ECU SKODA YETI 2017 Owner´s Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2017, Model line: YETI, Model: SKODA YETI 2017Pages: 200, PDF Size: 28.93 MB

Page 157 of 200

WARNINGAlways properly secure the fire extinguisher - there is a risk of injury in the

event of sudden braking or a vehicle collision.

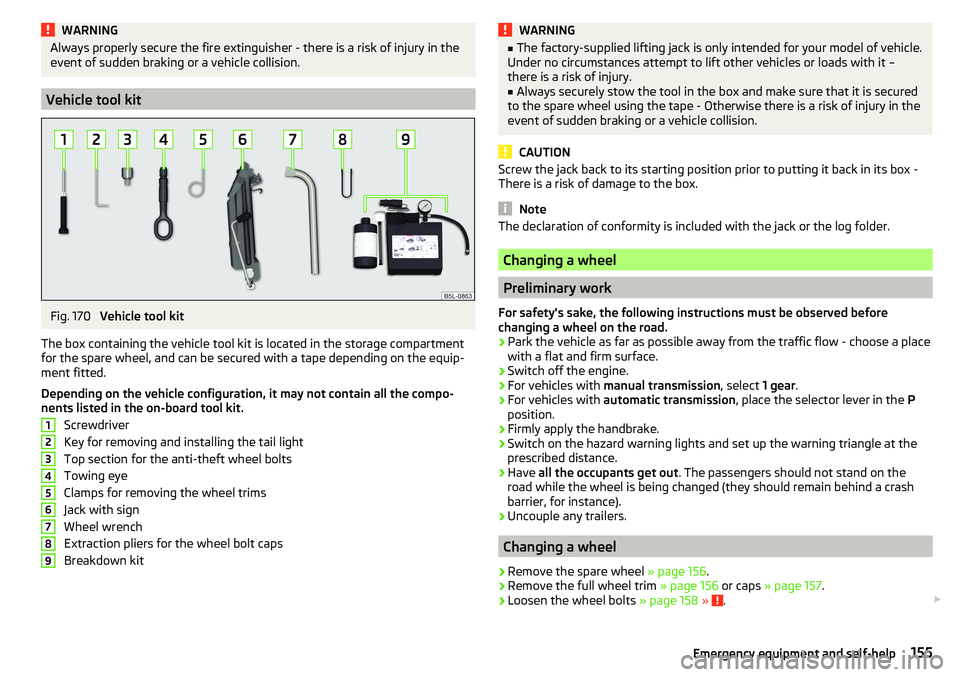

Vehicle tool kit

Fig. 170

Vehicle tool kit

The box containing the vehicle tool kit is located in the storage compartment

for the spare wheel, and can be secured with a tape depending on the equip-

ment fitted.

Depending on the vehicle configuration, it may not contain all the compo-

nents listed in the on-board tool kit.

Screwdriver

Key for removing and installing the tail light

Top section for the anti-theft wheel bolts

Towing eye

Clamps for removing the wheel trims

Jack with sign

Wheel wrench

Extraction pliers for the wheel bolt caps

Breakdown kit

123456789WARNING■ The factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances attempt to lift other vehicles or loads with it –

there is a risk of injury.■

Always securely stow the tool in the box and make sure that it is secured

to the spare wheel using the tape - Otherwise there is a risk of injury in the

event of sudden braking or a vehicle collision.

CAUTION

Screw the jack back to its starting position prior to putting it back in its box -

There is a risk of damage to the box.

Note

The declaration of conformity is included with the jack or the log folder.

Changing a wheel

Preliminary work

For safety's sake, the following instructions must be observed before

changing a wheel on the road.

›

Park the vehicle as far as possible away from the traffic flow - choose a place

with a flat and firm surface.

›

Switch off the engine.

›

For vehicles with manual transmission , select 1 gear.

›

For vehicles with automatic transmission , place the selector lever in the P

position.

›

Firmly apply the handbrake.

›

Switch on the hazard warning lights and set up the warning triangle at the

prescribed distance.

›

Have all the occupants get out . The passengers should not stand on the

road while the wheel is being changed (they should remain behind a crash

barrier, for instance).

›

Uncouple any trailers.

Changing a wheel

›

Remove the spare wheel » page 156.

›

Remove the full wheel trim » page 156 or caps » page 157 .

›

Loosen the wheel bolts » page 158 » .

