engine SKODA YETI 2017 Owner´s Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2017, Model line: YETI, Model: SKODA YETI 2017Pages: 200, PDF Size: 28.93 MB

Page 160 of 200

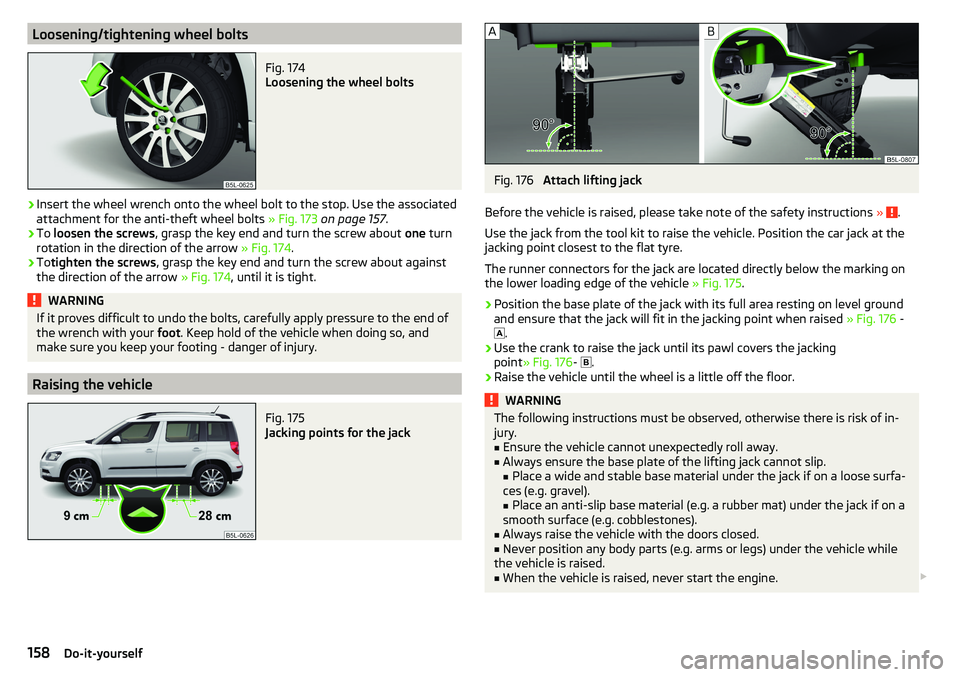

Loosening/tightening wheel boltsFig. 174

Loosening the wheel bolts

›

Insert the wheel wrench onto the wheel bolt to the stop. Use the associated

attachment for the anti-theft wheel bolts » Fig. 173 on page 157 .

›

To loosen the screws , grasp the key end and turn the screw about one turn

rotation in the direction of the arrow » Fig. 174.

›

Totighten the screws , grasp the key end and turn the screw about against

the direction of the arrow » Fig. 174, until it is tight.

WARNINGIf it proves difficult to undo the bolts, carefully apply pressure to the end of

the wrench with your foot. Keep hold of the vehicle when doing so, and

make sure you keep your footing - danger of injury.

Raising the vehicle

Fig. 175

Jacking points for the jack

Fig. 176

Attach lifting jack

Before the vehicle is raised, please take note of the safety instructions »

.

Use the jack from the tool kit to raise the vehicle. Position the car jack at the

jacking point closest to the flat tyre.

The runner connectors for the jack are located directly below the marking on

the lower loading edge of the vehicle » Fig. 175.

›

Position the base plate of the jack with its full area resting on level ground

and ensure that the jack will fit in the jacking point when raised » Fig. 176 -

.

›

Use the crank to raise the jack until its pawl covers the jacking

point » Fig. 176 -

.

›

Raise the vehicle until the wheel is a little off the floor.

WARNINGThe following instructions must be observed, otherwise there is risk of in-

jury.■

Ensure the vehicle cannot unexpectedly roll away.

■

Always ensure the base plate of the lifting jack cannot slip.

■ Place a wide and stable base material under the jack if on a loose surfa-

ces (e.g. gravel).

■ Place an anti-slip base material (e.g. a rubber mat) under the jack if on a

smooth surface (e.g. cobblestones).

