washer fluid SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 13 of 2053

GENERAL INFORMATION 0B -- 13

D AEW OO M Y_2000

OWNER INSPECTIONS AND SERVICES

WHILE OPERATING THE VEHICLE

Horn Operation

Blow the horn occasionally to make sure it works. Check

all the button locations.

Brake System Operation

Be alert for abnormal sounds, increased brake pedal

travel or repeated puling to one side when braking. Also,

if the brake warning light goes on, or flashes, something

may be wrong with part of the brake system.

Exhaust System Operation

Be alert to any changes inthe sound of the system or

the smell of the fumes. These are signs that the system

may be leaking or overheating. Have the system in-

spected and repaired immediately.

Tires, Wheels and Alignment Operation

Be alert to any vibration of the steering wheel or the

seats at normal highway speeds. This may mean a

wheel needs to be balanced. Also, a pull right or left on a

straight, level road may show the need for a tire pres-

sure adjustment or a wheel alignment.

Steering System Operation

Be alert to changes in the steering action. An inspection

is needed when the steering wheel is hard to turn or has

too much free play, or is unusual sounds are noticed

when turning or parking.

Headlight Aim

Take note of the light pattern occasionally. Adjust the

headlights if the beams seem improperly aimed.

AT EACH FUEL FILL

A fluid loss in any (except windshield washer) system

may indicate a problem. Have the system inspected and

repaired immediately.

Engine Oil Level

Check the oil level and add oil if necessary. The best

time to check the engine oil level is when the oil is warm.

1. After stopping the engine, wait a few minutes for the

oil to drain back to the oil pan.

2. Pull out the oil level indicator (dip stick).

3. Wipe it clean, and push the oil level indicator back

down all the way.

4. Pull out the oil level indicator and look at the oil level

on it.

5. Add oil, if needed, to keep the oil level above the low-

er mark. Avoid overfilling theengine, since this may

cause engine damage.

6. Push the indicator all the way back down into the en-

gine after taking the reading.If you check the oil level when the oil is cold, do not run

the engine first. The cold oil will not drain back to the pan

fast enough to give a true oil level reading.

Engine Coolant Level and Condition

Check the coolant level in the coolant reservoir tank and

add coolant if necessary. Inspect the coolant. Replace

dirty or rusty coolant.

Windshield Washer Fluid Level

Check the washer fluid level in the reservoir. Add fluid if

necessary.

AT LEAST TWICE A MONTH

Tire And Wheel Inspection and Pressure

Check

Check the tire for abnormal wear or damage. Also check

for damaged wheels. Check the tire pressure when the

tires are cold ( check the spare also, unless it is a stow-

away). Maintain the recommended pressures. Refer to

“Tire and Wheel” is in section 0B.

AT LEAST MONTHLY

Light Operation

Check the operation of the license plate light, the head-

lights (including the high beams), the parking lights, the

fog lights, the taillight, the brake lights, the turn signals,

the backup lights and the hazard warning flasher.

Fluid Leak Check

Periodically inspect the surface beneath the vehicle for

water, oil, fuel or other fluids, after the vehicle has been

parked for a while. Water dripping from the air condition-

ing system after use is normal. If you notice fuel leaks or

fumes, find the cause and correct it at once.

AT LEAST TWICE A YEAR

Power Steering System Reservoir Level

Check the power steering fluid level. Keep the power

steering fluid at the proper level. Refer to Section 6A,

Power Steering System.

Brake Master Cylinder Reservoir Level

Check the fluid and keep it at the proper level. A low fluid

level can indicate worn disc brake pads which may need

to be serviced. Check the breather hole in the reservoir

cover to be free from dirt and check for an open pas-

sage.

Weather- Strip Lubrication

Apply a thin film silicone grease using a clean cloth.

Page 16 of 2053

0B -- 16 GENERAL INFORMATION

D AEW OO M Y_2000

GENERAL DESCRIPTION AND SYSTEM OPERATION

GENERAL REPAIR INSTRUCTIONS

DIf a floor jack is used, the following precautions are

recommended.

DPark the vehicle on level ground, “block” the front or

rear wheels, set the jack against the frame, raise the

vehicle and support it with chassis stands and then

perform the service operation.

DBefore performing the service operation, disconnect

the negative battery cable in order to reduce the

chance of cable damaged and burning due to short --

cir cuiting.

DUse a cover on the body, the seats and the floor to

protect them against damage and contamination.

