coolant reservoir SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 13 of 2053

GENERAL INFORMATION 0B -- 13

D AEW OO M Y_2000

OWNER INSPECTIONS AND SERVICES

WHILE OPERATING THE VEHICLE

Horn Operation

Blow the horn occasionally to make sure it works. Check

all the button locations.

Brake System Operation

Be alert for abnormal sounds, increased brake pedal

travel or repeated puling to one side when braking. Also,

if the brake warning light goes on, or flashes, something

may be wrong with part of the brake system.

Exhaust System Operation

Be alert to any changes inthe sound of the system or

the smell of the fumes. These are signs that the system

may be leaking or overheating. Have the system in-

spected and repaired immediately.

Tires, Wheels and Alignment Operation

Be alert to any vibration of the steering wheel or the

seats at normal highway speeds. This may mean a

wheel needs to be balanced. Also, a pull right or left on a

straight, level road may show the need for a tire pres-

sure adjustment or a wheel alignment.

Steering System Operation

Be alert to changes in the steering action. An inspection

is needed when the steering wheel is hard to turn or has

too much free play, or is unusual sounds are noticed

when turning or parking.

Headlight Aim

Take note of the light pattern occasionally. Adjust the

headlights if the beams seem improperly aimed.

AT EACH FUEL FILL

A fluid loss in any (except windshield washer) system

may indicate a problem. Have the system inspected and

repaired immediately.

Engine Oil Level

Check the oil level and add oil if necessary. The best

time to check the engine oil level is when the oil is warm.

1. After stopping the engine, wait a few minutes for the

oil to drain back to the oil pan.

2. Pull out the oil level indicator (dip stick).

3. Wipe it clean, and push the oil level indicator back

down all the way.

4. Pull out the oil level indicator and look at the oil level

on it.

5. Add oil, if needed, to keep the oil level above the low-

er mark. Avoid overfilling theengine, since this may

cause engine damage.

6. Push the indicator all the way back down into the en-

gine after taking the reading.If you check the oil level when the oil is cold, do not run

the engine first. The cold oil will not drain back to the pan

fast enough to give a true oil level reading.

Engine Coolant Level and Condition

Check the coolant level in the coolant reservoir tank and

add coolant if necessary. Inspect the coolant. Replace

dirty or rusty coolant.

Windshield Washer Fluid Level

Check the washer fluid level in the reservoir. Add fluid if

necessary.

AT LEAST TWICE A MONTH

Tire And Wheel Inspection and Pressure

Check

Check the tire for abnormal wear or damage. Also check

for damaged wheels. Check the tire pressure when the

tires are cold ( check the spare also, unless it is a stow-

away). Maintain the recommended pressures. Refer to

“Tire and Wheel” is in section 0B.

AT LEAST MONTHLY

Light Operation

Check the operation of the license plate light, the head-

lights (including the high beams), the parking lights, the

fog lights, the taillight, the brake lights, the turn signals,

the backup lights and the hazard warning flasher.

Fluid Leak Check

Periodically inspect the surface beneath the vehicle for

water, oil, fuel or other fluids, after the vehicle has been

parked for a while. Water dripping from the air condition-

ing system after use is normal. If you notice fuel leaks or

fumes, find the cause and correct it at once.

AT LEAST TWICE A YEAR

Power Steering System Reservoir Level

Check the power steering fluid level. Keep the power

steering fluid at the proper level. Refer to Section 6A,

Power Steering System.

Brake Master Cylinder Reservoir Level

Check the fluid and keep it at the proper level. A low fluid

level can indicate worn disc brake pads which may need

to be serviced. Check the breather hole in the reservoir

cover to be free from dirt and check for an open pas-

sage.

Weather- Strip Lubrication

Apply a thin film silicone grease using a clean cloth.

