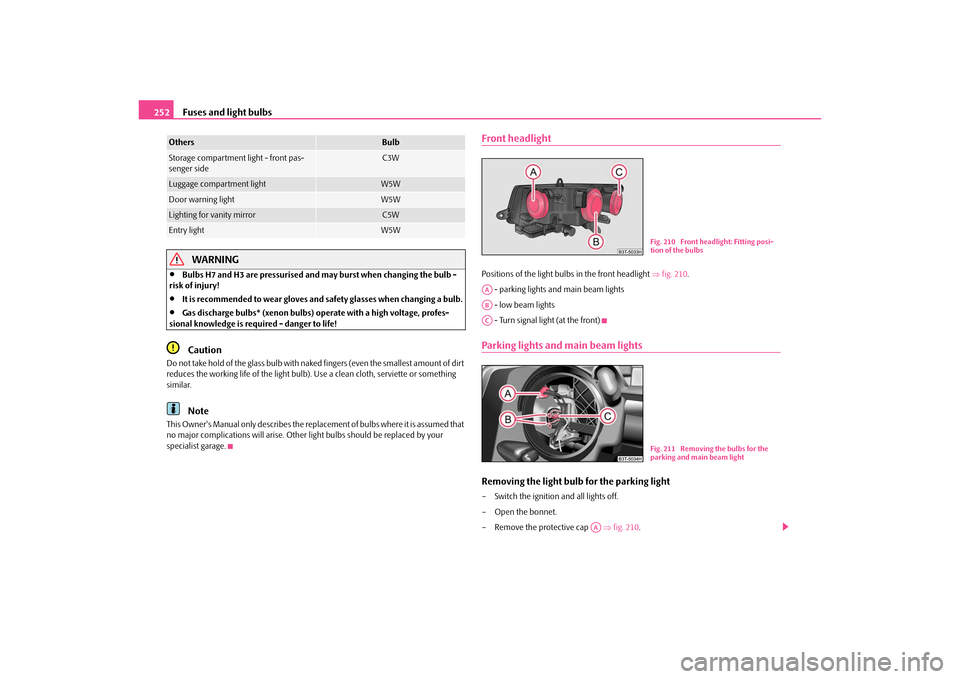

252WARNING

Bulbs H7 and H3 are pressurised and may burst when changing the bulb -

risk of injury!

It is recommended to wear gloves and safety glasses when changing a bulb.

Gas discharge bulbs* (xenon bulbs) operate with a high voltage, profes-

sional knowledge is required - danger to life!Caution

Do not take hold of the glass bulb with naked fingers (even the smallest amount of dirt

reduces the working life of the light bulb). Use a clean cloth, serviette or something

similar.

Note

This Owner's Manual only describes the replacement of bulbs where it is assumed that

no major complications will arise. Other light bulbs should be replaced by your

specialist garage.

Front headlightPositions of the light bulbs in the front headlight fig. 210 .

- parking lights and main beam lights

- low beam lights

- Turn signal light (at the front)Parking lights and main beam lightsRemoving the light bulb for the parking light– Switch the ignition and all lights off.

– Open the bonnet.

– Remove the protective cap fig. 210.

