service SSANGYONG KORANDO 1997 Service User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 32 of 2053

1A1 -- 12 GENERAL ENGINE INFORMATION

D AEW OO M Y_2000

GENERAL INFORMATION

CLEANLINESS AND CARE

An automobile engine is a combination of many ma-

chined, honed, polished and lapped surfaces with toler-

ances that are measured in the ten-thousandths of an

inch. When any internal engine parts are serviced, care

and cleanliness are important. A liberal coating of enigne

oil should be applied to friction areas during assembly, to

protect and lubricate the surfaces on initial operation.

Proper cleaning and protection of machined surfaces and

friction areas is part of the repair procedure. This is con-

sidered standard shop practice even if not specifically

stated.

Whenever valve train components are removed for ser-

vice, they should be kept in order. They should be

installed in the same locations, and with the same mating

surfaces, as when they were removed.

Battery cables should be disconnected before any major

work is performed on the engine. Failure to disconnectcables may result in damage to wire harness or other

electrical parts.

ON-ENGINE SERVICE

Caution: Disconnect the negative battery cable be -

fore removing or installing any electrical unit, or

when a tool or equipment could easily come in con-

tact with exposed electrical terminals. Disconnect -

ing this cable will help prevent personal injury and

damage to the vehicle. The ignition must also be in

LOCK unless otherwise noted.

Notice:Any time the air cleaner is removed, the intake

opening should be covered. Thiswill protect against ac-

cidental entrance of foreign material, which could follow

the intake passage into the cylinder and cause exten-

sive damage when the engine is started.

Page 33 of 2053

D AEW OO M Y_2000

SECTION 1B1

M162 ENGINE MECHANICAL

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless other -

wise noted.

TABLE OF CONTENTS

Specifications 1B1 -- 2............................

Fastener Tightening Specifications 1B1 -- 2..........

Special Tools 1B1 -- 4.............................

Special Tools Table 1B1-- 4.......................

Maintenance and Repair 1B1 -- 7...................

On-- Vehicle Service 1B1-- 7.........................

Engine Assembly 1B1-- 7.........................

Crankcase Ventilation System 1B1-- 14.............

Generator 1B1-- 16..............................

Engine Mount 1B1-- 17...........................

Poly V-- Belt 1B1 -- 18.............................

Tensioning Device 1B1-- 20.......................

Poly V-- Belt Inspection 1B1-- 21...................

Cylinder Head Cover 1B1-- 24.....................

Cylinder Head Front Cover 1B1 -- 26...............

Cylinder Head 1B1-- 28...........................

Timing Gear Case Cover 1B1-- 31.................

Crankshaft Sealing Rear Cover 1B1-- 33...........

Belt Pulley and Vibration Damper 1B1-- 35..........

Crankshaft Front Radial Seal 1B1-- 38.............

Crankshaft Rear Radial Seal 1B1-- 40..............

Crankshaft 1B1-- 41.............................

Flywheel / Driven Plate 1B1 -- 47...................

Camshaft Adjuster 1B1-- 50.......................

Camshaft Sprocket Bolt 1B1-- 52..................

Camshaft 1B1-- 54..............................

Camshaft Timing Position 1B1 -- 59................Valve Spring 1B1 -- 62............................

Valve Stem Seal 1B1-- 66........................

Chain Tensioner 1B1-- 67.........................

Timing Chain 1B1-- 70............................

Tensioning Rail 1B1-- 75..........................

Cylinder Head Guide Rail 1B1-- 76.................

Crankcase Guide Rail 1B1-- 77....................

Crankshaft Sprocket 1B1-- 78.....................

Piston 1B1-- 80..................................

Connecting Rod 1B1-- 83.........................

Piston Ring 1B1 -- 85.............................

Engine Oil Specification 1B1-- 87..................

Oil Pan 1B1-- 88.................................

Engine Oil and Oil Filter Element 1B1-- 90..........

Oil Filter 1B1-- 92................................

Oil Pump 1B1-- 94...............................

Oil Pressure Relief Valve 1B1-- 96.................

Oil Non-Return Valve 1B1-- 97....................

Oil Dipstick Guide Tube 1B1-- 98..................

Unit Repair 1B1 -- 99..............................

Oil Gallery in Crankcase 1B1 -- 99..................

Oil Gallery in Cylinder Head 1B1-- 101..............

