fuel cap SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 4 of 2053

0B -- 4 GENERAL INFORMATION

D AEW OO M Y_2000

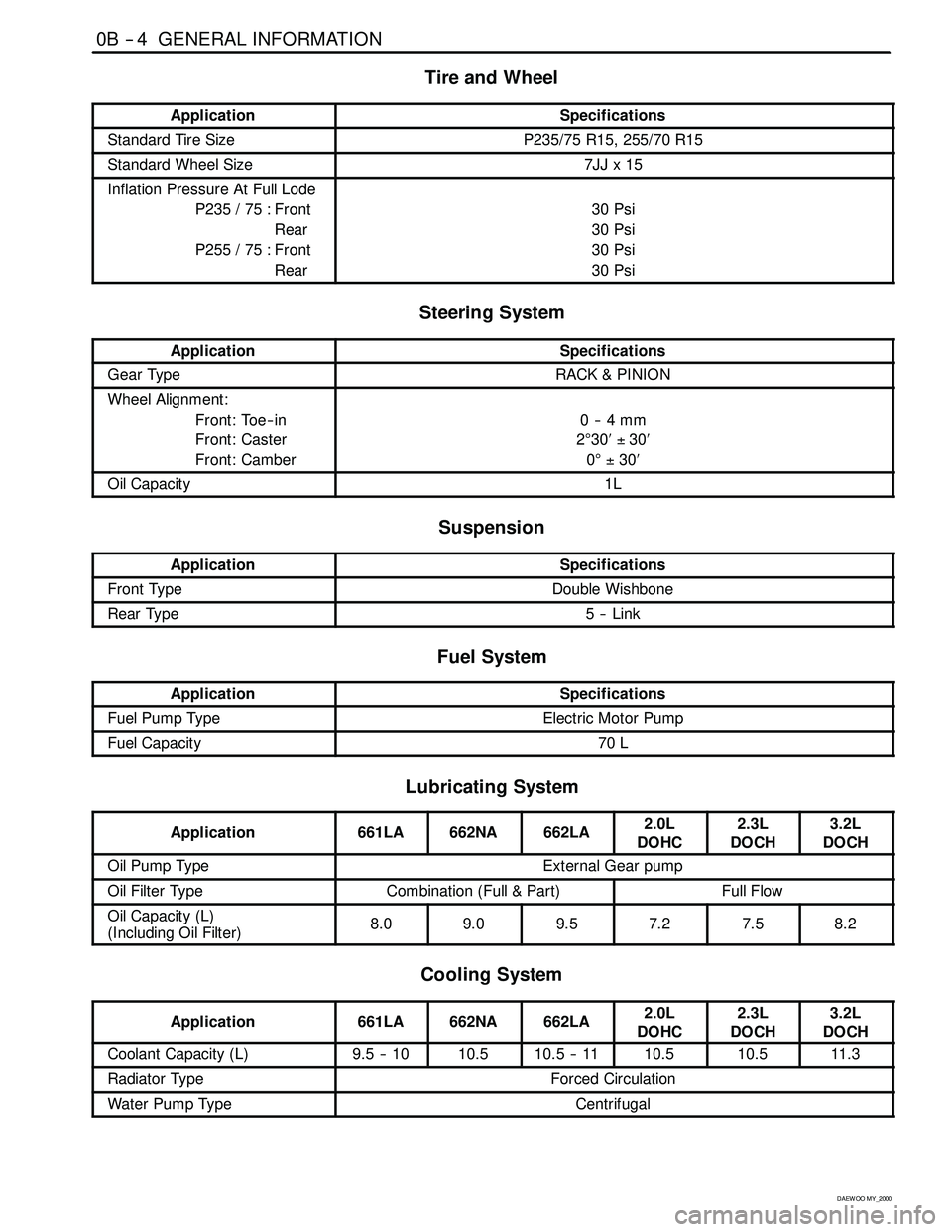

Tire and Wheel

ApplicationSpecifications

Standard Tire SizeP235/75 R15, 255/70 R15

Standard Wheel Size7JJx15

Inflation Pressure At Full Lode

P235 / 75 : Front

Rear

P255 / 75 : Front

Rear

30 Psi

30 Psi

30 Psi

30 Psi

Steering System

ApplicationSpecifications

Gear TypeRACK & PINION

Wheel Alignment:

Front: Toe -- in

Front: Caster

Front: Camber

0--4mm

2°30′±30′

0°±30′

Oil Capacity1L

Suspension

ApplicationSpecifications

Front TypeDouble Wishbone

Rear Type5--Link

Fuel System

ApplicationSpecifications

Fuel Pump TypeElectric Motor Pump

Fuel Capacity70 L

Lubricating System

Application661LA662NA662LA2.0L

DOHC2.3L

DOCH3.2L

DOCH

Oil Pump TypeExternal Gear pump

Oil Filter TypeCombination (Full & Part)Full Flow

Oil Capacity (L)

(Including Oil Filter)8.09.09.57.27.58.2

Cooling System

Application661LA662NA662LA2.0L

DOHC2.3L

DOCH3.2L

DOCH

Coolant Capacity (L)9.5 -- 1010.510.5 -- 1110.510.511. 3

Radiator TypeForced Circulation

Water Pump TypeCentrifugal

Page 14 of 2053

0B -- 14 GENERAL INFORMATION

D AEW OO M Y_2000

EACH TIME THE OIL IS CHANGED

Brake System Inspection

This inspection should be done when the wheels are re-

moved for rotation. Inspect the lines and the hoses for

proper hookup, binding, leaks, cracks, chafing, etc. In-

spect the disc brake pads for wear. Inspect the rotors for

surface condition. Inspect other brake parts, the parking

brake, etc., at the same time. Inspect the brakes more

often if habit or conditions result in frequent braking.