■

Always raise the vehicle with the doors closed.

■

Never position any body parts (e.g. arms or legs) under the vehicle while

the vehicle is raised.

■

When the vehicle is raised, never start the engine.

158Do-it-yourself

Page 162 of 200

Preparing to use the breakdown kitRead and observe

on page 159 first.

For safety's sake, the following instructions must be observed before

undertaking a wheel repair on a road.

›

Park the vehicle as far as possible away from the traffic flow - choose a place

with a flat and firm surface.

›

Switch off the engine.

›

For vehicles with manual transmission , select 1. gear.

›

For vehicles with automatic transmission , place the selector lever in the P

position.

›

Firmly apply the handbrake.

›

Switch on the hazard warning lights and set up the warning triangle at the

prescribed distance.

›

Have all the occupants get out . While the repair is being carried out, the pas-

sengers should not stand on the road (instead they should remain behind a

crash barrier, for instance).

›

Uncouple any trailers.

Sealing and inflating tyres

Read and observe

on page 159 first.

Sealing

›

Unscrew the valve cap from the damaged tyre.

›

Insert the valve remover

2

» Fig. 177 on page 159 on the valve insert, so that

the valve insert fits into the slot of the valve remover.

›

Unscrew the valve insert and place it on a clean base (rag, paper etc.).

›

Forcefully shake bottle

10

» Fig. 177 on page 159 several times.

›

Firmly screw the inflation hose

3

onto the tyre inflater bottle

10

. The film on

the bottle cap is pierced.

›

Remove the plug from the inflation hose

3

and insert the bottle onto the

tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

›

Remove the filler plug from the tyre valve.

›

Screw in the valve insert with the valve remover

2

.

Inflating

›

Screw the tyre inflation hose

8

» Fig. 177 on page 159 firmly onto the tyre

valve.

› For vehicles with

manual transmission , set the lever in the neutral position.›On vehicles with automatic transmission , place the selector lever in the P

position.›

Check that the screw for the tire pressure reduction

6

is closed.

›

Start the engine.

›

Plug the connector

4

into 12 volt socket » page 79.

›

Switch on the air compressor with the ON and OFF switch

9

.

›

Once tyre inflation pressure of 2.0-2.5 bar has been reached, turn off the air

compressor. Maximum run time of 6 minutes » .

›

If you cannot reach an air pressure of 2.0 - 2.5 bar, unscrew the tyre inflation

hose

8

from the tyre valve.

›

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent

to “distribute” in the tyre.

›

Firmly screw the tyre inflation hose

8

back onto the tyre valve and repeat

the inflation process.

›

Stick the sticker

1

» Fig. 177 on page 159 on the dashboard in the driver's

field of view.

At a tyre inflation pressure of 2.0–2.5 bar, the journey can be continued at a

maximum speed of 80 km/h or 50 mph.

WARNING■ If the tire does not inflate at least. 2.0 bar, the damage is too great. The

sealing agent cannot be used to seal the tyre. Stop driving! Seek help

from a specialist garage.■

The tyre inflation hose and air compressor may get hot as the tyre is be-

ing inflated – risk of burning.

CAUTION

Switch off the air compressor if it has been running for as much as 6 minutes –

There is a risk of damage to the compressor! Allow the air compressor to cool a

few minutes before switching it on again.

Information on driving with repaired tyres

Read and observe

on page 159 first.

The inflation pressure of the repaired tyre must be checked after driving for 10

minutes.

If the tyre inflation pressure is 1.3 bar or less

›

The tyre cannot be properly sealed with the breakdown kit.

Stop driving!

Seek help from a specialist garage.

160Do-it-yourself

Page 163 of 200

If the tyre inflation pressure is 1.3 bar or more›Set the tyre pressure back to the correct value » page 151.›

Continue driving carefully to the nearest specialist garage at a maximum

speed of 80 km/h (50 mph).

WARNINGA tyre filled with sealant has the same driving characteristics as a standard

tyre. The following guidelines must be observed.■

Do not drive faster than 80 km/h (50 mph).

