check engine light SSANGYONG KORANDO 1997 Service Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1234 of 2053

AUTOMATIC TRANSMISSION 5A-139

SSANGYONG MY2002

DTC P1743 Solenoid 3 Circuit Short

If diagnosing for a possible intermittent short or

open condition, move or massage the wiring

harness while observing test equipment for a

change.

Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.3. Checks if the S3 circuit in the transmission is mal-

functioning.

4. Check cable in the transmission for short to

ground.

6. Check resistance between S3 terminal A and B.

Standard value is 22 - 30 Ω.

9. Check connections of other connectors.

- Go to Step 11 - 1Perform a Transmission Control Module (TCM) System

Check.

Is the check performed?

1. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

3. Record and then clear DTCs.

4. Operate the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool display P1743?

1. Turn the ignition OFF.

2. Disconnect the 10-way transmission connector.

(additional DTCs will set)

3. Connect Solenoid/Thermistor Electrical Tester

(STET) to the 10-way transmission connector of

transmission side and to the good ground.

4. Turn the mode knob of STET to 3 and push the red

button.

Does the bulb of close circuit on the solenoids side of

STET illuminate?

1. Remove the valve cover. Refer to the Transmission

in this section.

2. With a test light connected to B+, probe the wiring

harness from 10-way transmission connector to

Solenoid 3 (S3) on the valve body.

Does the test light illuminate?

Repair the short to ground in the wiring harness.

Is the repair complete?

Using a Digital Volt Meter (DVM), measure the resis-

tance between S3 terminal A and B.

Is the resistance within the specified value?

Replace the S3.

Is the action complete?

1. Disconnect the TCM connector A.

2. With a test light connected to B+, probe the wiring

harness from 10-way transmission connector

terminal 3 to TCM terminal A10.

Does the test light illuminate?

Check for a poor connection at the 10-way transmission

connector and TCM connector and repair the malfunc-

tioning terminals as necessary.

Is a repair necessary?

StepAction Value(s) Yes No

2

3

- Go to Step 2 Go to “TCM

Diagnostic

System Check”

- Go to Step 4 Go to Step 8

5

6 4

- Go to Step 11 -

7

8

9

- Go to Step 5 Go to Step 9

- Go to Step 11 Go to Step 10

- Go to Step 3Go to

“Diagnostic

Aids”

20 - 30 ΩGo to

“Diagnostic

Aids” Go to Step 7

- Go to Step 5 Go to Step 6

Page 1238 of 2053

AUTOMATIC TRANSMISSION 5A-143

SSANGYONG MY2002

DTC P1744 Solenoid 4 Circuit Short

Inspect the wiring for poor electrical connections

at the TCM and at the 10-way transmission

connector. Look for possible bent, backed out,

deformed or damaged terminals. Check for weak

terminal tension as well. Also check for chafed wires

that could short to bare metal or other wiring.

Inspect for broken wire inside the insulation.

If diagnosing for a possible intermittent short or

open condition, move or massage the wiring

harness while observing test equipment for a

change.Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.

3. Checks if the S4 circuit in the transmission is mal-

functioning.

4. Check cable in the transmission for short to

ground.

6. Check resistance between S4 terminal A and B.

Standard value is 22 - 30 Ω.

9. Check connections of other connectors.

- Go to Step 11 - 1Perform Transmission Control Module (TCM) System

Check.

Is the check performed?

1. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

3. Record and then clear DTCs.

4. Operate the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool display P1744?

1. Turn the ignition OFF.

2. Disconnect the 10-way transmission connector.

(additional DTCs will set)

3. Connect Solenoid/Thermistor Electrical Tester

(STET) to the 10-way transmission connector of

transmission side and to the good ground.

4. Turn the mode knob of STET to 4 and push the red

button.

Does the bulb of close circuit on the solenoids side of

STET illuminate?

1. Remove the valve cover. Refer to the Transmission

in this section.

2. With a test light connected to B+, probe the wiring

harness from 10-way transmission connector to

Solenoid 4 (S4) on the valve body.

Does the test light illuminate?