Steering, Suspension and Front Drive Axle

Boot And Seal Inspection

Inspect the front and rear suspension and the steering

system for damaged, loose or missing parts, signs of

wear or lack of lubrication. Inspect the power steering

line and the hoses for proper hookup, binding, leaks,

cracks, chafing, etc. Clean and inspect the drive axle

boot and seals for damage, tears or leakage. Replace

the seals if necessary.

Exhaust System Inspection

Inspect the complete system (including the catalytic

converter if equipped). Inspect the body near the ex-

haust system. Look for broken, damaged, missing, or

out -- of -- position parts as well as open seams, holes,

loose connections, or other conditions which could

cause heat buildup in the floor pan or could let exhaust

fumes seep into the trunk or passenger compartment.

Throttle Linkage Inspection

Inspect the throttle linkage for interference or binding,

damaged, or missing parts. Lubricate all linkage joints

and throttle cable joints, the intermediate throttle shaft

bearing, the return spring at throttle valve assembly, and

the accelerator pedal sliding face with suitable grease.

Check the throttle cable for free movements.

Engine Drive Belts

Inspect all belts for cracks, fraying, wear and proper ten-

sion. Adjust or replace the belts as needed.

Hood Latch Operation

When opening the hood, note the operation of the sec-

ondary latch. It should keep the hood from opening all

the way when the primary latch is released. The hood

must close firmly.

AT LEAST ANNUALLY

Lap and Shoulder Belts Condition and Operation

Inspect the belt system including: the webbing, the

buckles, the latch plates, the retractor, the guide loops

and the anchors.

Movable Head Restraint Operation

On vehicles with movable head restraints, the restraints

must stay in the desired position.

Spare Tire and Jack Storage

Be alert to rattles in the rear of the vehicle. The spare

tire, all the jacking equipment, and the tools must be se-

curely stowed at all times. Oil the jack ratchet or the

screw mechanism after each use.

Key Lock Service

Lubricate the key lock cylinder.

Body Lubrication Service

Lubricate all the body door hinges including the hood,

the fuel door, the rear compartment hinges and the

latches, the glove box and the console doors, and any

folding seat hardware.

Underbody Flushing

Flushing the underbody will remove any corrosive mate-

rials used for ice and snow removal and dust control. At

least every spring clean the underbody. First, loosen the

sediment packed in closed areas of the vehicle. Then

flush the underbody with plain water.

Engine Cooling System

Inspect the coolant and freeze protection fluid. If the

fluid is dirty or rusty, drain, flush and refill the engine

cooling system with new coolant. Keep the coolant at

the proper mixture in order to ensure proper freeze

protection, corrosion protection and engine operating

temperature. Inspect the hoses. Replace the cracked,

swollen, or deteriorated hoses. Tighten the clamps.

Clean the outside of the radiator and the air conditioning

condenser. Wash the filler cap and the neck. Pressure

test the cooling system and the cap in order to help en-

sure proper operation.

