heating SKODA SUPERB 2014 2.G / (B6/3T) Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2014, Model line: SUPERB, Model: SKODA SUPERB 2014 2.G / (B6/3T)Pages: 246, PDF Size: 17.16 MB

Page 180 of 246

Artificial leather, cloths and Alcantara®

Read and observe

and on page 176 first.

Artificial leather

Clean artificial leather with a damp cloth.

If this method does not completely clean the artificial leather, use a mild soap

solution or cleaning products specially designed for this purpose.

Fabric

Clean upholstery cover materials and cloth trims on doors, boot cover, etc. us-

ing specific cleaning agents, e.g., dry foam.

Use a soft sponge, brush, or commercially available microfibre cloth.

Use a cloth and special detergent to clean the roof trim.

Remove any lumps on the cover fabric and any fabric residue using a brush.

Remove stubborn hair using a “cleaning glove”.

Alcantara ®

Dust and fine dirt particles in pores, creases and seams may chafe and damage

the surface.

If you leave your vehicle parked in the open for lengthy periods, protect the Al-

cantara ®

seat covers from the direct rays of the sun to prevent fading.

Minor changes in colour caused by use are normal.

CAUTION

■ Do not use any leather cleaners on Alcantara ®

seat covers.■For Alcantara ®

seat covers do not use any solvents, floor wax, shoe cream,

stain remover, or similar agents.■

Avoid leaving the vehicle in bright sunlight for long periods of time in order

to stop the fabric from bleaching. If the vehicle is parked outside for long peri-

ods of time, cover the fabric to protect it from direct sunlight.

■

Some clothing materials, e.g. dark denim, do not have sufficient colour fast-

ness. This can cause damage or clearly visible discolouration to seat covers,

even when used correctly. This applies particularly to light-coloured seat cov-

ers. This does not relate to a fault in the seat cover, but rather to poor colour

fastness of the clothing textiles.

Seat covers

Read and observe

and on page 176 first.

Electrically heated seats

Do not clean the covers by moistening, as this can damage the seat heating

system.

Use a specific cleaning agent such as dry foam or similar to clean the covers.

Seats without seat heating

Thoroughly vacuum the seat covers with a vacuum cleaner before cleaning.

Clean the seat covers with a damp cloth or cleaning products specially de-

signed for this purpose.

Indented points arising on the fabrics by everyday use, can be removed by

brushing against the direction of hair with a damp brush.

Always clean all parts of the covers, so that there are no visible edges. Then

allow the seat to dry completely.

CAUTION

■ Regularly remove dust from the seat covers using a vacuum cleaner.■Electrically heated seats must not be dried after cleaning by switching on the

heater.■

Do not sit on wet seats - risk of seat deformation.

■

Always clean the seats “from seam to seam”.

Seat belts

Read and observe

and on page 176 first.

The belt webbing must always be kept clean.

Wash dirty seat belts with mild soapy water.

Remove coarse dirt with a soft brush.

Dirty belt webbing may impair the correct functioning of the inertia reel.

WARNING■ The seat belts must not be removed for cleaning.■Never clean the seat belts chemically as chemical cleaning products could

