tow SSANGYONG KORANDO 1997 Service Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1085 of 2053

SSANGYONG MY2002

4F-102 ABS AND TCS

ACCELERATION SENSOR

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the acceleration sensor connector. It

is located at the rear of audio system.

3. Remove the acceleration sensor mounting bolts.

Installation Notice

SYSTEM FUSE

Removal and Installation Procedure

The ABS/TCS system fuse, EF11, is located in the

engine fuse block. Counting from the battery toward

the surge tank, it is the first system fuse in the row.

KAA4F410

KAA4F420

Tightening Torque 7 Nm (62 lb-in)

4. Installation should follow the removal procedure in

the reverse order.

INDICATORS

The indicator lamps ABS and EBD and TCS are part of

the instrument cluster. Refer to Section 9E, instrumenta-

tion/ Driver information, for removal and replacement

details.

Page 1133 of 2053

AUTOMATIC TRANSMISSION 5A-39

SSANGYONG MY2002

4. Place a fluid container below the fluid filler plug.

5. Clean all dirt from around the fluid filler plug.

Remove the fluid filler plug. Clean the filler plug

and check that there is no damage to the ‘O’ ring.

If fluid drains through the filler hole the transmis-

sion may have been overfilled. When the fluid

stops draining the fluid level is correct. Install

the fluid filler plug and tighten it to 33 Nm (24

lb-ft).

If fluid does not drain through the filler hole, the

transmission fluid level may be low. Install the

filler pump into the filler hole. Lower the vehicle

with the filler pump still connected and partially

fill the fluid through the filler hole.

Start the vehicle in P (Park) with the parking

brake and the brake applied. With the engine

idling, move the gear shift. control lever through

the gear ranges, pausing a few seconds in each

range and adding the fluid until gear application

is felt.

Return the gear shift lever to P (Park).

Turn the engine OFF and raise the vehicle. When

the three minutes passed after the engine

stopped, remove the filler pump.

Check if the fluid level is aligned with the bottom

of the filler hole. If not, add a small quantity of

fluid to the correct level. Install the fluid filler

plug and tighten it to 33 Nm (24 lb-ft).

If fluid does not drain through the filler hole al-

though adding a total of 1.5 liters, the transmission

should be inspected for fluid leaks and any leaks

should be fixed before setting the transmission

fluid level.

6. When the fluid level checking procedure is com-

pleted, wipe any fluid around the filler plug with a

rag or shop towel.

Fluid Level Set After Service

1. Depending on the service procedure performed,

add the following amounts of fluid through the filler

plug hole prior to adjusting the fluid level:

Converter empty 8.0 liters (8.5 quarts)

Converter full 3.8 liters (4.0 quarts)

2. Follow steps 1 through 4 of the Fluid Level Diagnosis

Procedure.

3. Clean all dirt from around the fluid filler plug.

Remove the fluid filler plug. Clean the filler plug

and check that there is no damage to the ‘O’ ring.

4. Lower the vehicle with the filler pump still connected

and start the vehicle in P (Park) with the parking

brake and the brake applied. With the engine idling,

move the gear shift control lever through the gear

ranges, pausing a few seconds in each range and

adding the fluid until gear application is felt.Then add an additional 0.5 litres of fluid. Return

the gear shift lever to P (Park). Turn the engine OFF

and raise the vehicle. Install the fluid filler plug and

tighten it to 33 Nm (24 lb-ft).

5. Drive the vehicle at 3.5 to 4.5 kilometers with light

throttle so that the engine does not exceed 2500

rpm.

This should result in the transmission temperature

being in the range 50 - 60 °C (82 - 140 °F). With the

brake applied, move the shift lever through the gear

ranges, pausing a few seconds in each range at

the engine idling.

6. Return the gear shift lever to P (Park).

Turn the en-gine OFF and raise the vehicle on the

hoist, if applicable, ensuring the vehicle is level.

When the three minutes passed after the engine

stopped, remove the filler plug.

Check if the fluid level is aligned with the bottom of

the filler hole. If not, add a small quantity of fluid to

the correct level. Install the fluid filler plug and

tighten it to 33 Nm (24 lb-ft).

7. Wipe any fluid around the filler plug with a rag or

shop towel.

FLUID LEAK DIAGNOSIS AND

REPAIR

The cause of most external leaks can generally be lo-

cated and repaired with the transmission in the vehicle.

Methods for Locating Leaks

General Method

1. Verify that the leak is transmission fluid.

2. Thoroughly clean the suspected leak area.

3. Drive the vehicle for approximately 25 km (15 miles)

or until the transmission reaches normal operating

temperature (88 °C, 190 °F).