DHandle brake fluid and antifreeze solution with care

as they can cause paint damage.

DThe use of proper tools, and the recommended es-

sential and available tools where specified, are impor-

tant for efficient and reliable performance of the

service repairs.

DUse genuine DAEWOO parts.DDiscard used cotter pins, gaskets, O -- rings, oil seals,

lock washers and self -- locking nuts. Prepare new

ones for installation. Normal function of these parts

cannot be maintained if these parts are reused.

DKeep the disassembled parts neatly in groups to facil-

itate proper and smooth reassembly.

DKeep attaching bolts and nuts separated, as they

vary in hardness and design depending on the posi-

tion of the installation.

DClean the parts before inspection or reassembly.

DAlso clean the oil parts, etc. Use compressed air to

make certain they are free of restrictions.

DLubricate rotating and sliding faces of parts with oil or

grease before installation.

DWhen necessary, use a sealer on gaskets to prevent

leakage.

DCarefully observe all specifications for bolt and nut

torques.

DWhen service operation is completed, make a final

check to be sure service was done properly and the

problem was corrected.

Page 1109 of 2053

AUTOMATIC TRANSMISSION 5A-15

SSANGYONG MY2002

3-4

OWC

X

X

X

X

X 1-2

OWC

X B2

X

X B1

X

X C4

X

X

X

Gear set-sprag-centre support

C1 -C2 -C3 -C4 clutch sub-assembly

Pump assembly

Valve body assembly

One, or a combination of selective washers are used

between the input shaft flange and the number 4

bearing to control the transmission end float. This

arrangement allows for extensive subassembly testing

and simplistic final assembly during production.

A general description of the operation of the Power

Train System is detailed below.

First gear is engaged by applying the C2 clutch and

locking the 1-2 One Way Clutch (1-2 OWC). The 1-2

shift is accomplished by applying the B1 band and

overrunning the 1-2 OWC. The 2-3 shift is

accomplished by applying the C1 clutch and releasingthe B1 band. The 3-4 shift is accomplished by re-

applying the B1 band and overrunning the 3-4 OWC.

Reverse gear is engaged by applying the C3 clutch

and the B2 band.

The C4 clutch is applied in the Manual 1, 2 and 3 ranges

to provide engine braking. In addition, the C4 clutch

is also applied in the Drive range for second and third

gears to eliminate objectionable freewheel coasting.

The B2 band is also applied in the Manual 1 range to

accomplish the low-overrun shift.

Both the front and rear servos are dual area designs

to allow accurate friction element matching without the

need for secondary regulator valves. All the friction

elements have been designed to provide low shift

energies and high static capacities when used with

the new low static co-efficient transmission fluids. Non-

asbestos friction materials are used throughout.

Gear

First

Second

Third

Fourth

Reverse

Manual 1Gear

Ratio

2.741

1.508

1.000

0.708

2.428

2.741C1

X

XC2

X

X

X

X

XC3

XLU

CLUTCH

X*

X ELEMENTS ENGAGED

* For Certain Vehicle Applications, Refer to the Owner's Manual.

KAA5A250

Page 1271 of 2053

5A-176 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Planet Carrier Assembly and Centre Support

1. Check the carrier and planet assembly for any

damage or irregularity and ensure that all pinions

rotate freely and that the pinion end float is within

0.10 mm - 0.50 mm.

2. Install the One Way Clutch (OWC) retainer (1) to

the planet carrier with the inner edge pointing down-

wards. Inspect the OWC race and the sprag

assemblies for wear or damage. Replace if

necessary.

3. Install the outer (3) race in the drum. Press the

race to the bottom of the drum and install the

retaining circlip (2). Ensure the circlip is firmly

seated in its groove.

4. Install the OWC (1) into the outer race with the lip

edge uppermost. Lubricate the sprags with auto-

matic transmission fluid.

5. Check that the plugs are fitted to the centre

support, then assemble the centre support into

the OWC, ensuring that the support will rotate in

an anti-clock-wise direction only.

6. Lubricate the No. 9 needle bearing and washer

with petroleum jelly and fit them to the rear face

of the planet carrier.

7. In s t a l l th e

KAA5A0A0

KAA5A760

KAA5A750

KAA5A560

Tightening Torque20 - 27 Nm

(15 - 20 lb-ft)

Page 1272 of 2053

AUTOMATIC TRANSMISSION 5A-177

SSANGYONG MY2002

Adaptor Housing Assembly

1. Install a new seal to the adaptor housing.

2. Position a new gasket onto the adaptor housing.

Notice: Do not use petroleum jelly to hold the gasket

in position.

