check transmission fluid SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 26 of 2053

1A1 -- 6 GENERAL ENGINE INFORMATION

D AEW OO M Y_2000

DIAGNOSIS

OIL LEAK DIAGNOSIS

Most fluid oil leaks are easily located and repaired by

visually finding the leak and replacing or repairing the

necessary parts. On some occasions a fluid leak may be

difficult to locate or repair. The following procedures may

help you in locating and repairing most leaks.

Finding the Leak

1. Identify the fluid. Determine whether it is engine oil,

automatic transmission fluid, power steering fluid,

etc.

2. Identify where the fluid is leaking from.

2.1 After running the vehicle at normal operating

temperature, park the vehicle over a large sheet

of paper.

2.2 Wait a few minutes.

2.3 You should be able to find the approximate loca-

tion of the leak by the drippings on the paper.

3. Visually check around the suspected component.

Check around all the gasket mating surfaces for

leaks. A mirror is useful for finding leaks in areas that

are hard to reach.

4. If the leak still cannot be found, it may be necessary

to clean the suspected area with a degreaser, steam

or spray solvent.

4.1 Clean the area well.

4.2 Dry the area.

4.3 Operate the vehicle for several miles at normal

operating temperature and varying speeds.

4.4 After operating the vehicle, visually check the

suspected component.

4.5 If you still cannot locate the leak, try using the

powder or black light and dye method.

Powder Method

1. Clean the suspected area.

2. Apply an aerosol-- type powder (such as foot powder)

to the suspected area.

3. Operate the vehicle under normal operating condi-

toins.

4. Visually inspect the suspected component. You

should be able to trace the leak path over the white

powder surface to the source.

Black Light and Dye Method

A dye and light kit is available for finding leaks, Refer to

the manufacturer ’s directions when using the kit.

1. Pour the specified amount of dye into the engine oil fill

tube.

2. Operate the vehicle normal operating conditions as

directed in the kit.

3. Direct the light toward the suspected area. The dyed

fluid willappear as a yellow path leading to the

source.

Repairing the Leak

Once the origin of the leak has been pinpointed and

traced back to its source, the cause of the leak must be

determined n order for it to be repaired properly. If a gas-

ket is replaced, but the sealing flange is bent, the new

gasket will not repair the leak. Thebent flange must be

repaired also. Before attempting to repair a leak, check

for the following conditions and correct them as they

may cause a leak.

Gaskets

DThe fluid level/pressure is too high.

DThe crankcase ventilation system is malfunctioning.

DThe fasteners are tightened improperly or the threads

are dirty or damaged.

DThe flanges or the sealing surface is warped.

DThere are scratches, burrs or other damage to the

sealing surface.

DThe gasket is damaged or worn.

DThere is cracking or porosity of the component.

DAn improper seal was used (where applicable).

Seals

DThe fluid level/pressure is too high.

DThe crankcase ventilation system is malfunctioning.

DThe seal bore is damaged (scratched, burred or

nicked).

DThe seal is damaged or worn.

DImproper installation is evident.

DThere are cracks in the components.

DThe shaft surface is scratched, nicked or damaged.

DA loose or worn bearing is causing excess seal wear.