destroy the fabric. 178General Maintenance

Page 182 of 246

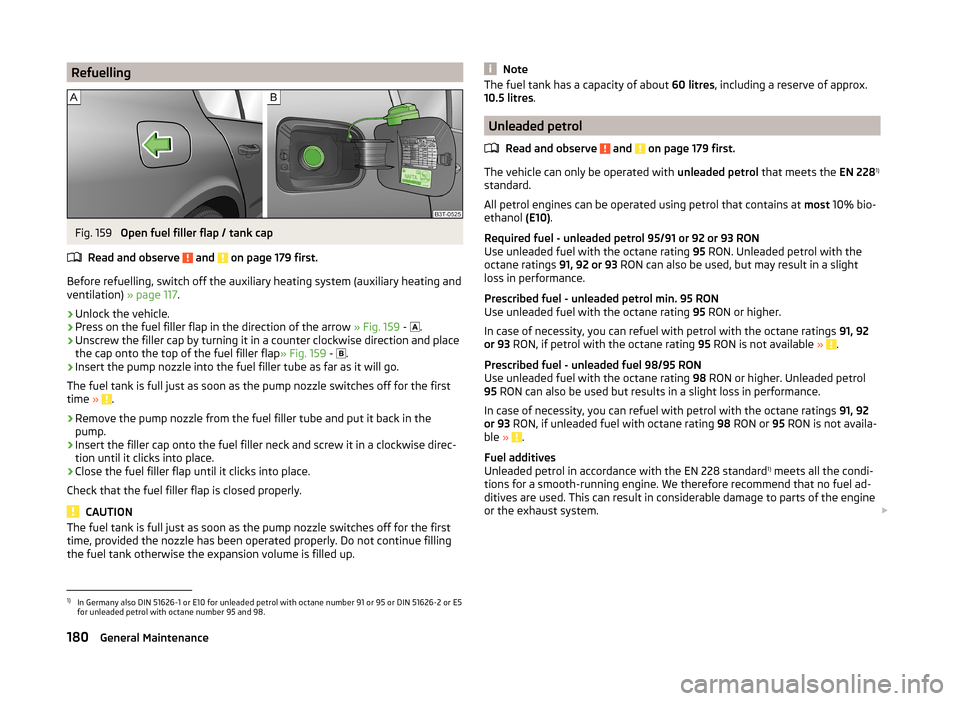

RefuellingFig. 159

Open fuel filler flap / tank cap

Read and observe

and on page 179 first.

Before refuelling, switch off the auxiliary heating system (auxiliary heating and ventilation) » page 117.

›

Unlock the vehicle.

›

Press on the fuel filler flap in the direction of the arrow » Fig. 159 -

.

›

Unscrew the filler cap by turning it in a counter clockwise direction and place

the cap onto the top of the fuel filler flap » Fig. 159 -

.

›

Insert the pump nozzle into the fuel filler tube as far as it will go.

The fuel tank is full just as soon as the pump nozzle switches off for the first

time »

.

›

Remove the pump nozzle from the fuel filler tube and put it back in the

pump.

›

Insert the filler cap onto the fuel filler neck and screw it in a clockwise direc-

tion until it clicks into place.

›

Close the fuel filler flap until it clicks into place.

Check that the fuel filler flap is closed properly.

CAUTION

The fuel tank is full just as soon as the pump nozzle switches off for the first

time, provided the nozzle has been operated properly. Do not continue filling

the fuel tank otherwise the expansion volume is filled up.NoteThe fuel tank has a capacity of about 60 litres, including a reserve of approx.

10.5 litres .

Unleaded petrol

Read and observe

and on page 179 first.

The vehicle can only be operated with unleaded petrol that meets the EN 2281)

standard.

All petrol engines can be operated using petrol that contains at most 10% bio-

ethanol (E10).

Required fuel - unleaded petrol 95/91 or 92 or 93 RON

Use unleaded fuel with the octane rating 95 RON. Unleaded petrol with the

octane ratings 91, 92 or 93 RON can also be used, but may result in a slight

loss in performance.

Prescribed fuel - unleaded petrol min. 95 RON

Use unleaded fuel with the octane rating 95 RON or higher.

In case of necessity, you can refuel with petrol with the octane ratings 91, 92

or 93 RON, if petrol with the octane rating 95 RON is not available »

.

Prescribed fuel - unleaded fuel 98/95 RON

Use unleaded fuel with the octane rating 98 RON or higher. Unleaded petrol

95 RON can also be used but results in a slight loss in performance.

In case of necessity, you can refuel with petrol with the octane ratings 91, 92

or 93 RON, if unleaded fuel with octane rating 98 RON or 95 RON is not availa-

ble »

.

Fuel additives

Unleaded petrol in accordance with the EN 228 standard 1)

meets all the condi-

tions for a smooth-running engine. We therefore recommend that no fuel ad-

ditives are used. This can result in considerable damage to parts of the engine

or the exhaust system.

1)

In Germany also DIN 51626-1 or E10 for unleaded petrol with octane number 91 or 95 or DIN 51626-2 or E5

for unleaded petrol with octane number 95 and 98.

180General Maintenance

Page 183 of 246

CAUTION■Even filling the tank with leaded petrol that does not meet the standards

once can lead to serious damage to parts of the exhaust system!■

If a fuel other than unleaded fuel which complies to the above mentioned

standards (e.g. leaded petrol) is used by mistake, do not start the engine or

switch on the ignition! Extensive damage to engine parts can occur! We rec-

ommend that you have the fuel system cleaned by a specialist garage.

CAUTION

■ If, in an emergency, the vehicle has to be refuelled with petrol of a lower oc-

tane number than the one prescribed, the journey must only be continued at

medium engine speeds and a low engine load. Driving at high engine revs or a

high engine load can severely damage the engine! Refuel using petrol of the

prescribed octane number as soon as possible.■

Engine parts can be damaged if petrol with a lower octane number than the

one prescribed is used.

■

Even in the event of an emergency, petrol of a lower octane number than 91

RON must not be used, otherwise the engine can be severely damaged!

