charging SSANGYONG KORANDO 2012 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 195 of 1082

06-18

Maximizes the intake air charging efficiency (Approx. 15%) -Optimizes the exhaust gas flow rate by controlling the vanes inside the turbine housing with the E-

Actuator. 1.

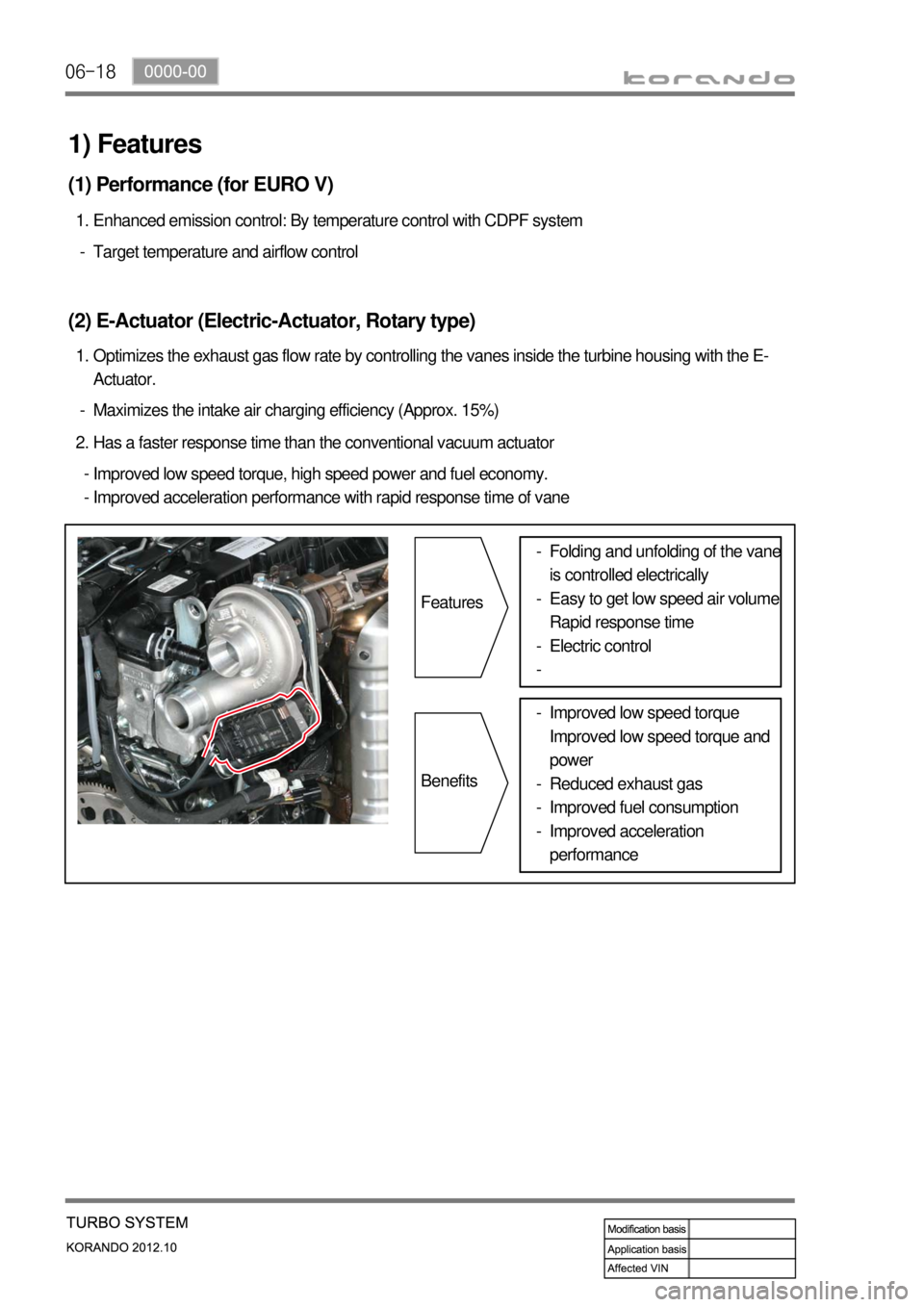

(2) E-Actuator (Electric-Actuator, Rotary type)

Target temperature and airflow control -Enhanced emission control: By temperature control with CDPF system 1.

(1) Performance (for EURO V)

Has a faster response time than the conventional vacuum actuator 2.

Improved low speed torque, high speed power and fuel economy.

Improved acceleration performance with rapid response time of vane -

-

1) Features

Features

BenefitsFolding and unfolding of the vane

is controlled electrically

Easy to get low speed air volume

Rapid response time

Electric control -

-

-

-

Improved low speed torque

Improved low speed torque and

power

Reduced exhaust gas

Improved fuel consumption

Improved acceleration

performance -

-

-

-

Page 219 of 1082

09-70000-00

(1) Checking

Using battery tester ▶

PASS (11.0 V or more): Explain to the customer that the battery is reusable.

Need to be charged (9.0 to 11.0 V): Charge the battery with a charger and reinstall it. Explain it to the

customer.