Page 152 of 2053

1D1 -- 16 M162 ENGINE COOLING

D AEW OO M Y_2000

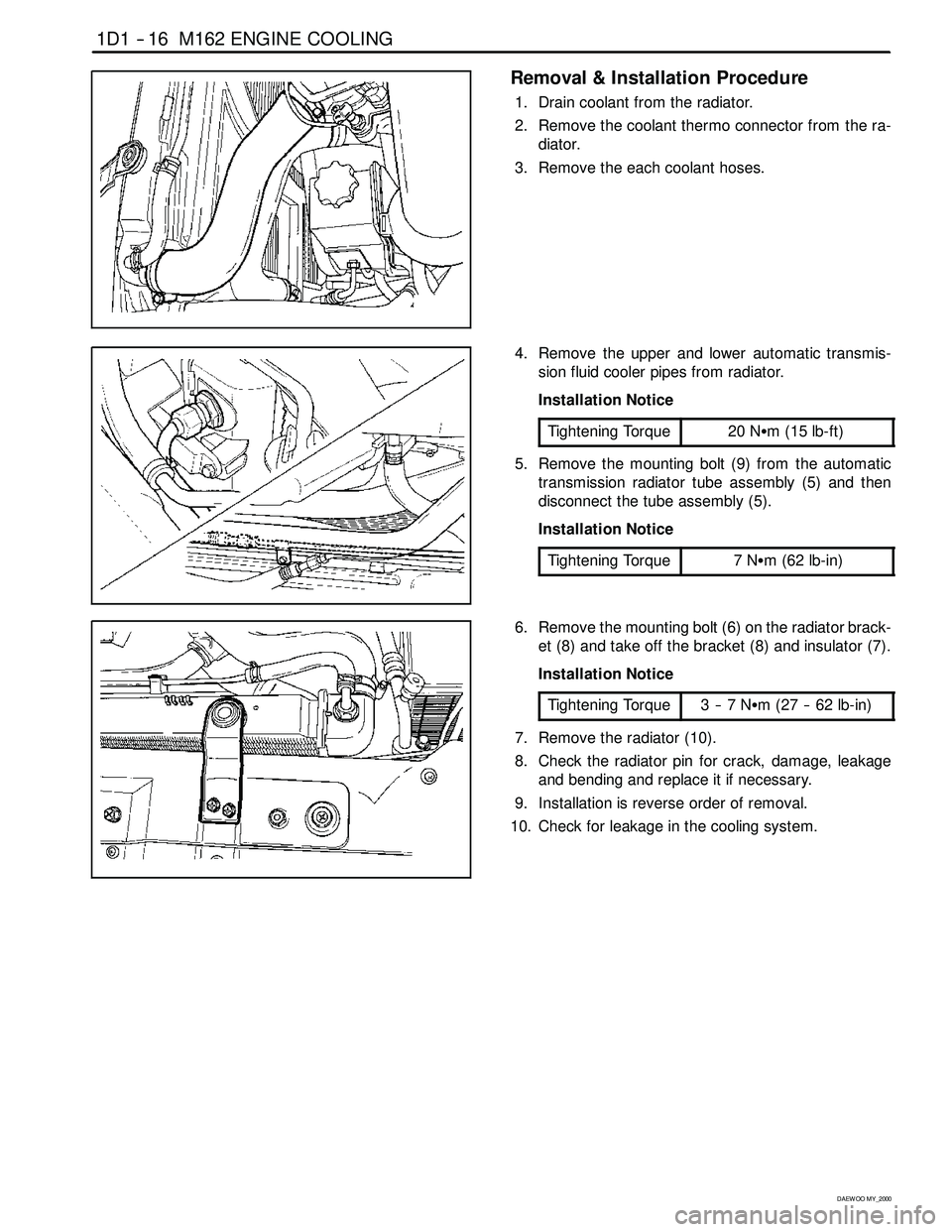

Removal & Installation Procedure

1. Drain coolant from the radiator.

2. Remove the coolant thermo connector from the ra-

diator.

3. Remove the each coolant hoses.

4. Remove the upper and lower automatic transmis-

sion fluid cooler pipes from radiator.

Installation Notice

Tightening Torque

20 NSm (15 lb-ft)

5. Remove the mounting bolt (9) from the automatic

transmission radiator tube assembly (5) and then

disconnect the tube assembly (5).

Installation Notice

Tightening Torque

7NSm(62lb-in)

6. Remove the mounting bolt (6) on the radiator brack-

et (8) and take off the bracket (8) and insulator (7).

Installation Notice

Tightening Torque

3--7NSm (27 -- 62 lb-in)

7. Remove the radiator (10).

8. Check the radiator pin for crack, damage, leakage

and bending and replace it if necessary.

9. Installation is reverse order of removal.

10. Check for leakage in the cooling system.

Page 291 of 2053

GENERAL ENGINE INFORMATION 1A2 -- 7

D AEW OO M Y_2000

DIAGNOSIS

OIL LEAK DIAGNOSIS

Most fluid oil leaks are easily located and repaired by

visually finding the leak and replacing or repairing the

necessary parts. On some occasions a fluid leak may be

difficult to locate or repair. The following procedures may

help you in locating and repairing most leaks.

Finding the Leak

1. Identify the fluid. Determine whether it is engine oil,

automatic transmission fluid, power steering fluid,

etc.

2. Identify where the fluid is leaking from.

2.1 After running the vehicle at normal operating

temperature, park the vehicle over a large sheet

of paper.

2.2 Wait a few minutes.

2.3 You should be able to find the approximate loca-

tion of the leak by the drippings on the paper.

3. Visually check around the suspected component.

Check around all the gasket mating surfaces for

leaks. A mirror is useful for finding leaks in areas that

are hard to reach.