Page 15 of 2053

GENERAL INFORMATION 0B -- 15

D AEW OO M Y_2000

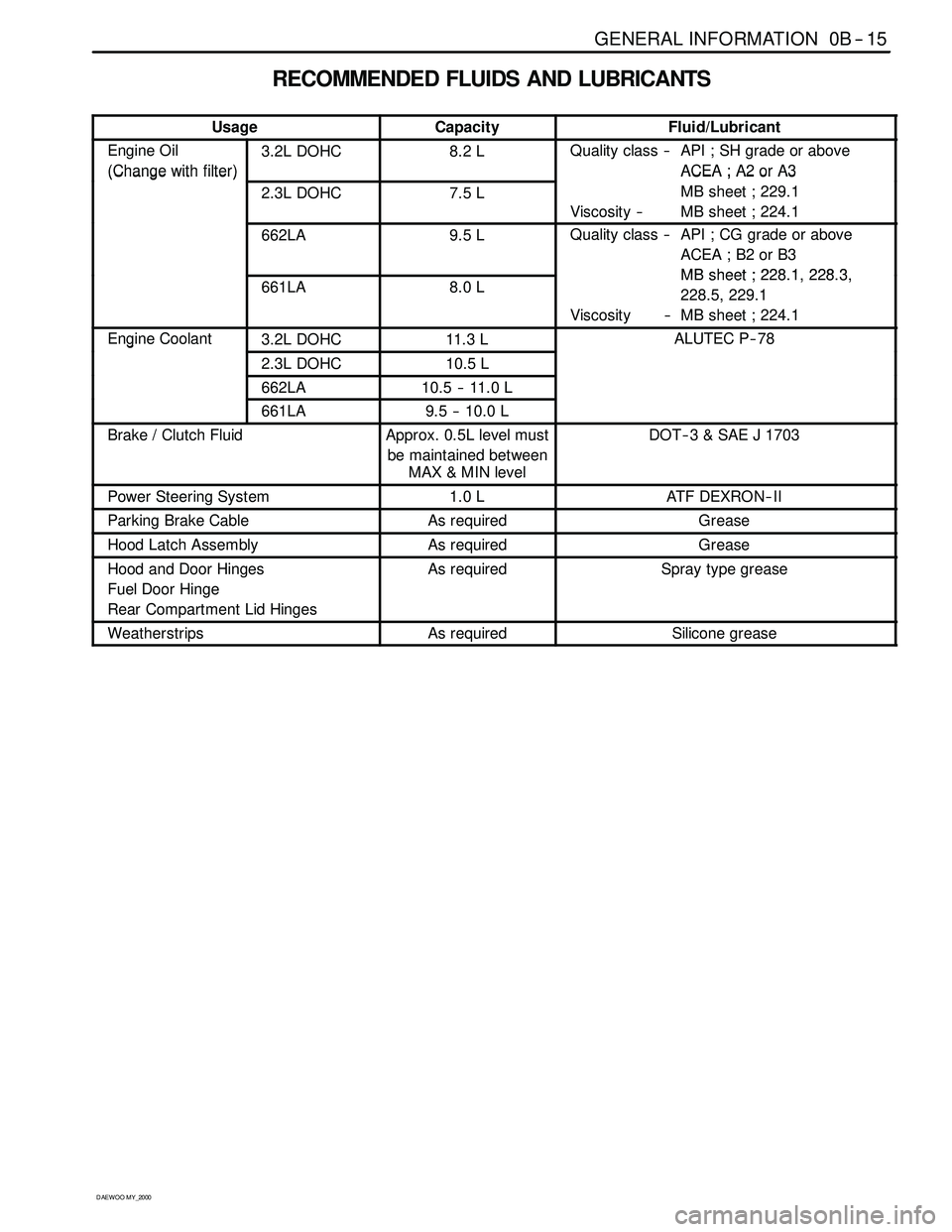

RECOMMENDED FLUIDS AND LUBRICANTS

UsageCapacityFluid/Lubricant

Engine Oil

(Change with filter)3.2L DOHC8.2 LQuality class -- API ; SH grade or above

ACEA ; A2 or A3

(Changewithfilter)