Repair the short to ground in the wiring harness.

Is the repair complete?

Using a Digital Volt Meter (DVM), measure the resis-

tance between S4 terminal A and B.

Is the resistance within the specified value?

Replace the S4.

Is the action complete?

1. Disconnect the TCM connector A.

2. With a test light connected to B+, probe the wiring

harness from 10-way transmission connector

terminal 4 to TCM terminal A4.

Does the test light illuminate?

StepAction Value(s) Yes No

2

3

-

Go to Step 2 Go to “TCM

Diagnostic

System Check”

- Go to Step 4 Go to Step 8

5

6 4

- Go to Step 5 Go to Step 6

- Go to Step 11 -

7

8

- Go to Step 5 Go to Step 9

- Go to Step 3Go to

“Diagnostic

Aids”

20 - 30 ΩGo to

“Diagnostic

Aids” Go to Step 7

Page 1242 of 2053

AUTOMATIC TRANSMISSION 5A-147

SSANGYONG MY2002

DTC P1745 Solenoid 5 Circuit Short

Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.

3. Checks if the S5 circuit in the transmission is mal-

functioning.4. Check cable in the transmission for short to

ground.

6. Check resistance between S5 terminal A and B.

Standard value is 3.6 - 5.5 Ω.

10. Check connections of other connectors.

- Go to Step 12 - 1Perform Transmission Control Module (TCM) System

Check.

Is the check performed?

1. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

3. Record and then clear DTCs.

4. Operate the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool display P1745?

1. Turn the ignition OFF.

2. Disconnect the 10-way transmission connector.

(additional DTCs will set)

3. Connect Solenoid/Thermistor Electrical Tester

(STET) to the 10-way transmission connector of

transmission side.

4. Turn the mode knob of STET to 5 and push the red

button.

Does the bulb of close circuit on the solenoids side of

STET illuminate?

1. Remove the valve cover. Refer to the Transmission

in this section.

2. With a test light connected to B+ probe the wiring

harnesses from 10-way transmission connector to

Solenoid 5 (S5) on the valve body.

Does the test light illuminate?

Repair the short to ground in the wiring harness.

Is the repair complete?

Using a Digital Volt Meter (DVM), measure the resis-

tance between S5 terminal A and B.

Is the resistance within the specified value?

Replace the S5.

Is the action complete?

1. Disconnect the TCM connector A.

2. With a test light connected to B+, probe the wiring

harness from 10-way transmission connector

terminal 5 to TCM terminal.

Does the test light illuminate?

Probe the wiring harness from 10-way transmission

connector terminal 8 to TCM terminal A1.

Does the test light illuminate?

Check for a poor connection at the 10-way transmission

connector and TCM connector and repair the malfunc-

tioning terminals as necessary.

Is a repair necessary?

StepAction Value(s) Yes No

2

3

-

Go to Step 2 Go to “TCM

Diagnostic

System Check”

- Go to Step 4 Go to Step 8

5

6 4

- Go to Step 5 Go to Step 6

- Go to Step 12 -

7

8

9

- Go to Step 5 Go to Step 9

10

- Go to Step 5 Go to Step 10

- Go to Step 12 Go to Step 11

- Go to Step 3Go to

“Diagnostic

Aids”

3.6 - 5.5 ΩGo to

“Diagnostic

Aids” Go to Step 7

Page 1249 of 2053

AUTOMATIC TRANSMISSION 5A-151

SSANGYONG MY2002

DTC P1746 Solenoid 6 Circuit Short

If diagnosing for a possible intermittent short or

open condition, move or massage the wiring

harness while observing test equipment for a

change.

Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.

3. Checks if the S6 circuit in the transmission is mal-

functioning.4. Check cable in the transmission for short to

ground.

6. Check resistance between S6 terminal A and B.

Standard value is 22 - 30 Ω.

9. Check connections of other connectors.

- Go to Step 11 - 1Perform a Transmission Control Module (TCM) System

Check.

Is the check performed?

1. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

3. Record and then clear DTCs.

4. Operate the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool display P1746?

1. Turn the ignition OFF.

2. Disconnect the 10-way transmission connector.

(additional DTCs will set)

3. Connect Solenoid/Thermistor Electrical Tester

(STET) to the 10-way transmission connector of

transmission side and to the good ground.

4. Turn the mode knob of STET to 6 and push the red

button.

Does the bulb of close circuit on the solenoids side of

STET illuminate?

1. Remove the valve cover. Refer to the Transmission

in this section.

2. With a test light connected to B+, probe the wiring

harness from 10-way transmission connector to

Solenoid 6 (S6) on the valve body.

Does the test light illuminate?

Repair the short to ground in the wiring harness.

Is the repair complete?

Using a Digital Volt Meter (DVM), measure the

resistance between S6 terminal A and B.

Is the resistance within the specified value?

Replace the S6.

Is the action complete?

1. Disconnect the TCM connector A.

2. With a test light connected to B+, probe the wiring

harness from 10-way transmission connector

terminal 6 to TCM terminal A12.

Does the test light illuminate?

Check for a poor connection at the 10-way transmission

connector and TCM connector and repair the malfunc-

tioning terminals as necessary.

Is a repair necessary?

StepAction Value(s) Yes No

2

3

-

Go to Step 2 Go to “TCM

Diagnostic

System Check”

- Go to Step 4 Go to Step 8

5

6 4

- Go to Step 5 Go to Step 6

- Go to Step 11 -

7

8

9

- Go to Step 5 Go to Step 9

- Go to Step 11 Go to Step 10

- Go to Step 3Go to

“Diagnostic

Aids”

20 - 30 ΩGo to

“Diagnostic

Aids” Go to Step 7

Page 1253 of 2053

AUTOMATIC TRANSMISSION 5A-155

SSANGYONG MY2002

DTC P1747 Solenoid 7 Circuit Short

If diagnosing for a possible intermittent short or

open condition, move or massage the wiring

harness while observing test equipment for a

change.

Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.

3. Checks if the S7 circuit in the transmission is mal-

functioning.4. Check cable in the transmission for short to

ground.

7. Check resistance between S7 terminal A and B.

Standard value is 22 - 30 Ω.

10. Check connections of other connectors.

- Go to Step 15 Go to Step 7 1Perform a Transmission Control Module (TCM) System

Check.

Is the check performed?

1. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

3. Record and then clear DTCs.

4. Operate the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool display P1747?

1. Turn the ignition OFF.

2. Disconnect the 10-way transmission connector.

(additional DTCs will set)

3. Connect Solenoid/Thermistor Electrical Tester

(STET) to the 10-way transmission connector of

transmission side and to the good ground.

4. Turn the mode knob of STET to 7 and push the red

button.

Does the bulb of close circuit on the solenoids side of

STET illuminate?

1. Remove the pump assembly. Refer to the Pump in

this section.

2. With a test light connected to B+, probe the wiring

harness from 10-way transmission connector to

contact point attached onto the transmission case.

Does the test light illuminate?

Repair the short to ground in the wiring harness.

Is the repair complete?

With a test light connected to B+, probe the wiring

harness from contact point attached onto the trans-

mission case to S7.

Does the test light illuminate?

Using a Digital Volt Meter (DVM), measure the

resistance between S7 terminal A and B.

Is the resistance within the specified value?

Replace the S7.

Is the action complete?

1. Disconnect the TCM connector A.

2. With a test light connected to B+, probe the wiring

harness from 10-way transmission connector

terminal 7 to TCM terminal A9.

Does the test light illuminate?

StepAction Value(s) Yes No

2

3

-

Go to Step 2 Go to “TCM

Diagnostic

System Check”

- Go to Step 4 Go to Step 8

5

6 4

- Go to Step 5 Go to Step 6

- Go to Step 12 -

7

8

9

- Go to Step 12 -

- Go to Step 5 Go to Step 10

- Go to Step 3Go to

“Diagnostic

Aids”

20 - 30 ΩGo to

“Diagnostic

Aids”

Go to Step 8

Page 1509 of 2053

SSANGYONG MY2002

7A-8 HEATING AND VENTILATION SYSTEM

BLOWER ELECTRICAL

Refer to “Non A/C Diagrams” for electrical schematic diagram of the circuits described in this procedure.