Page 40 of 2053

1B1 -- 8 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

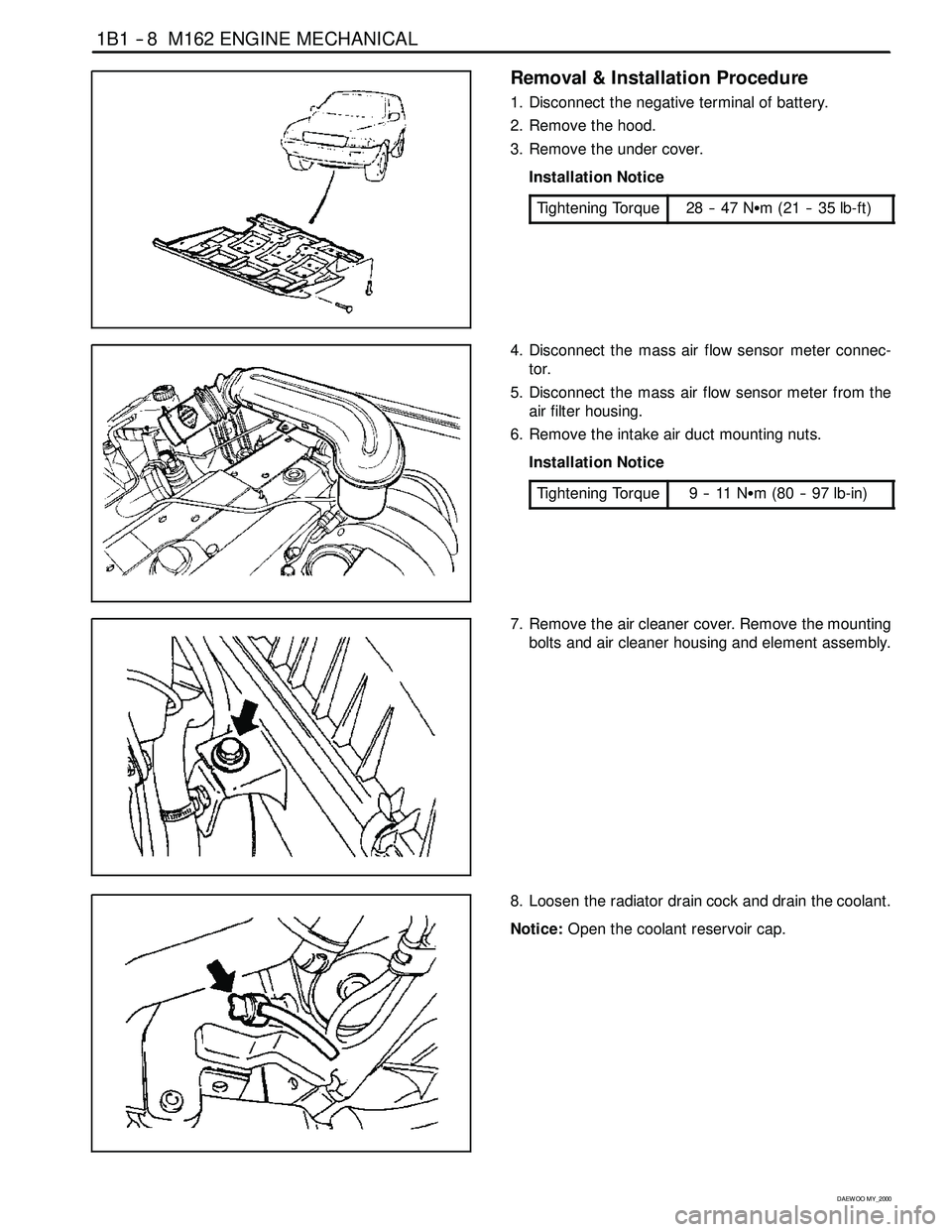

Removal & Installation Procedure

1. Disconnect the negative terminal of battery.

2. Remove the hood.

3. Remove the under cover.

Installation Notice

Tightening Torque

28 -- 47 NSm (21 -- 35 lb-ft)

4. Disconnect the mass air flow sensor meter connec-

tor.