2.3L DOHC7.5 L

ACEA;A2orA3

MB sheet ; 229.1

Viscosity -- MB sheet ; 224.1

662LA9.5 LQuality class -- API ; CG grade or above

ACEA ; B2 or B3

MBsheet;22812283661LA8.0 LMBsheet ; 228.1, 228.3,

228.5, 229.1

Viscosity -- MB sheet ; 224.1

Engine Coolant3.2L DOHC11. 3 LALUTEC P-- 78g

2.3L DOHC10.5 L

662LA10.5 -- 11.0 L

661LA9.5 -- 10.0 L

Brake / Clutch FluidApprox. 0.5L level must

be maintained between

MAX&MINlevelDOT -- 3 & SAE J 1703

Power Steering System1.0 LATF DEXRON--II

Parking Brake CableAs requiredGrease

Hood Latch AssemblyAs requiredGrease

Hood and Door Hinges

Fuel Door Hinge

Rear Compartment Lid HingesAs requiredSpray type grease

WeatherstripsAs requiredSilicone grease

Page 22 of 2053

1A1 -- 2 GENERAL ENGINE INFORMATION

D AEW OO M Y_2000

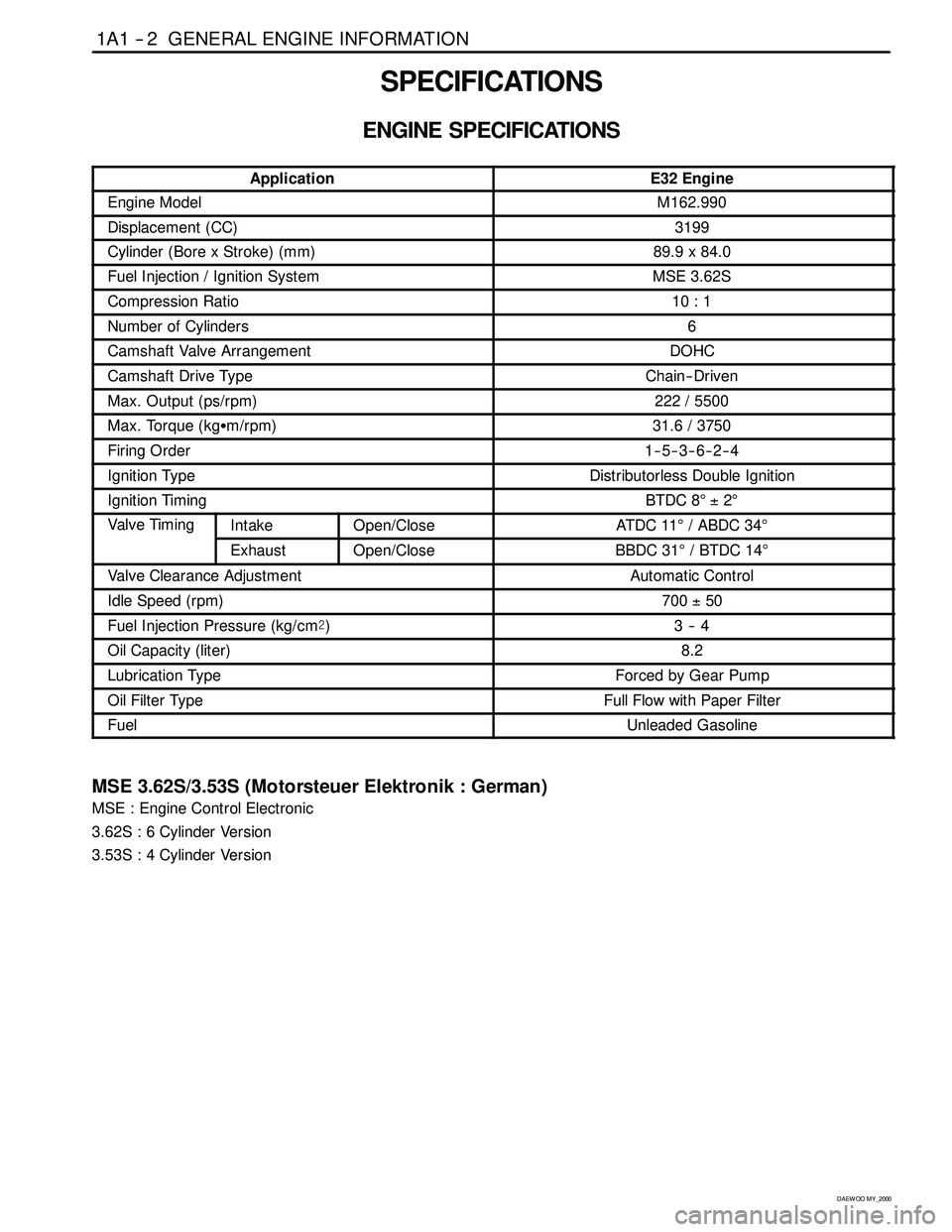

SPECIFICATIONS

ENGINE SPECIFICATIONS

ApplicationE32 Engine

Engine ModelM162.990

Displacement (CC)3199

Cylinder (Bore x Stroke)(mm)89.9 x 84.0

Fuel Injection / Ignition SystemMSE 3.62S

Compression Ratio10 : 1

Number of Cylinders6

Camshaft Valve ArrangementDOHC

Camshaft Drive TypeChain-- Driven

Max. Output (ps/rpm)222 / 5500

Max. Torque (kgSm/rpm)31.6 / 3750

Firing Order1--5--3--6--2--4

Ignition TypeDistributorless Double Ignition

Ignition TimingBTDC 8°±2°

Valve TimingIntakeOpen/CloseAT DC 11°/ ABDC 34°g

ExhaustOpen/CloseBBDC 31°/BTDC14°

Valve Clearance AdjustmentAutomatic Control

Idle Speed (rpm)700±50

Fuel Injection Pressure (kg/cm@)3--4

Oil Capacity (liter)8.2

Lubrication TypeForced by Gear Pump

Oil Filter TypeFull Flow with Paper Filter

FuelUnleaded Gasoline

MSE 3.62S/3.53S (Motorsteuer Elektronik : German)