4. If the leak still cannot be found, it may be necessary

to clean the suspected area with a degreaser, steam

or spray solvent.

4.1 Clean the area well.

4.2 Dry the area.

4.3 Operate the vehicle for several miles at normal

operating temperature and varying speeds.

4.4 After operating the vehicle, visually check the

suspected component.

4.5 If you still cannot locate the leak, try using the

powder or black light and dye method.

Powder Method

1. Clean the suspected area.

2. Apply an aerosol-- type powder (such as foot powder)

to the suspected area.

3. Operate the vehicle under normal operating condi-

toins.

4. Visually inspect the suspected component. You

should be able to trace the leak path over the white

powder surface to the source.

Black Light and Dye Method

A dye and light kit is available for finding leaks, Refer to

the manufacturer ’s directions when using the kit.

1. Pour the specified amount of dye into the engine oil fill

tube.

2. Operate the vehicle normal operating conditions as

directed in the kit.

3. Direct the light toward the suspected area. The dyed

fluid willappear as a yellow path leading to the

source.

Repairing the Leak

Once the origin of the leak has been pinpointed and

traced back to its source, the cause of the leak must be

determined n order for it to be repaired properly. If a gas-

ket is replaced, but the sealing flange is bent, the new

gasket will not repair the leak. Thebent flange must be

repaired also. Before attempting to repair a leak, check

for the following conditions and correct them as they

may cause a leak.

Gaskets

DThe fluid level/pressure is too high.

DThe crankcase ventilation system is malfunctioning.

DThe fasteners are tightened improperly or the threads

are dirty or damaged.

DThe flanges or the sealing surface is warped.

DThere are scratches, burrs or other damage to the

sealing surface.

DThe gasket is damaged or worn.

DThere is cracking or porosity of the component.

DAn improper seal was used (where applicable).

Seals

DThe fluid level/pressure is too high.

DThe crankcase ventilation system is malfunctioning.

DThe seal bore is damaged (scratched, burred or

nicked).

DThe seal is damaged or worn.

DImproper installation is evident.

DThere are cracks in the components.

DThe shaft surface is scratched, nicked or damaged.

DA loose or worn bearing is causing excess seal wear.

Page 411 of 2053

1D2 -- 16 M161 ENGINE COOLING

D AEW OO M Y_2000

Removal & Installation Procedure

1. Drain coolant from the radiator.

2. Remove the coolant thermo connector from the ra-

diator.

3. Remove the each coolant hoses.

4. Remove the automatic transmission fluid cooler

pipes from radiator.

Installation Notice

Tightening Torque

20 NSm (15 lb-ft)

5. Remove all the bolts (7) from the radiator bracket (9)

and remove the bracket (9) and insulator (8).

Installation Notice

Tightening Torque

3--7NSm (27 -- 62 lb-in)

6. Remove the radiator (10).

7. Check the radiator pin for crack, damage, leakage

and bending and replace it if necessary.

8. Installation is reverse order of removal.

9. Check for leakage in the cooling system.

Page 545 of 2053

1A3 -- 10 GENERAL ENGINE INFORMATION

D AEW OO M Y_2000

DIAGNOSIS

OIL LEAK DIAGNOSIS

Most fluid oil leaks are easily located and repaired by

visually finding the leak and replacing or repairing the

necessary parts. On some occasions a fluid leak may be

difficult to locate or repair. The following procedures may

help you in locating and repairing most leaks.

Finding the Leak

1. Identify the fluid. Determine whether it is engine oil,

automatic transmission fluid, power steering fluid,

etc.

2. Identify where the fluid is leaking from.

2.1 After running the vehicle at normal operating

temperature, park the vehicle over a large sheet

of paper.

2.2 Wait a few minutes.

2.3 You should be able to find the approximate loca-

tion of the leak by the drippings on the paper.

3. Visually check around the suspected component.

Check around all the gasket mating surfaces for

leaks. A mirror is useful for finding leaks in areas that

are hard to reach.

4. If the leak still cannot be found, it may be necessary

to clean the suspected area with a degreaser, steam

or spray solvent.

4.1 Clean the area well.

4.2 Dry the area.

4.3 Operate the vehicle for several miles at normal

operating temperature and varying speeds.

4.4 After operating the vehicle, visually check the

suspected component.

4.5 If you still cannot locate the leak, try using the

powder or black light and dye method.