5. Disconnect the mass air flow sensor meter from the

air filter housing.

6. Remove the intake air duct mounting nuts.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

7. Remove the air cleaner cover. Remove the mounting

bolts and air cleaner housing and element assembly.

8. Loosen the radiator drain cock and drain the coolant.

Notice:Open the coolant reservoir cap.

Page 138 of 2053

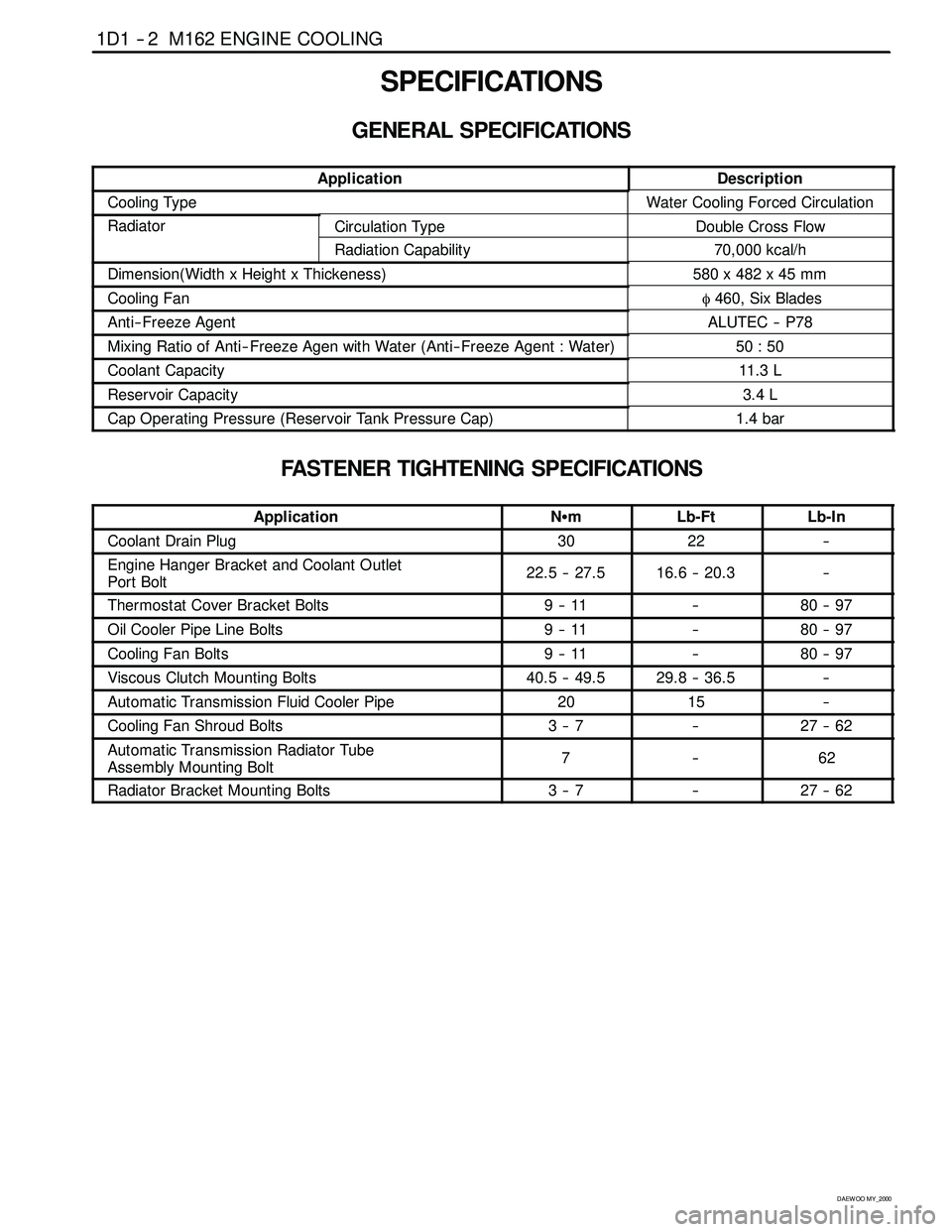

1D1 -- 2 M162 ENGINE COOLING

D AEW OO M Y_2000

SPECIFICATIONS

GENERAL SPECIFICATIONS

ApplicationDescription

Cooling TypeWater Cooling Forced Circulation

RadiatorCirculation TypeDouble Cross Flow

Radiation Capability70,000 kcal/h

Dimension(Width x Height x Thickeness)580 x 482 x 45 mm

Cooling Fanφ460, Six Blades

Anti-- Freeze AgentALUTEC -- P78

Mixing Ratio of Anti-- Freeze Agen with Water (Anti-- Freeze Agent : Water)50 : 50

Coolant Capacity11. 3 L

Reservoir Capacity3.4 L

Cap Operating Pressure (Reservoir Tank Pressure Cap)1.4 bar

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb-FtLb-In

Coolant Drain Plug3022--

Engine Hanger Bracket and Coolant Outlet

Port Bolt22.5 -- 27.516.6 -- 20.3--

Thermostat Cover Bracket Bolts9--11--80 -- 97

Oil Cooler Pipe Line Bolts9--11--80 -- 97

Cooling Fan Bolts9--11--80 -- 97

Viscous Clutch Mounting Bolts40.5 -- 49.529.8 -- 36.5--

Automatic Transmission Fluid Cooler Pipe2015--

Cooling Fan Shroud Bolts3--7--27 -- 62

Automatic Transmission Radiator Tube

Assembly Mounting Bolt7--62

Radiator Bracket Mounting Bolts3--7--27 -- 62

Page 140 of 2053

1D1 -- 4 M162 ENGINE COOLING

D AEW OO M Y_2000

DIAGNOSIS

SYSTEM LEAKAGE TEST

Tools Required

124 589 15 21 00 Tester

Test Procedure

