check engine SKODA SUPERB 2013 2.G / (B6/3T) Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2013, Model line: SUPERB, Model: SKODA SUPERB 2013 2.G / (B6/3T)Pages: 274, PDF Size: 17.31 MB

Page 211 of 274

WARNING (Continued)■If you intend to work underneath the vehicle, you must secure the vehicle

from rolling away and support it with suitable supporting blocks; the car jack

is not sufficient – risk of injury!■

Never cover the engine with additional insulation material (e.g. with a cover)

– risk of fire!

■

The bonnet must always be properly closed when driving. Therefore, the

lock must always be checked after closing the bonnet in order to ensure that

it has engaged properly.

■

If you notice that the lock is not properly engaged while driving, stop the ve-

hicle immediately and close the bonnet – risk of accident!

CAUTION

Always top up using the correct specification of fluids. This may result in major

operating problems and also vehicle damage!

For the sake of the environment

In view of the requirements for the environmentally friendly disposal of fluids and the special tools and knowledge required for such work, we recommend that flu-

ids be changed by a specialist garage.

Note

■ Please consult a specialist garage for any questions relating to fluids.■Fluids with the correct specifications can be purchased from ŠKODA Original Ac-

cessories.

Opening and closing the bonnetFig. 161

Bonnet release lever/release lever

First read and observe the introductory information and safety warn- ings

on page 206.

Opening

›

Pull the release lever under the dash panel in the direction of the arrow

1

» Fig. 161 .

Before opening the bonnet, ensure that the arms of the windscreen wipers are

correctly in place against the windscreen otherwise the paintwork could be dam-

aged.

›

Press the release lever in the direction of the arrow

2

» Fig. 161 and the bonnet

is unlocked.

›

Grasp the bonnet and lift up until it is held open by the pressurised gas spring.

Closing

›

Pull the bonnet down far enough to overcome the force of the pressurised gas spring.

›

Close the bonnet from a height of approximately 20 cm with a slight swing

WARNINGCheck that the bonnet is closed properly.

CAUTION

Never open the bonnet using the locking lever » Fig. 161

.

208General Maintenance

Page 213 of 274

In Winter, the washing water should always be mixed with antifreeze even if the

vehicle has heated windscreen washer nozzles.

Under exceptional circumstances, methylated spirits can also be used if no screen

cleaner with antifreeze is available. The concentration of methylated spirits must

not be more than 15 %. The freeze protection at this concentration is sufficient

only to -5 °C.

CAUTION

■ Under no circumstances must radiator antifreeze or other additives be added to

the windscreen washer fluid.■

If the vehicle is fitted with a headlight cleaning system, only cleaning products

which do not attack the polycarbonate coating of the headlights must be added

to the windscreen washer fluid.

■

Do not remove the filter from the windscreen washer fluid reservoir when refill-

ing, as this may cause contamination of the liquid transportation system, leading

in turn to a windscreen washer system malfunction.

Engine oil

Introduction

This chapter contains information on the following subjects:

Specifications and capacity

210

Checking the oil level

211

Replenishing

212

Changing

212

The engine has been factory-filled with a high-grade oil that can be use through-

out the year - except in extreme climate zones.

The engine oils are undergoing continuous further development. Thus the infor-

mation stated in this Owner's Manual is only correct at the time of publication.

ŠKODA Service Partners are informed about the latest changes by the manufac-

turer. We therefore recommend that the oil change be completed by a ŠKODA

Service Partner.

The specifications (VW standards) stated in the following can be indicated sepa-

rately or together with other specifications on the bottle.

The oil capacities include oil filter change. Check the oil level when filling; do not

over fill. The oil level must be between the markings » page 211.WARNING■

The engine compartment of your car is a hazardous area. The following

warning instructions must be followed at all times when working in the en-

gine compartment » page 206.■

Do not continue your journey if for some reason it is not possible to top up

the engine oil . Switch off the engine and seek assistance from a specialist

garage.

■

If the oil level is above level

A

» Fig. 164 on page 211, do not continue to

drive! Switch off the engine and seek assistance from a specialist garage.