Need to be replaced (9.0 V or more): The battery should be replaced due to overdischarging. -

-

-

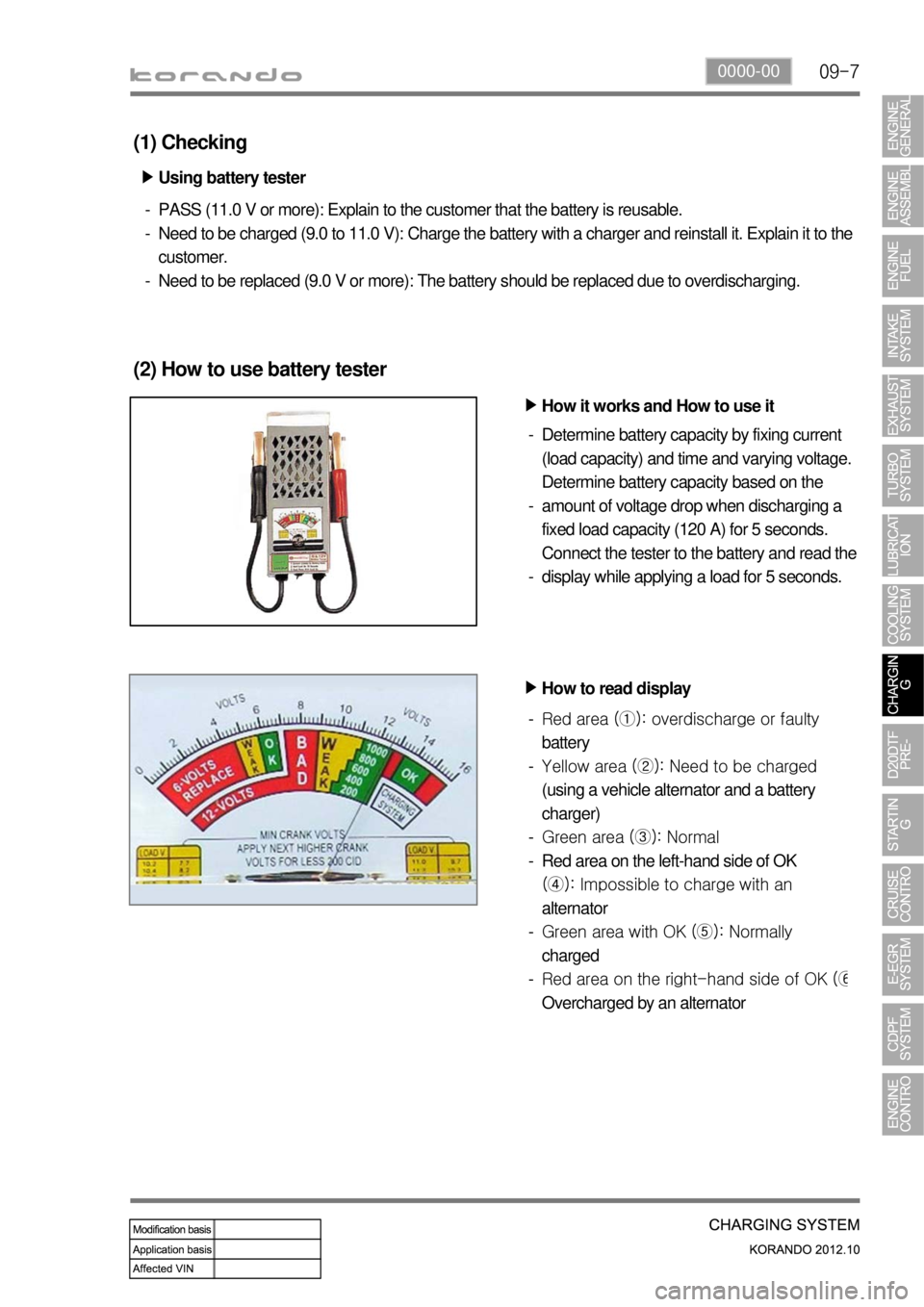

(2) How to use battery tester

How it works and How to use it ▶

Determine battery capacity by fixing current

(load capacity) and time and varying voltage.

Determine battery capacity based on the

amount of voltage drop when discharging a

fixed load capacity (120 A) for 5 seconds.

Connect the tester to the battery and read the

display while applying a load for 5 seconds. -

-

-

How to read display ▶

Red area (①): overdischarge or faulty

battery

Yellow area (②): Need to be charged

(using a vehicle alternator and a battery

charger)