Powder Method

1. Clean the suspected area.

2. Apply an aerosol-- type powder (such as foot powder)

to the suspected area.

3. Operate the vehicle under normal operating condi-

tions.

4. Visually inspect the suspected component. You

should be able to trace the leak path over the white

powder surface to the source.

Black Light and Dye Method

A dye and light kit is available for finding leaks, Refer to

the manufacturer ’s directions when using the kit.

1. Pour the specified amount of dye into the engine oil fill

tube.

2. Operate the vehicle normal operating conditions as

directed in the kit.

3. Direct the light toward the suspected area. The dyed

fluid willappear as a yellow path leading to the

source.

Repairing the Leak

Once the origin of the leak has been pinpointed and

traced back to its source, the cause of the leak must be

determined n order for it to be repaired properly. If a gas-

ket is replaced, but the sealing flange is bent, the new

gasket will not repair the leak. Thebent flange must be

repaired also. Before attempting to repair a leak, check

for the following conditions and correct them as they

may cause a leak.

Gaskets

DThe fluid level/pressure is too high.

DThe crankcase ventilation system is malfunctioning.

DThe fasteners are tightened improperly or the threads

are dirty or damaged.

DThe flanges or the sealing surface is warped.

DThere are scratches, burrs or other damage to the

sealing surface.

DThe gasket is damaged or worn.

DThere is cracking or porosity of the component.

DAn improper seal was used (where applicable).

Seals

DThe fluid level/pressure is too high.

DThe crankcase ventilation system is malfunctioning.

DThe seal bore is damaged (scratched, burred or

nicked).

DThe seal is damaged or worn.

DImproper installation is evident.

DThere are cracks in the components.

DThe shaft surface is scratched, nicked or damaged.

DA loose or worn bearing is causing excess seal wear.

Page 1095 of 2053

SECTION 5A

AUTOMATIC TRANSMISSION

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless

otherwise noted.

TABLE OF CONTENTS

Description and Operation . . . . . . . . . . . . . . . . . 5A-2

BTRA M74 4WD Automatic Transmission . . . . . . 5A-2

Operators Interfaces . . . . . . . . . . . . . . . . . . . . . 5A-2

Control Systems . . . . . . . . . . . . . . . . . . . . . . . . 5A-3

Electronic Control System . . . . . . . . . . . . . . . . . 5A-3

Hydraulic Control System . . . . . . . . . . . . . . . . . . 5A-9

Hydraulic Control Circuit . . . . . . . . . . . . . . . . . . 5A-10

Power Train System . . . . . . . . . . . . . . . . . . . . . 5A-14

Power Flows . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-18

Park and Neutral . . . . . . . . . . . . . . . . . . . . . . . 5A-20

Reverse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-22

Manual 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-24

Drive 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-26

Drive 2 and Manual 2 . . . . . . . . . . . . . . . . . . . . 5A-28

Drive 3 and Manual 3 . . . . . . . . . . . . . . . . . . . . 5A-30

Drive 3 Lock Up and Manual 3 Lock Up . . . . . . 5A-32

Drive 4 (Overdrive) . . . . . . . . . . . . . . . . . . . . . 5A-34

Drive 4 Lock Up . . . . . . . . . . . . . . . . . . . . . . . . 5A-36

Diagnostic Information and Procedures . . . . . 5A-38

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-38

Basic Knowledge Required . . . . . . . . . . . . . . . 5A-38

Functional Check Procedure . . . . . . . . . . . . . . . 5A-38

Transmission Fluid Level Service Procedure . . . 5A-38

Fluid Leak Diagnosis and Repair . . . . . . . . . . . 5A-39

Electrical / Garage Shift Test . . . . . . . . . . . . . . 5A-40

Road Test Procedure . . . . . . . . . . . . . . . . . . . . 5A-40

Electronic Adjustments . . . . . . . . . . . . . . . . . . 5A-40

Symptom Diagnosis . . . . . . . . . . . . . . . . . . . . . 5A-41

Drive Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-41

Faulty Shift Pattern . . . . . . . . . . . . . . . . . . . . . . 5A-42Shift Quality Faults . . . . . . . . . . . . . . . . . . . . . . 5A-44