1. Loosen the cap a little and release pressure and re-

move the cap.

Notice:For the risk of scalding, cap must not be opened

unless the coolant temperature is below 90°C.

2. Fill coolant up to upper edge (arrow) of reservoir.

3. Connect the special tool to the reservoir filler cap and

apply 1.4 bar of pressure.

Tester 124 589 15 21 00

4. If the pressure on the tester drops, check leakage at

the all coolant hoses and pipes and each connec-

tions. Replace or retighten if necessary.

Page 142 of 2053

1D1 -- 6 M162 ENGINE COOLING

D AEW OO M Y_2000

6. Remove the de-- aeration hose clamp in the coolant

pump and remove the de-- aeration hose.

7. Fill up the coolant through the coolant reservoir

tank.

Notice

DMatchtheanti--freezeandthewaterratioto50:50.

DSupplement the coolant until the coolant overflows to

the deaeration hose.

8. Insert the de--aeration hose and completely tighten

the clamp.

9. Check the coolant level in the coolant reservoir tank.

10. Warm up(until thermostat is opened) the engine and

recheck the coolant level in the reservoir tank and fill

up the coolant if necessary.

Page 301 of 2053

1B2 -- 8 M161 ENGINE MECHANICAL

D AEW OO M Y_2000

Removal & Installation Procedure

1. Disconnect the negative terminal of battery.

2. Remove the hood.

3. Remove the under cover.

Installation Notice

Tightening Torque

28 -- 47 NSm (21 -- 35 lb-ft)

4. Disconnect the coupling of HFM sensor and remove

the air cleaner cross pipe.

5. Remove the air cleaner cover. Remove the mounting

bolts and air cleaner housing and element assembly.

6. Loosen the radiator drain cock and drain the coolant.

Notice:Open the coolant reservoir cap.