CAUTION

■ In no case may fuel additives with metal components be used, especially not

with manganese and iron content. LRP(lead replacement petrol) fuels with

metallic components may not be used. There is a risk of causing considerable

damage to parts of the engine or exhaust system!■

Fuels with metallic content may not be used. There is a risk of causing con-

siderable damage to parts of the engine or exhaust system!

Note

■ Unleaded petrol that has a higher octane number than that required by the

engine can be used without limitations.■

On vehicles with prescribed unleaded petrol 95/91, 92 or 93 RON, the use of

petrol with a higher octane number than 95 RON does not result in a noticea-

ble power increase or a lower fuel consumption.

■

On vehicles using prescribed unleaded petrol of min. 95 RON, the use of pet-

rol with a higher octane number than 95 RON can increase the power and re-

duce fuel consumption.

Diesel fuel

Read and observe

and on page 179 first.

The vehicle can only be operated with diesel fuel that meets the EN 5901)

standard.

All diesel engines can be operated using diesel fuel with at most 7% biodiesel

(B7) 2)

.

On the Indian market, your vehicle will only be able to run on diesel fuel com-

pliant with standard IS 1460/Bharat IV. If diesel fuel which complies with this

standard is not available, you can refuel with diesel fuel according to standard

IS 1460/Bharat III in case of emergency.

Operation in winter - Winter-grade diesel fuel

In the cold season, only use “winter-grade diesel fuel” which will still operate properly even at a temperature of -20 °C.

It is often the case in countries with different climatic conditions that diesel

fuels available have a different temperature characteristic. ŠKODA Partners

and filling stations in the relevant country will be able to provide you with in-

formation regarding the diesel fuels available.

Preheating fuel

The vehicle is fitted with a fuel filter preheating system. This secures opera-

tion of a vehicle using diesel fuel down to an environmental temperature of

-25 °C.

Diesel fuel additives

Additives, so-called “flow improvers ” (petrol and similar agents) should not be

mixed with the diesel fuel. This can cause serious damage to engine or ex-

haust system parts.

1)

In Germany also DIN 51628, in Austria ÖNORM C 1590, in Russia GOST R 52368-2005 / EN 590:2004.

2)

In Germany according to the DIN 52638 standard, in Austria ÖNORM C 1590, in France EN 590.

181Inspecting and replenishing

Page 189 of 246

ReplenishingRead and observe

and on page 185 first.

›

Check the oil level » page 186.

›

Unscrew the cap of the engine oil filler opening » Fig. 161 on page 184 .

›

Replenish the oil in portions of 0.5 litres in accordance with the correct speci-

fications » page 185 .

›

Check the oil level » page 186.

›

Carefully screw on the oil filler opening cap and push the dipstick in fully.

Changing

Read and observe

and on page 185 first.

The engine oil must be changed according to prescribed service intervals or ac-

cording to the service interval display » Service plan .

Coolant

Introduction

This chapter contains information on the following subjects:

Capacity

188

Checking the coolant level

188

Replenishing

188

The coolant consists of water with coolant additive. This mixture guarantees

antifreeze protection, protects the cooling/heater system against corrosion

and prevents lime formation.

Vehicles exported to countries with a mild climate are already factory-filled

with a coolant which offers antifreeze protection down to about -25 ℃. In

these countries, the concentration of coolant additive should be at least 40%.

Vehicles exported to countries with a cold climate are already factory-filled

with a coolant which offers antifreeze protection down to about -35 °C. In

these countries, the concentration of coolant additive should be at least 50%.

If a higher concentration of antifreeze is required for climatic reasons, the con-

centration of coolant additive can be increased up to a maximum of 60% (anti-

freeze protection down to approx. -40 °C).

When refilling, only use the same antifreeze identified on the coolant expan-

sion vessel » Fig. 164 on page 188 .WARNING■

The engine compartment of your car is a hazardous area. The following

warning instructions must be followed at all times when working in the en-

gine compartment » page 182.■

Do not continue your journey if for some reason it is not possible to fill

with coolant under the current circumstances

. Switch off the engine and

seek assistance from a specialist garage.

CAUTION

■ The concentration of coolant additive in the coolant must never be under

40%.■

Over 60% of coolant additive in the coolant reduces the antifreeze protec-

tion and cooling effect.

■

A coolant additive that does not comply with the correct specifications can

significantly reduce the corrosion protection.

■

Any faults resulting from corrosion may cause a loss of coolant and can con-

sequently result in major engine damage!

■

Do not fill the coolant above the mark

A

» Fig. 164 on page 188 .

■

If a fault causes the engine to overheat, we recommend visiting a specialist

garage, as otherwise serious engine damage may occur.

■

Additional headlights and other attached components in front of the air inlet

impair the cooling efficiency of the coolant.