Green area (③): Normal

Red area on the left-hand side of OK

(④): Impossible to charge with an

alternator

Green area with OK (⑤): Normally

charged

Red area on the right-hand side of OK (

⑥

Overcharged by an alternator -

-

-

-

-

-

Page 223 of 1082

09-110000-00

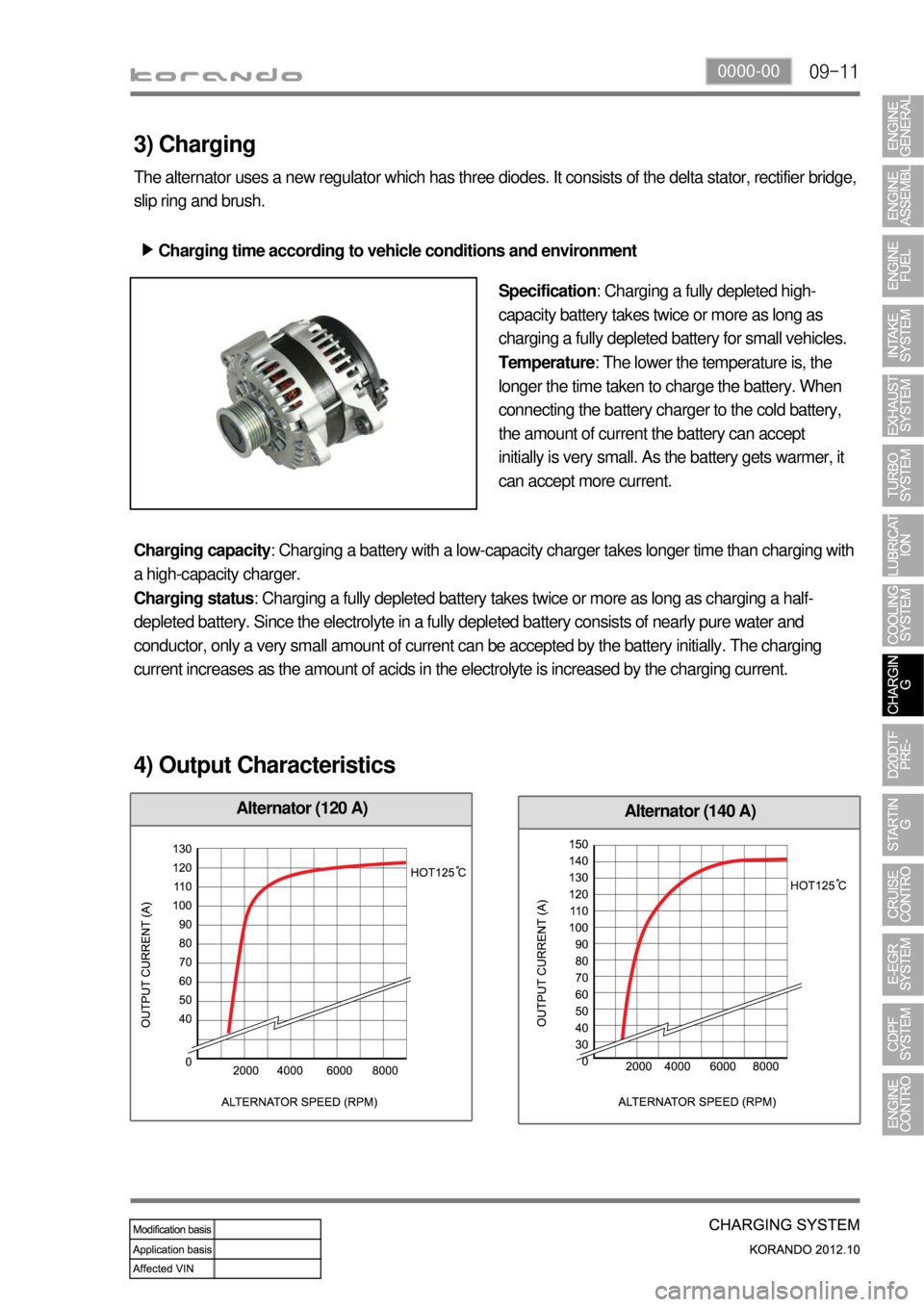

Alternator (140 A)Alternator (120 A)

3) Charging

The alternator uses a new regulator which has three diodes. It consists of the delta stator, rectifier bridge,

slip ring and brush.

Charging time according to vehicle conditions and environment ▶

Specification: Charging a fully depleted high-

capacity battery takes twice or more as long as

charging a fully depleted battery for small vehicles.

Temperature: The lower the temperature is, the

longer the time taken to charge the battery. When

connecting the battery charger to the cold battery,

the amount of current the battery can accept

initially is very small. As the battery gets warmer, it

can accept more current.

Charging capacity: Charging a battery with a low-capacity charger takes longer time than charging with

a high-capacity charger.

Charging status: Charging a fully depleted battery takes twice or more as long as charging a half-

depleted battery. Since the electrolyte in a fully depleted battery consists of nearly pure water and

conductor, only a very small amount of current can be accepted by the battery initially. The charging

current increases as the amount of acids in the electrolyte is increased by the charging current.