Step

1

2

3

4

5

6

7

8

9

10

Action

Verify the customer’s complaint.

Are the customer’s concerns verified?

Does the blower run at any speed?

1. Disconnect the power connector from the blower

motor under the dashboard on the passenger side

of the vehicle.

2. Turn the ignition ON.

3. Turn the blower ON.

4. Test the voltage on the connector. The terminal

connected to the BLK/WHT wire is positive and

the terminal connected to the BLU/YEL wire is

negative.

Is the voltage within the specified range?

Replace the blower motor.

Is the repair complete?

Check fuse EF2 in the engine fuse block and F19 in

the I/P fuse block.

Is the fuse blown?

1. Turn the ignition ON.

2. Use a short detector to locate the following

possible short:

From the fuse EF2 to terminal 30 of blower

motor relay.

From the fuse F19 to terminal 86 of blower

motor relay.

From the terminal 87 of blower motor relay to

blower motor.

3. Repair any short.

4. Replace any blown fuse.

Is the repair complete?

1. Turn the ignition ON.

2. Remove the blower motor relay.

3. Using test light check the continuity between

following terminals and ground:

Terminal 30 of blower motor relay.

Terminal 86 of blower motor relay.

Does the test light come on?

Repair the open circuit.

Is the repair complete?

1. Turn the ignition OFF.

2. Set the blower motor switch at 4.

3. Using ohmmeter, measure the resistance between

terminal 85 of blower motor relay and ground.

Is the resistance within specified value?

Repair open circuit.

Is the repair complete?Yes

Go to Step 2

Go to Step 16

Go to Step 4

System OK

Go to Step 6

System OK

Go to Step 9

System OK

Go to Step 11

System OKNo

System OK

Go to Step 3

Go to Step 5

-

Go to Step 7

-

Go to Step 8

-

Go to Step 10

-

Value(s)

-

11 - 14 v

≈ 0 Ω

Page 1781 of 2053

SQUEAKS AND RATTLES 9K-3

SSANGYONG MY2002

Check for a lack of lubrication of the door hinge pins.ChecksActionOperate the doors and listen for squeaks.

Lubricate the door hinge pins with light oil and coat

with lithium grease.

Squeak Coming From Console When Shifting Manual Transaxle

(Condition Occurs In Cold Weather with a Cold Engine)

Check the manual transaxle control lever lower boot.ChecksActionMove the control lever between gears and listen for

squeaks.

Remove the floor console and replace the lower shift

boot or apply talcum powder to the lower shift boot.

Squeak When Operating Doors

Check for vibration of the fuse box cover against the

instrument panel side trim.ChecksActionTap on thecoverwith a fingerandlisten fora buzz.

Apply 6.35 mm (0.250 inch) by 25.4 mm (1.00 inch)

felt pads to the side trim where the cover makes

contact.

Squeak Coming From Instrument Cluster Trim Plate

Check for rubbing of the cluster trim plate on the

instrument panel.ChecksActionTest drive the vehicle in order to verify this condi-

tion.

Remove the instrument cluster trim plate and install

felt tape to the edges.

Buzz From the Left Side of Instrument Panel

Check the door lock solenoid.

Check for rattling electrical connectors inside the door

trim panel.ChecksActionRemove the door trim panel and check if the sole-

noid is loose.

Tighten the solenoid bolts.

Tap on the trim panel and listen for a rattle.

Remove the trim panel and wrap foam padding

around the connectors as required.

Rattle Coming From Door

Page 1864 of 2053

HOW TO USE ELECTRICAL WIRING DIAGRAM HOW TO USE ELECTRICAL WIRING DIAGRAM HOW TO USE ELECTRICAL WIRING DIAGRAM HOW TO USE ELECTRICAL WIRING DIAGRAM

HOW TO USE ELECTRICAL WIRING DIAGRAM

1-3 1-31-3 1-3

1-3

Connector

Diode

Fuse in engine room fuse & relay box

Fuse in passenger room fuse box

GroundJoint - Inline wire connected pointSplice pack(Junction connector) C CC C

C

D DD D

D

Ef EfEf Ef

Ef

F FF F

F

G GG G

G

J JJ J

J

S SS S

S

2. 2.2. 2.