■

Never cover the radiator - there is a risk of the engine overheating.

187Inspecting and replenishing

Page 190 of 246

CapacityRead and observe

and on page 187 first.

Coolant capacity (in litres) 1)

Petrol enginesCapacity1.4 ltr./92 kW TSI7.71.8 ltr./112 kW TSI

1.8 ltr./118 kW TSI8.62.0 ltr./147 kW TSI8.63.6 l/191 kW FSI9.0Diesel enginesCapacity1.6 ltr./77 kW TDI CR8.42.0 ltr./103 kW TDI CR8.42.0 ltr./125 kW TDI CR8.4

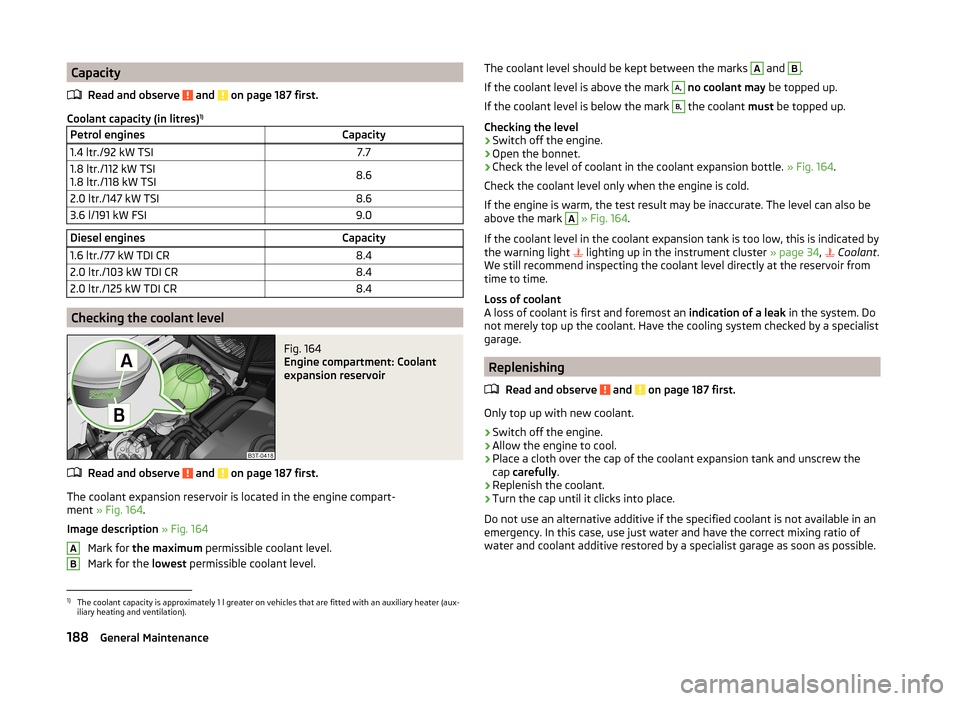

Checking the coolant level

Fig. 164

Engine compartment: Coolant

expansion reservoir

Read and observe and on page 187 first.

The coolant expansion reservoir is located in the engine compart-

ment » Fig. 164 .

Image description » Fig. 164

Mark for the maximum permissible coolant level.

Mark for the lowest permissible coolant level.

ABThe coolant level should be kept between the marks A and B.

If the coolant level is above the mark A,

no coolant may be topped up.

If the coolant level is below the mark

B,

the coolant must be topped up.

Checking the level

›

Switch off the engine.

›

Open the bonnet.

›

Check the level of coolant in the coolant expansion bottle. » Fig. 164.

Check the coolant level only when the engine is cold.

If the engine is warm, the test result may be inaccurate. The level can also be

above the mark

A

» Fig. 164 .

If the coolant level in the coolant expansion tank is too low, this is indicated by

the warning light lighting up in the instrument cluster

» page 34,

Coolant

.

We still recommend inspecting the coolant level directly at the reservoir from

time to time.

Loss of coolant

A loss of coolant is first and foremost an indication of a leak in the system. Do

not merely top up the coolant. Have the cooling system checked by a specialist

garage.

Replenishing

Read and observe

and on page 187 first.

Only top up with new coolant.

›

Switch off the engine.

›

Allow the engine to cool.

›

Place a cloth over the cap of the coolant expansion tank and unscrew the

cap carefully .

›

Replenish the coolant.

›

Turn the cap until it clicks into place.

Do not use an alternative additive if the specified coolant is not available in an

emergency. In this case, use just water and have the correct mixing ratio of

water and coolant additive restored by a specialist garage as soon as possible.