After Teardown Faults . . . . . . . . . . . . . . . . . . . 5A-46

Trouble Code Diagnosis - Gasoline Vehicle . . 5A-48

TCM Diagnostic System Overview . . . . . . . . . . 5A-48

Clearing Trouble Codes . . . . . . . . . . . . . . . . . . 5A-48

Diagnostic Trouble Codes . . . . . . . . . . . . . . . . 5A-48

Trouble Code Diagnosis - Diesel Vehicle . . . . . 5A-50

TCM Diagnostic System Overview . . . . . . . . . . 5A-50

Clearing Trouble Codes . . . . . . . . . . . . . . . . . . 5A-50

Diagnostic Trouble Codes . . . . . . . . . . . . . . . . 5A-50

Repair Instructions . . . . . . . . . . . . . . . . . . . . . . 5A-157

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . . . 5A-157

Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-157

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-160

Rebuild Warnings . . . . . . . . . . . . . . . . . . . . . . 5A-160

Disassembly Procedure . . . . . . . . . . . . . . . . . . 5A-161

Assembly Procedure . . . . . . . . . . . . . . . . . . . . 5A-171

Front and Rear Band Adjustment . . . . . . . . . . . 5A-199

Gear Shift Control Lever . . . . . . . . . . . . . . . . . . 5A-202

Kickdown Switch . . . . . . . . . . . . . . . . . . . . . . . 5A-202

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-203

General Specification . . . . . . . . . . . . . . . . . . . . 5A-203

Fastener Tightening Specifications . . . . . . . . . . 5A-205

Schematic and Routing Diagrams . . . . . . . . . . 5A-206

TCM Wiring Diagrams (Gasoline Engine) . . . . . 5A-206

TCM Wiring Diagrams (Diesel Engine) . . . . . . . 5A-208

Connector End View . . . . . . . . . . . . . . . . . . . . . 5A-210

Special Tools and Equipment . . . . . . . . . . . . . 5A-211

Special Tools Table . . . . . . . . . . . . . . . . . . . . . 5A-211

Page 1132 of 2053

5A-38 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

DIAGNOSIS

BASIC KNOWLEDGE REQUIRED

You must be familliar with some basic electronics to

use this section of the Service Manual. They will help

you to follow diagnostic procedures.

Notice: Lack of the basic knowledge of this transmis-

sion when performing diagnostic procedures could re-

sult in incorrect diagnostic performance or damage to

transmission components. Do not, under any circum-

stances, attempt to diagnose a transmission problem

without this basic knowledge.

Notice: If a wire is probed with a sharp instrument

and not properly sealed afterward, the wire will corrode

and an open circuit will result.

Diagnostic test probes are now available that allow

you to probe individual wires without leaving the wire

open to the environment. These probe devices are

inexpensive and easy to install, and they permanently

seal the wire from corrosion.

Special Tools

You should be able to use a Digital Volt Meter (DVM),

a circuit tester, jumper wires or leads and a line

pressure gauge set. The functional check procedure

is designed to verify the correct operation of electronic

components in the transmission. This will eliminate the

unnecessary removal of transmission components.

FUNCTIONAL CHECK

PROCEDURE

Begin with the Functional Check Procedure which pro-

vides a general outline of how to diagnose automatic

transmission. The following functional check procedure

will indicate the proper path of diagnosing the transmis-

sion by describing the basic checks and then referenc-

ing the locations of the specific checks.

Check the fluid level according to the Fluid Level

Service Procedure.

Check the transmission fluid leak.

Check if the transmission fluid is not burnt by smell.

Notice: The specific fluid used in this transmission

turns brown during normal operation. Brown fluid

does not indicate a transmission fault.

Ensure that the transmission is not in Limp Home

Mode (LHM).

Check the battery terminals and the earth connec-

tions for corrosion or looseness.

Check that the cooler flow is not restricted.

Check all electrical plug connections for tightness.

Use on-board diagnostic tool or a scan tool to see

if any transmission trouble codes have been set.

DIAGNOSTIC INFORMATION AND PROCEDURES

Refer to the appropriate “Diagnostic Trouble Code

(DTC)” information and repair the vehicle as

directed. After repairing the vehicle, perform the

road test and verify that the code has not set again.

Perform the Electrical/Garage Shift Tests.

Perform the Road Test Procedure in this section.

Inspect the oil and check for metal or other contami-

nants in the oil pan.

TRANSMISSION FLUID LEVEL

SERVICE PROCEDURE

This procedure is to be used when checking a concern

with the fluid level in a vehicle. A low fluid level will

result in slipping and loss of drive/ reverse or delay on

engagement of drive/ reverse when the vehicle is cold.