2.

CIRCUIT IDENTIFICA CIRCUIT IDENTIFICACIRCUIT IDENTIFICA CIRCUIT IDENTIFICA

CIRCUIT IDENTIFICA

TION SYMBOL TION SYMBOLTION SYMBOL TION SYMBOL

TION SYMBOL

3. 3.3. 3.

3.

FUNCTION OF PO FUNCTION OF POFUNCTION OF PO FUNCTION OF PO

FUNCTION OF PO

WER SUPPL WER SUPPLWER SUPPL WER SUPPL

WER SUPPL

Y LINE (NUMBER) Y LINE (NUMBER)Y LINE (NUMBER) Y LINE (NUMBER)

Y LINE (NUMBER)

IDENTIFICATION IDENTIFICATIONIDENTIFICATION IDENTIFICATION

IDENTIFICATION

SYMBOL SYMBOLSYMBOL SYMBOL

SYMBOLMEANING MEANINGMEANING MEANING

MEANINGPower supply No Power supply NoPower supply No Power supply No

Power supply No

Power supply condition Power supply conditionPower supply condition Power supply condition

Power supply condition

Battery Voltage(B+) supply in Ignition Switch "ON" and "ST" (IGN 1)Battery Voltage(B+) supply in Ignition Switch "ON" (IGN 2)

Battery Voltage(B+) supply in Ignition Switch "ON" and "ACC"

Battery Voltage(B+) supply directly regardless of Ignition Switch

Ground connected to battery(–)Battery Voltage(B+) supply in Head Lamp Switch 1st and 2nd step(Illumination circuit) 15 1515 15

15

15A 15A15A 15A

15A

15C 15C15C 15C

15C

30 3030 30

30

31 3131 31

31

58 5858 58

58

Abbreviation AbbreviationAbbreviation Abbreviation

Abbreviation

Color ColorColor Color

Color

Brown

Green

Violet

Pink

White

Orange

Light Green Br BrBr Br

Br

G GG G

G

V VV V

V

P PP P

P

W WW W

W

Or OrOr Or

Or

Lg LgLg Lg

Lg

Abbreviation AbbreviationAbbreviation Abbreviation

Abbreviation

Color ColorColor Color

Color

Sky Blue

Red

Blue

Yellow

Gray

Black Sb SbSb Sb

Sb

R RR R

R

L LL L

L

Y YY Y

Y

Gr GrGr Gr

Gr

B BB B

B

4. 4.4. 4.

4.

WIRING HARNESS COLOR IDENTIFICA WIRING HARNESS COLOR IDENTIFICAWIRING HARNESS COLOR IDENTIFICA WIRING HARNESS COLOR IDENTIFICA

WIRING HARNESS COLOR IDENTIFICA

TION TIONTION TION

TION5. 5.5. 5.

5.

HO HOHO HO

HO

W W W W

W

T TT T

T

O CHECK O CHECK O CHECK O CHECK

O CHECK

TERMINAL NUMBER OF CONNECT TERMINAL NUMBER OF CONNECTTERMINAL NUMBER OF CONNECT TERMINAL NUMBER OF CONNECT

TERMINAL NUMBER OF CONNECT

OR OROR OR

OR

- Terminal number is given based on Female Terminal Connector

ex) Terminal Number 4 of C901 connection

LockingTerminal Number 4

of total 6 pins

Male Connector

(W/H Fuel Tank)

4

C901

Female Connector

(W/H Floor) C901

W/H Floor132

465

Page 1865 of 2053

HOW TO USE ELECTRICAL WIRING DIAGRAM HOW TO USE ELECTRICAL WIRING DIAGRAM HOW TO USE ELECTRICAL WIRING DIAGRAM HOW TO USE ELECTRICAL WIRING DIAGRAM

HOW TO USE ELECTRICAL WIRING DIAGRAM

1-3 1-31-3 1-3

1-3

Connector

Diode

Fuse in engine room fuse & relay box

Fuse in passenger room fuse box

GroundJoint - Inline wire connected pointSplice pack(Junction connector) C CC C

C

D DD D

D

Ef EfEf Ef

Ef

F FF F

F

G GG G

G

J JJ J

J

S SS S

S

2. 2.2. 2.