1)

The coolant capacity is approximately 1 l greater on vehicles that are fitted with an auxiliary heater (aux-

iliary heating and ventilation).

188General Maintenance

Page 208 of 246

›Do not remove the foreign body, e.g. screw or nail, from the tyre.›Unscrew the valve cap.›

Use the valve remover

1

to unscrew the valve core and place it on a clean

surface (rag, paper, etc.).

Sealing and inflating the tyre

Read and observe

on page 205 first.

Sealing

›

Shake the tyre inflator bottle

10

» Fig. 181 on page 205 vigorously several

times.

›

Firmly screw the inflation hose

3

onto the tyre inflator bottle

10

in a clock-

wise direction. The film on the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and plug the open end fully onto

the tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

›

Remove the empty tyre inflator bottle from the valve.

›

Screw the valve core back into the tyre valve using the valve remover

1

.

Inflating

›

Screw the air compressor tyre inflation hose

5

» Fig. 181 on page 205 firmly

onto the tyre valve.

›

Check that the air release valve

7

is closed.

›

Start the engine and run it in idle.

›

Plug the connector

9

into 12 Volt socket » page 89, Cigarette lighter .

›

Switch on the air compressor with the ON and OFF switch

8

.

›

Allow the air compressor to run until a pressure of 2.0 - 2.5 bar is achieved.

Maximum run time of 8 minutes »

›

Switch off the air compressor.

›

If you cannot reach an air pressure of 2.0 – 2.5 bar, unscrew the tyre inflation

hose

5

from the tyre valve.

›

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent

to “distribute” in the tyre.

›

Firmly screw the tyre inflation hose

5

back onto the tyre valve and repeat

the inflation process.

›

If you cannot reach the required tyre inflation pressure here either, this

means the tyre has sustained too much damage. You cannot seal with tyre with the breakdown kit »

.

›

Switch off the air compressor.

›

Remove the tyre inflation hose

5

from the tyre valve.

Once a tyre inflation pressure of 2.0 – 2.5 bar is reached, continue the journey

at a maximum speed of 80 km/h (50 mph).

Check the tyre inflation pressure after driving for 10 minutes » page 206.WARNING■

The tyre inflation hose and air compressor may get hot as the tyre is be-

ing inflated – there is a risk of injury.■

Do not place the hot tyre inflation hose or hot air compressor on flamma-

ble materials – there is a risk of fire.

■

If you cannot inflate the tyre to at least 2.0 bar, this means the damage

sustained was too serious. The sealing agent cannot be used to seal the

tyre.

Do not drive the vehicle. Seek help from a specialist garage.

CAUTION

Switch off the air compressor after running 8 minutes at the latest – there is a

risk of overheating. Allow the air compressor to cool a few minutes before

switching it on again.

Check after 10 minutes' driving

Read and observe

on page 205 first.

Check the tyre inflation pressure after driving for 10 minutes!

If the tyre pressure is 1.3 bar or less

›

Do not drive the vehicle! You cannot properly seal with tyre with the

breakdown kit.

If the tyre pressure is 1.3 bar or more

›

Adjust the tyre inflation pressure to the correct value (see inside of fuel filler

cap).

›

Continue driving carefully to the nearest specialist garage at a maximum speed of 80 km/h (50 mph).

206Do-it-yourself

Page 218 of 246

CAUTION■“Never repair” fuses or replace them with a fuse of a higher amperage – risk

of fire! This may also cause damage at another part of the electrical system.■

If a newly inserted fuse blows again after a short time, have the electrical

system checked as quickly as possible by a specialist garage.

■

A blown fuses is recognisable by the molten metal strip. Replace the faulty

fuse with a new one of the same amperage.

Note

■

We recommend always carrying replacement fuses in the vehicle. A box of

replacement fuses can be purchased from ŠKODA Original Accessories.■

There can be several power consuming devices for one fuse.

■

Multiple fuses may exist for a single power consuming device.