155Emergency equipment and self-help

Page 158 of 200

›Jack up the vehicle

» page 158 until the wheel that needs changing is clear of

the ground.›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper,

etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Tighten the wheel bolts opposite each other using the wheel wrench (“pull- ing crossways”) » page 158.

›

Replace the wheel trim » page 156 and caps » page 157 .

When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect » page 150 .

All bolts must be clean and must turn easily. If screws are corroded and diffi-

cult to move, these must be replaced.

WARNING■ Undo the wheel bolts just a little (about one turn), provided the vehicle

has not yet been jacked up. Otherwise the wheel could come loose and fall

off – risk of injury.■

Under no circumstances must the bolts be greased or oiled - cause an ac-

cident.

Subsequent steps

After changing the wheel, the following work must be carried out.

›

Stow the replaced wheel in the well under the floor covering of the luggage

compartment and secure with a locking screw.

›

Stow the vehicle tool kit in the space provided.

›

Check tyre pressure on the mounted wheel and adjust if necessary and, with

vehicles with tyre pressure monitoring, save the tyre pressure values in the

system » page 123 .

›

Have the tightening torque of the wheel bolts checked as soon as possible.

The prescribed tightening torque is 120 Nm.

Replace the damaged wheel or consult a specialist garage about repair op-

tions.

WARNINGTightening torque which is too high can damage the threads and this can

result in permanent deformation of the contact surfaces on the rim. Where

tightening torque is too low, the wheels may become loose while driving -

There is a risk of an accident. Therefore drive cautiously and only at a mod-

erate speed until the tightening torque has been checked.

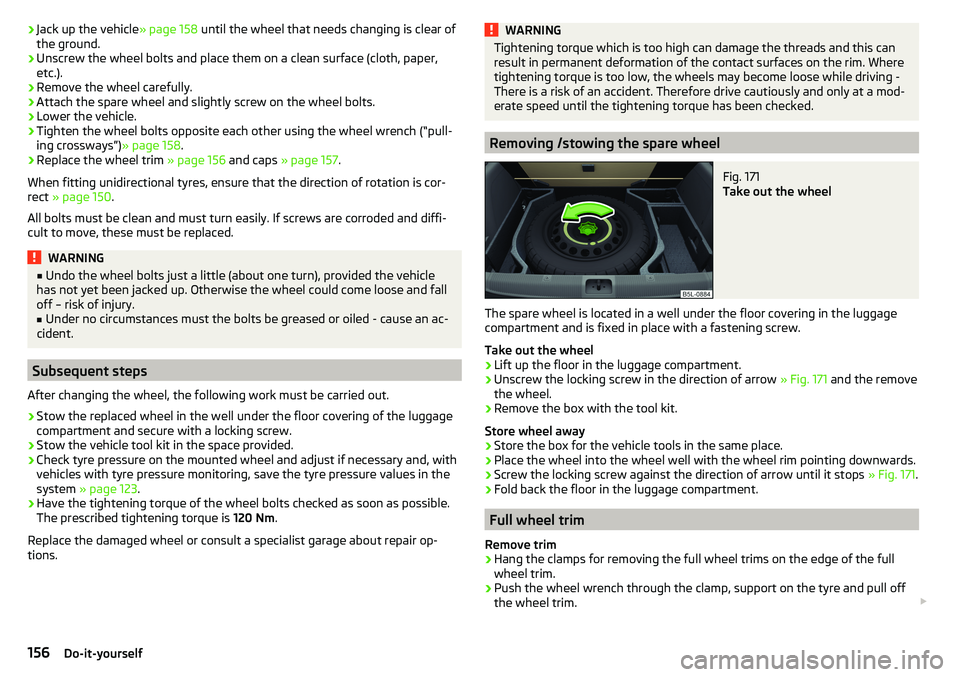

Removing /stowing the spare wheel

Fig. 171

Take out the wheel

The spare wheel is located in a well under the floor covering in the luggage

compartment and is fixed in place with a fastening screw.

Take out the wheel

›

Lift up the floor in the luggage compartment.

›

Unscrew the locking screw in the direction of arrow » Fig. 171 and the remove

the wheel.

›

Remove the box with the tool kit.

Store wheel away

›

Store the box for the vehicle tools in the same place.

›

Place the wheel into the wheel well with the wheel rim pointing downwards.