MSE : Engine Control Electronic

3.62S : 6 Cylinder Version

3.53S : 4 Cylinder Version

Page 34 of 2053

1B1 -- 2 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

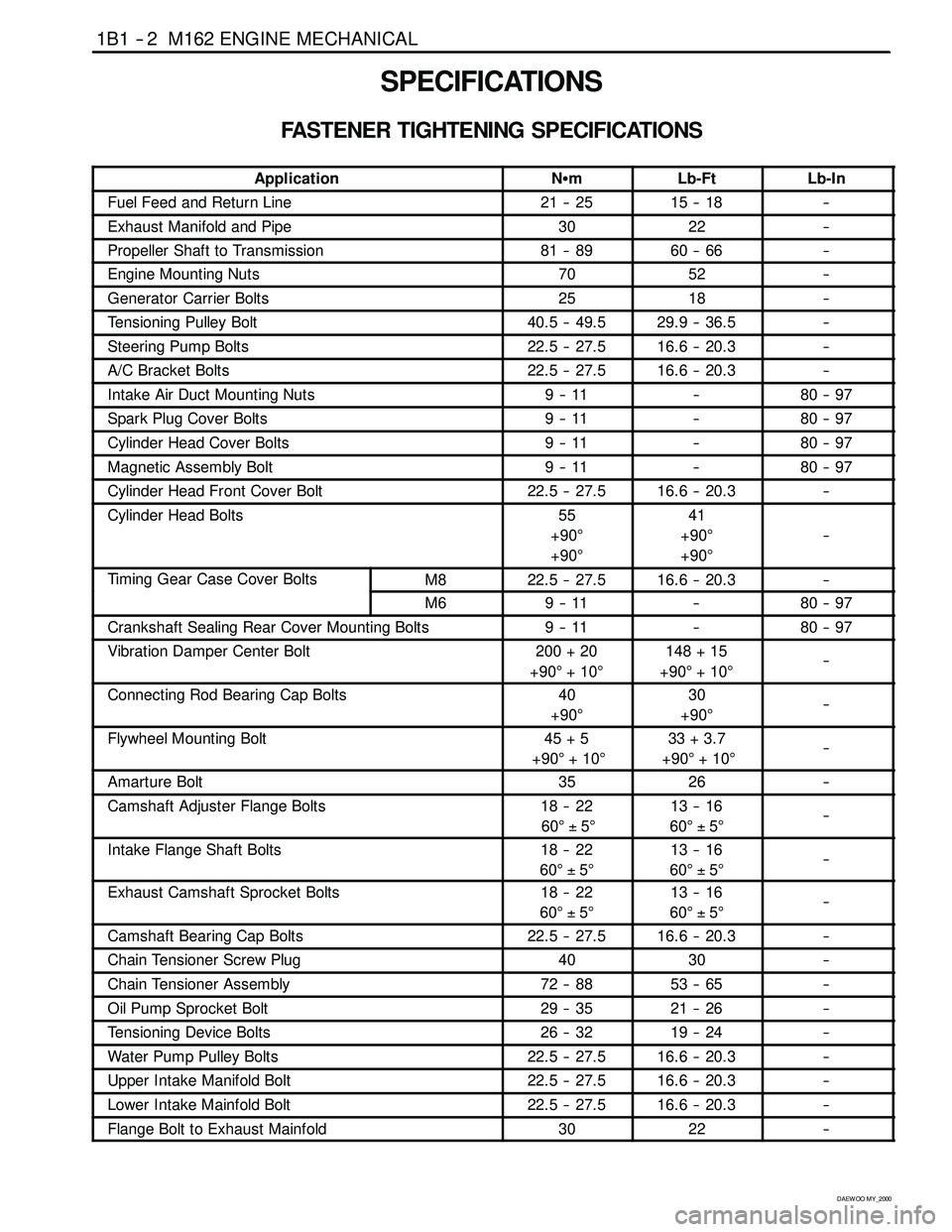

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb-FtLb-In

Fuel Feed and Return Line21 -- 2515 -- 18--

Exhaust Manifold and Pipe3022--

Propeller Shaft to Transmission81 -- 8960 -- 66--

Engine Mounting Nuts7052--

Generator Carrier Bolts2518--

Tensioning Pulley Bolt40.5 -- 49.529.9 -- 36.5--

Steering Pump Bolts22.5 -- 27.516.6 -- 20.3--

A/C Bracket Bolts22.5 -- 27.516.6 -- 20.3--

Intake Air Duct Mounting Nuts9--11--80 -- 97

Spark Plug Cover Bolts9--11--80 -- 97

Cylinder Head Cover Bolts9--11--80 -- 97

Magnetic Assembly Bolt9--11--80 -- 97

Cylinder Head Front Cover Bolt22.5 -- 27.516.6 -- 20.3--

Cylinder Head Bolts55

+90°

+90°41

+90°

+90°

--

Timing Gear Case Cover BoltsM822.5 -- 27.516.6 -- 20.3--g

M69--11--80 -- 97

Crankshaft Sealing Rear Cover Mounting Bolts9--11--80 -- 97

Vibration Damper Center Bolt200 + 20

+90°+10°148 + 15

+90°+10°--

Connecting Rod Bearing Cap Bolts40

+90°30

+90°--

Flywheel Mounting Bolt45 + 5

+90°+10°33 + 3.7

+90°+10°--

Amarture Bolt3526--

Camshaft Adjuster Flange Bolts18 -- 22

60°±5°13 -- 16

60°±5°--

Intake Flange Shaft Bolts18 -- 22

60°±5°13 -- 16

60°±5°--

Exhaust Camshaft Sprocket Bolts18 -- 22

60°±5°13 -- 16

60°±5°--

Camshaft Bearing Cap Bolts22.5 -- 27.516.6 -- 20.3--

Chain Tensioner Screw Plug4030--

Chain Tensioner Assembly72 -- 8853 -- 65--

Oil Pump Sprocket Bolt29 -- 3521 -- 26--

Tensioning Device Bolts26 -- 3219 -- 24--

Water Pump Pulley Bolts22.5 -- 27.516.6 -- 20.3--

Upper Intake Manifold Bolt22.5 -- 27.516.6 -- 20.3--

Lower Intake Mainfold Bolt22.5 -- 27.516.6 -- 20.3--

Flange Bolt to Exhaust Mainfold3022--

Page 169 of 2053

1F1 -- 6 M162 ENGINE CONTROLS

D AEW OO M Y_2000

SPECIAL TOOLS AND EQUIPMENT

SPECIAL TOOLS TABLE

YAA1F890

661 589 00 46 00

Fuel Tank Cap Wrench

KAA1F490

103 589 00 21 00

Fuel Pressure Gauge

Page 207 of 2053

1F1 -- 44 M162 ENGINE CONTROLS

D AEW OO M Y_2000

Measure the Fuel Delivery from the Fuel Pump

1. Disconnect the return pipe from fuel distributor and insert the appropriate hose into it.

2. Place the hose end into the beaker with the minimum capacity of 1 Liter

3. Turn the ignition switch to “ON” position.

4. Connect the terminal No. 33 and No. 5 of ECM with a service wire.

5. Measure the fuel delivery from the fuel pump

Specified Value

1 Liter/max. 35 sec.

Notice:Check the fuel filter and fuel line when the fuel delivery is not within specified value.

Measure the Current Consumption of Fuel Pump

1. Remove the fuel pump relay from fuse and relay box in trunk, and turn the ignition switch to “ON” position.

2. Using a multimeter, measure the current consumption by connecting the terminal No. 30 and No. 87 of the fuel

pump relay connector.

Specified Value

5~9A

Notice:Replace the fuel pump relay if the measured value is over 9 A.

