engine SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 320 of 2053

M161 ENGINE MECHANICAL 1B2 -- 27

D AEW OO M Y_2000

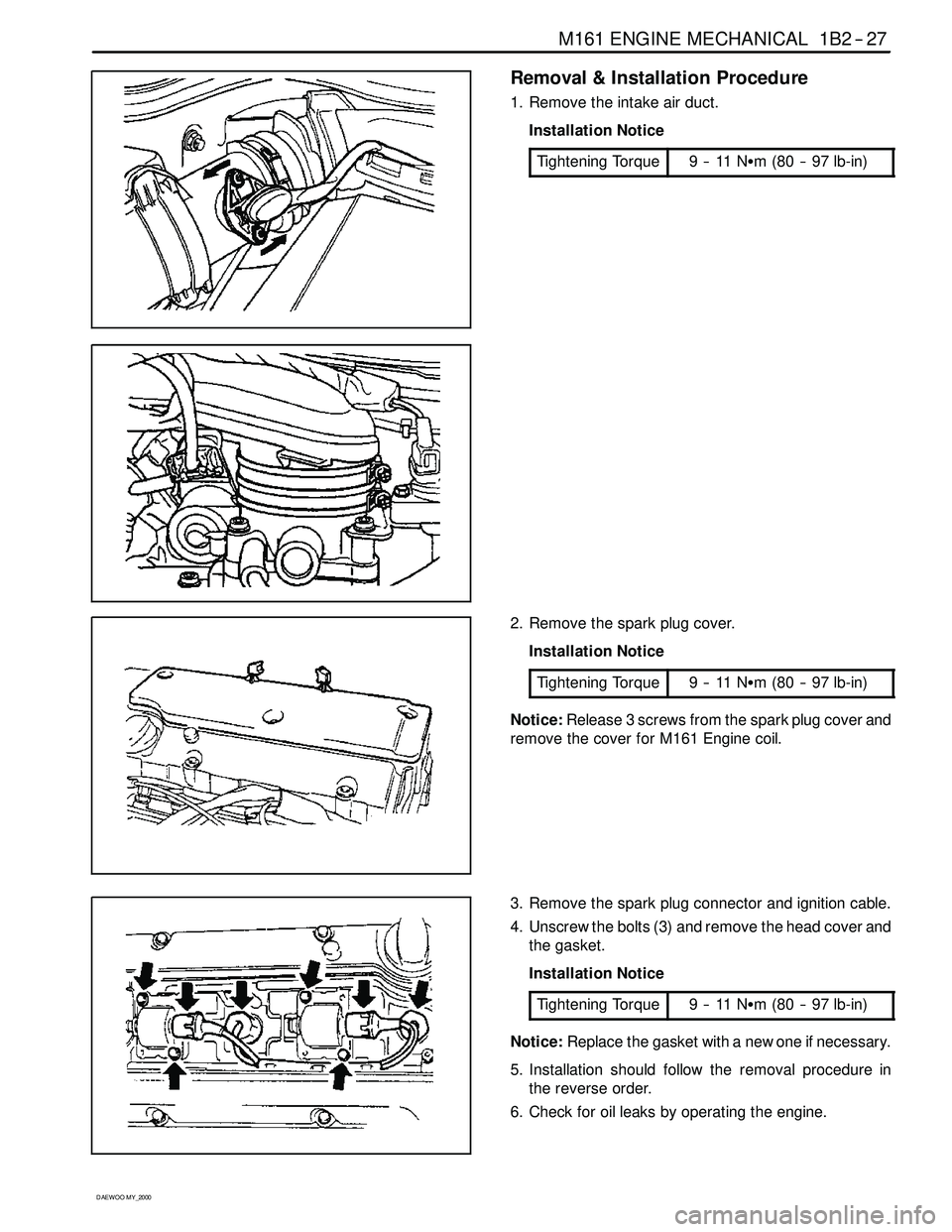

Removal & Installation Procedure

1. Remove the intake air duct.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

2. Remove the spark plug cover.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

Notice:Release 3 screws from the spark plug cover and

remove the cover for M161 Engine coil.