■

Avoid accelerating at full throttle, sharp braking and fast cornering.

Jump-starting

Introduction

This chapter contains information on the following subjects:

Jump-starting using the battery from another vehicle

161WARNING■ The following instructions must be followed at all times when working on

the engine compartment » page 142.■

When handling the vehicle battery, the following warnings must be ob-

served » page 147 .

■

A discharged vehicle battery may already freeze at temperatures just be-

low 0 °C. If the battery is frozen, do not carry out a jump start with the bat-

tery of another vehicle – There is a risk of explosion and injury!

■

Never jump-start vehicle batteries with an electrolyte level that is too low

– There is a risk of explosion and caustic burns!

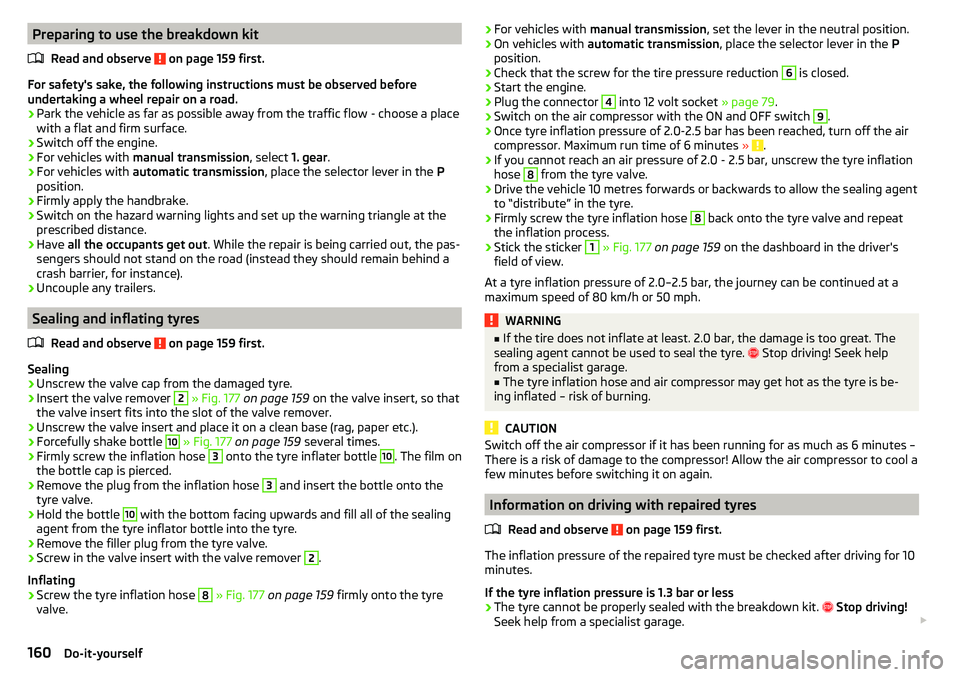

Jump-starting using the battery from another vehicleFig. 178

Jump-starting:

- Discharged battery,

- power-supplying bat-

tery / ground point of the engine for the START-STOP system

Read and observe

on page 161 first.

If, because of a discharged battery, it is not possible to start the engine, the

battery of another vehicle can be used to start the engine. To do this, jump-

start cables are required which have a sufficiently large cross-section and in-

sulated terminal clamps.

The rated voltage of the two batteries must be 12 V. The capacity (Ah) of the

power-supplying battery must not be significantly lower than the capacity of

the discharged battery.

The jump-start cables must be attached in the following sequence.

›

Attach clamp

1

to the positive terminal of the discharged battery.

›

Attach clamp

2

to the positive terminal of the power-supplying battery.

›

Attach clamp

3

to the negative terminal of the power-supplying battery.

›

For vehicles with the START-STOPsystem, attach clamp

4

to the earth point

of the engine

A

» Fig. 178 .

›

For vehicles without the START-STOPsystem, attach clamp

4

to a solid

metal part firmly attached to the engine block or directly to the engine block.

Starting engine

›

Start the engine on the vehicle providing the power and allow it to idle.

›

Initiate the starting process in the vehicle with the discharged battery.