Page 397 of 2053

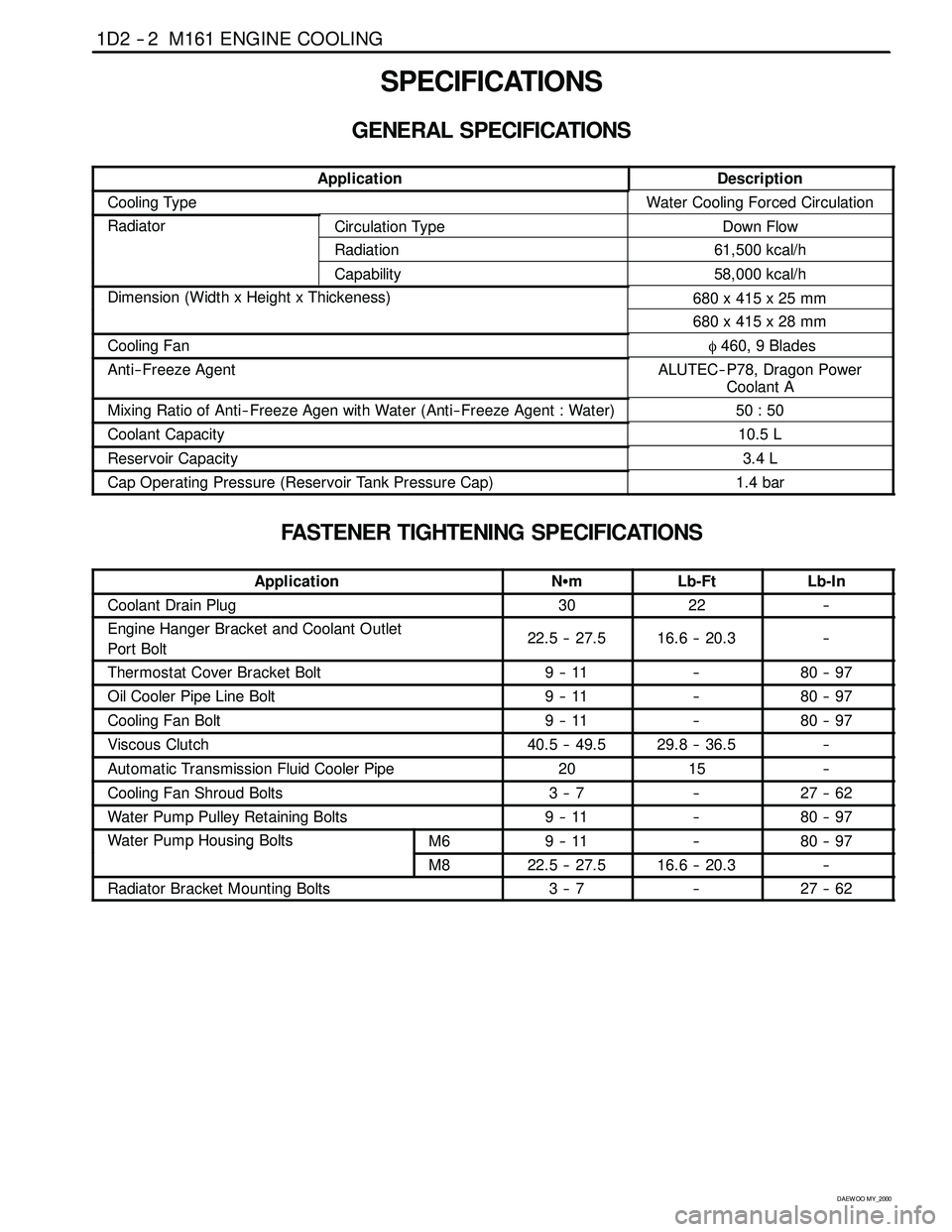

1D2 -- 2 M161 ENGINE COOLING

D AEW OO M Y_2000

SPECIFICATIONS

GENERAL SPECIFICATIONS

ApplicationDescription

Cooling TypeWater Cooling Forced Circulation

RadiatorCirculation TypeDown Flow

Radiation61,500 kcal/h

Capability58,000 kcal/h

Dimension (Width x Height x Thickeness)680 x 415 x 25 mm(g)