CAUTION

Do not pour any additives into the engine oil – risk of serious damage to the en-

gine parts!

Note

■ Before a long drive we recommend that you purchase and carry with you engine

oil which complies with the specification for your vehicle.■

We recommend that you use oils from ŠKODA Original Accessories.

■

If your skin has come into contact with oil, it must be washed thoroughly.

Specifications and capacity

First read and observe the introductory information and safety warn-

ings

on page 210.

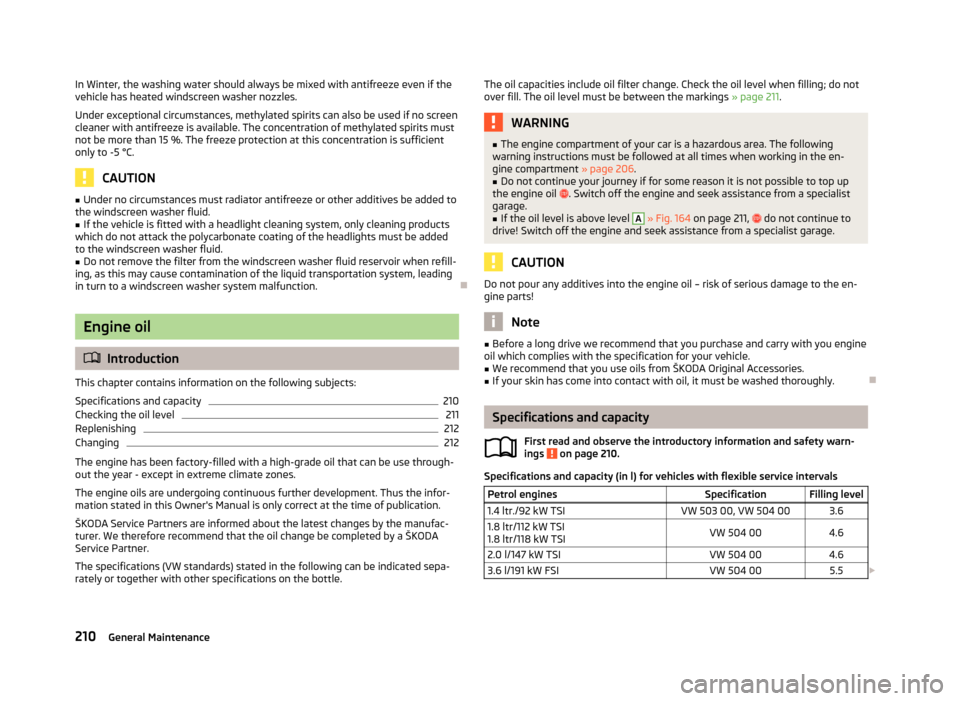

Specifications and capacity (in l) for vehicles with flexible service intervals

Petrol enginesSpecificationFilling level1.4 ltr./92 kW TSIVW 503 00, VW 504 003.61.8 ltr/112 kW TSI

1.8 ltr/118 kW TSIVW 504 004.62.0 l/147 kW TSIVW 504 004.63.6 l/191 kW FSIVW 504 005.5 210General Maintenance

Page 214 of 274

Diesel enginesa)SpecificationFilling level1.6 l./77 kW TDI CRVW 507 004.32.0 ltr/103 kW TDI CR DPFVW 507 004.32.0 ltr/125 kW TDI CR DPFVW 507 004.3a)

Engine oil VW 505 01 can optionally be used in diesel engines

without a DPF.

Specifications and capacity (in l) for vehicles with fixed service intervals

Petrol enginesSpecificationFilling lev- el1.4 ltr./92 kW TSIVW 501 01, VW 502 003.61.8 ltr/112 kW TSI

1.8 ltr/118 kW TSIVW 502 004.62.0 l/147 kW TSIVW 502 004.63.6 l/191 kW FSIVW 502 005.5Diesel engines a)SpecificationFilling lev-

el1.6 l./77 kW TDI CRVW 507 004.32.0 ltr/103 kW TDI CR DPFVW 507 004.32.0 ltr/125 kW TDI CR DPFVW 507 004.3a)

Engine oil VW 505 01 can optionally be used in diesel engines without a DPF.