3. Apply additional Loctite 202 or equivalent as required

to the adapter housing bolts. Install the adaptor

housing and torque the bolts to specification.

Installation Notice

Front Servo Assembly

1. Lubricate the cover ‘O’ ring with automatic

transmission fluid and fit to the cover.

2. Lubricatethepiston‘O’ rings with automatic trans-

mission fluid and fit to the piston.

3. Assemble the piston, push rod, spring, belleville

washer, seat and retaining ring.

4. Fit the piston push rod assembly into the front

servo cover.

5. Install the front servo block and spring into the

case.

6. Install the front servo assembly into the case.

KAA5A0C0

KAA5A520 KAA5A0B0

Tightening Torque30 - 35 Nm

(22 - 26 lb-ft)

7. Compress the servo cover and fit the servo cover

retaining circlip, aligning the gap with the pan rail,

and ensuring that it is completely seated in its

groove.

Notice: Ensure that the front servo snap ring is

installed correctly. Orient the circlip with the gap at

the bottom, near the pan rail.

KAA5A0D0

Page 1278 of 2053

AUTOMATIC TRANSMISSION 5A-183

SSANGYONG MY2002

C3 Clutch and Reverse Sun Gear Assembly

Tools Required

0555-336259Clutch Spring Compressor

0555-336260Clutch Pack Clearance Kit

1. Check the orifices in the cylinder are clear of ob-

structions.

2. Check the C3 cylinder bush outside diameter and

the centre support inside diameter are in good

condition and not damaged. Coat the sealing rings

with automatic transmission fluid and fit into the

C3 cylinder grooves.

3. Check the reverse sun gear splines, grooves and

thrust face for condition. Coat the ‘O’ ring with

automatic transmission fluid and fit it to the groove

of the reverse sun gear.

4. Lubricate the C3 washer with petroleum jelly and

fit to the inner face of the reverse sun gear.

5. Install the reverse sun gear in the C3 cylinder,

ensuring that the ‘O’ ring compression is

adequate but not excessive.

Notice: ‘O’ rings must not be twisted in the

grooves.

KAA5A0P0

6. Coat the C3 piston ‘O’ rings with automatic trans-

mission fluid and fit the small ‘O’ ring onto the

inner ring and the large ‘O’ ring onto the outer

ring of the C3 piston.

7. Check that the bleed orifices of the piston are

clean and clear of obstructions.

8. Install the C3 piston in the cylinder until the

outside diameter of the piston enters the inside

diameter of the cylinder.

Notice: Take care not to cut the ‘O’ ring.

9. Assemble the spring and spring retainer on the

piston. Using 0555-336259 clutch spring

compressor compress the spring sufficiently to

enable the installation of the retaining circlip,

ensuring that the circlip is firmly seated in the

groove, and remove the tool.

10. Fit the C3 wave plate to the C3 piston face,

ensuring that one crest of the wave plate of the

C3 piston face is aligned over one of the piston

orifices.

KAA5A0Q0

KAA5A730

Page 1280 of 2053

AUTOMATIC TRANSMISSION 5A-185

SSANGYONG MY2002

Notice: With the clutch pack supporting a weight

of 2kg, the clearance between the snap ring and

the top of the pressure plate is to be between 1.07

- 1.45 mm.

15. If new friction plates are being fitted, remove the

clutch pack and soak the friction elements in auto-

matic transmission fluid for a minimum of five min-

utes prior to reassembly.

Notice: The clutch pack clearance must be taken

before the elements are soaked in automatic

transmission fluid.

Forward Sun Gear and C3 Clutch Pack

Assembly

1. Fit the No. 7 needle bearing assembly over the

for-ward sun gear, ensuring that the thrust washer

is between the bearing and the sun gear.

2. Lubricate the lipped thrust plate with petroleum

jelly and fit the thrust plate onto the reverse sun

gear.

KAA5A0U0 KAA5AOTA

3. Align and fit the C3 clutch assembly over the for-

ward sun gear.

4. Lubricate the No. 6 needle bearing with petroleum

jelly and fit it to the thrust plate. Ensure the lugs

on the outside diameter of the bearing fit in the

thrust plate counterbore.

5. Align and fit the plastic thrust washer to the thrust

plate with petroleum jelly.