4. Park the vehicle over clean paper or cardboard.

5. Turn the engine OFF and look for fluid spots on the

paper.

6. Make the necessary repairs to correct the leak.

Powder Method

1. Thoroughly clean the suspected leak area.

2. Apply an aerosol type powder (foot powder) to the

suspected leak area.

3. Drive the vehicle for approximately 25 km (15 miles)

or until the transmission reaches normal operating

temperature (88 °C, 190 °F).

4. Turn the engine OFF.

5. Inspect the suspected leak area and trace the leak

path through the powder to find the source of the

leak.

6. Make the necessary repairs.

Page 1317 of 2053

MANUAL TRANSMISSION 5B-9

SSANGYONG MY2002

SEMI-REMOTE KIT DISASSEMBLY AND ASSEMBLY

YAD5B110

1 Remote Shift

2 Shift Lever

3 Shift Inner Boot

4 Lining Shift Socket

5 Control Housing Arm Insulator

6 Control Housing Arm

7 Bushing

8 Shift Rod Link

9 Washer

10 Clip

11 Shift Rod Pin

12 Cover Assembly

13 Shift Tower Cover14 Bolt

15 Breather Hose Bar

16 Control Shift Spring

17 Offset Control Lever

18 Retainer Ring

19 Pin

20 Shift Rail

21 Grove Pin

22 Pin & Clip

23 Joint Assembly

24 Joint Housing

25 Bushing

Page 1320 of 2053

SSANGYONG MY2002

5B-12 MANUAL TRANSMISSION

1 Remote Shift

2 Shift Lever

3 Shift Inner Boot

4 Lining Shift Socket

5 Control Housing Arm Insulator

6 Control Housing Arm

7 Bushing

8 Shift Rod Link

9 Washer

10 Clip

11 Shift Rod Pin

12 Cover Assembly

13 Shift Tower Cover

14 Bolt

15 Bleeder Hose Barb

16 Control Shift Spring

17 Offset Control Lever

18 Retainer Ring

19 Pin

20 Shift Rail

21 Groove Pin

22 Pin and Clip

23 Joint Assembly

24 Joint Housing

25 Bushing

26 Bolt

27 Bolt

28 O-ring

29 Shaft Rail

30 Case Cover

31 Cap Plug

32 Insert

33 Selecter Plate

34 Selecter Arm

35 Inlockter Plate

36 Selecter Arm Pin

37 Selecter Plate

38 Insert

39 Shift Fork

40 Output Shaft

41 Retainer Ring

42 Washer

43 Inner Corn

44 Outer-Race

45 1-2nd Blocking-Ring

46 Output Shaft Assembly

47 Insert

48 Ball

49 Spring

50 Reverse Sliding Gear

51 1-2nd Blocking-Ring

52 Outer Corn Race

53 Inner Corn

54 Sleeve Bearing

55 Sleeve

56 Needle Bearing

57 1st Speed Driven Gear58 Bearing Corn

59 Bearing Cup

60 Thrust Bearing

61 Thrust Race

62 Blocking-Ring

63 Spring

64 Insert

65 Synchronizer Sleeve

66 Spring

67 Blocking-Ring

68 Synchronizer

69 3rd Speed Gear

70 Needle Bearing

71 Spacer

72 Snap Ring

73 Washer

74 2nd Speed Gear

75 Needle Bearing

76 Spacer

77 Synchronizer Sleeve

78 Bearing

79 O-Ring

80 Bearing

81 Corn Bearing

82 Shaft Gear

83 Counter Shaft Gear

84 Corn Bearing

85 Roll Pin

86 Shift 5th Fork

87 Insert

88 Shift Rail

89 Reverse Fork

90 Spring

91 Retainer Ring

92 Shift Lever

93 5th Speed Driven Gear

94 Snap Ring

95 Bearing Cap

96 Shim

97 Rear Retainer

98 Bolt

99 5th Speed Driven Gear

100 Blocking 5th-Ring

101 Hub Bearing

102 Insert

103 Sleeve

104 Spring

105 Spring

106 Synchronizer

107 5th Synchronizer Retainer

108 Snap Ring

109 Oil Ring Funnel

110 Roll Pin

111 Reverse Idler Shaft

112 Reverse Idler Gear

113 O-Ring

114 Cross member Mounting Hole

Page 1333 of 2053

MANUAL TRANSMISSION 5B-25

SSANGYONG MY2002

7. Remove the offset lever from the extension

housing with the detent ball and spring.