Page 246 of 2053

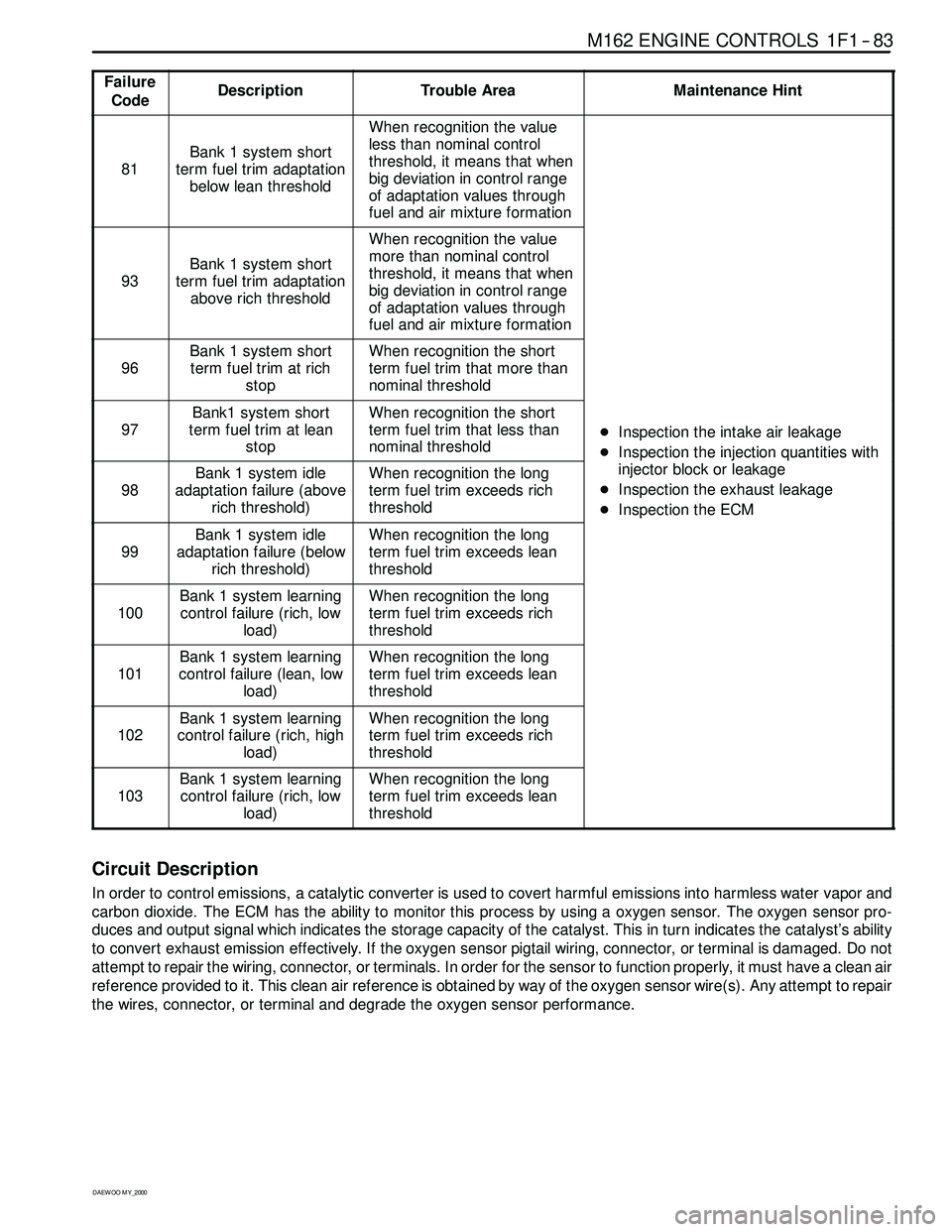

M162 ENGINE CONTROLS 1F1 -- 83

D AEW OO M Y_2000

Failure

CodeDescriptionTrouble AreaMaintenance Hint

81

Bank 1 system short

term fuel trim adaptation

below lean threshold

When recognition the value

less than nominal control

threshold, it means that when

big deviation in control range

of adaptation values through

fuel and air mixture formation

93

Bank 1 system short

term fuel trim adaptation

above rich threshold

When recognition the value

more than nominal control

threshold, it means that when

big deviation in control range

of adaptation values through

fuel and air mixture formation

96

Bank 1 system short

term fuel trim at rich

stopWhen recognition the short

term fuel trim that more than

nominal threshold

97

Bank1 system short

term fuel trim at lean

stopWhen recognition the short

term fuel trim that less than

nominal threshold

DInspection the intake air leakage

DIns

pection the injectionquantities with

98

Bank 1 system idle

adaptation failure (above

rich threshold)When recognition the long

term fuel trim exceeds rich

threshold

DInspectiontheinjectionquantitieswith

injector block or leakage

DInspection the exhaust leakage

DInspection the ECM

99

Bank 1 system idle

adaptation failure (below

rich threshold)When recognition the long

term fuel trim exceeds lean

threshold

p

100

Bank 1 system learning

control failure (rich, low

load)When recognition the long

term fuel trim exceeds rich

threshold

101

Bank 1 system learning

control failure (lean, low

load)When recognition the long

term fuel trim exceeds lean

threshold

102

Bank 1 system learning

control failure (rich, high

load)When recognition the long

term fuel trim exceeds rich

threshold

103

Bank 1 system learning

control failure (rich, low

load)When recognition the long

term fuel trim exceeds lean

threshold

Circuit Description

In order to control emissions, a catalytic converter is used to covert harmful emissions into harmless water vapor and

carbon dioxide. The ECM has the ability to monitor this process by using a oxygen sensor. The oxygen sensor pro-

duces and output signal which indicates the storage capacity of the catalyst. This in turn indicates the catalyst’s ability

to convert exhaust emission effectively. If the oxygen sensor pigtail wiring, connector, or terminal is damaged. Do not

attempt to repair the wiring, connector, or terminals. In order for the sensor to function properly, it must have a clean air

reference provided to it. This clean air reference is obtained by way of the oxygen sensor wire(s). Any attempt to repair

the wires, connector, or terminal and degrade the oxygen sensor performance.