3. Remove the spark plug connector and ignition cable.

4. Unscrew the bolts (3) and remove the head cover and

the gasket.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

Notice:Replace the gasket with a new one if necessary.

5. Installation should follow the removal procedure in

the reverse order.

6. Check for oil leaks by operating the engine.

Page 321 of 2053

1B2 -- 28 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

CYLINDER HEAD FRONT COVER

Preceding Work: Removal of cylinder head cover

Removal of thermostat housing assembly

Removal of engine hanger bracket

1 Bolt (M6 X 16, 3 pieces)

9--11 NSm (80-- 97 lb-in) .....................

2 Camshaft Adjuster

3 Bolt (M8 X 35, 2 pieces)

22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) .............

4 Bolt (M6 X 22, 6 pieces)

9--11 NSm (80-- 97 lb-in) .....................5 Front Cover (E23 : M161.973)

6 Front Cover (E20 : M161.943)

7 Sleeve

8 O -- ring Replace............................

9 Thermostat Housing

Page 322 of 2053

M161 ENGINE MECHANICAL 1B2 -- 29

D AEW OO M Y_2000

Removal & Installation Procedure

1. Disconnect the camshaft adjuster connector and re-

move the camshaft adjuster (E23 engine only).

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

2. Remove the cylinder head front cover.

Installation Notice

Tightening

Torque (3)

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

Tightening

Torque (4)9--11NSm

(80 -- 97 lb-in)

Apply the sealant at the mating surface of the cylinder

head and the front cover.

3. Remove the O -- ring.

Installation Notice

Replace the O -- ring with new one and apply the seal-

ant.

4. Installation should follow the removal procedure in

the reverse order.

Page 323 of 2053

1B2 -- 30 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

CYLINDER HEAD

Preceding Work: Removal of cylinder head cover

Removal of cylinder head front cover

Removal of intake manifold

Removal of cylinder head lower line (intake manifold side)

1 Cylinder Head Bolt (M12 X 100, 10 pieces)

1ststep55NSm (41 lb-ft) ...................

2nd step 90°rotation added

3rdstep90°rotation added

3 Bolt (M8 X 35, 4 pieces)

22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) .............4 Camshaft Bearing cap

5 Cylinder Head

6 Gasket Replace...........................

7 Dowel Sleeve Note........................

Page 324 of 2053

M161 ENGINE MECHANICAL 1B2 -- 31

D AEW OO M Y_2000

Tools Required

617589001000 AllenWrenchSocket

116 589 20 33 00 Sliding Hammer

116 589 01 34 00 Threaded Pin

111 589 03 15 00 Holding Pin

Removal & Installation Procedure

1. Rotate the crankshaft so that the piston of number 1

cylinder is at ATDC 20.

2. Put the holding pin 111 589 03 15 00 into the cam-

shaft bearing cap (number 1, 6).

3. Put the alignment marks (arrows) on the timing chain

and camshaft sprocket.

4. Remove the chain tensioner.

Installation Notice

Tightening Torque

72 -- 88 NSm (53 -- 65 lb-ft)

5. Remove the exhaust camshaft sprocket.

Installation Notice

Ti

ghteningTo rque

1st step: 18 -- 22 NSm

(13 -- 16 lb-ft)

TighteningTorque

2nd step: 60°±5°

Notice:The flange bolt is designed to be used only

once, so always replace with new one.

Page 325 of 2053

1B2 -- 32 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

6. Remove the intake camshaft sprocket (E20 engine).

7. Remove the camshaft adjuster (E23, M161.970 en-

gine).

Installation Notice (Flange Bolt)

Ti

ghteningTo rque

1st step: 18 -- 22 NSm

(13 -- 16 lb-ft)

TighteningTorque

2nd step: 60°±5°

Notice:The flange bolt is designed to be used only

once, so always replace with new one.