8. Remove the roll pin from either the offset lever or

extension housing.

YAD5B510

YAD5B520

YAD5B540

YAD5B530

9. Remove the counter shaft thrust race and bearing.

10. Carefully remove the oiling funnel from the end of

the counter shaft.

11. Using a 10 mm wrench, remove the 10 bolts from

the shift cover.

Notice: For assembly, note the location of the two

bolts.

12. Lift up the shift cover after sliding it toward the

drain plug about 3 cm. At this time remove sealer

bond.

Page 1381 of 2053

TRANSFER CASE 5D1-11

SSANGYONG MY2002

DIAGNOSIS

While the transfer case control unit (TCCU) is active it

periodically monitors its inputs and outputs. If a fault

is detected the 4WD CHECK lamp is illuminated and a

fault code is stored in the TCCU memory.

When requested, fault codes are downloaded to scan

tool through a diagnostic connector (K-line) serial com

munication.

SELF-DIAGNOSTIC TESTS

TCCU Internal Function

When the ignition is turned on the TCCU tests its read

only memory (ROM) and random access memory

(RAM). If there is a fault, the TCCU immediately resets

itself and re-tests the ROM and RAM. If the fault

persists the TCCU continues to reset and re-test until

the fault is corrected or the ignition is turned off. All

TCCU functions are inhibited until the fault is corrected.

The 4WD CHECK lamp is not illuminated if there is a

ROM or RAM fault.

If the ROM/RAM passes the electronically erasable

programmable read only memory (EEPROM) is tested.

If there is a fault the 4WD CHECK lamp is illuminated

and the TCCU continues to operate using the default

calibration data stored in ROM. Fault codes are not

stored when there is an EEPROM fault.

An EEPROM fault can only be cleared by cycling

ignition OFF-ON.

Shift Motor Assembly Test

If the TCCU detects a shift motor or position encoder

fault continuously for one second the 4WD CHECK

lamp is turned on and the appropriate fault code is

stored in memory.

1. A shift motor fault when the motor is off is defined

as follows:

Motor HI-LO circuits are shorted to ground.

Motor LO-HI circuits are shorted to ground.

Motor circuits are open.

2. A shift motor fault when the motor is energized is

defined as follows:

Motor HI-LO circuits are shorted to ground.

Motor LO-HI circuits are shorted to ground.

Motor HI-LO circuits are shorted to motor LO

HI circuits.

Motor circuits are open.

3. A position encoder fault is defined as follows:

Any position code which does not correspond

to the valid 9 codes.

A short to ground on any of the encoder lines.

4. If no shifts are in progress when a failure occurs

the TCCU will not respond to any shift commands.5. If a shift command has been received but not

acted upon when a failure occurred the TCCU

would cancel the command and not respond to

any subsequent shift commands.

6. If a shift command is in progress when an invalid

position code is confirmed it will be halted and

the TCCU will turn the motor toward the high

position. Afterwards the TCCU will not respond to

any shift commands.

7. If the shift motor or position encoder assembly

failures, other than a motor failure which occurs

when the motor is energized, recovers continuously

for one second the TCCU will function normally.

The 4WD CHECK lamp is turned off but the fault

code will remain in memory.

8. A motor failure (i.e. open or short circuit) which

occurs when the motor is energized can only be

cleared by cycling the ignition OFF-ON.

Front Speed Sensor Test

If a front speed sensor fault is detected continuously

for 0.5 second the 4WD CHECK lamp is illuminated.

The TCCU then responds as follows:

1. If the system is in high range the TCCU uses the

rear speed sensor to determine the EMC touch off

level and wheel slip control is suspended.

2. If the system is in low range, the EMC duty cycle

is set to maximum, independent of vehicle speed,

until the system is shifted out of low range.

3. All electric shift activity is halted until the Ignition

is cycled. If a shift is in progress it will be

completed.

If the front speed sensor recovers continuously for O.5

second the TCCU will function normally. The 4WD

CHECK lamp is turned off but the fault code will remain

in memory.

Rear Speed Sensor Test

If a rear speed sensor fault is detected continuously

for 0.5 second the 4WD CHECK lamp is illuminated.

The TCCU then responds as follows:

1. If the system is in high range the TCCU uses the

front speed sensor to determine the EMC touch

off level and wheel slip control is suspended.

2. If the system is in low range, the EMC duty cycle

is set to maximum independent of vehicle speed

until the system is shifted out of low range.

3. All electric shift activity is halted until the Ignition

is cycled. If a shift is in progress it will be

completed.