6. Install the assembly over the forward sun gear

shaft against the No. 6 needle bearing.

7. Place the assembly to one side.

KAA5A0W0KAA5A0V0

Page 1396 of 2053

SSANGYONG MY2002

5D1-74 TRANSFER CASE

KAA5D470

KAA5D480

KAA5D490

KAA5D500

28. Remove the external snap ring from the input shaft.

29. Place the input shaft in a vise and remove the

bear ing.

30. Remove the thrust washer, thrust plate and the

sun gear off the input shaft.

Assembly Procedure

Important: Lubricate all parts with automatic transmis-

sion fluid (ATF) or equivalent before assemble. Remove

all traces of gasket sealant from the front case and

mounting adapter mating surfaces

1. Install the front output shaft bearing, if removed.

Notice: Press the bearing in straight, making sure

it is not cocked in the bore.

2. Install the internal snap ring that retains the front

output shaft bearing. 33. Remove the external snap ring retaining the front

output shaft.

34. Remove the front output shaft/flange.

35. Remove and discard front output shaft oil seal,

as required.

36. Remove the internal snap ring and remove the front

output shaft bearing, as required. 31. Position the input shaft on SST input shaft support.

32. Remove the needle bearing and bushing using

SST bearing installer/remover, as required.

Notice: Under normal use, the needle bearing and

bushing may not require replacement. After

inspection, If replacement is required, the bushing

and needle bearing must be replaced as a set.