Core Plugs in Crankcase 1B1-- 104................

Cylinder Bore 1B1-- 106..........................

Crankcase Mating Surface 1B1-- 108..............

Cylinder Head Mating Surface 1B1-- 110...........

Page 39 of 2053

M162 ENGINE MECHANICAL 1B1 -- 7

D AEW OO M Y_2000

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

ENGINE ASSEMBLY

Page 68 of 2053

1B1 -- 36 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

Components

1 Center Bolt (M18 x 50)

2 Center Bolt Washer

3 Vibration Damper and Pulley Assembly

4Key

5 Crankshaft Front Seal

6 Timing Gear Case Cover7 Crankshaft Sprocket (Camshaft Driven)

8 Crankshaft Sprocket (Oil pump Driven)

9 Crankshaft

10 Oil Pan

11 Oil Pan Gasket

12 Oil Pan Mounting Bolt (M6 x 22)

ServiceDataStandard

Permissble Deviation of The Vibration DamperRadial Runout0.6 mmp

Axial Runout0.6 mm

Page 75 of 2053

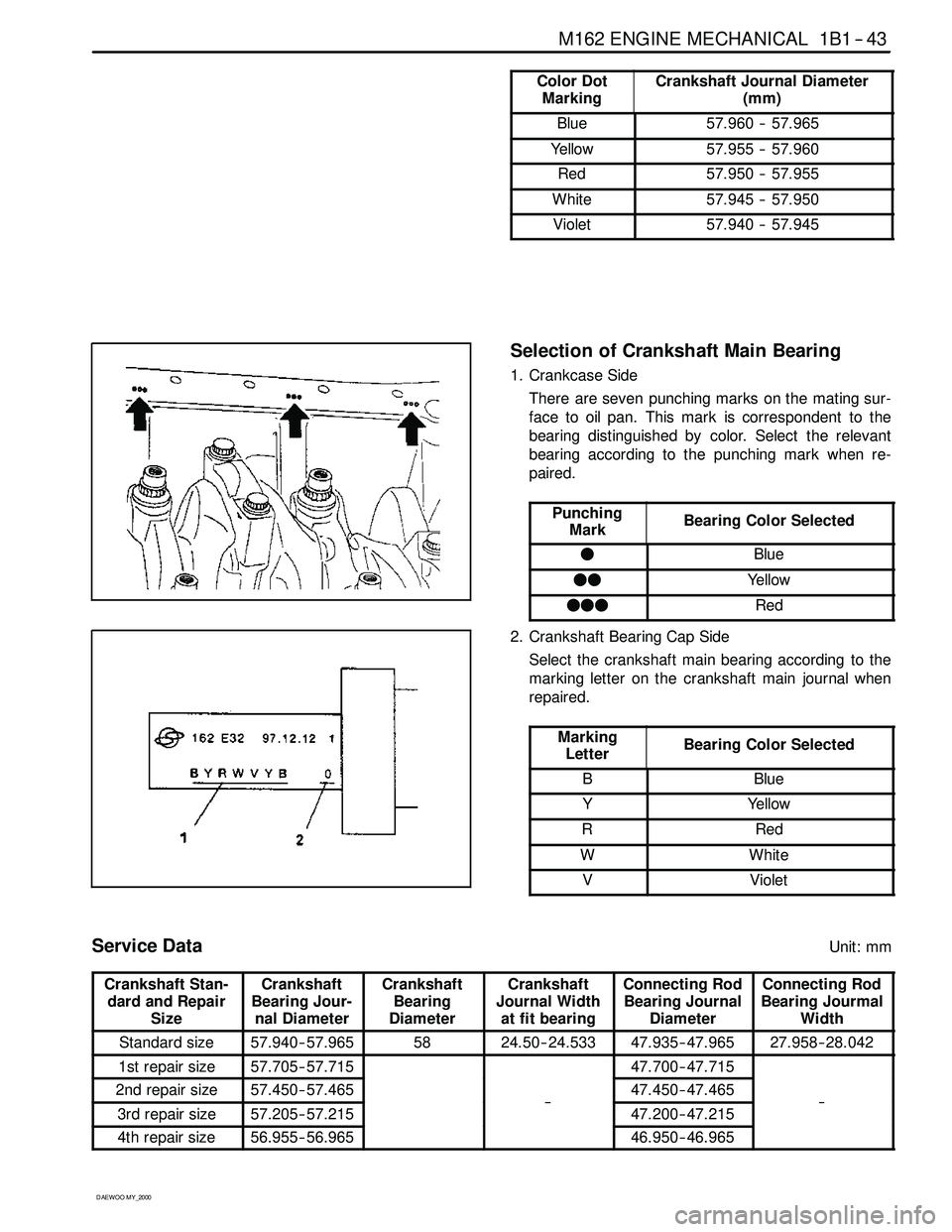

M162 ENGINE MECHANICAL 1B1 -- 43

D AEW OO M Y_2000

Color Dot

MarkingCrankshaft Journal Diameter

(mm)