4. If the rear speed sensor recovers continuously for

0.5 second the TCCU will function normally. The

4WD CHECK lamp is turned off but the fault code

will remain in memory.

Page 1397 of 2053

TRANSFER CASE 5D1-75

SSANGYONG MY2002

KAA5D510

KAA5D520

KAA5D460

3. Install the front output shaft oil seal using oil seal

installer, if removed.

4. Install the front output shaft/flange and install the

snap ring.

8. Assemble the planetary carrier to the sun gear and

input shaft and install the internal snap ring to the

planetary carrier.

9. While expanding the tanged snap ring with SST

snap ring pliers install planetary carrier assembly.

10. Install the high-low shift fork and collar as an

assembly.

Notice: Make sure that the nylon wear pads are

installed on the shift fork and snapped securely

into place. 6. Slide the sun gear, thrust plate and thrust washer

into position on the input shaft.

Notice: The recessed face of the sun gear and

the snap ring groove on the bearing outer race

should be toward the rear of the transfer case.

The stepped face of the thrust washer should face

toward the bearing.

7. Install the bearing over the input shaft using input

shaft bearing installer SST. Install the external snap

ring. 5. Install a new input shaft needle bearing and a new

bushing, if removed. Keep the following steps to

install the bearing and the bushing:

Position the input shaft on input shaft support.

Press a new needle bearing into the end of the

input shaft until it seats in the input shaft using

bearing remover/installer.

Press in a new bushing.

Page 1398 of 2053

SSANGYONG MY2002

5D1-76 TRANSFER CASE

KAA5D440

KAA5D430

KAA5D420

KAA5D410

11. Install the output shaft and oil pump in the input

shaft

Notice:

If a new pump is used, align the flat of the

output shaft and the flat of the pump. Slide the

pump onto the rear output shaft.

Do not remove the plastic insert from the bore

of the new pump. Discard it after it slides out

during pump installation to the rear output shaft.

While turning the output shaft, prime the pump

through the oil filter pickup tube or housing inlet

hole with clean ATF or equivalent.

12. Install the magnet in the slot in the front case just

above the oil filter leg.

13. Install the thrust washer on the rear output shaft.

14. Install the chain, drive sprocket and driven

sprocket as an assembly over the output shafts.

Notice: The driven sprocket on the front output

shaft must be installed with the marking REAR

facing toward the rear case, if so marked.

15. Install front propeller shaft speed sensor tooth

wheel onto the front output shaft.

19. Install cam and coil housing assembly onto rear

out-put shaft.

20. Install thrust bearing assembly onto output shaft.

21. Install the rear output shaft bearing, if removed.

Notice: Make sure that the bearing is not cocked

in the bore.

22. Install the internal snap ring that retains the

bearing to the rear case. 16. Install clutch pack assembly onto the rear output

shaft

17. Install snap ring onto the rear output shaft.

Notice: If the snap ring will not install, the thrust

washer inside the clutch pack may not be seated

properly.

18. Install wave spring, apply cam and balls.

Page 1399 of 2053

TRANSFER CASE 5D1-77

SSANGYONG MY2002

KAA5D420

KAA5D590

23. Install the clutch coil and tighten three bolts.

Installation Notice

Caution: Do not kink or trap the wire while

seating the clutch coil to the case.

24. Install the pin on the tang end of the helical cam

into the hole in the front case.

25. Position the torsion spring tangs so that they are

pointing toward the top side of the transfer case

and just touching the high-low shift fork.

Caution: Do not bend the helical cam during

installation to the front case because of possible

damage to the pin at the tang end of the motor

shaft.

26. Install the shift rail through the high-low shift fork

and make sure that the reverse gear shift rail is

seated in the front case bore.

27. Install rear propeller shaft speed sensor toothed

wheel, vehicle speedometer gear and rear output

shaft seal if removed. Use oil seal installer or equiv-

alent.