4) Output Characteristics

Page 224 of 1082

09-12

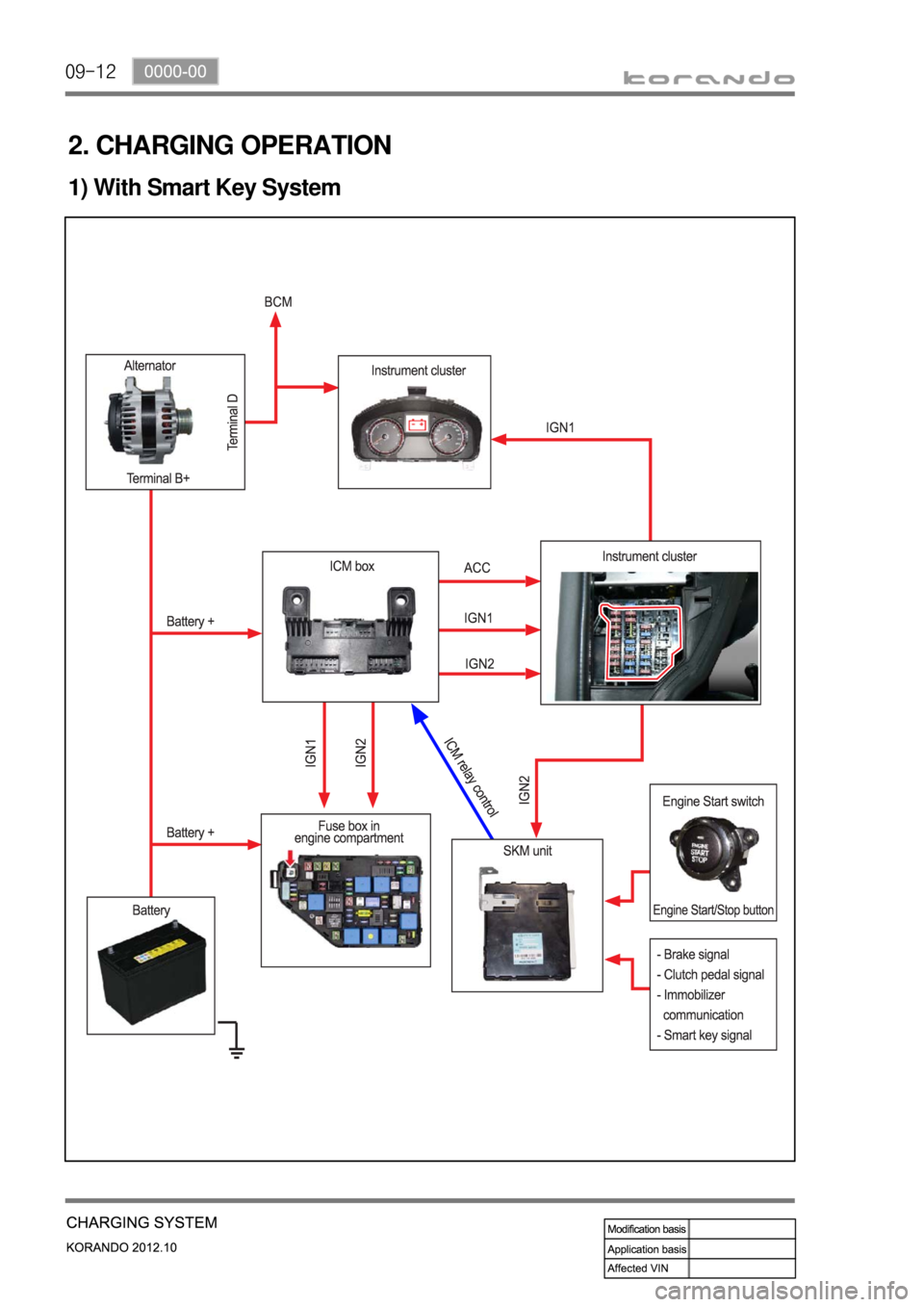

2. CHARGING OPERATION

1) With Smart Key System

Page 445 of 1082

09-91452-01

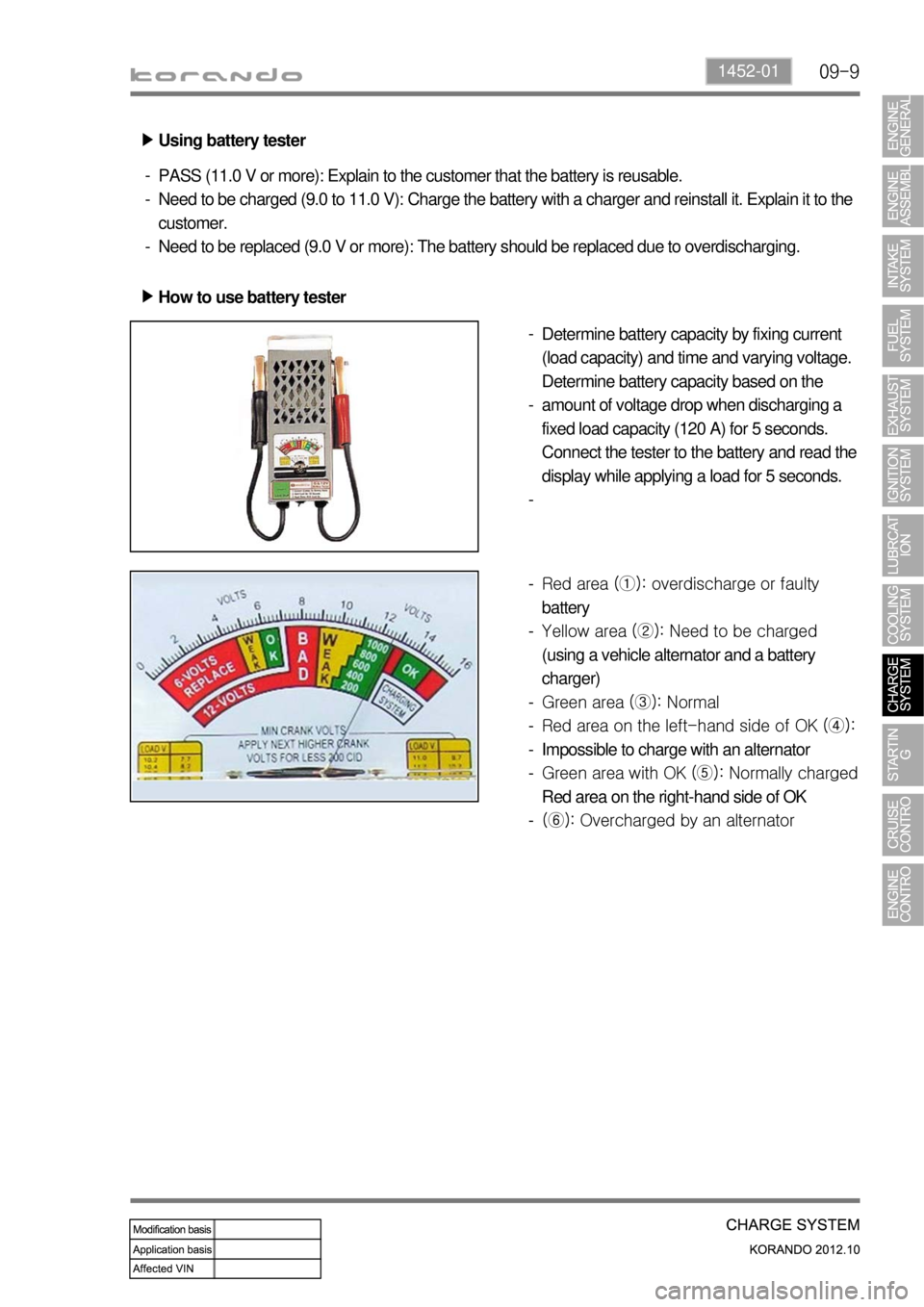

Using battery tester ▶

PASS (11.0 V or more): Explain to the customer that the battery is reusable.