›

Screw the locking screw against the direction of arrow until it stops » Fig. 171.

›

Fold back the floor in the luggage compartment.

Full wheel trim

Remove trim

›

Hang the clamps for removing the full wheel trims on the edge of the full

wheel trim.

›

Push the wheel wrench through the clamp, support on the tyre and pull off

the wheel trim.

156Do-it-yourself

Page 168 of 200

Selector lever-emergency unlockingFig. 188

Remove / release the selector lever

›

Firmly apply the handbrake.

›

Insert a slot screwdriver or similar tool into the gap in the arrow area

1

» Fig. 188 and lift the cover in arrow direction

2

.

›

Press on the yellow plastic part in the direction of arrow

3

, simultaneously

press the lock button in the selector lever handle and put the lever in posi-

tion N.

If the selector lever is moved again to position P, it is once again blocked.

CAUTION

Make sure when lifting not to damage cover parts by the screwdriver in the

shift lever environment.

Replacing windscreen wiper blades

Introduction

This chapter contains information on the following subjects:

Replacing the windscreen wiper blades

166

Replacing the rear window wiper blade

167WARNINGReplace the windscreen wiper blades once or twice a year for safety rea-

sons.Replacing the windscreen wiper bladesFig. 189

Setting the service position for

the wiper arms

Fig. 190

Changing the windscreen wiper blade

Read and observe

on page 166 first.

Before replacing the windscreen wiper blades, close the bonnet and put the

windscreen wiper arms into the service position.

Setting the service position

›

Switch the ignition on and off again.

›

Push the lever in the direction of arrow » Fig. 189 within 10 seconds and hold

for approximately 2 seconds.

Removing the wiper blade

›

Lift the wiper arm from the windscreen in the direction of

1

» Fig. 190 .

›

Tilt the wiper blade to the stop in the same direction.

›

Grip the wiper arm and press securing latch

A

down in the direction of arrow

2

.

›

Remove the wiper blade in the direction of the arrow

3

.

166Do-it-yourself

Page 169 of 200

Attaching the windscreen wiper blade›Slide the windscreen wiper blade in the opposite direction to arrow 3 until it

locks into place. Check that the windscreen wiper blade is correctly attached.›

Fold the windscreen wiper arm back to the windscreen.

›

Turn on the ignition and press the lever in the direction of the arrow

» Fig. 189 .

The windscreen wiper arms move into the home position.

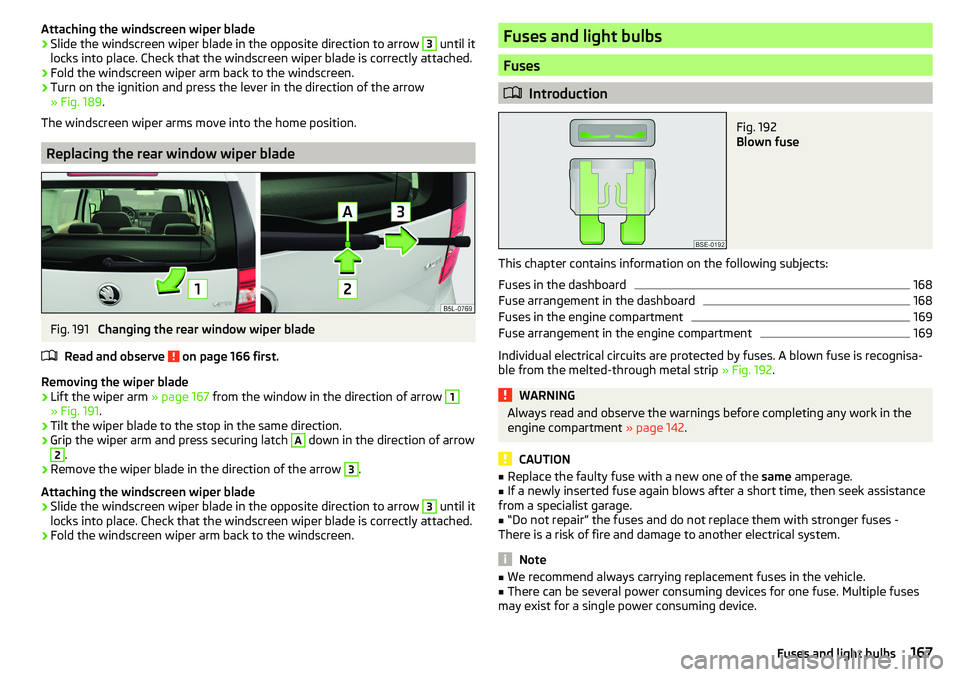

Replacing the rear window wiper blade

Fig. 191

Changing the rear window wiper blade

Read and observe

on page 166 first.