Blue57.960 -- 57.965

Yellow57.955 -- 57.960

Red57.950 -- 57.955

White57.945 -- 57.950

Violet57.940 -- 57.945

Selection of Crankshaft Main Bearing

1. Crankcase Side

There are seven punching marks on the mating sur-

face to oil pan. This mark is correspondent to the

bearing distinguished by color. Select the relevant

bearing according to the punching mark when re-

paired.

Punching

Mark

Bearing Color Selected

FBlue

FFYellow

FFFRed

2. Crankshaft Bearing Cap Side

Select the crankshaft main bearing according to the

marking letter on the crankshaft main journal when

repaired.

Marking

Letter

Bearing Color Selected

BBlue

YYellow

RRed

WWhite

VViolet

Service DataUnit: mm

Crankshaft Stan-

dard and Repair

SizeCrankshaft

Bearing Jour-

nal DiameterCrankshaft

Bearing

DiameterCrankshaft

Journal Width

at fit bearingConnecting Rod

Bearing Journal

DiameterConnecting Rod

Bearing Jourmal

Width

Standard size57.940-- 57.9655824.50-- 24.53347.935-- 47.96527.958-- 28.042

1st repair size57.705-- 57.71547.700-- 47.715

2nd repair size57.450-- 57.46547.450-- 47.465

3rd repair size57.205-- 57.215--47.200-- 47.215--

4th repair size56.955-- 56.96546.950-- 46.965

Page 78 of 2053

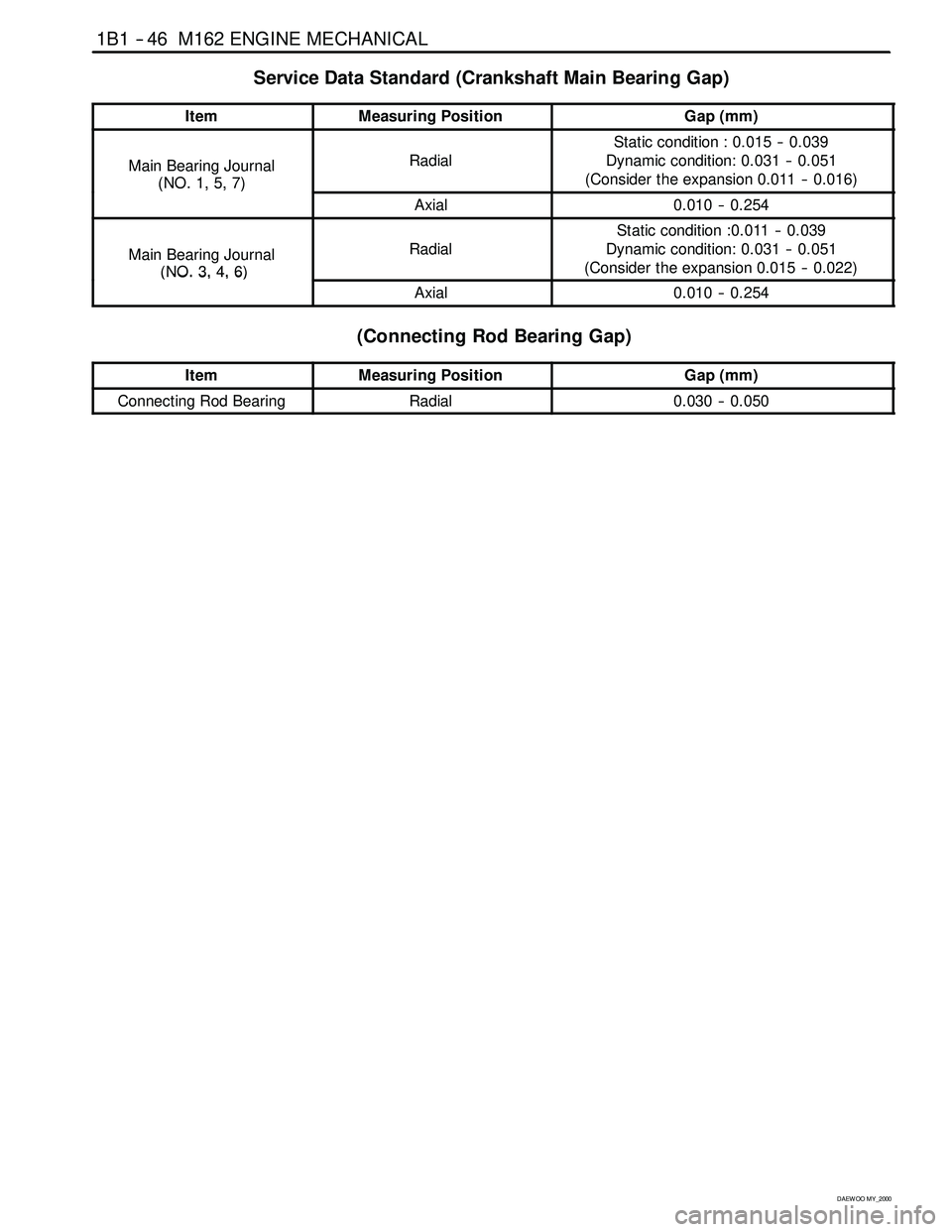

1B1 -- 46 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

Service Data Standard (Crankshaft Main Bearing Gap)

ItemMeasuring PositionGap (mm)

Main Bearing Journal

(NO.1,5,7)

Radial

Static condition : 0.015 -- 0.039

Dynamic condition: 0.031 -- 0.051

(Consider the expansion 0.011 -- 0.016)

(NO.1,5,7)

Axial0.010 -- 0.254

Main Bearing Journal

(NO. 3,4,6)

Radial

Static condition :0.011 -- 0.039

Dynamic condition: 0.031 -- 0.051

(Consider the expansion 0.015 -- 0.022)

(NO.3,4,6)

Axial0.010 -- 0.254

(Connecting Rod Bearing Gap)

ItemMeasuring PositionGap (mm)