Need to be charged (9.0 to 11.0 V): Charge the battery with a charger and reinstall it. Explain it to the

customer.

Need to be replaced (9.0 V or more): The battery should be replaced due to overdischarging. -

-

-

How to use battery tester ▶

Determine battery capacity by fixing current

(load capacity) and time and varying voltage.

Determine battery capacity based on the

amount of voltage drop when discharging a

fixed load capacity (120 A) for 5 seconds.

Connect the tester to the battery and read the

display while applying a load for 5 seconds. -

-

-

Red area (①): overdischarge or faulty

battery

Yellow area (②): Need to be charged

(using a vehicle alternator and a battery

charger)

Green area (③): Normal

Red area on the left-hand side of OK (④):

Impossible to charge with an alternator

Green area with OK (⑤): Normally charged

Red area on the right-hand side of OK

(⑥): Overcharged by an alternator -

-

-

-

-

-

-

Page 449 of 1082

09-131452-01

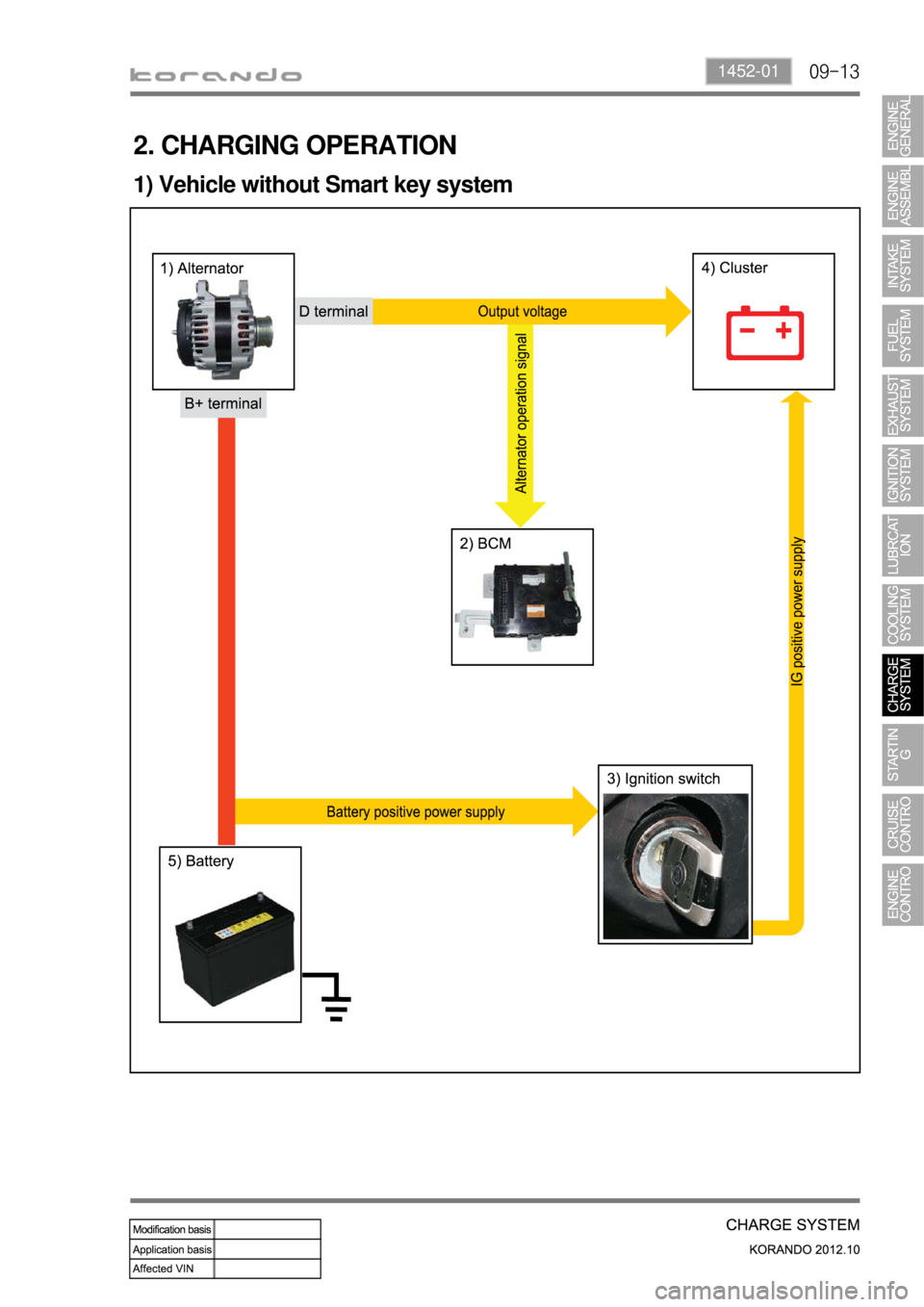

2. CHARGING OPERATION

1) Vehicle without Smart key system

Page 514 of 1082

14-8

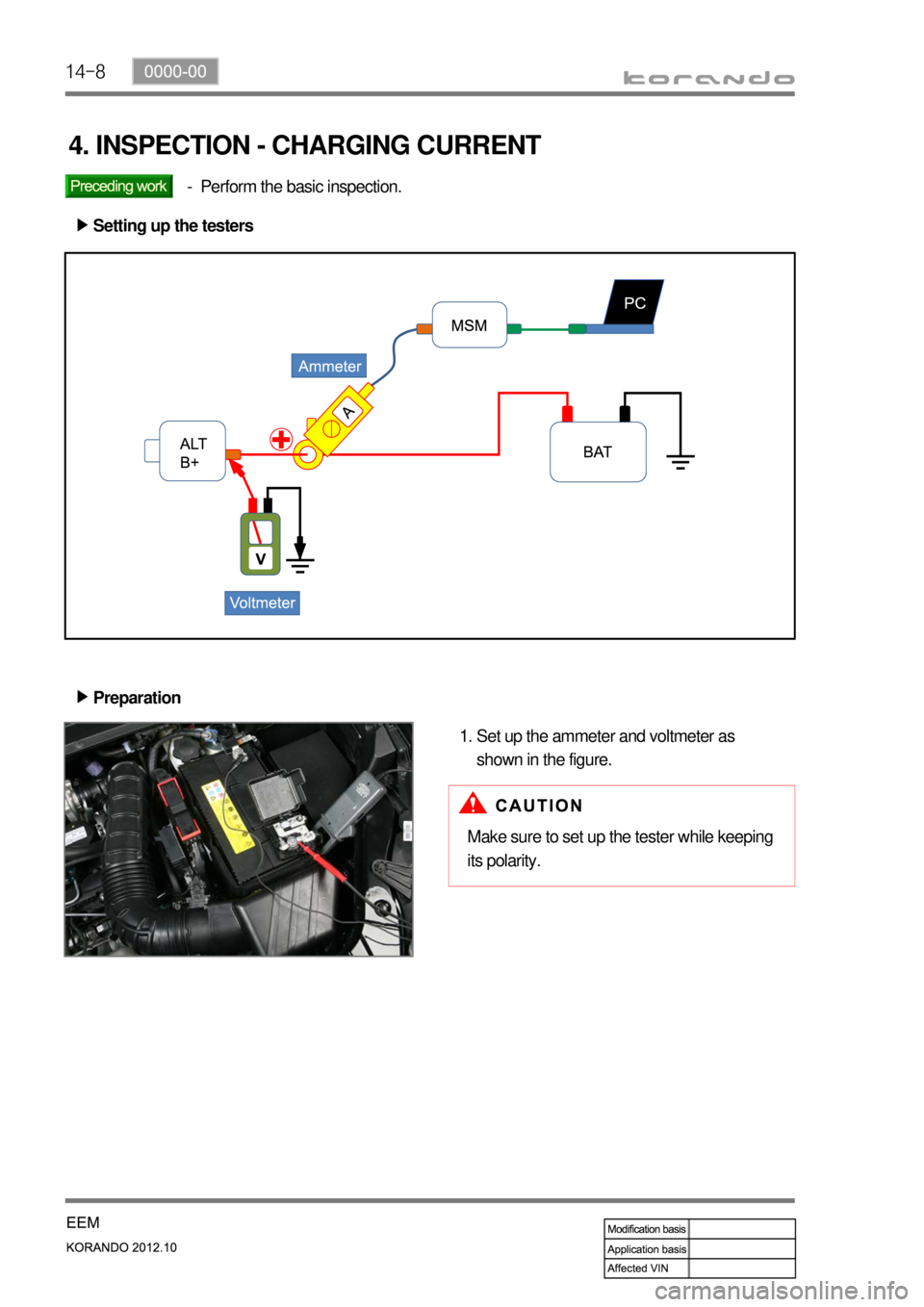

4. INSPECTION - CHARGING CURRENT

Perform the basic inspection. -

Setting up the testers ▶

Preparation ▶

Set up the ammeter and voltmeter as

shown in the figure. 1.

Make sure to set up the tester while keeping

its polarity.