680 x 415 x 28 mm

Cooling Fanφ460, 9 Blades

Anti-- Freeze AgentALUTEC-- P78, Dragon Power

Coolant A

Mixing Ratio of Anti-- Freeze Agen with Water (Anti-- Freeze Agent : Water)50 : 50

Coolant Capacity10.5 L

Reservoir Capacity3.4 L

Cap Operating Pressure (Reservoir Tank Pressure Cap)1.4 bar

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb-FtLb-In

Coolant Drain Plug3022--

Engine Hanger Bracket and Coolant Outlet

Port Bolt22.5 -- 27.516.6 -- 20.3--

Thermostat Cover Bracket Bolt9--11--80 -- 97

Oil Cooler Pipe Line Bolt9--11--80 -- 97

Cooling Fan Bolt9--11--80 -- 97

Viscous Clutch40.5 -- 49.529.8 -- 36.5--

Automatic Transmission Fluid Cooler Pipe2015--

Cooling Fan Shroud Bolts3--7--27 -- 62

Water Pump Pulley Retaining Bolts9--11--80 -- 97

Water Pump Housing BoltsM69--11--80 -- 97pg

M822.5 -- 27.516.6 -- 20.3--

Radiator Bracket Mounting Bolts3--7--27 -- 62

Page 399 of 2053

1D2 -- 4 M161 ENGINE COOLING

D AEW OO M Y_2000

DIAGNOSIS

SYSTEM LEAKAGE TEST

Tools Required

124 589 15 21 00 Tester

Test Procedure

1. Loosen the cap a little and release pressure and re-

move the cap.

Notice:For the risk of scalding, cap must not be opened

unless the coolant temperature is below 90°C.

2. Fill coolant up to upper edge (arrow) of reservoir.

3. Connect the special tool to the reservoir filler cap and

apply 1.4 bar of pressure.

Tester 124 589 15 21 00

4. If the pressure on the tester drops, check leakage at

the all coolant hoses and pipes and each connec-

tions. Replace or retighten if necessary.

Page 401 of 2053

1D2 -- 6 M161 ENGINE COOLING

D AEW OO M Y_2000

4. After complete draining of the coolant, remove the

hose connector to drain plug and reinstall the drain

plug.

Installation Notice

Tightening Torque

30 NSm (22 lb-ft)

5. Tighten the radiator lower drain cock.

6. Remove the de-- aeration hose clamp in the water

pump and remove the de-- aeration hose.

7. Fill up the coolant through the coolant reservoir

tank.

Notice

DMatchtheanti--freezeandthewaterratioto50:50.

DSupplement the coolant until the coolant overflows to

the deaeration hose.

8. Insert the de--aeration hose and completely tighten

the clamp.

9. Check the coolant level in the coolant reservoir tank.

10. Warm up(until thermostat is opened) the engine and

recheck the coolant level in the reservoir tank and fill

up the coolant if necessary.

Page 410 of 2053

M161 ENGINE COOLING 1D2 -- 15

D AEW OO M Y_2000

REMOVAL AND INSTALLATION OF RADIATOR

Preceding Work: Removal of cooling fan shroud

1 Inlet Hose

2 Hose (to Engine)

3 Hose (to 3-- way Connector)

4 Make-- up Hose (to Coolant Reservoir)

5 3-- way Connector

6 Automatic Transmission Oil Cooling Hose

(A/T Equippend Vehicle)7 Bolt (M6 X 20, 4 pieces)

3--7 NSm (27-- 62 lb-in) .....................

8 Insulator

9 Radiator Bracket

10 Radiator