2.

CIRCUIT IDENTIFICA CIRCUIT IDENTIFICACIRCUIT IDENTIFICA CIRCUIT IDENTIFICA

CIRCUIT IDENTIFICA

TION SYMBOL TION SYMBOLTION SYMBOL TION SYMBOL

TION SYMBOL

3. 3.3. 3.

3.

FUNCTION OF PO FUNCTION OF POFUNCTION OF PO FUNCTION OF PO

FUNCTION OF PO

WER SUPPL WER SUPPLWER SUPPL WER SUPPL

WER SUPPL

Y LINE (NUMBER) Y LINE (NUMBER)Y LINE (NUMBER) Y LINE (NUMBER)

Y LINE (NUMBER)

IDENTIFICATION IDENTIFICATIONIDENTIFICATION IDENTIFICATION

IDENTIFICATION

SYMBOL SYMBOLSYMBOL SYMBOL

SYMBOLMEANING MEANINGMEANING MEANING

MEANINGPower supply No Power supply NoPower supply No Power supply No

Power supply No

Power supply condition Power supply conditionPower supply condition Power supply condition

Power supply condition

Battery Voltage(B+) supply in Ignition Switch "ON" and "ST" (IGN 1)Battery Voltage(B+) supply in Ignition Switch "ON" (IGN 2)

Battery Voltage(B+) supply in Ignition Switch "ON" and "ACC"

Battery Voltage(B+) supply directly regardless of Ignition Switch

Ground connected to battery(–)Battery Voltage(B+) supply in Head Lamp Switch 1st and 2nd step(Illumination circuit) 15 1515 15

15

15A 15A15A 15A

15A

15C 15C15C 15C

15C

30 3030 30

30

31 3131 31

31

58 5858 58

58

Abbreviation AbbreviationAbbreviation Abbreviation

Abbreviation

Color ColorColor Color

Color

Brown

Green

Violet

Pink

White

Orange

Light Green Br BrBr Br

Br

G GG G

G

V VV V

V

P PP P

P

W WW W

W

Or OrOr Or

Or

Lg LgLg Lg

Lg

Abbreviation AbbreviationAbbreviation Abbreviation

Abbreviation

Color ColorColor Color

Color

Sky Blue

Red

Blue

Yellow

Gray

Black Sb SbSb Sb

Sb

R RR R

R

L LL L

L

Y YY Y

Y

Gr GrGr Gr

Gr

B BB B

B

4. 4.4. 4.

4.

WIRING HARNESS COLOR IDENTIFICA WIRING HARNESS COLOR IDENTIFICAWIRING HARNESS COLOR IDENTIFICA WIRING HARNESS COLOR IDENTIFICA

WIRING HARNESS COLOR IDENTIFICA

TION TIONTION TION

TION5. 5.5. 5.

5.

HO HOHO HO

HO

W W W W

W

T TT T

T

O CHECK O CHECK O CHECK O CHECK

O CHECK

TERMINAL NUMBER OF CONNECT TERMINAL NUMBER OF CONNECTTERMINAL NUMBER OF CONNECT TERMINAL NUMBER OF CONNECT

TERMINAL NUMBER OF CONNECT

OR OROR OR

OR

- Terminal number is given based on Female Terminal Connector

ex) Terminal Number 4 of C901 connection

LockingTerminal Number 4

of total 6 pins

Male Connector

(W/H Fuel Tank)

