dimensions SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1 of 2053

D AEW OO M Y_2000

SECTION 0B

GENERAL INFORMATION

TABLE OF CONTENTS

Specifications 0B-- 2.............................

Technical Data 0B-- 2............................

Vehicle Dimensions and Weights 0B-- 6............

Standard Bolts Specifications 0B-- 7...............

Maintenance and Repair 0B-- 8....................

Maintenance and Lubrication 0B-- 8...............

Normal Vehicle Use 0B-- 8........................

Explanation of Scheduled Maintenance

Services 0B-- 8...............................

Scheduled Maintenance Charts

(Gasoline Engine) 0B-- 9.......................

Scheduled Maintenance Charts

(Diesel Engine) 0B-- 11.........................

Owner Inspections and Services 0B-- 13...........While Operating the Vehicle 0B-- 13...............

At Each Fuel Fill 0B-- 13..........................

At Least Twice A Month 0B-- 13...................

At Least Monthly 0B-- 13.........................

At Least Twice a Year 0B-- 13.....................

Each Time The Oil is Changed 0B-- 14.............

At Least Annually 0B-- 14.........................

Recommended Fluids and Lubricants 0B-- 15.......

General Description and System

Operation 0B--16................................

General Repair Instructions 0B-- 16................

Vehicle Identification Number System 0B-- 17.......

Vehicle Lifting Procedures 0B-- 20.................