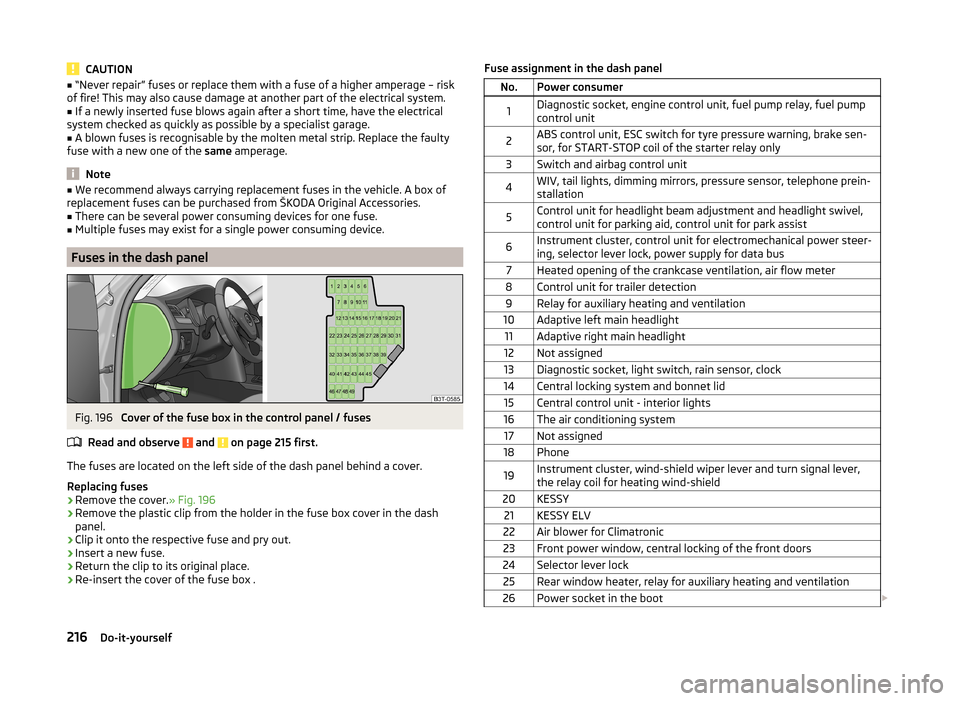

Fuses in the dash panel

Fig. 196

Cover of the fuse box in the control panel / fuses

Read and observe

and on page 215 first.

The fuses are located on the left side of the dash panel behind a cover.

Replacing fuses

›

Remove the cover. » Fig. 196

›

Remove the plastic clip from the holder in the fuse box cover in the dash

panel.

›

Clip it onto the respective fuse and pry out.

›

Insert a new fuse.

›

Return the clip to its original place.

›

Re-insert the cover of the fuse box .

Fuse assignment in the dash panelNo.Power consumer1Diagnostic socket, engine control unit, fuel pump relay, fuel pump

control unit2ABS control unit, ESC switch for tyre pressure warning, brake sen-

sor, for START-STOP coil of the starter relay only3Switch and airbag control unit4WIV, tail lights, dimming mirrors, pressure sensor, telephone prein-

stallation5Control unit for headlight beam adjustment and headlight swivel,

control unit for parking aid, control unit for park assist6Instrument cluster, control unit for electromechanical power steer-

ing, selector lever lock, power supply for data bus7Heated opening of the crankcase ventilation, air flow meter8Control unit for trailer detection9Relay for auxiliary heating and ventilation10Adaptive left main headlight11Adaptive right main headlight12Not assigned13Diagnostic socket, light switch, rain sensor, clock14Central locking system and bonnet lid15Central control unit - interior lights16The air conditioning system17Not assigned18Phone19Instrument cluster, wind-shield wiper lever and turn signal lever,

the relay coil for heating wind-shield20KESSY21KESSY ELV22Air blower for Climatronic23Front power window, central locking of the front doors24Selector lever lock25Rear window heater, relay for auxiliary heating and ventilation26Power socket in the boot 216Do-it-yourself

Page 219 of 246

No.Power consumer27Fuel pump relay, control unit for fuel pump, injection valves28Electric boot lid29Haldex30Climate controlled front seats31DVD pre-installation32Front power window, central locking system of the rear doors33Electric sliding/tilting roof34Alarm, spare horn35front and rear lighter36Headlight cleaning system37Heated front seats38Heated rear seats39Rear window wiper40Fan air-conditioning system, relay for auxiliary heating and ventila-

tion41Not assigned42Light switch43Control unit for trailer detection44Control unit for trailer detection45Control unit for trailer detection46Switch for seat heating47Telephone preinstallation48Preparation for the aftermarket radio49Only for START-STOP: Central control unit, DC-DC converter, the