1 Flange Shaft

2FlangeBolt

3 Compression Spring

4 Adjust Piston

5 Camshaft Sprocket

6 Seal Cover

7Nut

8. Remove the guide rail pin using the sliding hammer

116 589 20 33 00 (02) and the threaded pin 116 589

01 34 00 (03).

Notice:Apply the sealant on guide rail pin when installa-

tion.

9. Unscrew the bolts (A).

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

Bolt (A) : (M8 X 35, 4 pieces)

Page 326 of 2053

M161 ENGINE MECHANICAL 1B2 -- 33

D AEW OO M Y_2000

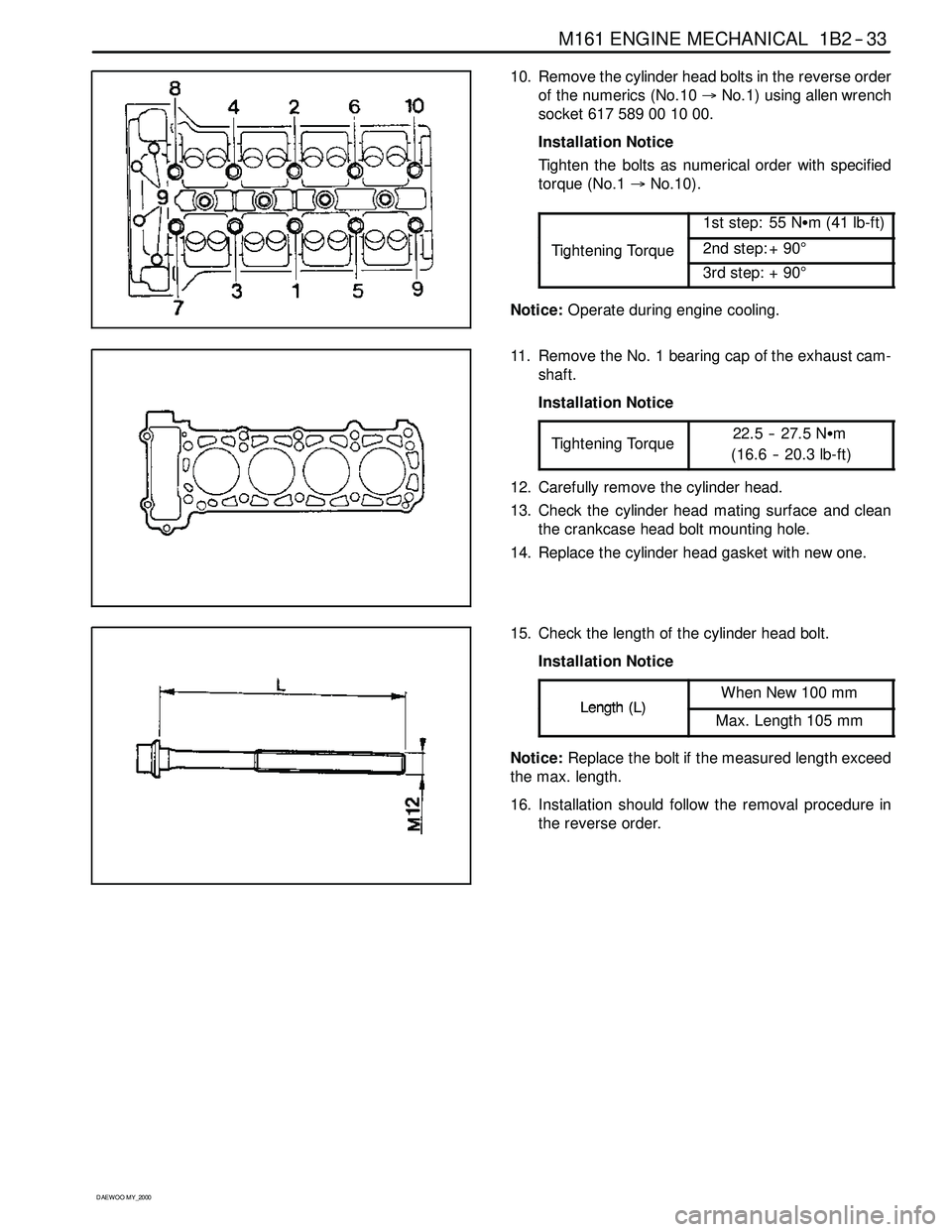

10. Remove the cylinder head bolts in the reverse order

of the numerics (No.10→No.1) using allen wrench

socket617589001000.

Installation Notice

Tighten the bolts as numerical order with specified

torque (No.1→No.10).

1st step: 55 NSm (41 lb-ft)

Tightening Torque2nd step: + 90°ggq

3rd step: + 90°

Notice:Operate during engine cooling.

11. Remove the No. 1 bearing cap of the exhaust cam-

shaft.

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

12. Carefully remove the cylinder head.

13. Check the cylinder head mating surface and clean

the crankcase head bolt mounting hole.

14. Replace the cylinder head gasket with new one.

15. Check the length of the cylinder head bolt.

Installation Notice

Length(L)When New 100 mmLength(L)Max. Length 105 mm

Notice:Replace the bolt if the measured length exceed

the max. length.

16. Installation should follow the removal procedure in

the reverse order.

Page 327 of 2053

1B2 -- 34 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

TIMING GEAR CASE COVER