Page 258 of 2053

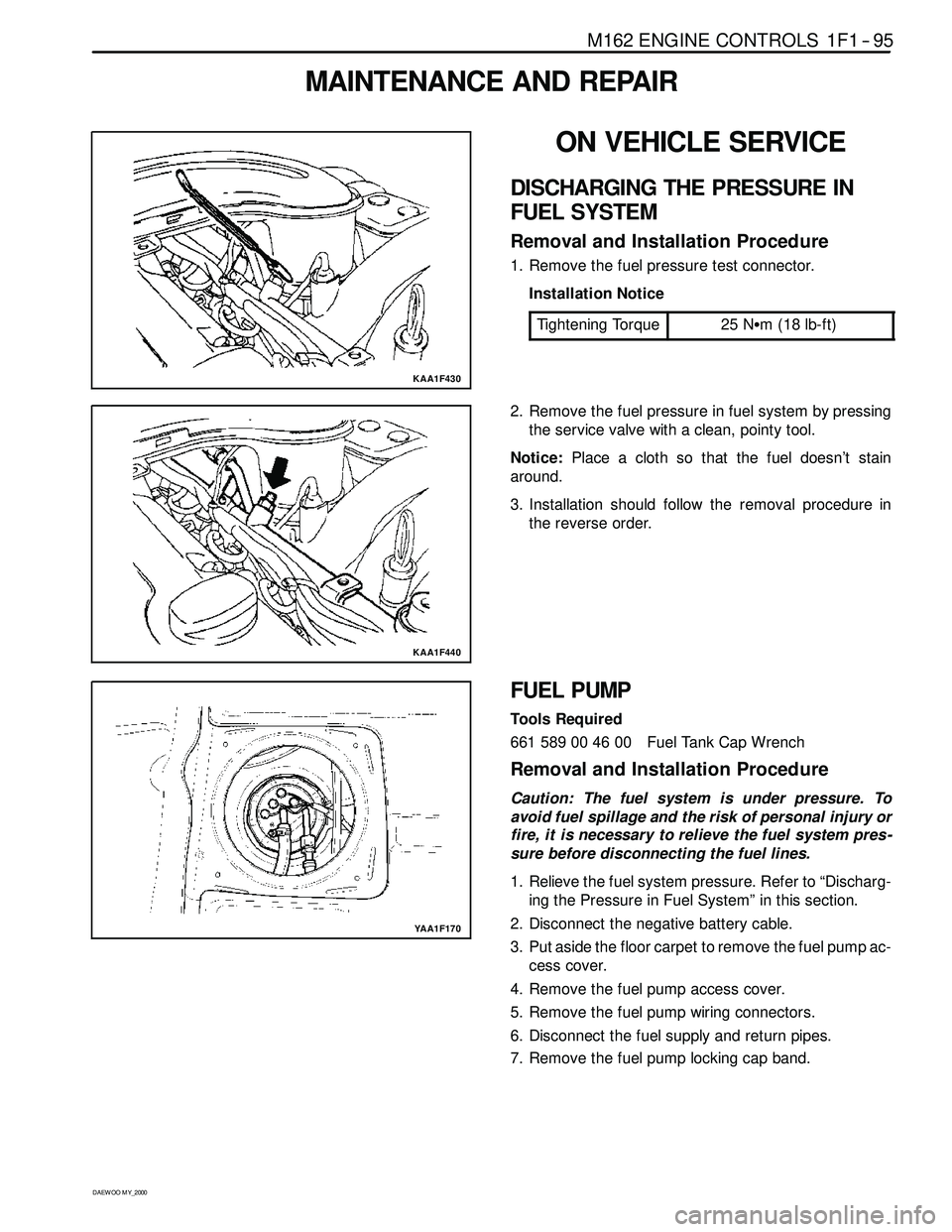

M162 ENGINE CONTROLS 1F1 -- 95

D AEW OO M Y_2000

MAINTENANCE AND REPAIR

KAA1F430

ON VEHICLE SERVICE

DISCHARGING THE PRESSURE IN

FUEL SYSTEM

Removal and Installation Procedure

1. Remove the fuel pressure test connector.

Installation Notice

Tightening Torque

25 NSm (18 lb-ft)

KAA1F440

2. Remove the fuel pressure in fuel system by pressing

the service valve with a clean, pointy tool.

Notice:Place a cloth so that the fuel doesn’t stain

around.

3. Installation should follow the removal procedure in

the reverse order.

YAA1F170

FUEL PUMP

Tools Required

661 589 00 46 00 Fuel Tank Cap Wrench

Removal and Installation Procedure

Caution: The fuel system is under pressure. To

avoid fuel spillage and the risk of personal injury or

fire, it is necessary to relieve the fuel system pres -

sure before disconnecting the fuel lines.

1. Relieve the fuel system pressure. Refer to “Discharg-

ing the Pressure in Fuel System” in this section.