›

If the engine does not start within 10 s, then cancel the starting procedure

and repeat after half a minute.

›

Remove the jump start cables in the reverse order as attachment.

161Emergency equipment and self-help

Page 164 of 200

WARNING■Never clamp the jump cable to the negative terminal of the discharged

battery -There is a risk of an explosion.■

The non-insulated parts of the terminal clamps must never touch each

other – risk of short circuit!

■

The jump-start cable connected to the positive terminal of the battery

must not come into contact with electrically conducting parts of the vehicle

– risk of short circuit!

■

Position the jump cables so that they cannot be caught in rotating parts

in the engine compartment - danger of injuries and the risk of vehicle dam-

age.

Towing the vehicle

Information about the towing process

Fig. 179

Braided tow rope / Spiral tow rope

To tow with a tow rope, only use a braided synthetic fibre rope » Fig. 179 -

»

.

Attach the tow rope or the tow bar to the towing eyes at the front

» page 163 , towing eyes at the rear » page 163 or to the towing device of

the trailer device » page 124 .

Conditions for towing. Cars with automatic gearboxes must not be towed with the rear wheels

raised - there is a risk of gearbox damage!

If the gearbox has no oil, your vehicle must be towed with the front axle

raised clear of the ground or on a breakdown vehicle or trailer.

The maximum towing speed is 50 km/h.

The vehicle must be transported on a special breakdown vehicle or trailer

if it is not possible to tow in the vehicle in the way described or if the tow-

ing distance is greater than 50 km.

Driver of the tow vehicle›

On vehicles with manual transmission , engage gear slowly when starting.

›

On vehicles with automatic transmission , accelerate with particular care.

›

Only then approach correctly when the rope is taut.

Driver of the towed vehicle

›

If possible, the vehicle should be towed with the engine running. The brake

booster and power steering only operate if the engine is running, otherwise

much greater force has to be applied to the brake pedal and more power has

to be expended for steering.

›

If it is not possible to start the engine, switch on the ignition so that the

steering wheel does not lock and so that the turn signal lights, windscreen

wipers and windscreen washer system can be used.

›

Take the vehicle out of gear or move the selector lever into position N if the

vehicle is fitted with an automatic gearbox.

›

Keep the tow rope taut at all times during the towing procedure.

WARNING■ Spiral tow ropes must not be used for towing » Fig. 179- , the towing

eye may unscrew out of the vehicle - There is a risk of an accident.■

Ensure tow rope is not twisted - risk of accident.

CAUTION

■ Do not tow-start the engine – There is a risk of damaging the engine. The

battery from another vehicle can be used as a jump-start aid » page 161, Jump-

starting .■

For off-road towing manoeuvres, there is a risk to both vehicles that the fas-

teners may become overloaded and damaged.

Note

We recommend that you use a tow rope from ŠKODA Original Accessories.162Do-it-yourself

Page 169 of 200

Attaching the windscreen wiper blade›Slide the windscreen wiper blade in the opposite direction to arrow 3 until it

locks into place. Check that the windscreen wiper blade is correctly attached.›

Fold the windscreen wiper arm back to the windscreen.

›

Turn on the ignition and press the lever in the direction of the arrow

» Fig. 189 .

The windscreen wiper arms move into the home position.