Page 6 of 2053

0B -- 6 GENERAL INFORMATION

D AEW OO M Y_2000

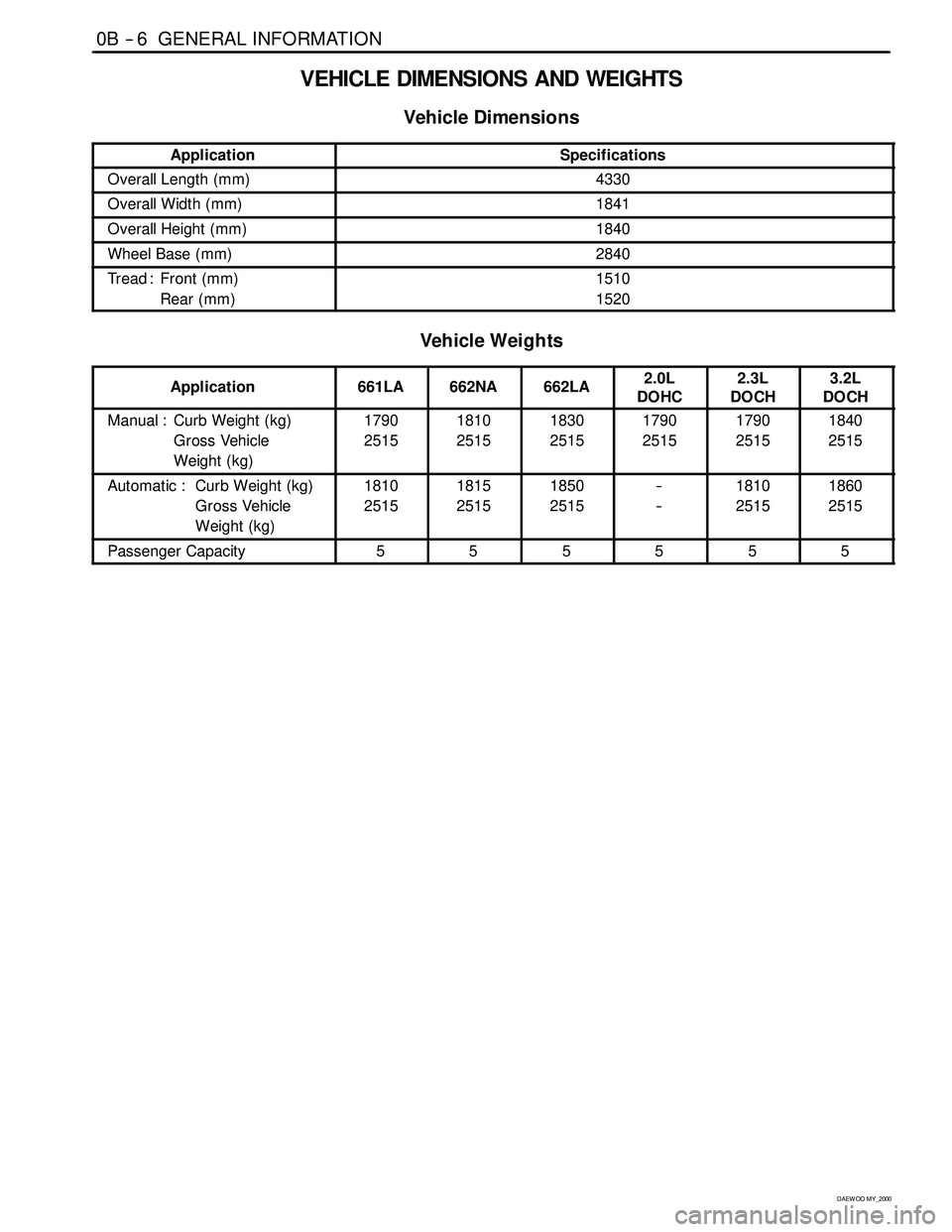

VEHICLE DIMENSIONS AND WEIGHTS

Vehicle Dimensions

ApplicationSpecifications

Overall Length(mm)4330

Overall Width (mm)1841

Overall Height (mm)1840

Wheel Base(mm)2840

Tread : Front (mm)

Rear (mm)1510

1520

Vehicle Weights

Application661LA662NA662LA2.0L

DOHC2.3L

DOCH3.2L

DOCH

Manual : Curb Weight (kg)

Gross Vehicle

Weight (kg)1790

25151810

25151830

25151790

25151790

25151840

2515

Automatic : Curb Weight (kg)

Gross Vehicle

Weight (kg)1810

25151815

25151850

2515--

--1810

25151860

2515

Passenger Capacity555555

Page 713 of 2053

1B3 -- 164 OM600 ENGINE MECHANICAL

D AEW OO M Y_2000

Service Data

Piston clearanceMax. 0.12 mm

Piston crown protrusion in TDC position0.735 -- 0.965 mm

Connecting rod bushing diameter26.012 -- 26.018 mm

Connecting Rod Bolt Dimensions

ThreadM9 x 1

Stretch shaft(C) diameter (new)7.4-0.1mm

Minimum stretch shaft diameter (C)7.1 mm

Length(L)(new)52-0.3mm

Tools Required

000 589 04 14 00 Tensioning Strap

001 589 53 21 00 Dial Gauge

363 589 02 21 00 Dial Gauge Holder

Page 857 of 2053

TIRE AND WHEELS 2E-3

SSANGYONG MY2002

TIRE CHAIN USAGE

Due to limited tire-to-body clearance on certain

vehicles, recommendations for tire chain use are

published in the Owner’s Manual. When tire chains

need to be used, most current Ssangyong vehicles

require SAE Class “S” tire chains. These may also be

designated as 1100 Series, type PL tire chains. These

chains are specifically designed to limit the “fly off”

effect which occurs when the wheel rotates.

Be sure that only fine-link chains are used which do

not add more than 15 mm (0.590 inch), including the

lock, to the tread surface and the inner sides of the

tires. Manufacturers of tire chains have a specific chain

size for each tire size to ensure a proper fit when the chain

is installed. Be sure to purchase the correct chains for the

tires on which they are to be used. Use rubber adjusters to

take up any slack or clearance in loose chains.

Use of chains may adversely affect vehicle handling.

When tire chains are installed, follow these precautions:

Adjust speed to road conditions.

Avoid sharp turns.

Avoid locked-wheel braking.

To prevent chain damage to the vehicle, install the

chains on the front tires as tightly as possible. Tighten

them again after driving 0.4 to 0.8 kilometer (0.3 to 0.5

mile). The use of chains on the rear tires is not recom-

mended because they may contact the vehicle and pos-

sibly damage it. If chains must be used on the rear

tires, be sure there is sufficient clearance between the

chains and the body. Do not exceed 70 km/h (45 mph)

or the chain manufacturer’s speed limit, if lower. Avoid

large bumps, potholes, severe turns and any other

maneuvers which could cause the tires to bounce.

Follow any other instructions of the chain manufacturer

which do not disagree with the above instructions.

REPLACEMENT TIRES

A tire performance criteria (TPC) specification number

is molded in the sidewall near the tire size of all original

equipment tires. This specification number assures that

the tire meets performance standards for traction, en

durance, dimensions, noise, handling and rolling

resistance. Usually a specific TPC number is assigned

to each tire size.

Caution: Do not mix different types of tires on the

same vehicle such as radial, bias and bias-belted

tires except in emergencies, because vehicle han-

dling may be seriously affected and may result in

loss of control.Use only replacement tires with the same size, load

range, and construction as the original. The use of any

other tire size or construction type may seriously affect

ride, handling, speedometer/odometer calibration, ve-

hicle ground clearance, and tire clearance to the body

and the chassis. This does not apply to the spare tire

furnished with the vehicle.