The vehicle is first checked for transmission diagnostic

messages on the scan tool. If the oil level is low, it is

possible to register a vehicle speed signal fault.

The vehicle is to be test driven to determine if there is

an abnormal delay when selecting drive or reverse, or

loss of drive. One symptom of low fluid level is a

momentary loss of drive when driving the vehicle around

a corner. Also when the transmission fluid level is low,

a loss of drive may occur when the transmission fluid

temperature is low.

If there is no loss of drive when the vehicle is driven

warm and a vehicle speed signal fault is registered,

then fluid should be added to the transmission.

When adding or changing transmission fluid use only

Castrol TQ 95 automatic transmission fluid. The use of

incorrect fluid will cause the performance and durability

of the transmission to be severely degraded.

Fluid Level Diagnosis procedure

1. If the vehicle is at operating temperature allow the

vehicle to cool down for two hours, but no greater

than four hours. Or if the vehicle is at cool status,

start the engine and allow the engine to idle for

approximately 5 minutes or, if possible, drive the

vehicle for a few kilometers. This will allow the

transmission to be within the correct temperature

range. Transmission fluid level should be checked

at temperature 50 - 60 °C (82 - 140 °F).

Caution: Removal of the fluid filler plug when

the transmission fluid is hot may cause injury if

fluid drains from the filler hole.

2. With the brake pedal pressed, move the gear shift

control lever through the gear ranges, pausing a

few seconds in each range. Return the gear shift

control lever to P (Park). Turn the engine OFF.

3. Park the vehicle on a hoist, inspection pit or similar

raised level surface. The vehicle must be control

level to obtain a correct fluid level measurement.

Page 1133 of 2053

AUTOMATIC TRANSMISSION 5A-39

SSANGYONG MY2002

4. Place a fluid container below the fluid filler plug.

5. Clean all dirt from around the fluid filler plug.

Remove the fluid filler plug. Clean the filler plug

and check that there is no damage to the ‘O’ ring.

If fluid drains through the filler hole the transmis-

sion may have been overfilled. When the fluid

stops draining the fluid level is correct. Install

the fluid filler plug and tighten it to 33 Nm (24

lb-ft).

If fluid does not drain through the filler hole, the

transmission fluid level may be low. Install the

filler pump into the filler hole. Lower the vehicle

with the filler pump still connected and partially

fill the fluid through the filler hole.

Start the vehicle in P (Park) with the parking

brake and the brake applied. With the engine

idling, move the gear shift. control lever through

the gear ranges, pausing a few seconds in each

range and adding the fluid until gear application

is felt.

Return the gear shift lever to P (Park).

Turn the engine OFF and raise the vehicle. When

the three minutes passed after the engine

stopped, remove the filler pump.

Check if the fluid level is aligned with the bottom

of the filler hole. If not, add a small quantity of

fluid to the correct level. Install the fluid filler

plug and tighten it to 33 Nm (24 lb-ft).

If fluid does not drain through the filler hole al-

though adding a total of 1.5 liters, the transmission

should be inspected for fluid leaks and any leaks

should be fixed before setting the transmission

fluid level.

6. When the fluid level checking procedure is com-

pleted, wipe any fluid around the filler plug with a

rag or shop towel.

Fluid Level Set After Service

1. Depending on the service procedure performed,

add the following amounts of fluid through the filler

plug hole prior to adjusting the fluid level:

Converter empty 8.0 liters (8.5 quarts)

Converter full 3.8 liters (4.0 quarts)

2. Follow steps 1 through 4 of the Fluid Level Diagnosis

Procedure.

3. Clean all dirt from around the fluid filler plug.

Remove the fluid filler plug. Clean the filler plug

and check that there is no damage to the ‘O’ ring.

4. Lower the vehicle with the filler pump still connected

and start the vehicle in P (Park) with the parking

brake and the brake applied. With the engine idling,

move the gear shift control lever through the gear

ranges, pausing a few seconds in each range and

adding the fluid until gear application is felt.Then add an additional 0.5 litres of fluid. Return

the gear shift lever to P (Park). Turn the engine OFF

and raise the vehicle. Install the fluid filler plug and

tighten it to 33 Nm (24 lb-ft).

5. Drive the vehicle at 3.5 to 4.5 kilometers with light

throttle so that the engine does not exceed 2500

rpm.

This should result in the transmission temperature

being in the range 50 - 60 °C (82 - 140 °F). With the

brake applied, move the shift lever through the gear

ranges, pausing a few seconds in each range at

the engine idling.