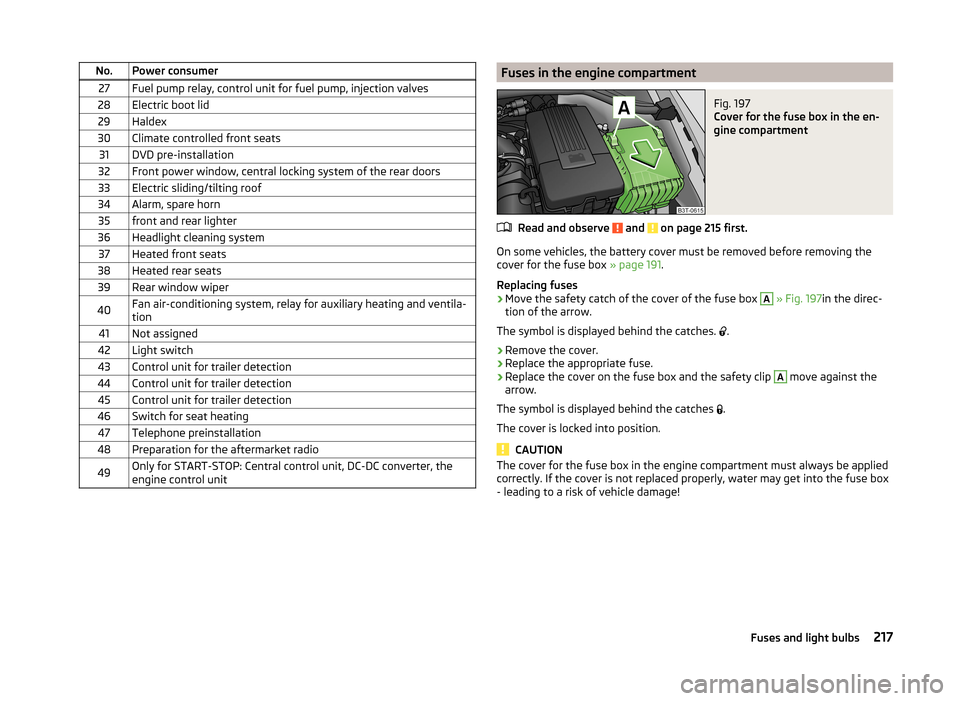

engine control unitFuses in the engine compartmentFig. 197

Cover for the fuse box in the en-

gine compartment

Read and observe and on page 215 first.

On some vehicles, the battery cover must be removed before removing the

cover for the fuse box » page 191.

Replacing fuses

›

Move the safety catch of the cover of the fuse box

A

» Fig. 197 in the direc-

tion of the arrow.

The symbol is displayed behind the catches. .

›

Remove the cover.

›

Replace the appropriate fuse.

›

Replace the cover on the fuse box and the safety clip

A

move against the

arrow.

The symbol is displayed behind the catches .

The cover is locked into position.

CAUTION

The cover for the fuse box in the engine compartment must always be applied

correctly. If the cover is not replaced properly, water may get into the fuse box

- leading to a risk of vehicle damage!217Fuses and light bulbs

Page 220 of 246

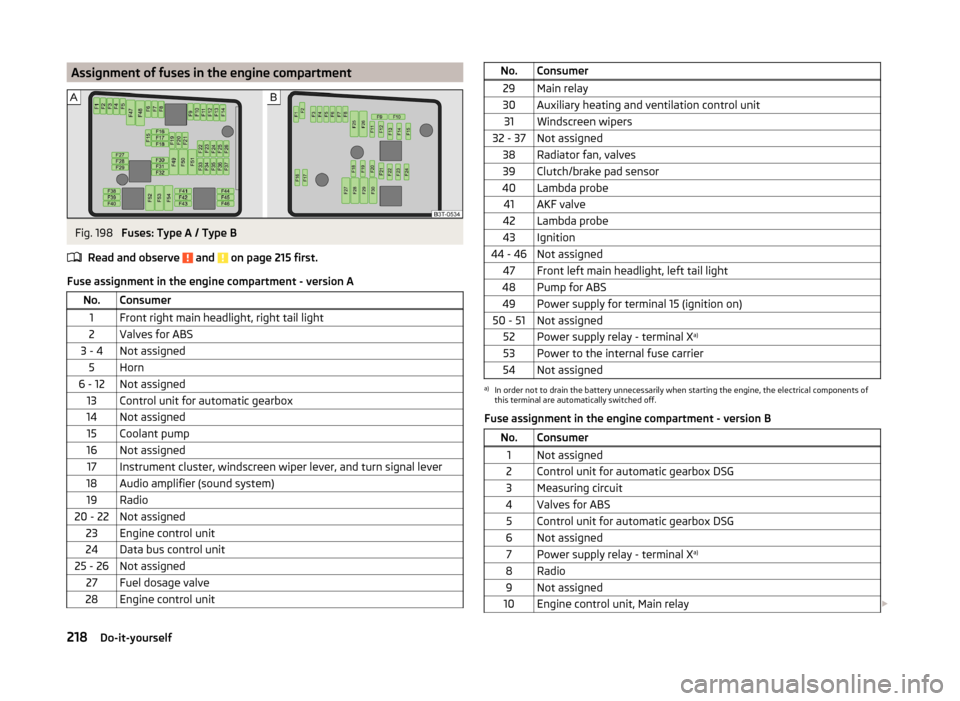

Assignment of fuses in the engine compartmentFig. 198

Fuses: Type A / Type B

Read and observe

and on page 215 first.