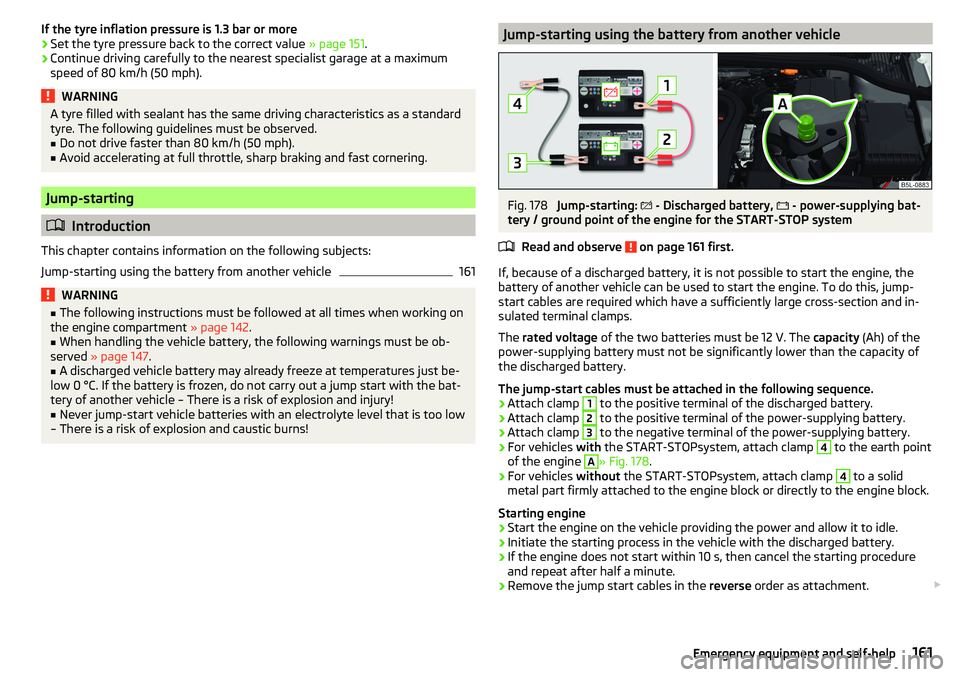

Replacing the rear window wiper blade

Fig. 191

Changing the rear window wiper blade

Read and observe

on page 166 first.

Removing the wiper blade

›

Lift the wiper arm » page 167 from the window in the direction of arrow

1

» Fig. 191.

›

Tilt the wiper blade to the stop in the same direction.

›

Grip the wiper arm and press securing latch

A

down in the direction of arrow

2

.

›

Remove the wiper blade in the direction of the arrow

3

.

Attaching the windscreen wiper blade

›

Slide the windscreen wiper blade in the opposite direction to arrow

3

until it

locks into place. Check that the windscreen wiper blade is correctly attached.

›

Fold the windscreen wiper arm back to the windscreen.

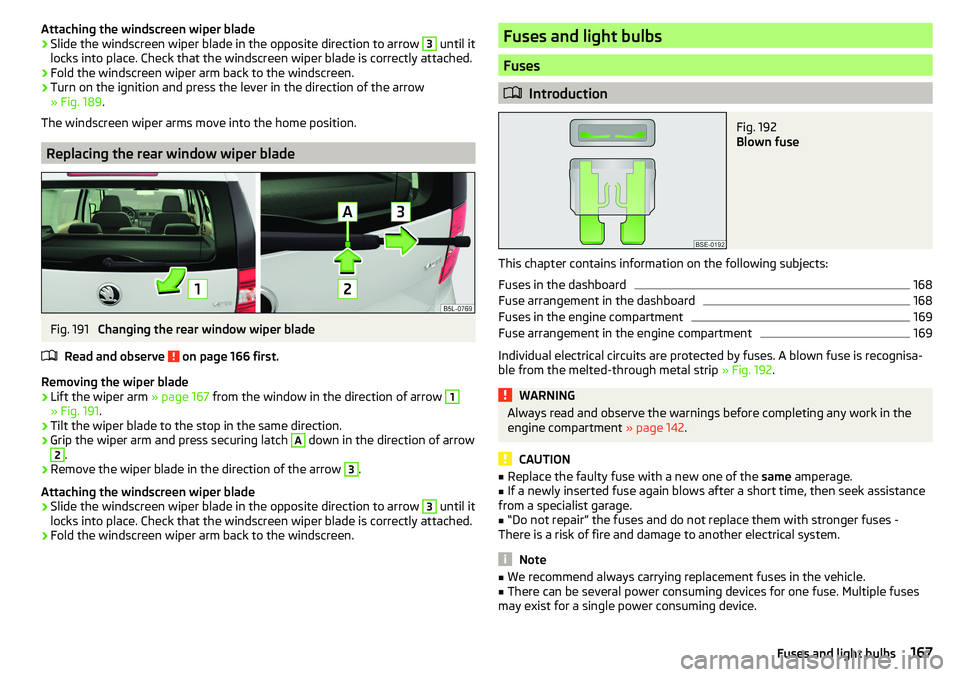

Fuses and light bulbs

Fuses

Introduction

Fig. 192

Blown fuse

This chapter contains information on the following subjects:

Fuses in the dashboard

168

Fuse arrangement in the dashboard

168

Fuses in the engine compartment

169

Fuse arrangement in the engine compartment

169

Individual electrical circuits are protected by fuses. A blown fuse is recognisa-

ble from the melted-through metal strip » Fig. 192.