Storage compartment light - front pas-

senger side

C3W

Luggage compartment light

W5W

Door warning light

W5W

Lighting for vanity mirror

C5W

Entry light

W5W

Others

Bulb

Fig. 210 Front headlight: Fitting posi-

tion of the bulbs

AAABAC

Fig. 211 Removing the bulbs for the

parking and main beam light

AA

s3fg.2.book Page 252 Friday, April 30, 2010 12:17 PM

Page 278 of 287

Index277

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

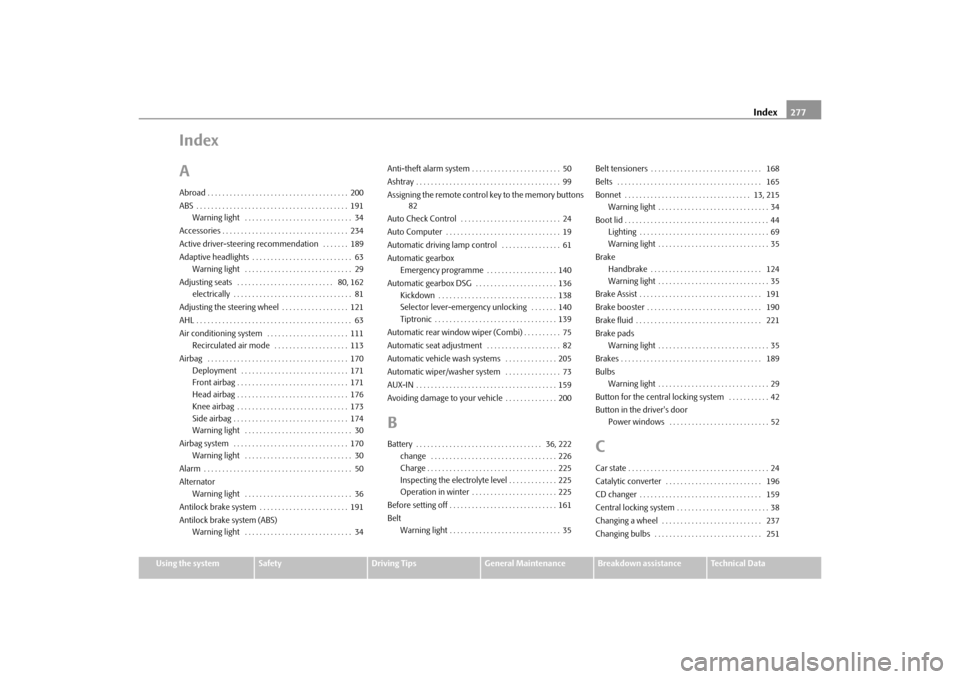

Index

AAbroad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

ABS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Active driver-steering recommendation . . . . . . . 189

Adaptive headlights . . . . . . . . . . . . . . . . . . . . . . . . . . . 63 Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Adjusting seats . . . . . . . . . . . . . . . . . . . . . . . . . . 80, 162 electrically . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Adjusting the steering wheel . . . . . . . . . . . . . . . . . . 121

AHL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Air conditioning system . . . . . . . . . . . . . . . . . . . . . . 111 Recirculated air mode . . . . . . . . . . . . . . . . . . . . 113

Airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170 Deployment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Front airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Head airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Knee airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Side airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Airbag system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170 Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Alternator Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Antilock brake system . . . . . . . . . . . . . . . . . . . . . . . . 191

Antilock brake system (ABS) Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 Anti-theft alarm system . . . . . . . . . . . . . . . . . . . . . . . . 50

Ashtray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Assigning the remote control key to the memory buttons

82

Auto Check Control . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Auto Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Automatic driving lamp control . . . . . . . . . . . . . . . . 61

Automatic gearbox Emergency programme . . . . . . . . . . . . . . . . . . . 140

Automatic gearbox DSG . . . . . . . . . . . . . . . . . . . . . . 136 Kickdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Selector lever-emergency unlocking . . . . . . . 140

Tiptronic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Automatic rear window wiper (Combi) . . . . . . . . . . 75

Automatic seat adjustment . . . . . . . . . . . . . . . . . . . . 82

Automatic vehicle wash systems . . . . . . . . . . . . . . 205

Automatic wiper/washer system . . . . . . . . . . . . . . . 73

AUX-IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Avoiding damage to your vehicle . . . . . . . . . . . . . . 200

BBattery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36, 222 change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Inspecting the electrolyte level . . . . . . . . . . . . . 225

Operation in winter . . . . . . . . . . . . . . . . . . . . . . . 225

Before setting off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Belt Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 Belt tensioners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Bonnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13, 215

Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Boot lid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44 Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Brake Handbrake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Brake Assist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Brake booster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Brake fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Brake pads Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Bulbs Warning light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Button for the central locking system . . . . . . . . . . . 42

Button in the driver's door Power windows . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

CCar state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Catalytic converter . . . . . . . . . . . . . . . . . . . . . . . . . . 196

CD changer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Central locking system . . . . . . . . . . . . . . . . . . . . . . . . . 38

Changing a wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Changing bulbs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

s3fg.2.book Page 277 Friday, April 30, 2010 12:17 PM