Connecting Rod BearingRadial0.030 -- 0.050

Page 79 of 2053

M162 ENGINE MECHANICAL 1B1 -- 47

D AEW OO M Y_2000

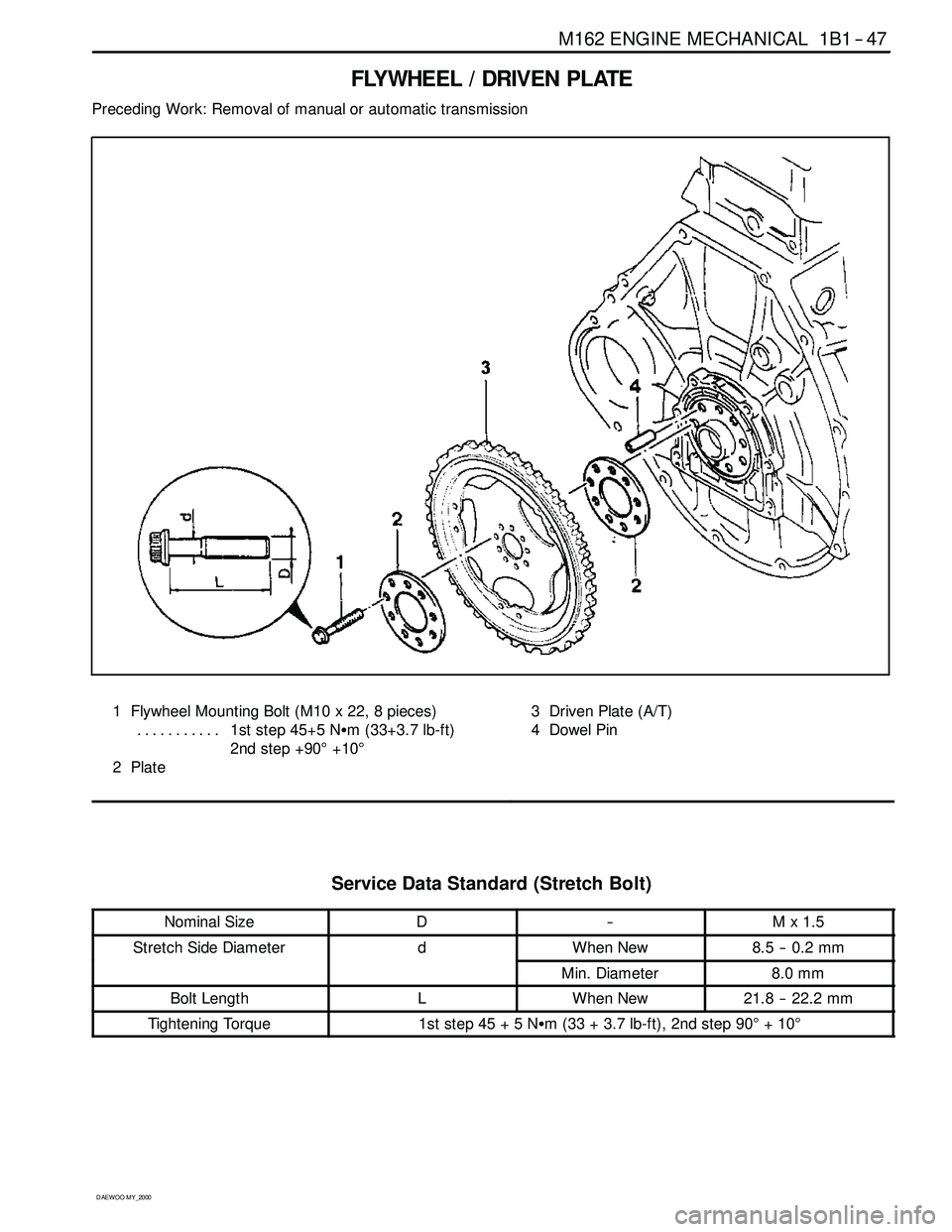

FLYWHEEL / DRIVEN PLATE

Preceding Work: Removal of manual or automatic transmission

1 Flywheel Mounting Bolt (M10 x 22, 8 pieces)

1st step 45+5 NSm (33+3.7 lb-ft) ...........

2nd step +90°+10°

2Plate3 Driven Plate (A/T)

4 Dowel Pin

Service Data Standard (Stretch Bolt)