WARNINGAlways read and observe the warnings before completing any work in the

engine compartment » page 142.

CAUTION

■

Replace the faulty fuse with a new one of the same amperage.■If a newly inserted fuse again blows after a short time, then seek assistance

from a specialist garage.■

“Do not repair” the fuses and do not replace them with stronger fuses -

There is a risk of fire and damage to another electrical system.

Note

■ We recommend always carrying replacement fuses in the vehicle.■There can be several power consuming devices for one fuse. Multiple fuses

may exist for a single power consuming device.167Fuses and light bulbs

Page 170 of 200

Fuses in the dashboardFig. 193

Distribution board cover.

Read and observe and on page 167 first.

The fuses are located on the left side of the dash panel behind a cover.

Replacing fuses

›

Remove the ignition key, turn off the lights and all electrical consumers.

›

Insert a screwdriver into the opening in the cover in the direction of the ar-

row » Fig. 193 .

›

Remove the cover of the fuse box and remove.

›

Remove the plastic clip from the holder in the fuse box cover in the dash

panel.

›

Use the clip to pull the fuse out, then insert a new fuse.

›

Re-insert the cover of the fuse box .

›

Replace the bracket at the original position.

Fuse arrangement in the dashboard

Fig. 194

Fuses

Read and observe and on page 167 first.No.Consumer1Heating of the gearbox vent (diesel engine)

Automatic gearbox2Towing hitch - left light3Trailer device - electrical outlet4Instrument cluster control lever under the steering wheel, camera5Air blower for heating, radiator fan, air conditioning system, Clima-

tronic6Rear window wiper7emergency call8Towing hitch - right light9Interior lighting, rear fog light10Rain sensor, light switch, diagnostic socket11Left side front headlight12Right side front headlight13Radio14Central control system, engine management system15Light switch16All-wheel drive17KESSY, steering lock18Diagnostic connector, engine control system, brake sensor, four-

wheel drive, START-STOP19ABS, ESP, switch for tyre air pressure control, parking aid, switch for

OFF ROAD mode, START STOP button20Airbag21Variable Service Interval - WIV, reversing lamps, dimmable mirrors,

pressure sensor, telephone preparation, air mass meter, headlamp

levelling and swivelling headlights22Instrument cluster, electromechanical power steering, databus23Central locking, boot lid24Electric windows - Rear25Rear window heater, auxiliary heating and ventilation26Power socket in the boot 168Do-it-yourself

Page 171 of 200

No.Consumer27Panoramic tilt / slide sunroof, electric operation of sun blinds28Fuel pump, injectors, AdBlue®

heating29Electric windows - front, outside mirror - Heating, fold-in function,

Adjusting the mirror surface3012 volt power outlet - front and rear31Headlight cleaning system32Heated front seats33Heating, air conditioning, Climatronic, remote control for auxiliary

heating34Car alarm, reserve horn35Automatic gearbox36Tow hitch

Fuses in the engine compartment

Fig. 195

Distribution board cover.

Read and observe and on page 167 first.

With some equipment, the battery cover must be opened before removing the

cover for the fuse box » page 148.

Replacing fuses

›

Turn the securing bracket

A

» Fig. 195 in direction of the arrow. The symbol

is displayed behind the catches. .

›

Remove the cover.

›

Replace the appropriate fuse.

›

Replace the cover on the fuse box and the safety clip

A

move against the

arrow. The symbol is displayed behind the catches .

CAUTIONThe cover of the fuse box in the engine compartment must always be used

correctly, otherwise water may penetrate into the fuse box – there is a risk of

damage to the vehicle!