CAUTION

■

If the above engine oils are not available, a different engine oil can be used in

an emergency. To prevent damage to the engine, a maximum of 0.5 litres only of

the following engine oils may be used until the next oil change: ■ For petrol engine models: ACEA A3/ACEA B4 or API SN/API SM;

■ For diesel engine models: ACEA C3 or API CJ-4.

Checking the oil levelFig. 164

Dipstick

First read and observe the introductory information and safety warn-

ings on page 210.

The dipstick indicates the level of oil in the engine » Fig. 164.

Checking the oil level

Ensure that the vehicle is positioned on a level surface and the engine has reached its operating temperature.

›

Switch off the engine.

Wait a few minutes until the engine oil flows back into the oil trough.

›

Open the bonnet.

›

Pull out the dipstick.

›

Wipe the dipstick with a clean cloth and insert it again to the stop.

›

Pull the dipstick out again and check the oil level.

Oil level within range

A

No oil must be refilled.

Oil level within range

B

Oil can be refilled. Afterwards, the oil level can lie in the range

A

.

Oil level within range

C

The engine must be topped up with oil so that the oil level at least reaches the

range

B

.

The engine consumes a little oil. The oil consumption may be as much as 0.5 l/

1 000 km depending on your style of driving and the conditions under which you operate your vehicle. Consumption may be slightly higher than this during the

first 5 000 kilometres.

211Inspecting and replenishing

Page 215 of 274

The oil level must be checked at regular intervals. We recommend after each time

you refuel or prior to making a long journey.

We recommend maintaining the oil level within the range A

, but not above , if

the engine has been operating at high loads, for example, during a lengthy motor-

way trip during the summer months, towing a trailer or negotiating a high moun- tain pass.

The indicator light in the instrument cluster will indicate whether the oil level is

too low » page 18 , Engine oil level . Check the oil level using the dipstick as

soon as possible. Add oil accordingly.

CAUTION

The oil level must not exceed the range A » Fig. 164 – there is a risk of damaging

the exhaust system.

Replenishing

First read and observe the introductory information and safety warn-

ings

on page 210.

›

Check the oil level » page 211.

›

Unscrew the cap of the engine oil filler opening » Fig. 162 on page 209.

›

Replenish the oil in portions of 0.5 litres in accordance with the correct specifi-

cations » page 210 .

›

Check the oil level » page 211.

›

Carefully screw on the oil filler opening cap and push the dipstick in fully.

Changing

First read and observe the introductory information and safety warn-ings

on page 210.

The engine oil must be changed according to pre-specified service inter-

vals » page 191 or according to the service interval display » page 30.

Coolant

Introduction

This chapter contains information on the following subjects:

Capacity

213

Checking the coolant level

213

Replenishing

214

The coolant consists of water with coolant additive. This mixture guarantees anti- freeze protection, protects the cooling/heater system against corrosion and pre-

vents lime formation.

Vehicles exported to countries with a mild climate are already factory-filled with

a coolant which offers antifreeze protection down to about -25 ℃. In these coun-

tries, the concentration of coolant additive should be at least 40%.

Vehicles exported to countries with a cold climate are already factory-filled with a

coolant which offers antifreeze protection down to about -35 °C. In these coun-

tries, the concentration of coolant additive should be at least 50%.

If a higher concentration of antifreeze is required for climatic reasons, the con-centration of coolant additive can be increased up to a maximum of 60% (anti-

freeze protection down to approx. -40 °C).

When refilling, only use the same antifreeze written on the antifreeze expansion tank » Fig. 165 on page 213.

WARNING■

The engine compartment of your car is a hazardous area. The following

warning instructions must be followed at all times when working in the en-

gine compartment » page 206.■

Do not continue your journey if for some reason it is not possible to fill with

coolant under the current circumstances . Switch off the engine and seek

assistance from a specialist garage.