Nominal SizeD--Mx1.5

Stretch Side DiameterdWhen New8.5 -- 0.2 mm

Min. Diameter8.0 mm

Bolt LengthLWhen New21.8 -- 22.2 mm

Tightening Torque1ststep45+5NSm (33 + 3.7 lb-ft), 2nd step 90°+10°

Page 109 of 2053

M162 ENGINE MECHANICAL 1B1 -- 83

D AEW OO M Y_2000

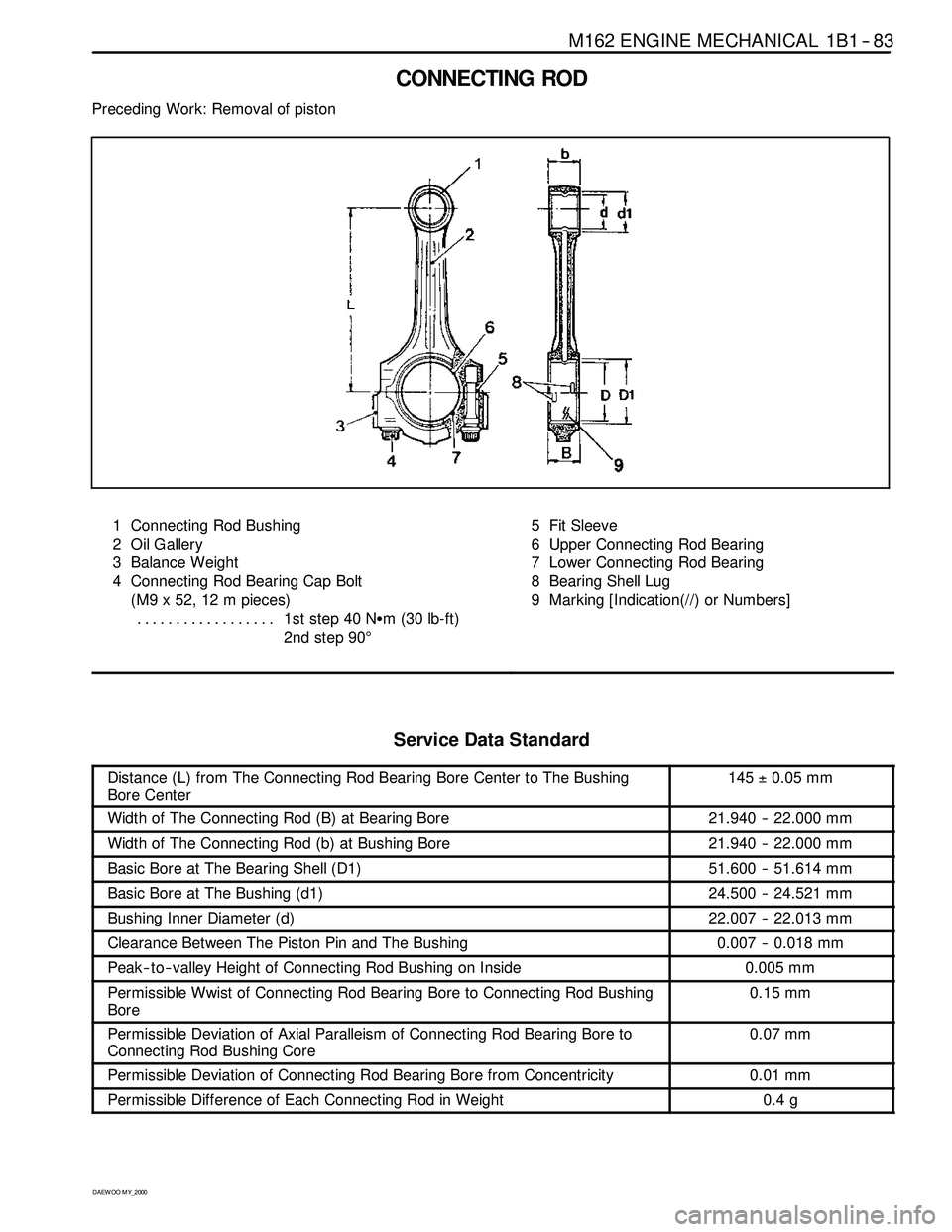

CONNECTING ROD

Preceding Work: Removal of piston

1 Connecting Rod Bushing

2 Oil Gallery

3 Balance Weight

4 Connecting Rod Bearing Cap Bolt

(M9 x 52, 12 m pieces)

1ststep40NSm (30 lb-ft) ..................