2. Disconnect the negative battery cable.

3. Put aside the floor carpet to remove the fuel pump ac-

cess cover.

4. Remove the fuel pump access cover.

5. Remove the fuel pump wiring connectors.

6. Disconnect the fuel supply and return pipes.

7. Remove the fuel pump locking cap band.

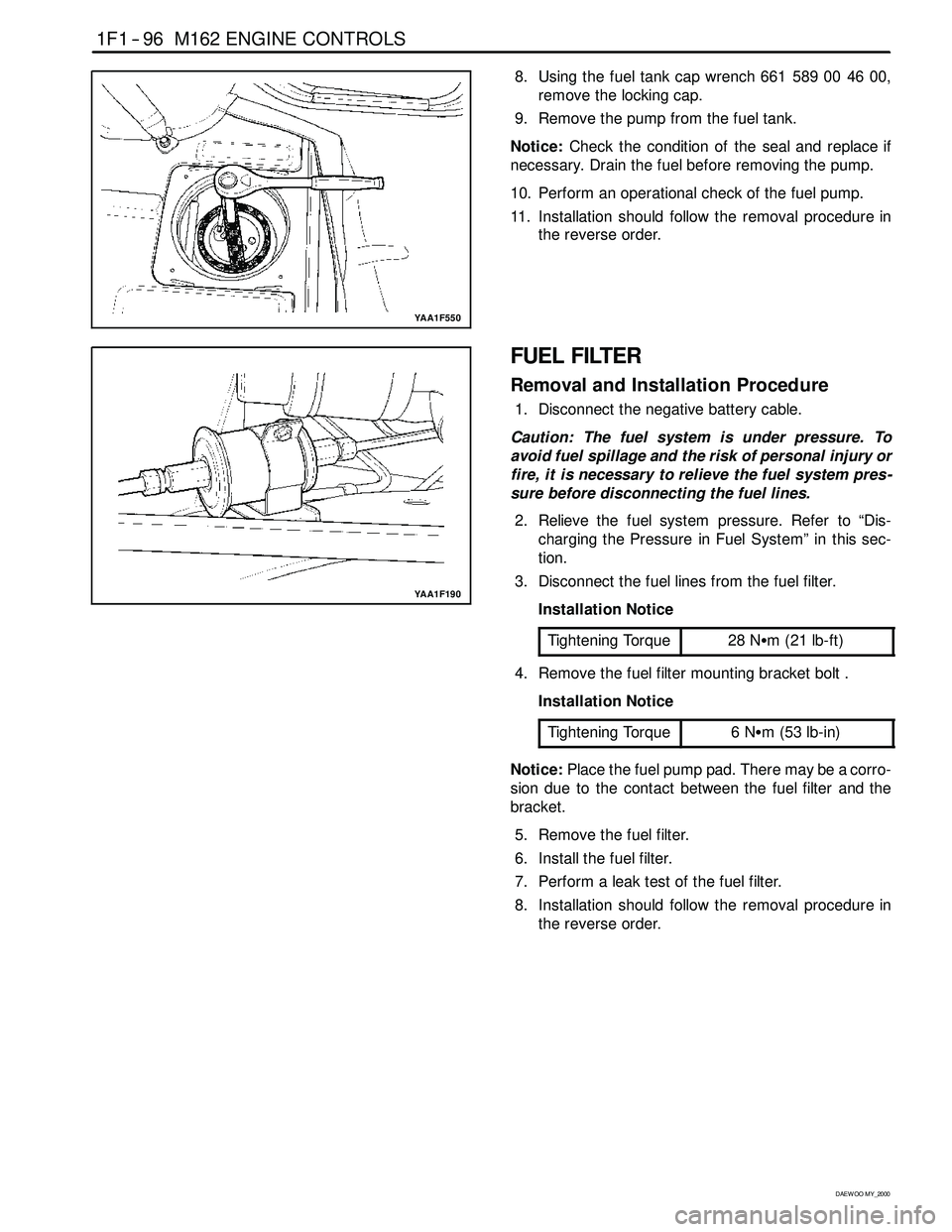

Page 259 of 2053

1F1 -- 96 M162 ENGINE CONTROLS

D AEW OO M Y_2000

YAA1F550

8. Using the fuel tank cap wrench 661 589 00 46 00,

remove the locking cap.

9. Remove the pump from the fuel tank.

Notice:Check the condition of the seal and replace if

necessary. Drain the fuel before removing the pump.

10. Perform an operational check of the fuel pump.

11. Installation should follow the removal procedure in

the reverse order.

YAA1F190

FUEL FILTER

Removal and Installation Procedure

1. Disconnect the negative battery cable.

Caution: The fuel system is under pressure. To

avoid fuel spillage and the risk of personal injury or

fire, it is necessary to relieve the fuel system pres -

sure before disconnecting the fuel lines.

2. Relieve the fuel system pressure. Refer to “Dis-

charging the Pressure in Fuel System” in this sec-

tion.

3. Disconnect the fuel lines from the fuel filter.

Installation Notice

Tightening Torque

28 NSm (21 lb-ft)

4. Remove the fuel filter mounting bracket bolt .

Installation Notice

Tightening Torque

6NSm (53 lb-in)

Notice:Place the fuel pump pad. There may be a corro-

sion due to the contact between the fuel filter and the

bracket.

5. Remove the fuel filter.

6. Install the fuel filter.

7. Perform a leak test of the fuel filter.

8. Installation should follow the removal procedure in

the reverse order.