6. Return the gear shift lever to P (Park).

Turn the en-gine OFF and raise the vehicle on the

hoist, if applicable, ensuring the vehicle is level.

When the three minutes passed after the engine

stopped, remove the filler plug.

Check if the fluid level is aligned with the bottom of

the filler hole. If not, add a small quantity of fluid to

the correct level. Install the fluid filler plug and

tighten it to 33 Nm (24 lb-ft).

7. Wipe any fluid around the filler plug with a rag or

shop towel.

FLUID LEAK DIAGNOSIS AND

REPAIR

The cause of most external leaks can generally be lo-

cated and repaired with the transmission in the vehicle.

Methods for Locating Leaks

General Method

1. Verify that the leak is transmission fluid.

2. Thoroughly clean the suspected leak area.

3. Drive the vehicle for approximately 25 km (15 miles)

or until the transmission reaches normal operating

temperature (88 °C, 190 °F).

4. Park the vehicle over clean paper or cardboard.

5. Turn the engine OFF and look for fluid spots on the

paper.

6. Make the necessary repairs to correct the leak.

Powder Method

1. Thoroughly clean the suspected leak area.

2. Apply an aerosol type powder (foot powder) to the

suspected leak area.

3. Drive the vehicle for approximately 25 km (15 miles)

or until the transmission reaches normal operating

temperature (88 °C, 190 °F).

4. Turn the engine OFF.

5. Inspect the suspected leak area and trace the leak

path through the powder to find the source of the

leak.

6. Make the necessary repairs.

Page 1134 of 2053

5A-40 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Dye and Black Light Method

1. Add dye to the transmission through the transmission

fluid filler plug. Follow the manufacturer’s recommen-

dation for the amount of dye to be used.

2. Use the black light to find the fluid leak.

3. Make the necessary repairs.

Repairing the Fluid Leak

Once the leak point is found the source of the leak

must be determined. The following list describes the

potential causes for the leak:

Fasteners are not torqued to specification.

Fastener threads and fastener holes are dirty or

corroded.

Gaskets, seals or sleeves are misaligned, damaged

or worn.

Damaged, warped or scratched seal bore or gasket

surface.

Loose or worn bearing causing excess seal or sleeve

wear.

Case or component porosity.

Fluid level is too high.

Plugged vent or damaged vent tube.

Water or coolant in fluid.

Fluid drain back holes plugged.

ELECTRICAL / GARAGE SHIFT

TEST

This preliminary test should be performed before a hoist

or road test to make sure electronic control inputs are

connected and operating. If the inputs are not checked

before operating the transmission, a simple electrical

condition could be misdiagnosed as a major

transmission condition.

A scan tool provides valuable information and must

be used on the automatic transmission for accurate

diagnosis.

1. Move gear shift control lever to P (Park) and set

the parking brake.

2. Connect scan tool to Data Link Connector (DLC)

terminal.

3. Start engine.

4. Turn the scan tool ON.

5. Verify that the appropriate signals are present.

These signals may include:

ENGINE SPEED

VEHICLE SPEED

THROTTLE POSITION

ACCEL. PEDAL POSITION

TRANSMISSION GEAR STATE

GEAR SHIFT LEVER POSITION

TRANSMISSION FLUID TEMPERATURE

CLOSED THROTTLE POSITION LEARN

OPEN THROTTLE POSITION LEARNT

CLOSED ACCEL. PEDAL POSITION LEARNT

OPEN ACCEL. PEDAL POSITION LEARNT

A/C COMPRESSOR STATUS

KICKDOWN SWITCH STATUS

4WD STATUS

MODE SWITCH

THROTTLE POSITION VOLTAGE

GEAR SHIFT LEVER POSITION VOLTAGE

TRANS. FLUID TEMPERATURE VOLTAGE

A/C SWITCH

KICKDOWN SWITCH VOLTAGE

4WD LAMP LOW VOLTAGE

4WD LAMP HIGH VOLTAGE

MODE SWITCH VOLTAGE

BATTERY VOLTAGE

6. Monitor the A/C COMPRESSOR STATUS signal

while pushing the A/C switch.

The A/C COMPRESSOR STATUS should come

ON when the A/C switch is pressed, and turn

OFF when the A/C switch is repushed.

7. Monitor the GEAR SHIFT LEVER POSITION signal

and move the gear shift control lever through all

the ranges.