Page 1400 of 2053

SSANGYONG MY2002

5D1-78 TRANSFER CASE

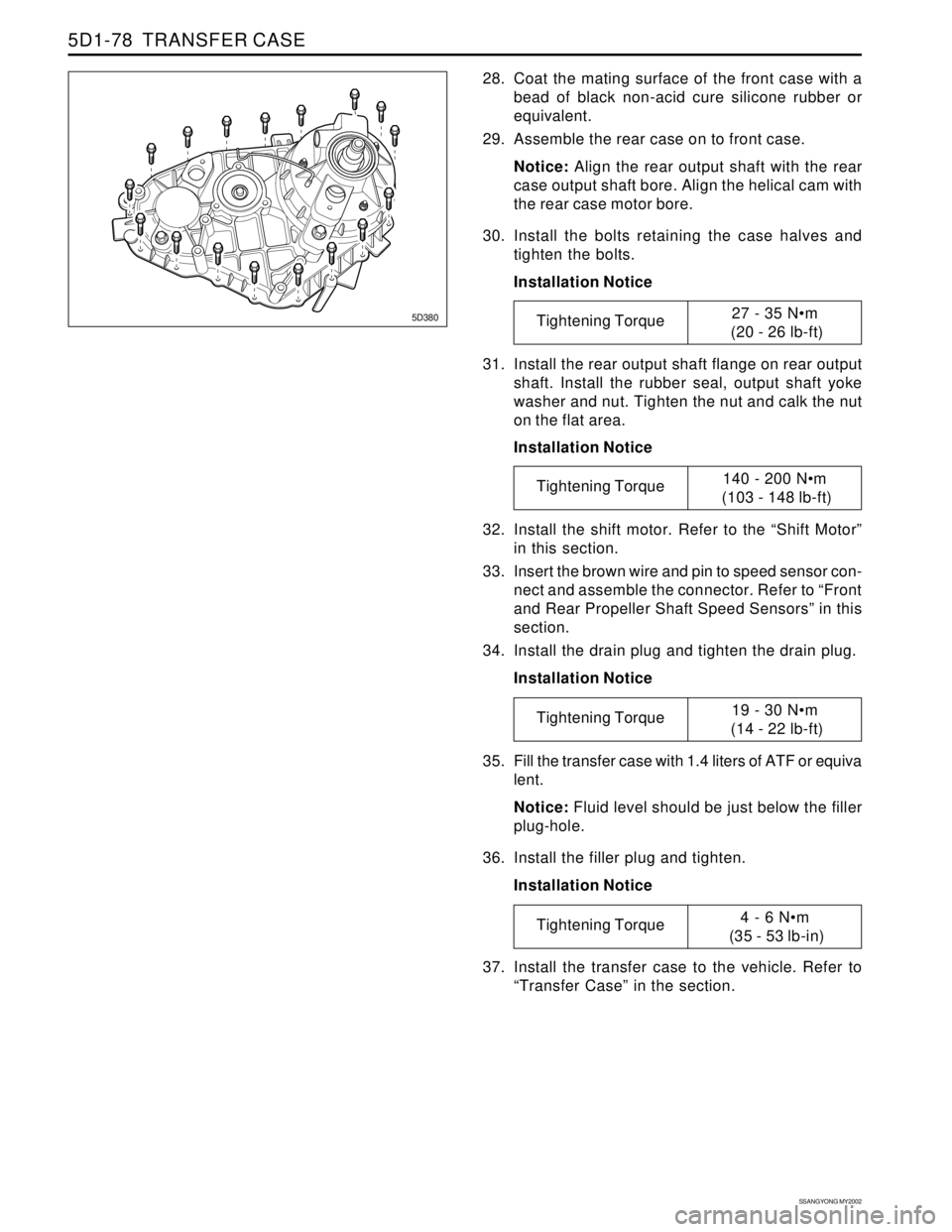

31. Install the rear output shaft flange on rear output

shaft. Install the rubber seal, output shaft yoke

washer and nut. Tighten the nut and calk the nut

on the flat area.

Installation Notice

32. Install the shift motor. Refer to the “Shift Motor”

in this section.

33. Insert the brown wire and pin to speed sensor con-

nect and assemble the connector. Refer to “Front

and Rear Propeller Shaft Speed Sensors” in this

section.

34. Install the drain plug and tighten the drain plug.

Installation Notice

35. Fill the transfer case with 1.4 liters of ATF or equiva

lent.

Notice: Fluid level should be just below the filler

plug-hole.

36. Install the filler plug and tighten.

Installation Notice

37. Install the transfer case to the vehicle. Refer to

“Transfer Case” in the section.

5D380

28. Coat the mating surface of the front case with a

bead of black non-acid cure silicone rubber or

equivalent.

29. Assemble the rear case on to front case.

Notice: Align the rear output shaft with the rear

case output shaft bore. Align the helical cam with

the rear case motor bore.

30. Install the bolts retaining the case halves and

tighten the bolts.

Installation Notice

Tightening Torque27 - 35 Nm

(20 - 26 lb-ft)

Tightening Torque140 - 200 Nm

(103 - 148 lb-ft)

Tightening Torque19 - 30 Nm

(14 - 22 lb-ft)

Tightening Torque4 - 6 Nm

(35 - 53 lb-in)