It is recommended that new tires be installed in pairs

on the same axle.

If it is necessary to replace only one tire, pair it with the

tire having the most tread to equalize the braking action.

Although they may appear different in tread design, tires

built by different manufacturers with identical TPC speci-

fications may be used on the same vehicle.

ALL SEASON TIRES

Most vehicles are now equipped with steel-belted all

season radial tires as standard equipment. These tires

qualify as snow tires, with a 37 percent higher average

rating for snow traction than the non-all season radial

tires previously used. Other performance areas, such

as wet traction, rolling resistance, tread life, and air

retention, have also been improved. This was done by

improvements in both tread design and tread

compounds. These tires are identified by an “M + S”

molded in the tire sidewall following the size number.

The suffix “MS” is also molded in the sidewall after

the TPC specification number.

The optional handling tires used on some vehicles are

not all season tires. These will not have the “MS” mark-

ing after the tire size or the TPC specification number.

PASSENGER METRIC SIZED TIRES

All Daewoo vehicles now use passenger (P) metric sized

tires. P-metric tires are available in two load ranges:

standard load (35 psi maximum) and extra load (41 psi

maximum). Most passenger vehicle tires are standard

load.

Most P-metric tire sizes do not have exact correspond-

ing alphanumeric tire sizes. For example, a P175/70R13

is not exactly equal in size and load-carrying capacity

to an FR70-13. For this reason, replacement tires should

be of the same TPC specification number as the origi-

nals. If P-metric tires must be replaced with other sizes,

consult a tire dealer. Tire companies can best recom-

mend the closest match of alphanumeric to P-metric

sizes within their own tire lines.

The metric term for measuring tire inflation pressure is

the kilopascal (kPa). Tire pressure may be printed in

both kPa and psi. One psi equals 6.895 kPa.

See the tire label or refer to “Tire Size and Pressure

Specifications” in this section for tire inflation

pressures.

Page 1803 of 2053

SECTION 9N

FRAME AND UNDERBODY

TABLE OF CONTENTS

Specifications.......................................................9N-2

Fastener Tightening Specifications.......................9N-2

Underbody Dimensions.......................................9N-3

Maintenance and Repair.....................................9N-7

On-Vehicle Service.................................................9N-7

Alignment Checking............................................9N-7Floor Pan Insulators.............................................9N-7

Engine Under Covers ...........................................9N-8

General Description and System Operation........9N-9

General Body Construction..................................9N-9

Engine Under Covers ...........................................9N-9

Page 1805 of 2053

FRAME AND UNDERBODY 9N-3

SSANGYONG MY2002

UNDERBODY DIMENSIONS

KAA9N010

Page 1809 of 2053

FRAME AND UNDERBODY 9N-7

SSANGYONG MY2002

ON-VEHICLE SERVICE

ALIGNMENT CHECKING

An accurate method of determining the alignment of

the underbody uses a measuring tram gauge. The tram

gauge set used to perform the recommended

measuring checks must include a vertical pointer able

to reach 457 mm (18 inches).

Two types of measurements can be made with a tram

gauge: direct point-to-point measurements and

measurements calculated on a horizontal plane (datum

line) parallel to the underbody. Point-to-point

measurements are generally taken on steering and

suspension engine compartment parts and simply

require the vertical pointers to be set equally.

For horizontal plane measurements, the vertical pointers

must be set as specified for each point to be measured.

Dimensions-to-gauge holes are measured to the center

of the holes and flush to the adjacent surface metal

unless otherwise specified. It is recommended that

the diagonal dimensions to the cross-body be checked

on both sides in order to verify the dimensional

accuracy of the vehicle underbody.

FLOOR PAN INSULATORS

The floor pan insulators have been designed for the

higher floor pan temperatures that result from the use

of the catalytic converter in the exhaust system.

Therefore, when servicing a vehicle, it is essential that

any insulators that may have been disturbed or removed

be reinstalled in the original sequence and location.

Also, if an insulator needs to be replaced, use only

the insula-tion specified for that location on the floor

pan.

When servicing or replacing interior insulators, observe

the following instructions.

•Install the insulators in the original position and

sequence. Butt the pieces together in order to

avoid gapping or overlapping.

If it is necessary to replace an insulator, use only

the specified insulation.

Use the original part to determine the amount of

re-placement material required and as a template

for cutting and fitting the new piece to the floor

pan.

When installing the insulator, do not enlarge any

cut-outs or holes that are used for the attachment

of interior parts such as the instrument panel or

the floor console.

MAINTENANCE AND REPAIR