Page 519 of 1082

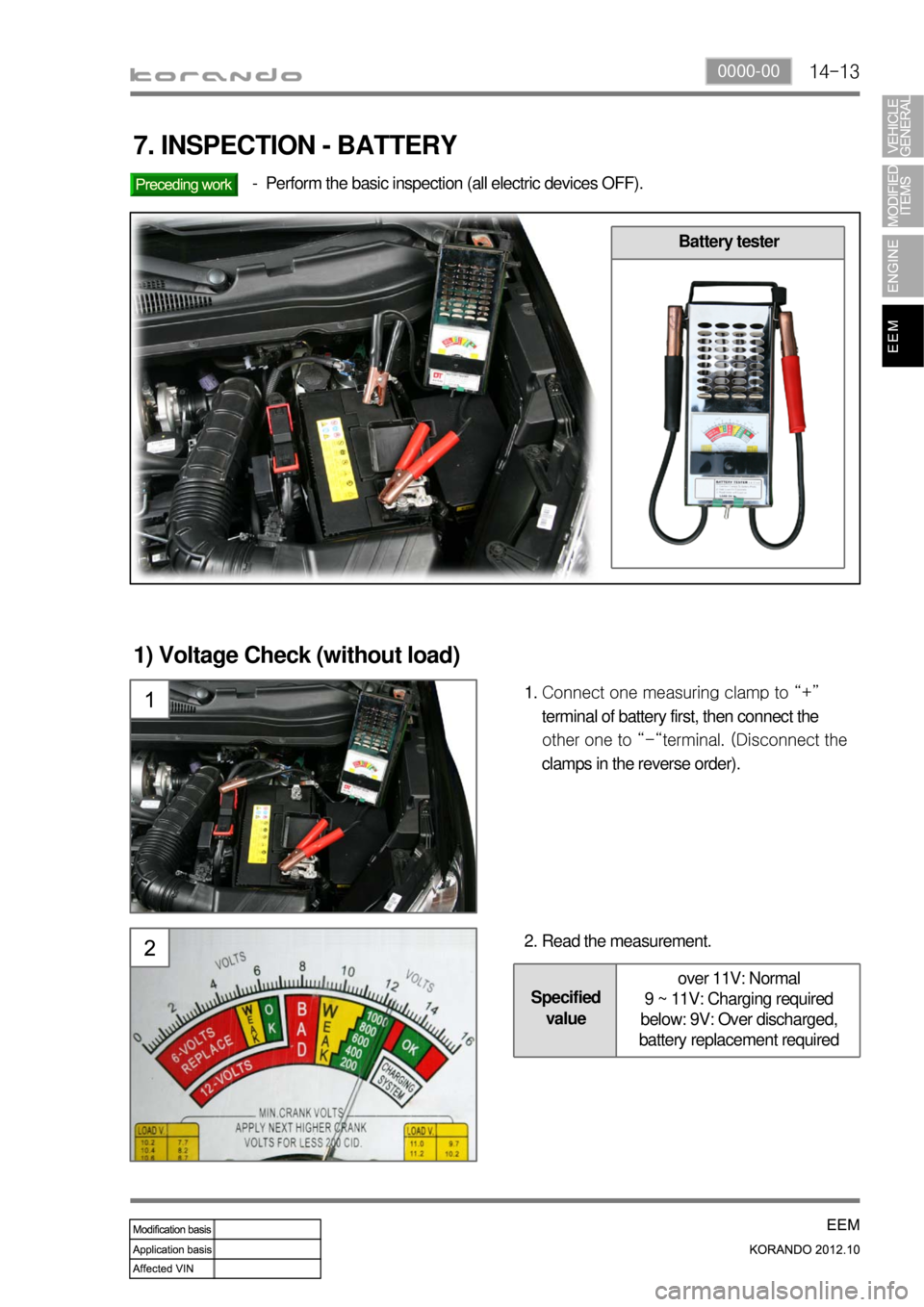

14-130000-00

Specified

valueover 11V: Normal

9 ~ 11V: Charging required

below: 9V: Over discharged,

battery replacement required

7. INSPECTION - BATTERY

Perform the basic inspection (all electric devices OFF). -

Battery tester

1) Voltage Check (without load)

Connect one measuring clamp to “+”

terminal of battery first, then connect the

other one to “-“terminal. (Disconnect the

clamps in the reverse order). 1.

Read the measurement. 2.

Page 520 of 1082

14-14

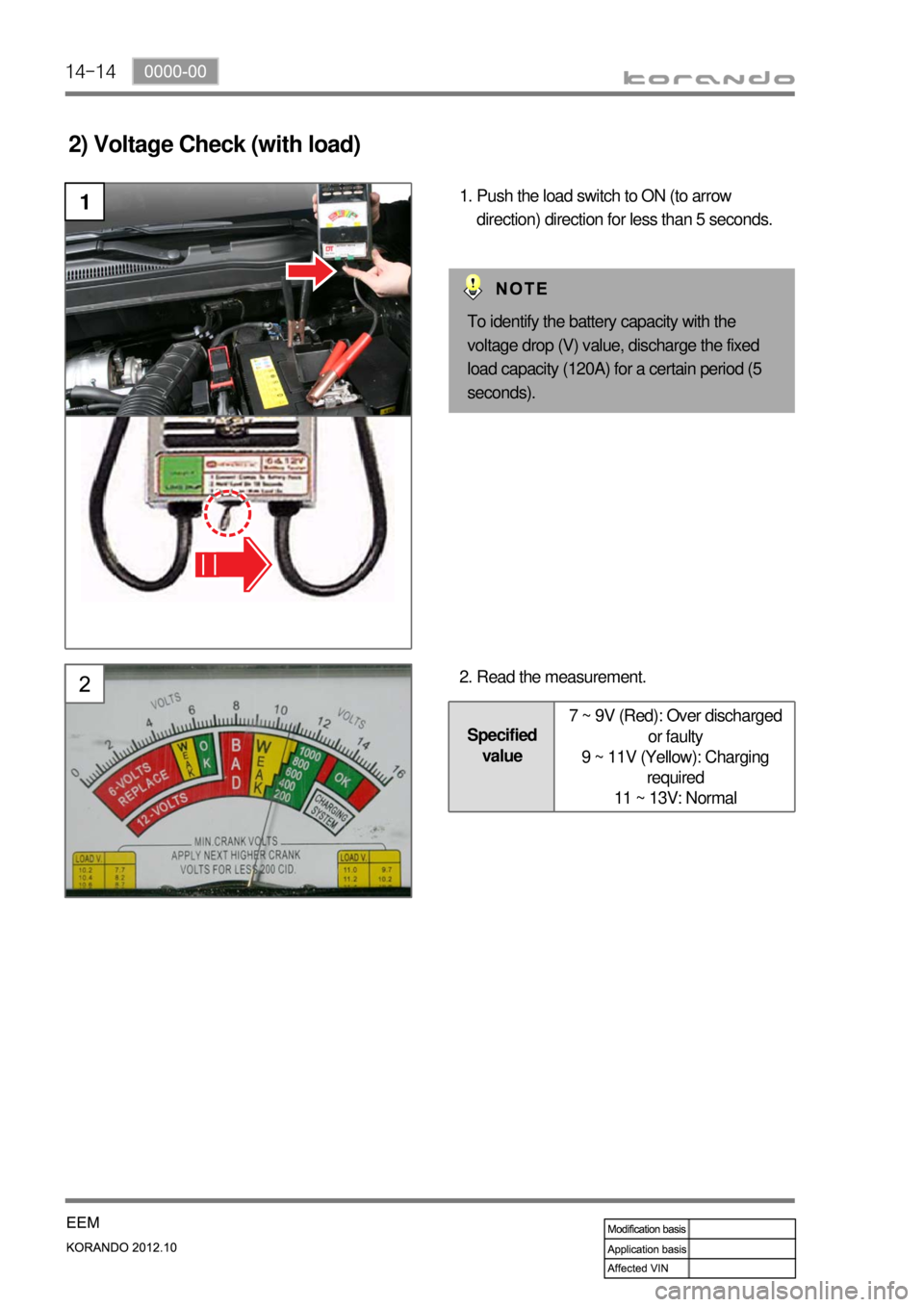

2) Voltage Check (with load)

1Push the load switch to ON (to arrow

direction) direction for less than 5 seconds. 1.