Removing the wiper blade

›

Lift the wiper arm » page 167 from the window in the direction of arrow

1

» Fig. 191.

›

Tilt the wiper blade to the stop in the same direction.

›

Grip the wiper arm and press securing latch

A

down in the direction of arrow

2

.

›

Remove the wiper blade in the direction of the arrow

3

.

Attaching the windscreen wiper blade

›

Slide the windscreen wiper blade in the opposite direction to arrow

3

until it

locks into place. Check that the windscreen wiper blade is correctly attached.

›

Fold the windscreen wiper arm back to the windscreen.

Fuses and light bulbs

Fuses

Introduction

Fig. 192

Blown fuse

This chapter contains information on the following subjects:

Fuses in the dashboard

168

Fuse arrangement in the dashboard

168

Fuses in the engine compartment

169

Fuse arrangement in the engine compartment

169

Individual electrical circuits are protected by fuses. A blown fuse is recognisa-

ble from the melted-through metal strip » Fig. 192.

WARNINGAlways read and observe the warnings before completing any work in the

engine compartment » page 142.

CAUTION

■

Replace the faulty fuse with a new one of the same amperage.■If a newly inserted fuse again blows after a short time, then seek assistance

from a specialist garage.■

“Do not repair” the fuses and do not replace them with stronger fuses -

There is a risk of fire and damage to another electrical system.

Note

■ We recommend always carrying replacement fuses in the vehicle.■There can be several power consuming devices for one fuse. Multiple fuses

may exist for a single power consuming device.167Fuses and light bulbs

Page 171 of 200

No.Consumer27Panoramic tilt / slide sunroof, electric operation of sun blinds28Fuel pump, injectors, AdBlue®

heating29Electric windows - front, outside mirror - Heating, fold-in function,

Adjusting the mirror surface3012 volt power outlet - front and rear31Headlight cleaning system32Heated front seats33Heating, air conditioning, Climatronic, remote control for auxiliary

heating34Car alarm, reserve horn35Automatic gearbox36Tow hitch

Fuses in the engine compartment

Fig. 195

Distribution board cover.

Read and observe and on page 167 first.

With some equipment, the battery cover must be opened before removing the

cover for the fuse box » page 148.

Replacing fuses

›

Turn the securing bracket

A

» Fig. 195 in direction of the arrow. The symbol

is displayed behind the catches. .

›

Remove the cover.

›

Replace the appropriate fuse.

›

Replace the cover on the fuse box and the safety clip

A

move against the

arrow. The symbol is displayed behind the catches .

CAUTIONThe cover of the fuse box in the engine compartment must always be used

correctly, otherwise water may penetrate into the fuse box – there is a risk of

damage to the vehicle!

Fuse arrangement in the engine compartment

Fig. 196

Fuses

Read and observe and on page 167 first.

No.Consumer1Not assigned2Automatic gearbox, AdBlue control system3Battery data module4ABS5Automatic gearbox6Not assigned7Power supply for terminal 15, starter8Radio, instrument cluster, telephone9Not assigned10Engine control system11Aux. heating and ventilation12Databus13Engine control system14Ignition15Lambda probe, fuel pump, glow plug system16Right headlight, right taillight17Horn 169Fuses and light bulbs

Page 175 of 200

CAUTIONFor vehicles with parking assistance, we recommend that after changing the

light bulb in the fog lights, the system is checked by a specialist.

Changing the bulb for the licence plate light

Fig. 203

Remove / replace the bulb for the number plate light

Read and observe

and on page 170 first.

›

Open the boot lid.

›

Push the light in the direction of arrow

1

» Fig. 203 until it comes loose.

›

Swivel out the lamp in the direction of the arrow

2

and remove it.

›

Remove the faulty bulb from the holder in the direction of the arrow

3

.

›

Insert a new bulb into the holder.

›

Reinsert the lamp in the opposite direction to the arrow

1

.

›

Push on the light until the spring clicks into place.

›

Close the boot lid.