CAUTION

■ The concentration of coolant additive in the coolant must never be under 40%.■Over 60% of coolant additive in the coolant reduces the antifreeze protection

and cooling effect. 212General Maintenance

Page 216 of 274

■A coolant additive that does not comply with the correct specifications can sig-

nificantly reduce the corrosion protection.■

Any faults resulting from corrosion may cause a loss of coolant and can conse-

quently result in major engine damage!

■

Do not fill the coolant above the mark

A

» Fig. 165 on page 213.

■

If a fault causes the engine to overheat, we recommend visiting a specialist ga-

rage, as otherwise serious engine damage may occur.

Capacity

First read and observe the introductory information and safety warn-

ings

on page 212.

Coolant capacity (in litres) 1)

Petrol enginesFilling level1.4 ltr./92 kW TSI7.71.8 ltr/112 kW TSI

1.8 ltr/118 kW TSI8.62.0 l/147 kW TSI8.63.6 l/191 kW FSI9.0Diesel enginesFilling level1.6 l./77 kW TDI CR8.42.0 ltr./103 kW TDI CR8.42.0 ltr./125 kW TDI CR8.4

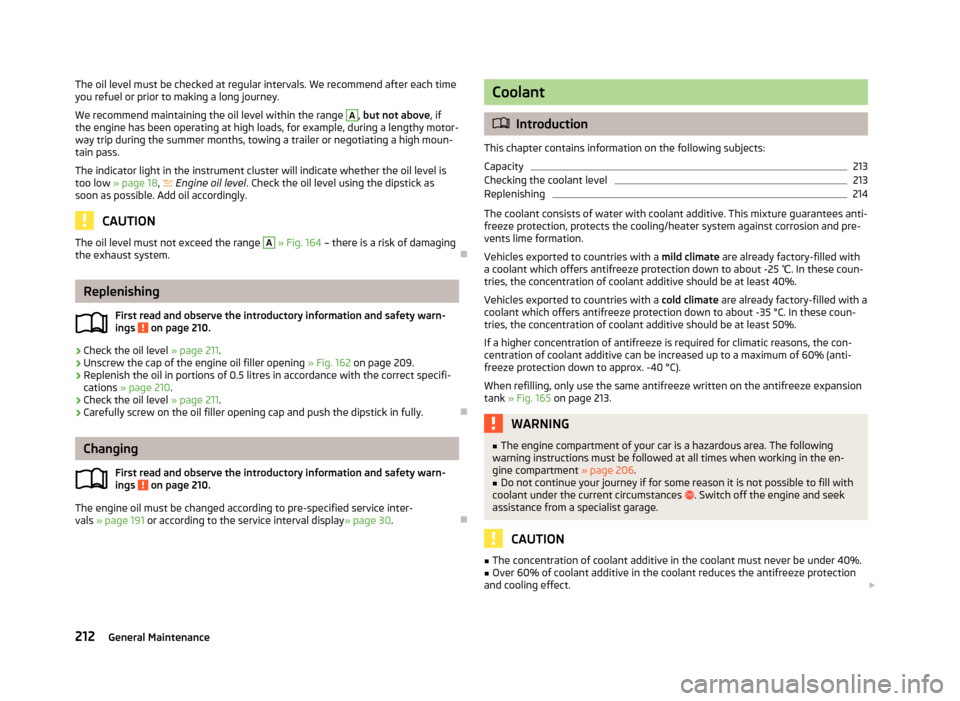

Checking the coolant levelFig. 165

Engine compartment: Coolant

expansion reservoir

First read and observe the introductory information and safety warn-

ings on page 212.

The coolant expansion bottle is located in the engine compartment.

Inspecting the coolant level

›

Switch off the engine.

›

Open the bonnet.

›

Check the level of coolant in the coolant expansion bottle. » Fig. 165.

Coolant level above mark

A

No coolant may be added.

The level may also rise slightly above the

A

marking when the engine is hot.

Coolant level between markings

A

and

B

Coolant may be added.

The coolant level must lie between the

A

and

B

markings when the engine is

cold.

Coolant level below mark

B

Coolant must be added.