Read the measurement. 2.

Specified

value7 ~ 9V (Red): Over discharged

or faulty

9 ~ 11V (Yellow): Charging

required

11 ~ 13V: Normal

To identify the battery capacity with the

voltage drop (V) value, discharge the fixed

load capacity (120A) for a certain period (5

seconds).

Page 523 of 1082

14-170000-00

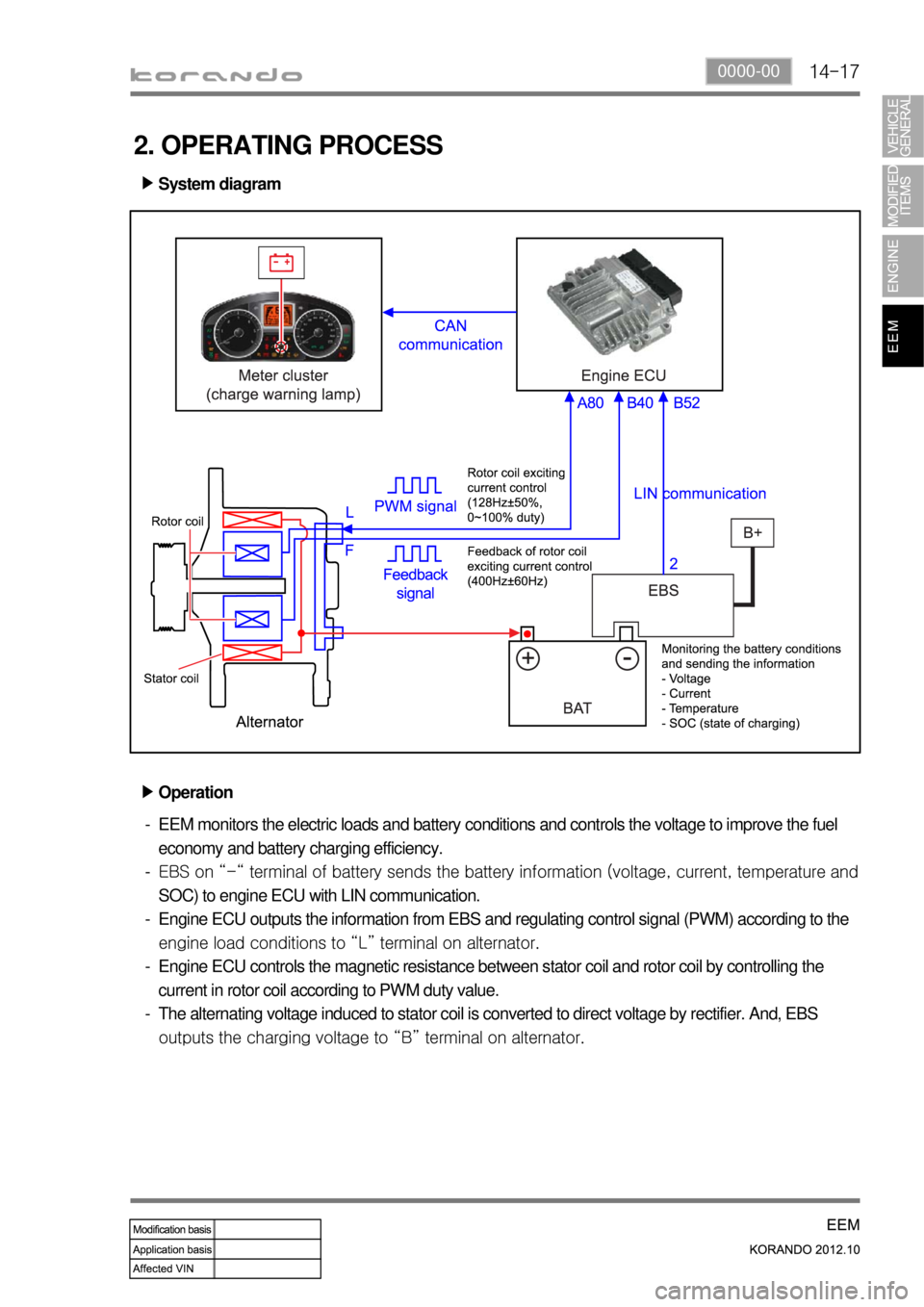

2. OPERATING PROCESS

System diagram ▶

Operation ▶

EEM monitors the electric loads and battery conditions and controls the voltage to improve the fuel

economy and battery charging efficiency.

EBS on “-“ terminal of battery sends the battery information (voltage, current, tem

perature and

SOC) to engine ECU with LIN communication.

Engine ECU outputs the information from EBS and regulating control signal (PWM) according to the

<008c0095008e00900095008c0047009300960088008b0047008a00960095008b0090009b009000960095009a0047009b0096004702c8007302c90047009b008c009900940090009500880093004700960095004700880093009b008c009900950088009b00

9600990055>

Engine ECU controls the magnetic resistance between stator coil and rotor coil by controlling the

current in rotor coil according to PWM duty value.

The alternating voltage induced to stator coil is converted to direct voltage by rectifier. And, EBS

<0096009c009b0097009c009b009a0047009b008f008c0047008a008f00880099008e00900095008e0047009d00960093009b0088008e008c0047009b0096004702c8006902c90047009b008c00990094009000950088009300470096009500470088009300

9b008c009900950088009b009600990055> -

-

-

-

-