Tightening Torque8 - 11 Nm

(6 - 8 lb-ft)

Page 1402 of 2053

SSANGYONG MY2002

5D2-2 TRANSFER CASE (PART TIME - 4408)

2WD Drive (Rear

Wheel Drive)

4WD Drive (High

Speed)

4WD Drive (Low

Speed)

2WD Drive

↔ 4WD

Drive (High Speed)

2WD Drive, 4WD

Drive (High Speed)

↔ 4WD Drive (Low

Speed)

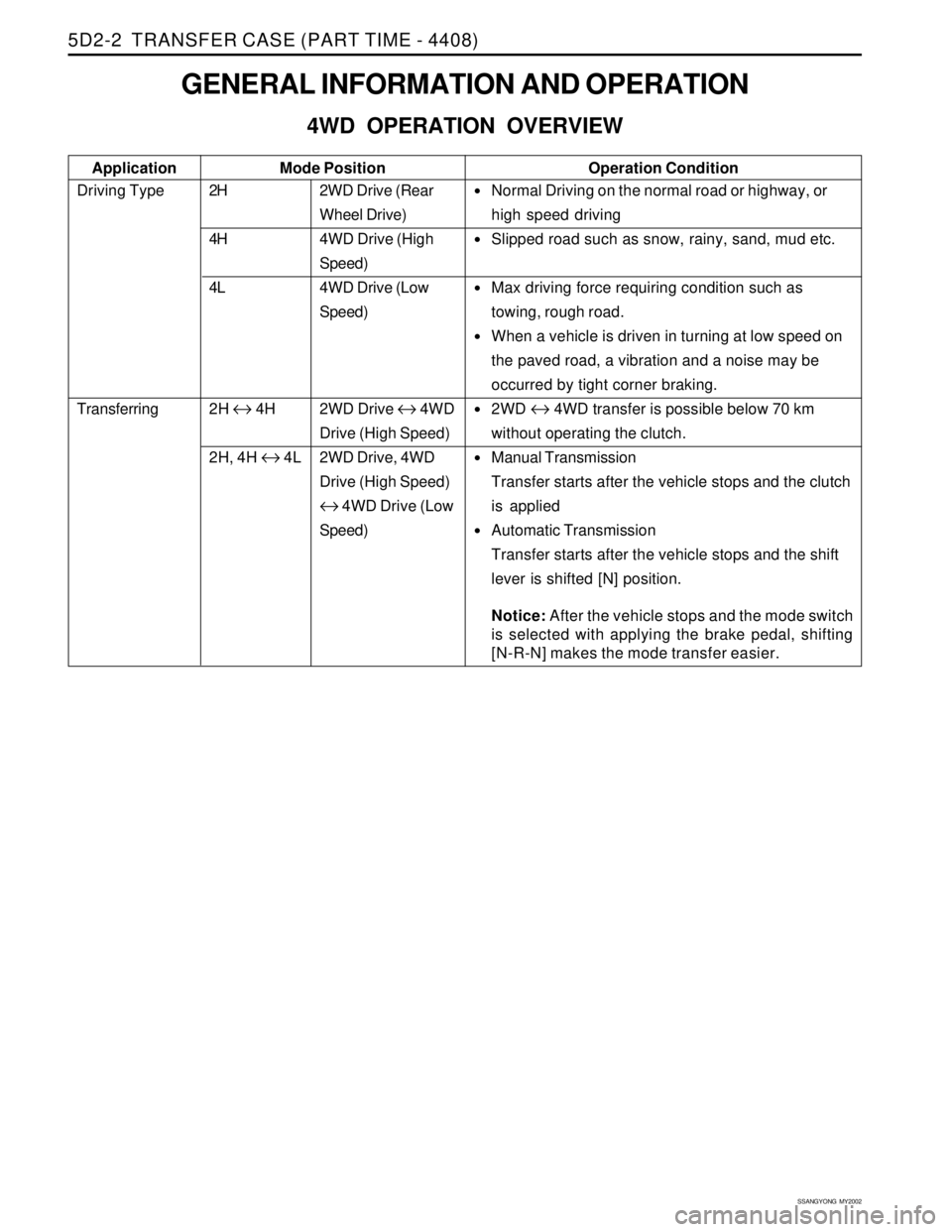

GENERAL INFORMATION AND OPERATION

4WD OPERATION OVERVIEW

Driving Type

Transferring2H

4H

4L

2H

↔ 4H

2H, 4H

↔ 4L Application

•Normal Driving on the normal road or highway, or

high speed driving

Slipped road such as snow, rainy, sand, mud etc.

Max driving force requiring condition such as

towing, rough road.

When a vehicle is driven in turning at low speed on

the paved road, a vibration and a noise may be

occurred by tight corner braking.

2WD ↔ 4WD transfer is possible below 70 km

without operating the clutch.

Manual Transmission

Transfer starts after the vehicle stops and the clutch

is applied

Automatic Transmission

Transfer starts after the vehicle stops and the shift

lever is shifted [N] position.

Notice: After the vehicle stops and the mode switch

is selected with applying the brake pedal, shifting

[N-R-N] makes the mode transfer easier.

Operation ConditionMode Position