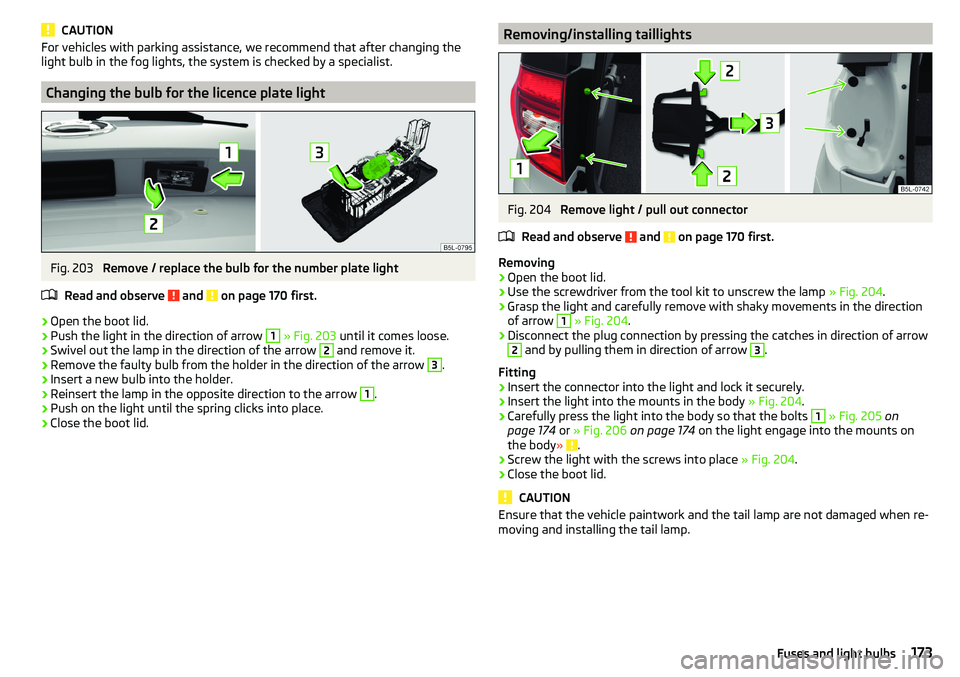

Removing/installing taillightsFig. 204

Remove light / pull out connector

Read and observe

and on page 170 first.

Removing

›

Open the boot lid.

›

Use the screwdriver from the tool kit to unscrew the lamp » Fig. 204.

›

Grasp the light and carefully remove with shaky movements in the direction

of arrow

1

» Fig. 204 .

›

Disconnect the plug connection by pressing the catches in direction of arrow

2

and by pulling them in direction of arrow

3

.

Fitting

›

Insert the connector into the light and lock it securely.

›

Insert the light into the mounts in the body » Fig. 204.

›

Carefully press the light into the body so that the bolts

1

» Fig. 205 on

page 174 or » Fig. 206 on page 174 on the light engage into the mounts on

the body »

.

›

Screw the light with the screws into place » Fig. 204.

›

Close the boot lid.

CAUTION

Ensure that the vehicle paintwork and the tail lamp are not damaged when re-

moving and installing the tail lamp.173Fuses and light bulbs

Page 176 of 200

Replacing the bulbs in the taillight assemblyFig. 205

Inner part of the light: Ground light

Fig. 206

Inner part of the light: Light with LED diodes

Read and observe

and on page 170 first.

Ground light

›

With the spanner from the vehicle tools unscrew the securing screw

A

» Fig. 205 .

›

Unlock the bulb holder using the locking latches in the areas » Fig. 205

marked with arrows and remove the bulb holder from the light.

›

Turn the respective bulb

B

until it stops counter-clockwise and remove it

from the bulb holder.

›

Insert a new bulb

B

into the holder and turn in a clockwise direction to the

stop.

›

Pull bulb

C

out of the socket and insert a new bulb.

›

Insert the lamp holder in the lamp and screw in the locking screw

A

» Fig. 205 .

Light with LED diodes›Unlock the bulb holder using the locking latches in the areas » Fig. 206

marked with arrows and remove the bulb holder from the light.›

Turn the respective light bulb » Fig. 206 until it stops counter-clockwise and

remove it from the bulb holder.

›

Insert a new bulb into the holder and turn in a clockwise direction to the

stop.

›

Insert the lamp holder in the lamp until it is secure.

174Do-it-yourself