Top up the coolant level to between the

A

and

B

markings when the engine is

cold.

1)

The coolant capacity is approximately 1 l greater on vehicles that are fitted with an auxiliary heater

(auxiliary heating and ventilation).

213Inspecting and replenishing

Page 217 of 274

If the coolant level in the coolant expansion tank is too low, this is indicated by

the warning light » page 16 , Coolant lighting up in the instrument cluster.

We still recommend inspecting the coolant level directly at the reservoir from

time to time.

Loss of coolant

A loss of coolant is first and foremost an indication of a leak in the system. Do

not merely top up the coolant. Have the cooling system checked by a specialist

garage.

Replenishing

First read and observe the introductory information and safety warn-

ings

on page 212.

Only top up with new coolant.

›

Switch off the engine.

›

Allow the engine to cool.

›

Place a cloth over the cap of the coolant expansion tank and unscrew the cap carefully .

›

Replenish the coolant.

›

Turn the cap until it clicks into place.

Do not use an alternative additive if the specified coolant is not available in an emergency. In this case, use just water and have the correct mixing ratio of waterand coolant additive restored by a specialist garage as soon as possible.

Brake fluid

Introduction

This chapter contains information on the following subjects:

Checking the brake fluid level

214

Changing

215WARNING■ The engine compartment of your car is a hazardous area. The following

warning instructions must be followed at all times when working in the en-

gine compartment » page 206.■

If the fluid level has dropped below the MIN marking » Fig. 166 on page 214,

do not continue your journey - there is a risk of an accident! Seek help from

a specialist garage.

■

Do not use used brake fluid - the function of the brake system may be im-

paired – risk of accident!

CAUTION

Brake fluid damages the paintwork of the vehicle.

Note

The brake fluid is changed as part of a compulsory inspection service.

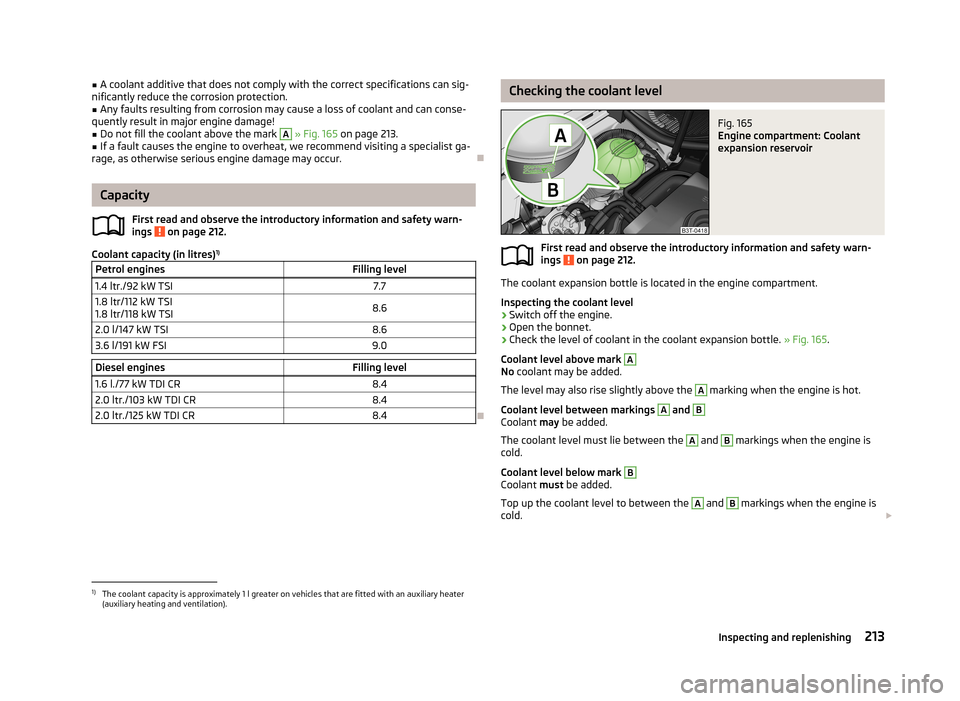

Checking the brake fluid level

Fig. 166

Engine compartment: Brake fluid

reservoir

First read and observe the introductory information and safety warn-

ings on page 214.