Verify that the GEAR SHIFT LEVER POSITION

value matches the gear range indicated on the

instrument panel or console.

Gear selections should be immediate and not

harsh.

8. Move gear shift control lever to neutral and monitor

the THROTTLE POSITION signal while increasing

and decreasing engine speed with the accelerator

pedal.

THROTTLE POSITION should increase with en-

gine speed.

ROAD TEST PROCEDURE

Perform the road test using a scan tool.

This test should be performed when traffic and road

conditions permit.

Observe all traffic regulations.

ELECTRONIC ADJUSTMENTS

Idle Speed Adjustments

Carry out the adjustments to the idle speed as detailed

in the workshop manual.

Vehicle Coding

The vehicle coding is integrated as part of the

diagnostic software. A scan tool has the function to

code the ve-hicle through the K-line.

Page 1135 of 2053

5A-40 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Dye and Black Light Method

1. Add dye to the transmission through the transmission

fluid filler plug. Follow the manufacturer’s recommen-

dation for the amount of dye to be used.

2. Use the black light to find the fluid leak.

3. Make the necessary repairs.

Repairing the Fluid Leak

Once the leak point is found the source of the leak

must be determined. The following list describes the

potential causes for the leak:

Fasteners are not torqued to specification.

Fastener threads and fastener holes are dirty or

corroded.

Gaskets, seals or sleeves are misaligned, damaged

or worn.

Damaged, warped or scratched seal bore or gasket

surface.

Loose or worn bearing causing excess seal or sleeve

wear.

Case or component porosity.

Fluid level is too high.

Plugged vent or damaged vent tube.

Water or coolant in fluid.

Fluid drain back holes plugged.

ELECTRICAL / GARAGE SHIFT

TEST

This preliminary test should be performed before a hoist

or road test to make sure electronic control inputs are

connected and operating. If the inputs are not checked

before operating the transmission, a simple electrical

condition could be misdiagnosed as a major

transmission condition.

A scan tool provides valuable information and must

be used on the automatic transmission for accurate

diagnosis.

1. Move gear shift control lever to P (Park) and set

the parking brake.

2. Connect scan tool to Data Link Connector (DLC)

terminal.

3. Start engine.

4. Turn the scan tool ON.

5. Verify that the appropriate signals are present.

These signals may include:

ENGINE SPEED

VEHICLE SPEED

THROTTLE POSITION

ACCEL. PEDAL POSITION

TRANSMISSION GEAR STATE

GEAR SHIFT LEVER POSITION

TRANSMISSION FLUID TEMPERATURE

CLOSED THROTTLE POSITION LEARN

OPEN THROTTLE POSITION LEARNT

CLOSED ACCEL. PEDAL POSITION LEARNT

OPEN ACCEL. PEDAL POSITION LEARNT

A/C COMPRESSOR STATUS

KICKDOWN SWITCH STATUS

4WD STATUS

MODE SWITCH

THROTTLE POSITION VOLTAGE

GEAR SHIFT LEVER POSITION VOLTAGE

TRANS. FLUID TEMPERATURE VOLTAGE

A/C SWITCH

KICKDOWN SWITCH VOLTAGE

4WD LAMP LOW VOLTAGE

4WD LAMP HIGH VOLTAGE

MODE SWITCH VOLTAGE

BATTERY VOLTAGE

6. Monitor the A/C COMPRESSOR STATUS signal

while pushing the A/C switch.

The A/C COMPRESSOR STATUS should come

ON when the A/C switch is pressed, and turn

OFF when the A/C switch is repushed.

7. Monitor the GEAR SHIFT LEVER POSITION signal

and move the gear shift control lever through all

the ranges.

Verify that the GEAR SHIFT LEVER POSITION

value matches the gear range indicated on the

instrument panel or console.

Gear selections should be immediate and not

harsh.

8. Move gear shift control lever to neutral and monitor

the THROTTLE POSITION signal while increasing

and decreasing engine speed with the accelerator

pedal.

THROTTLE POSITION should increase with en-

gine speed.

ROAD TEST PROCEDURE

Perform the road test using a scan tool.

This test should be performed when traffic and road

conditions permit.

Observe all traffic regulations.

ELECTRONIC ADJUSTMENTS

Idle Speed Adjustments

Carry out the adjustments to the idle speed as detailed

in the workshop manual.

Vehicle Coding

The vehicle coding is integrated as part of the

diagnostic software. A scan tool has the function to

code the ve-hicle through the K-line.