4

C901

Female Connector

(W/H Floor) C901

W/H Floor132

465

Page 1898 of 2053

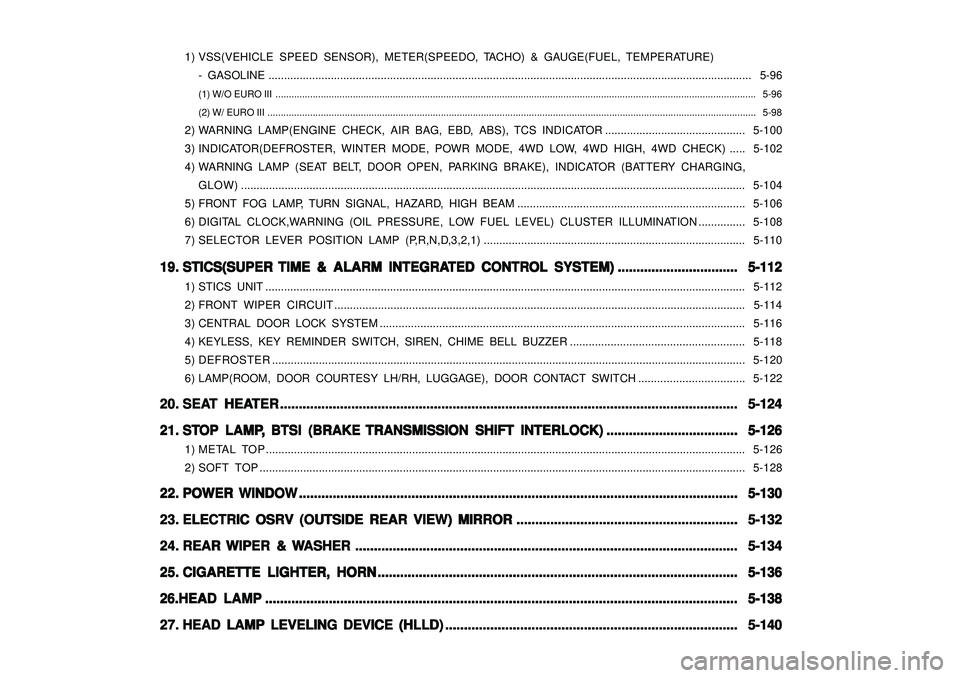

1) VSS(VEHICLE SPEED SENSOR), METER(SPEEDO, TACHO) & GAUGE(FUEL, TEMPERATURE)

- GASOLINE ........................................................................................................................................................... 5-96

(1) W/O EURO III .................................................................................................................................................................................... 5-96

(2) W/ EURO III ....................................................................................................................................................................................... 5-98

2) WARNING LAMP(ENGINE CHECK, AIR BAG, EBD, ABS), TCS INDICATOR............................................. 5-100

3) INDICATOR(DEFROSTER, WINTER MODE, POWR MODE, 4WD LOW, 4WD HIGH, 4WD CHECK)..... 5-102

4) WARNING LAMP (SEAT BELT, DOOR OPEN, PARKING BRAKE), INDICATOR (BATTERY CHARGING,

GLOW).................................................................................................................................................................. 5-104

5) FRONT FOG LAMP, TURN SIGNAL, HAZARD, HIGH BEAM ......................................................................... 5-106

6) DIGITAL CLOCK,WARNING (OIL PRESSURE, LOW FUEL LEVEL) CLUSTER ILLUMINATION............... 5-108

7) SELECTOR LEVER POSITION LAMP (P,R,N,D,3,2,1).................................................................................... 5-110

19. 19.19. 19.

19.

STICS(SUPER STICS(SUPER STICS(SUPER STICS(SUPER

STICS(SUPER

TIME & ALARM INTEGRA TIME & ALARM INTEGRATIME & ALARM INTEGRA TIME & ALARM INTEGRA

TIME & ALARM INTEGRA

TED CONTR TED CONTRTED CONTR TED CONTR

TED CONTR

OL SYSTEM) OL SYSTEM)OL SYSTEM) OL SYSTEM)

OL SYSTEM)

................................ ................................................................ ................................

................................