The brake fluid reservoir is located in the engine compartment.

›

Switch off the engine.

›

Open the bonnet.

›

Check the level of brake fluid in the reservoir » Fig. 166.

The level must be between the “MIN” and “MAX” markings.

214General Maintenance

Page 220 of 274

When working on the battery, the edge of the polyester battery cover1 » Fig. 167 is inserted between the battery and the side wall of the battery cov-

er.

Battery in the engine compartment›

Open the battery cover in the direction of the arrow

1

or press the interlock on

the side of the battery cover in the direction of the arrow

2

» Fig. 167 , fold the

cover up and remove.

The battery cover is installed in reverse order.

Battery in the boot

The battery is located in the left side compartment with the symbol » Fig. 90

on page 90.

Checking the battery electrolyte level

Fig. 168

Vehicle battery: Electrolyte level

indicator

First read and observe the introductory information and safety warn-

ings on page 215.

On vehicles with a vehicle battery fitted with a colour indicator, the so-called

magic eye » Fig. 168, the electrolyte level can be determined by looking at the

change in colour.

Air bubbles can influence the colour of the indicator. For this reason carefully

knock on the indicator before carrying out the check.

› Black colour - electrolyte level is correct.

› Colourless or light yellow colour - electrolyte level too low, the battery must be

replaced.

Vehicles with a START-STOP system are fitted with a battery control unit for checking the energy level for the recurring engine start.

We recommend that you have the acid level checked regularly by a specialist ga-rage, especially in the following cases.

› High external temperatures.

› Longer day trips.

› After each charge.

Winter time

The vehicle battery only has a proportion of the starting power in lower tempera-

tures. A discharged vehicle battery may already freeze at temperatures just be-

low 0 °C .

We therefore recommend that you have the battery checked and, if necessary, re-

charged by a specialist garage before the start of the winter.

CAUTION

For technical reasons, on vehicles with the description “AGM”, the electrolyte lev-

el cannot be checked.

Note

The battery acid level is also checked regularly by a specialist garage as part of

the inspection service.

Charging

First read and observe the introductory information and safety warn-ings

on page 215.

A properly charged vehicle battery is essential for reliably starting the engine.

›

Switch off the ignition and all of the electrical components.

›

Only when performing a “quick-charge”, disconnect both battery cables (first

“negative”, then “positive”).

›

Attach the terminal clamps of the charger to the battery terminals (red = “posi-

tive”, black = “negative”).

›

Plug the mains cable of the charger into the power socket and switch on the

device.

›

After charging has been successful: Switch off the charger and remove themains cable from the power socket.

›

Only then disconnect the charger's terminal clamps.

›

Reconnect the cables to the battery (first “positive”, then “negative”).

217Inspecting and replenishing

Page 221 of 274

It is not necessary to disconnect the cables of the battery if you recharge the ve-

hicle battery using low amperages (for example from a mini-charger). Refer to the

instructions of the charger manufacturer .

A charging current of 0.1 multiple of the total vehicle battery capacity (or lower)

must be used until full charging is achieved.

It is necessary to disconnect both cables before charging the battery with high

amperages, known as “ rapid charging”.

The vent plugs of the vehicle battery should not be opened for charging.WARNING“Quick-charging” the vehicle battery is dangerous and requires a special

charger and specialist knowledge.

CAUTION

On vehicles with the START/STOP system, the pole terminal of the charger must

not be connected directly to the negative terminal of the vehicle battery, but only

to the engine earth » page 236, Jump-starting in vehicles with the START-STOP

system .

Note

We therefore recommend that vehicle batteries be rapid charged by a specialist

garage.

Replace

First read and observe the introductory information and safety warn-

ings

on page 215.

When replacing a battery, the new vehicle battery must have the same capacity,

voltage, amperage and be the same size. Suitable vehicle battery types can be

purchased from a specialist garage.