2nd step 90°5 Fit Sleeve

6 Upper Connecting Rod Bearing

7 Lower Connecting Rod Bearing

8 Bearing Shell Lug

9 Marking [Indication(//) or Numbers]

ServiceDataStandard

Distance (L) from The Connecting Rod Bearing Bore Center to The Bushing

Bore Center145±0.05 mm

Width of The Connecting Rod (B) at Bearing Bore21.940 -- 22.000 mm

Width of The Connecting Rod (b) at Bushing Bore21.940 -- 22.000 mm

Basic Bore at The Bearing Shell (D1)51.600 -- 51.614 mm

Basic Bore at The Bushing (d1)24.500 -- 24.521 mm

Bushing Inner Diameter (d)22.007 -- 22.013 mm

Clearance Between The Piston Pin and The Bushing0.007 -- 0.018 mm

Peak -- to-- valley Height of Connecting Rod Bushing on Inside0.005 mm

Permissible Wwist of Connecting Rod Bearing Bore to Connecting Rod Bushing

Bore0.15 mm

Permissible Deviation of Axial Paralleism of Connecting Rod Bearing Bore to

Connecting Rod Bushing Core0.07 mm

Permissible Deviation of Connecting Rod Bearing Bore from Concentricity0.01 mm

Permissible Difference of Each Connecting Rod in Weight0.4 g

Page 133 of 2053

M162 ENGINE MECHANICAL 1B1 -- 107

D AEW OO M Y_2000

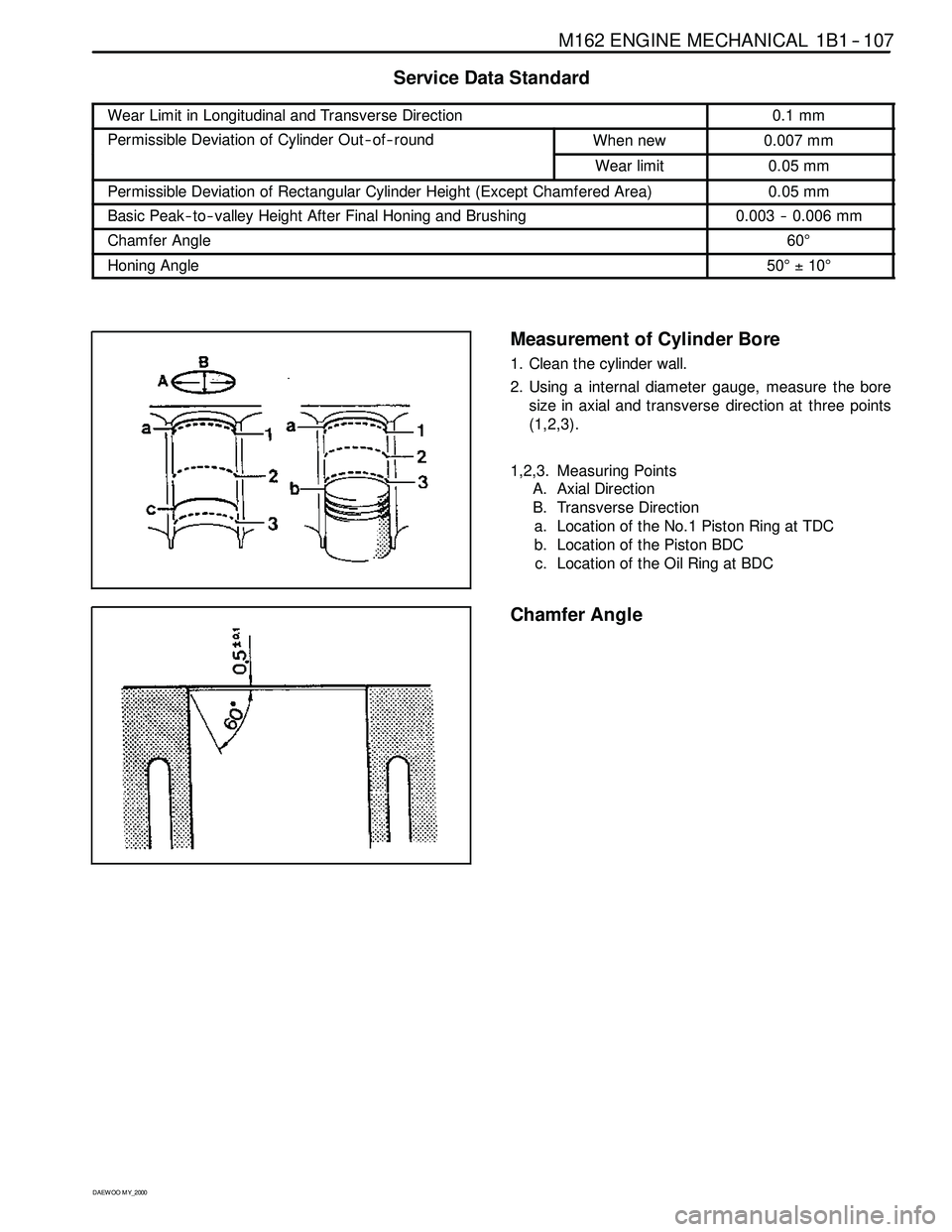

ServiceDataStandard

Wear Limit in Longitudinal and Transverse Direction0.1 mm

Permissible Deviation of Cylinder Out -- of -- roundWhen new0.007 mmy

Wear limit0.05 mm

Permissible Deviation of Rectangular Cylinder Height (Except Chamfered Area)0.05 mm

Basic Peak -- to-- valley Height After Final Honing and Brushing0.003 -- 0.006 mm

Chamfer Angle60°

Honing Angle50°±10°

Measurement of Cylinder Bore

1. Clean the cylinder wall.

2. Using a internal diameter gauge, measure the bore

size in axial and transverse direction at three points

(1,2,3).