Preceding Work: Removal of viscous clutch

Removal of cylinder head front cover

Removal of tensioning device

Removal of water pump

Removal of oil filter element

Removal of oil pan

Removal of generator bracket

1 Bolt (M8 X 60, 3 pieces)

22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) .............

2 Bolt (M8 X 75, 1 piece)

22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) .............3Seal

4 Timing gear case cover

5O--ring

6 Sleeve

Page 328 of 2053

M161 ENGINE MECHANICAL 1B2 -- 35

D AEW OO M Y_2000

Tools Required

116 589 20 33 00 Sliding Hammer

116 589 01 34 00 Threaded Pin

Removal & Installation Procedure

1. Remove the power steering belt pulley and A/C com-

pressor bracket.

2. Remove the oil line from power steering pump.

3. Rotate the crankshaft so that the piston of number,

cylinder is at ATDC20°.

4. Put the alignment marks (arrows) on the timing chain

and camshaft sprocket.

5. Remove the chain tensioner.

Installation Notice

Tightening Torque

72 -- 88 NSm (53 -- 65 lb-ft)

6. Remove the intake and exhaust camshaft sprocket

(remove the camshaft adjuster assembly in E23 en-

gine).

Installation Notice

Ti

ghteningTo rque

1st step: 18 -- 22 NSm

(13 -- 16 lb-ft)

TighteningTorque

2nd step: 60°±5°

Notice:The flange bolt is designed to be used only

once, so always replace with new one.

7. Remove the guide rail pin using the sliding hammer

116 589 20 33 00 (02) and the threaded pin 116 589

01 34 00 (03).

Notice:Apply the sealant on guide rail pin when installa-

tion.