We recommend having the battery replaced by a specialist garage, where the

new vehicle battery will be installed properly and the original battery will be dis-

posed of in accordance with national regulations.

Disconnecting or reconnecting

First read and observe the introductory information and safety warn-ings

on page 215.

On disconnecting and reconnecting the vehicle battery the following functions

are initially deactivated or are no longer able to operate fault-free.

OperationOperating measureElectrical power window (operational faults)» page 46Panoramic sliding roof (operational faults)» page 242Enter the radio/navigation system code num-

ber» User manual of the radio

or » user manual of the naviga-

tion systemSetting the clock» page 13Data in the multifunction display are deleted.» page 25

Note

We recommend having the vehicle checked by a specialist garage in order to en-

sure full functionality of all electrical systems.

Automatic load deactivation

First read and observe the introductory information and safety warn-ings

on page 215.

The vehicle voltage control unit automatically prevents the battery from discharg-

ing when the battery is put under high levels of strain. This manifests itself by the

following.

› The idling speed is raised to allow the generator to deliver more electricity to

the electrical system.

› Where necessary, large convenience consumers such as seat heaters and rear

window heaters have their power limited or are shut off completely in the event of an emergency.

218General Maintenance

Page 233 of 274

›Switch off the engine.›Move the gearshift lever into

Neutral or move the selector lever for the auto-

matic gearbox into position P .›

Firmly apply the handbrake.

›

If a trailer is connected, uncouple it.

›

Remove the vehicle tool kit » page 228 and the spare wheel » page 224 from

the boot.

Changing a wheel

First read and observe the introductory information and safety warn-

ings

on page 229.

›

Remove the full wheel trim » page 225 or caps » page 225 .

›

First of all slacken the anti-theft wheel bolt and then the other wheel

bolts » page 230 .

›

Jack up the vehicle until the wheel that needs changing is clear of the

ground » page 231 .

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper, etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Alternately tighten wheel bolts opposite (diagonally) with the wheel wrench.

Tighten the anti-theft wheel bolt last » page 230.

›

Replace the wheel trim or the caps.

Note

■

All bolts must be clean and must turn easily.■Under no circumstances grease or oil the wheel bolts!■

When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect » page 220 .

Follow-up work

First read and observe the introductory information and safety warn-

ings

on page 229.

The following steps must also be performed after changing the wheel.

› Stow and attach the replaced wheel in the spare wheel well using a special

bolt » page 224 .›

Stow the tool kit in the space provided and secure using the band.

›

Check the tyre pressure on the installed spare wheel as soon as possible.

›

Have the tightening torque of the wheel bolts checked with a torque wrench

as soon as possible.

›

Replace the damaged wheel or consult a specialist garage about repair options.

Note

■ If it is determined that the wheel bolts are corroded and difficult to turn when

changing the wheel, the bolts must be replaced before checking the tightening

torque.■

Drive cautiously and only at a moderate speed until the tightening torque has

been checked.