Fuse arrangement in the engine compartment

Fig. 196

Fuses

Read and observe and on page 167 first.

No.Consumer1Not assigned2Automatic gearbox, AdBlue control system3Battery data module4ABS5Automatic gearbox6Not assigned7Power supply for terminal 15, starter8Radio, instrument cluster, telephone9Not assigned10Engine control system11Aux. heating and ventilation12Databus13Engine control system14Ignition15Lambda probe, fuel pump, glow plug system16Right headlight, right taillight17Horn 169Fuses and light bulbs

Page 172 of 200

No.Consumer18Music amplifier19Windscreen wipers20Control valve for fuel pressure, high pressure pump21Lambda probe22Clutch pedal switch, brake pedal switch23Coolant pump, loading pressure control valve, switchover valve for

radiator, fuel pump24Active charcoal filter, exhaust gas recirculation valve, radiator fan25ABS26Left front headlight, left taillight27Glow plug system28Windscreen heater29Power to the internal fuse carrier (fuses no. 24,27,31,32), electrically

adjustable seats30Terminal X a)a)

In order not to drain the battery unnecessarily when starting the engine, the electrical components of

this terminal are automatically switched off.

Bulbs

Introduction

This chapter contains information on the following subjects:

Bulb arrangement in the front headlights

171

Changing bulbs for low and main beam (Halogen headlights)

171

Remove protective guard for foglights

171

Protective grille for removing fog lights- plug for Park Assist sensor

172

Changing light bulbs for fog lights

172

Changing the bulb for the licence plate light

173

Removing/installing taillights

173

Replacing the bulbs in the taillight assembly

174

We recommend having bulbs replaced by a specialist garage or seeking other

expert help in the event of any uncertainties.

▶ Switch off the ignition and all of the lights before replacing a bulb.

▶ Faulty bulbs must only be replaced with the same type of bulbs. The designa-

tion is located on the light socket or the glass bulb.

We recommend having the headlight settings checked by a specialist garage after replacing a bulb in the low, high or fog beam.

In the case of failure of a Xenon gas discharge bulb or an LED diode, visit a

specialist garage.WARNING■ Always read and observe the warnings before completing any work in the

engine compartment » page 142.■

Accidents can be caused if the road in front of the vehicle is not suffi-

ciently illuminated and the vehicle cannot or can only be seen with difficul-

ty by other road users.

■

Bulbs H7 and H4 are pressurised and may burst when changed - there is a

risk of injury. We therefore recommended wearing gloves and safety

glasses when changing a bulb.

■

Do not carry out any work on the Xenon gas discharge lamps - risk of

death!

CAUTION

Do not take hold of the glass bulb with naked fingers (even the smallest

amount of dirt reduces the working life of the light bulb). Use a clean cloth,

napkin, or similar.

Note

■ This Owner's Manual only describes the replacement of bulbs where it is pos-

sible to replace the bulbs on your own without any complications arising. Other

bulbs must be replaced by a specialist garage.■

We recommend that a box of replacement bulbs always be carried in the ve-

hicle.