Page 329 of 2053

1B2 -- 36 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

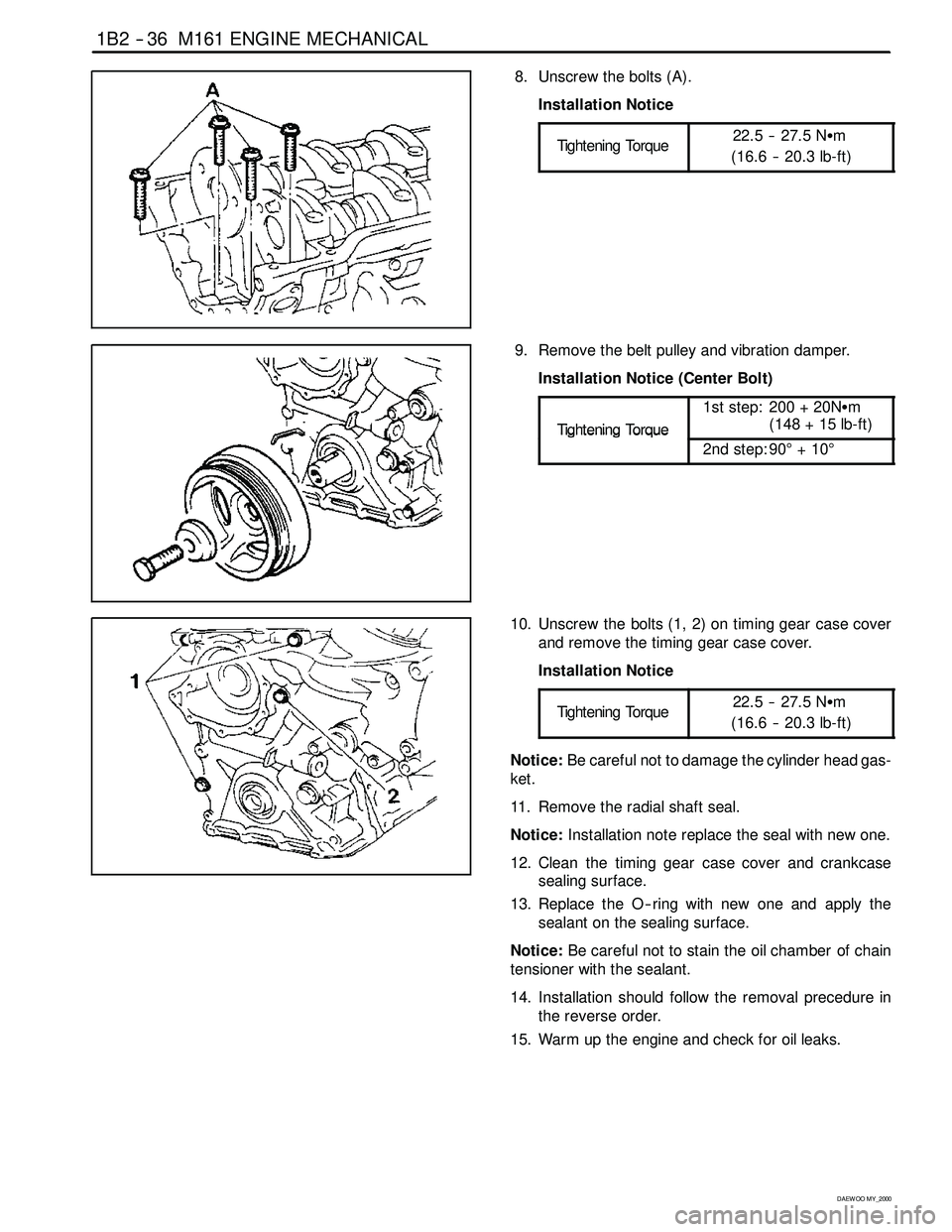

8. Unscrew the bolts (A).

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

9. Remove the belt pulley and vibration damper.

Installation Notice (Center Bolt)

Ti

ghteningTo rque

1st step: 200 + 20NSm

(148 + 15 lb-ft)

TighteningTorque

2nd step: 90°+10°

10. Unscrew the bolts (1, 2) on timing gear case cover

and remove the timing gear case cover.

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

Notice:Be careful not to damage the cylinder head gas-

ket.

11. Remove the radial shaft seal.

Notice:Installation note replace the seal with new one.

12. Clean the timing gear case cover and crankcase

sealing surface.

13. Replace the O -- ring with new one and apply the

sealant on the sealing surface.

Notice:Be careful not to stain the oil chamber of chain

tensioner with the sealant.

14. Installation should follow the removal precedure in

the reverse order.

15. Warm up the engine and check for oil leaks.