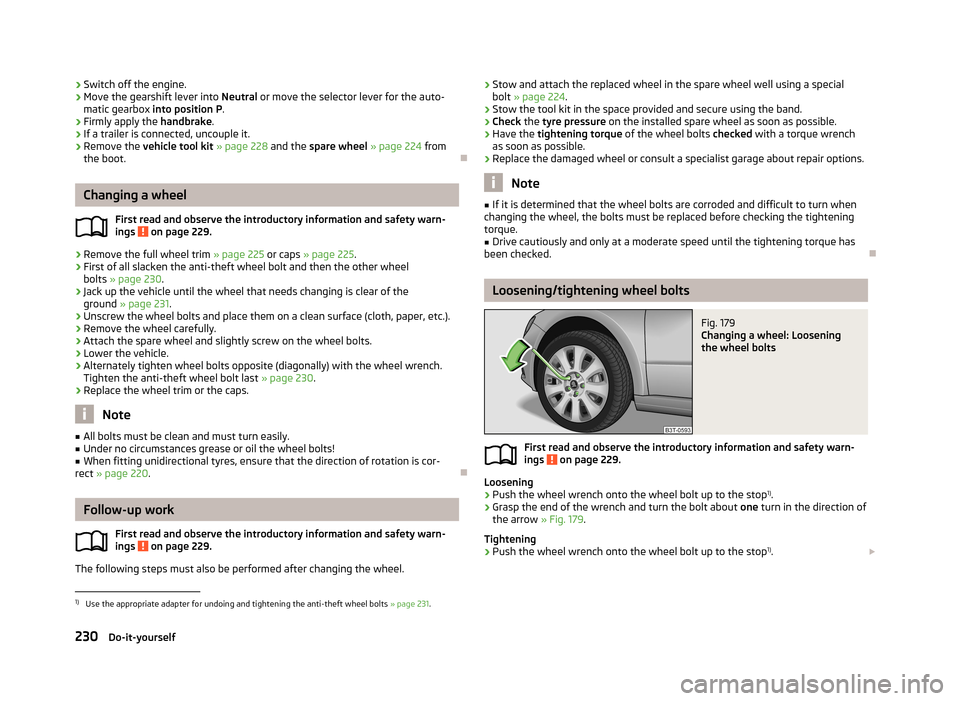

Loosening/tightening wheel bolts

Fig. 179

Changing a wheel: Loosening

the wheel bolts

First read and observe the introductory information and safety warn- ings on page 229.

Loosening

›

Push the wheel wrench onto the wheel bolt up to the stop 1)

.

›

Grasp the end of the wrench and turn the bolt about one turn in the direction of

the arrow » Fig. 179.

Tightening

›

Push the wheel wrench onto the wheel bolt up to the stop 1)

.

1)

Use the appropriate adapter for undoing and tightening the anti-theft wheel bolts

» page 231.

230Do-it-yourself

Page 236 of 274

Breakdown kitFig. 183

Components of the breakdown kit

First read and observe the introductory information and safety warn-

ings

on page 232.

The kit is located in a box under the floor covering in the luggage compartment.

Components of the breakdown kit Valve remover

Sticker with speed designation “max. 80 km/h”/“max. 50 mph”

Inflation hose with plug

Air compressor

Tyre inflation hose

Tyre inflation pressure indicator

Air release valve

ON and OFF switch

12 volt cable connector

Tyre inflator bottle with sealing agent

Replacement valve core

The valve remover

1

has a slot at its lower end which fits into the valve core.

This is the only way in which you can remove and re-install the valve core from

the tyre valve. The same also applies to the replacement valve core

11

.

1234567891011Preparations for using the breakdown kit

First read and observe the introductory information and safety warn-

ings

on page 232.

The following preparatory work must be carried out before using the breakdown

kit.

›

Park the vehicle as far away as possible from the flow of traffic. Park on as flat and firm a surface as possible.

›

If you are in flowing traffic, switch on the hazard warning light system and setup the warning triangle at the prescribed distance! The national legal require-

ments must be observed.

›

Let all of the occupants get out. While changing a tyre, the occupants of the

vehicle should not stand on the road (instead they should remain behind a crash

barrier).

›

Switch off the engine and move the gearshift lever into Neutral or move the se-

lector lever on the automatic gearbox into position P.

›

Firmly apply the handbrake.

›

Check that you can carry out the repairs with the breakdown kit » page 232.

›

If a trailer is connected, uncouple it.

›

Remove the breakdown kit from the boot.

›

Stick the sticker

2

» Fig. 183 on page 233 on the dash panel in view of the driv-

er.

›

Do not remove the foreign body, e.g. screw or nail, from the tyre.

›

Unscrew the valve cap.

›

Use the valve remover

1

to unscrew the valve core and place it on a clean sur-

face (rag, paper, etc.).

Sealing and inflating the tyre

First read and observe the introductory information and safety warn-

ings

on page 232.

Sealing

›

Forcefully shake the tyre inflator bottle

10

» Fig. 183 on page 233 several times.

›

Firmly screw the inflation hose

3

onto the tyre inflator bottle

10

in a clockwise

direction. The film on the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and plug the open end fully onto

the tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

233Emergency equipment and self-help