Fuse assignment in the engine compartment - version A

No.Consumer1Front right main headlight, right tail light2Valves for ABS3 - 4Not assigned5Horn6 - 12Not assigned13Control unit for automatic gearbox14Not assigned15Coolant pump16Not assigned17Instrument cluster, windscreen wiper lever, and turn signal lever18Audio amplifier (sound system)19Radio20 - 22Not assigned23Engine control unit24Data bus control unit25 - 26Not assigned27Fuel dosage valve28Engine control unitNo.Consumer29Main relay30Auxiliary heating and ventilation control unit31Windscreen wipers32 - 37Not assigned38Radiator fan, valves39Clutch/brake pad sensor40Lambda probe41AKF valve42Lambda probe43Ignition44 - 46Not assigned47Front left main headlight, left tail light48Pump for ABS49Power supply for terminal 15 (ignition on)50 - 51Not assigned52Power supply relay - terminal X a)53Power to the internal fuse carrier54Not assigneda)

In order not to drain the battery unnecessarily when starting the engine, the electrical components of

this terminal are automatically switched off.

Fuse assignment in the engine compartment - version B

No.Consumer1Not assigned2Control unit for automatic gearbox DSG3Measuring circuit4Valves for ABS5Control unit for automatic gearbox DSG6Not assigned7Power supply relay - terminal X a)8Radio9Not assigned10Engine control unit, Main relay

218Do-it-yourself

Page 221 of 246

No.Consumer11Auxiliary heating and ventilation control unit12Data bus control unit13Engine control unit14Ignition15Lambda probe (petrol engine), glow plug system relay and fuel

pump (diesel engine)16Front right main headlight, right tail light17Horn18Audio amplifier (sound system)19Windscreen wipers20Valve for metering fuel, coolant pump, high pressure pump21Lambda probe22Clutch pedal switch23Coil of the coolant pump relay valves, high-pressure pump24Radiator fan25Pump for ABS26Front left main headlight, left tail light27Control unit for glow plug system28Windscreen heater29Power to the internal fuse carrier30Power supply for terminal 15 (ignition on)a)

In order not to drain the battery unnecessarily when starting the engine, the electrical components of

this terminal are automatically switched off.

Bulbs

Introduction

This chapter contains information on the following subjects:

Headlights

220

Replacing the low beam bulb

220

Replacing bulb for main beam and daytime running lights

220

Replacing bulb for main beam

221

Replacing the bulb for the fog light

221Replacing the bulb for the licence plate light222Rear light (Superb Combi)222

Replacing bulbs in rear light (Superb Combi)

223

Some manual skills are required to change a bulb. For this reason, we recom-

mend having bulbs replaced by a specialist garage or seeking other expert help

in the event of any uncertainties.

› Switch off the ignition and all of the lights before replacing a bulb.

› Faulty bulbs must only be replaced with the same type of bulbs. The designa-

tion is located on the light socket or the glass bulb.

› A stowage compartment for replacement bulbs is located in a plastic box in

the spare wheel or underneath the floor covering in the boot.

WARNING■ Always read and observe the warnings before completing any work in the

engine compartment » page 182.■

Accidents can be caused if the road in front of the vehicle is not suffi-

ciently illuminated and the vehicle cannot or can only be seen with difficul-

ty by other road users.

■

Bulbs H7 H8 and H15 are pressurised and may burst when changing the

bulb - risk of injury! We therefore recommended wearing gloves and safety

glasses when changing a bulb.

■

Gas discharge bulbs (xenon bulbs) operate with a high voltage, professio-

nal knowledge is required – risk of death!

■

Switch off the respective vehicle light when changing the bulb.

CAUTION

Do not take hold of the glass bulb with naked fingers (even the smallest

amount of dirt reduces the working life of the light bulb). Use a clean cloth,

napkin, or similar.

Note

■ This Owner's Manual only describes the replacement of bulbs where it is pos-

sible to replace the bulbs on your own without any complications arising. Other

bulbs must be replaced by a specialist garage.■

We recommend that a box of replacement bulbs always be carried in the ve-

hicle. Replacement bulbs can be purchased from ŠKODAOriginal Accessories.

■

We recommend having the headlight settings checked by a specialist garage

after replacing a bulb in the main, low or fog beam.

■

In case of failure of a xenon gas discharge lamp or an LED diode, visit a spe-

cialist garage.

219Fuses and light bulbs