170Do-it-yourself

Page 173 of 200

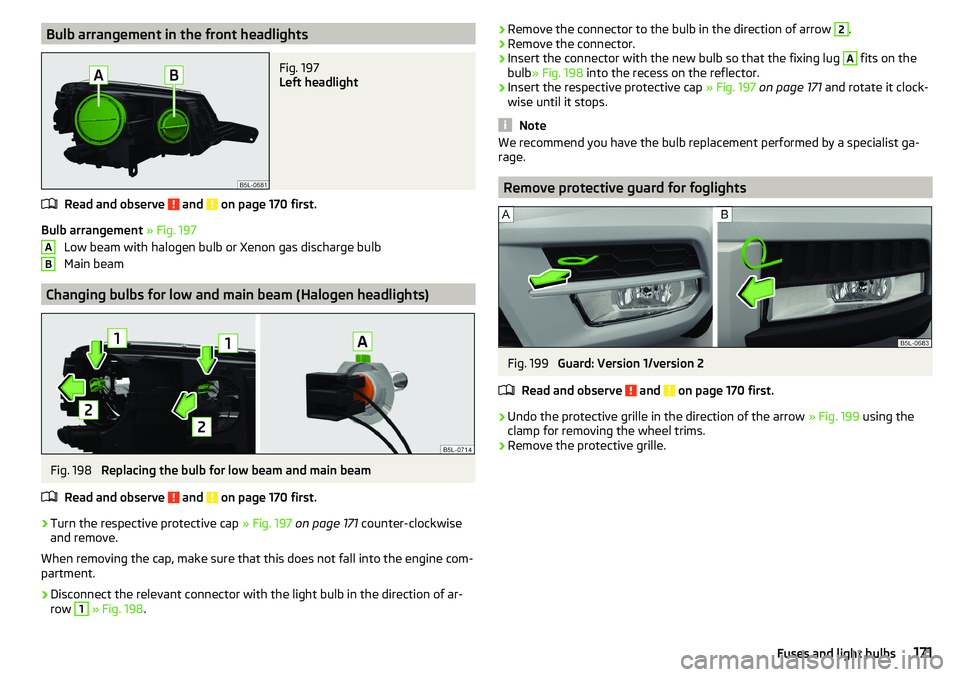

Bulb arrangement in the front headlightsFig. 197

Left headlight

Read and observe and on page 170 first.

Bulb arrangement » Fig. 197

Low beam with halogen bulb or Xenon gas discharge bulb

Main beam

Changing bulbs for low and main beam (Halogen headlights)

Fig. 198

Replacing the bulb for low beam and main beam

Read and observe

and on page 170 first.

›

Turn the respective protective cap » Fig. 197 on page 171 counter-clockwise

and remove.

When removing the cap, make sure that this does not fall into the engine com-

partment.

›

Disconnect the relevant connector with the light bulb in the direction of ar-

row

1

» Fig. 198 .

AB›Remove the connector to the bulb in the direction of arrow 2.›Remove the connector.›

Insert the connector with the new bulb so that the fixing lug

A

fits on the

bulb » Fig. 198 into the recess on the reflector.

›

Insert the respective protective cap » Fig. 197 on page 171 and rotate it clock-

wise until it stops.

Note

We recommend you have the bulb replacement performed by a specialist ga-

rage.

Remove protective guard for foglights

Fig. 199

Guard: Version 1/version 2

Read and observe

and on page 170 first.

›

Undo the protective grille in the direction of the arrow » Fig. 199 using the

clamp for removing the wheel trims.

›

Remove the protective grille.

171Fuses and light bulbs

Page 177 of 200

Technical data

Technical data

Basic vehicle data

Introduction

This chapter contains information on the following subjects:

Vehicle data

175

Operating weight

176

Payload

176

Measurement of fuel consumption and CO 2 emissions according to ECE

Regulations and EU Directives

177

Dimensions

178

Angle and gradeability

179

The details given in the vehicle's technical documentation always take prece-

dence over the details in the Owner's Manual.

The performance values listed were determined without performance-reduc- ing equipment, e.g. air conditioning system.

The values given have been determined in accordance with regulations and in

conditions prescribed by legal or technical provisions for determining the oper-

ating and technical data of vehicles.

The values listed are for the basic model without optional equipment.

Vehicle dataFig. 207

Vehicle data sticker/type plate

Vehicle data sticker

The vehicle data sticker » Fig. 207 -

is located on the base of the luggage

compartment and is also stuck into the Owner's Manual.

The vehicle data sticker contains the following data. Vehicle identification number (VIN)

Vehicle type

Gearbox code/paint number/interior equipment/engine output/engine code

Partial vehicle description

Approved tyre diameter in inches 1)

The approved tyres and rim sizes for your vehicle are listed in the vehicle's

technical documentation (the so called COC document) and this also states the

declaration of conformity.

Type plate

The type plate » Fig. 207 -

is located at the bottom of the B-pillar on the

right driver's side.

The type plate contains the following data. Vehicle manufacturers

Vehicle identification number (VIN)

Maximum permissible gross weight

Maximum permissible towed weight (towing vehicle and trailer)

1234567891)

Only valid for some countries.

175Technical data