1,2,3. Measuring Points

A. Axial Direction

B. Transverse Direction

a. Location of the No.1 Piston Ring at TDC

b. Location of the Piston BDC

c. Location of the Oil Ring at BDC

Chamfer Angle

Page 134 of 2053

1B1 -- 108 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

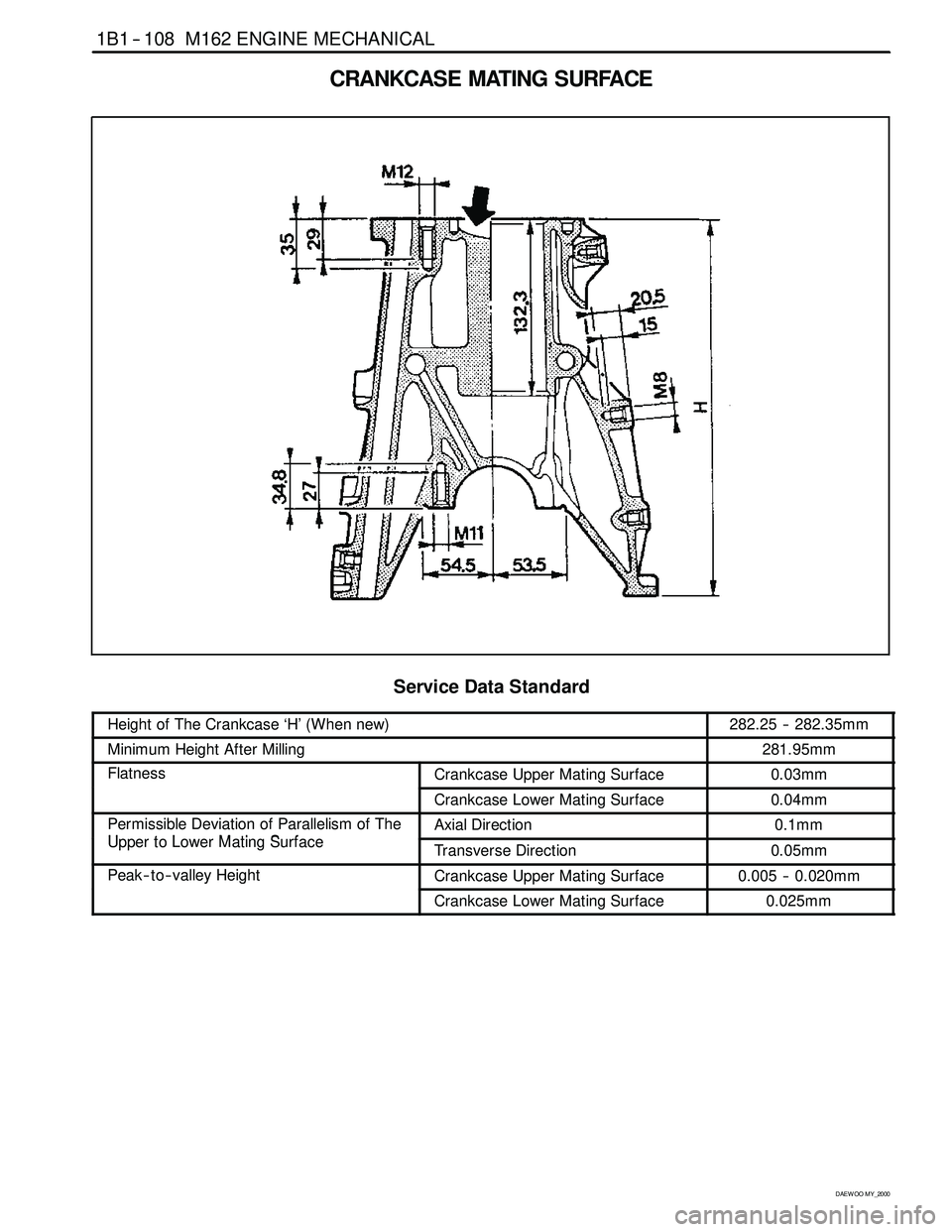

CRANKCASE MATING SURFACE

ServiceDataStandard

Height of The Crankcase ‘H’ (When new)282.25 -- 282.35mm

Minimum Height After Milling281.95mm

FlatnessCrankcase Upper Mating Surface0.03mm

Crankcase Lower Mating Surface0.04mm

Permissible Deviation of Parallelism of The

UtLMtiSf

Axial Direction0.1mm

Upper to Lower Mating SurfaceTransverse Direction0.05mm

Peak -- to-- valley HeightCrankcase Upper Mating Surface0.005 -- 0.020mmyg

Crankcase Lower Mating Surface0.025mm