5-112 5-112 5-112 5-112

5-112

1) STICS UNIT .......................................................................................................................................................... 5-112

2) FRONT WIPER CIRCUIT.................................................................................................................................... 5-114

3) CENTRAL DOOR LOCK SYSTEM ..................................................................................................................... 5-116

4) KEYLESS, KEY REMINDER SWITCH, SIREN, CHIME BELL BUZZER ........................................................ 5-118

5) DEFROSTER........................................................................................................................................................ 5-120

6) LAMP(ROOM, DOOR COURTESY LH/RH, LUGGAGE), DOOR CONTACT SWITCH .................................. 5-122

20. 20.20. 20.

20.

SEA SEASEA SEA

SEA

T HEA T HEAT HEA T HEA

T HEA

TER TERTER TER

TER

.......................................................................................................................... .................................................................................................................................................................................................................................................... ..........................................................................................................................

..........................................................................................................................

5-124 5-124 5-124 5-124

5-124

21. 21.21. 21.

21.

ST STST ST

ST

OP LAMP OP LAMPOP LAMP OP LAMP

OP LAMP

, ,, ,

,

BTSI (BRAKE BTSI (BRAKE BTSI (BRAKE BTSI (BRAKE

BTSI (BRAKE

TRANSMISSION SHIFT INTERLOCK) TRANSMISSION SHIFT INTERLOCK)TRANSMISSION SHIFT INTERLOCK) TRANSMISSION SHIFT INTERLOCK)

TRANSMISSION SHIFT INTERLOCK)

................................... ...................................................................... ...................................

...................................

5-126 5-126 5-126 5-126

5-126

1) METAL TOP .......................................................................................................................................................... 5-126

2) SOFT TOP............................................................................................................................................................ 5-128

22. 22.22. 22.

22.

POWER WINDOW POWER WINDOWPOWER WINDOW POWER WINDOW

POWER WINDOW

..................................................................................................................... .......................................................................................................................................................................................................................................... .....................................................................................................................

.....................................................................................................................

5-130 5-130 5-130 5-130

5-130

23. 23.23. 23.

23.

ELECTRIC OSRV (OUTSIDE REAR VIEW) MIRROR ELECTRIC OSRV (OUTSIDE REAR VIEW) MIRRORELECTRIC OSRV (OUTSIDE REAR VIEW) MIRROR ELECTRIC OSRV (OUTSIDE REAR VIEW) MIRROR

ELECTRIC OSRV (OUTSIDE REAR VIEW) MIRROR

........................................................... ...................................................................................................................... ...........................................................

...........................................................

5-132 5-132 5-132 5-132

5-132

24. 24.24. 24.

24.

REAR REAR REAR REAR

REAR

WIPER & WIPER & WIPER & WIPER &

WIPER &

W WW W

W

ASHER ASHERASHER ASHER

ASHER

...................................................................................................... ............................................................................................................................................................................................................ ......................................................................................................

......................................................................................................

5-134 5-134 5-134 5-134

5-134

25. 25.25. 25.

25.

CIGARETTE LIGHTER, HORN CIGARETTE LIGHTER, HORNCIGARETTE LIGHTER, HORN CIGARETTE LIGHTER, HORN

CIGARETTE LIGHTER, HORN

................................................................................................ ................................................................................................................................................................................................ ................................................................................................

................................................................................................

5-136 5-136 5-136 5-136

5-136

26.HEAD LAMP 26.HEAD LAMP26.HEAD LAMP 26.HEAD LAMP

26.HEAD LAMP

.............................................................................................................................. ............................................................................................................................................................................................................................................................ ..............................................................................................................................

..............................................................................................................................

5-138 5-138 5-138 5-138

5-138

27. 27.27. 27.

27.

HEAD LAMP LEVELING DEVICE (HLLD) HEAD LAMP LEVELING DEVICE (HLLD)HEAD LAMP LEVELING DEVICE (HLLD) HEAD LAMP LEVELING DEVICE (HLLD)

HEAD LAMP LEVELING DEVICE (HLLD)

.............................................................................. ............................................................................................................................................................ ..............................................................................

..............................................................................

5-140 5-140 5-140 5-140

5-140