Page 1664 of 2053

BODY WIRING SYSTEM 9A-13

SSANGYONG MY2002

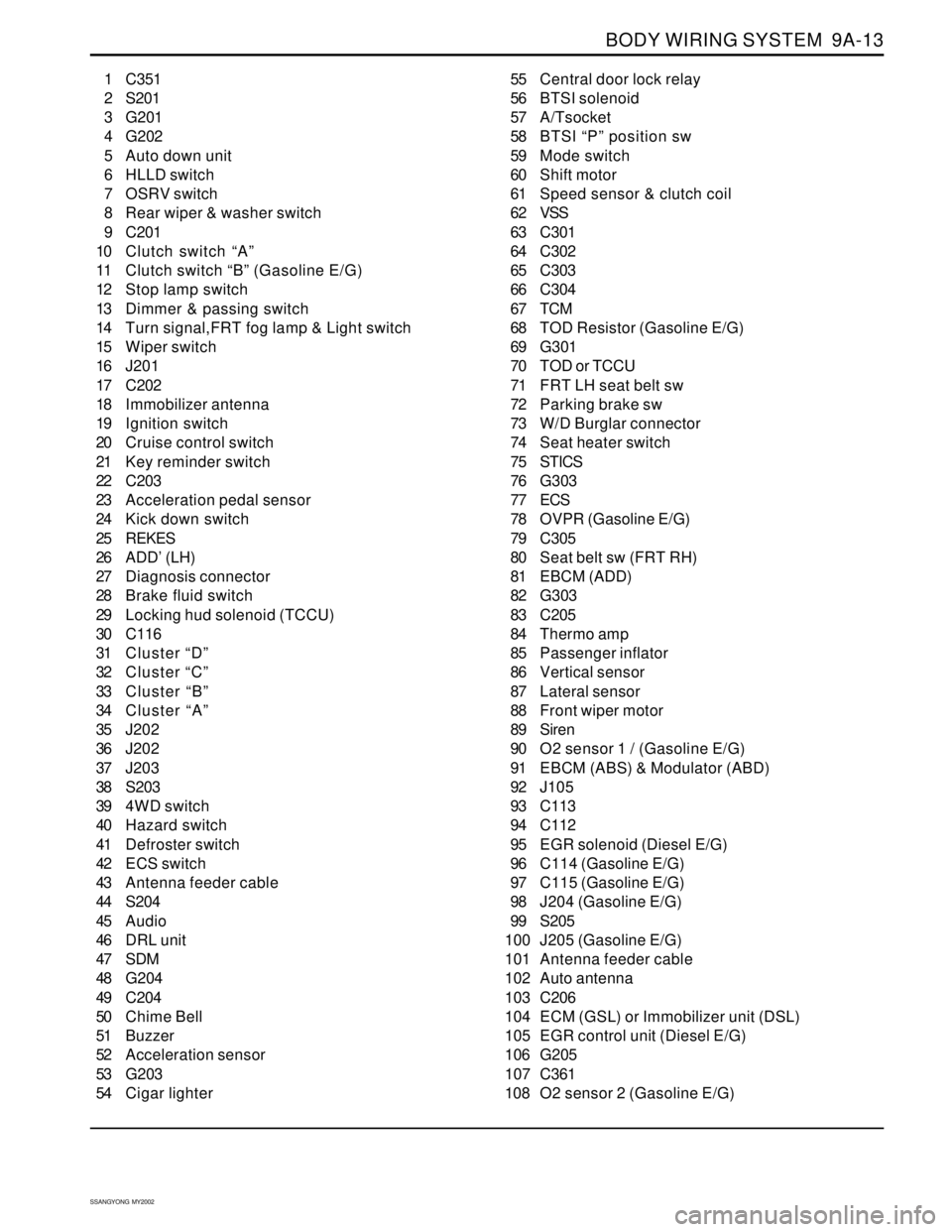

1 C351

2 S201

3 G201

4 G202

5 Auto down unit

6 HLLD switch

7 OSRV switch

8 Rear wiper & washer switch

9 C201

10 Clutch switch “A”

11 Clutch switch “B” (Gasoline E/G)

12 Stop lamp switch

13 Dimmer & passing switch

14 Turn signal,FRT fog lamp & Light switch

15 Wiper switch

16 J201

17 C202

18 Immobilizer antenna

19 Ignition switch

20 Cruise control switch

21 Key reminder switch

22 C203

23 Acceleration pedal sensor

24 Kick down switch

25 REKES

26 ADD’ (LH)

27 Diagnosis connector

28 Brake fluid switch

29 Locking hud solenoid (TCCU)

30 C116

31 Cluster “D”

32 Cluster “C”

33 Cluster “B”

34 Cluster “A”

35 J202

36 J202

37 J203

38 S203

39 4WD switch

40 Hazard switch

41 Defroster switch

42 ECS switch

43 Antenna feeder cable

44 S204

45 Audio

46 DRL unit

47 SDM

48 G204

49 C204

50 Chime Bell

51 Buzzer

52 Acceleration sensor

53 G203

54 Cigar lighter55 Central door lock relay

56 BTSI solenoid

57 A/Tsocket

58 BTSI “P” position sw

59 Mode switch

60 Shift motor

61 Speed sensor & clutch coil

62 VSS

63 C301

64 C302

65 C303

66 C304

67 TCM

68 TOD Resistor (Gasoline E/G)

69 G301

70 TOD or TCCU

71 FRT LH seat belt sw

72 Parking brake sw

73 W/D Burglar connector

74 Seat heater switch

75 STICS

76 G303

77 ECS

78 OVPR (Gasoline E/G)

79 C305

80 Seat belt sw (FRT RH)

81 EBCM (ADD)

82 G303

83 C205

84 Thermo amp

85 Passenger inflator

86 Vertical sensor

87 Lateral sensor

88 Front wiper motor

89 Siren

90 O2 sensor 1 / (Gasoline E/G)

91 EBCM (ABS) & Modulator (ABD)

92 J105

93 C113

94 C112

95 EGR solenoid (Diesel E/G)

96 C114 (Gasoline E/G)

97 C115 (Gasoline E/G)

98 J204 (Gasoline E/G)

99 S205

100 J205 (Gasoline E/G)

101 Antenna feeder cable

102 Auto antenna

103 C206

104 ECM (GSL) or Immobilizer unit (DSL)

105 EGR control unit (Diesel E/G)

106 G205

107 C361

108 O2 sensor 2 (Gasoline E/G)