SSANGYONG KORANDO 2012 Service Manual

KORANDO 2012

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57504/w960_57504-0.png

SSANGYONG KORANDO 2012 Service Manual

Page 337 of 1082

01-130000-00

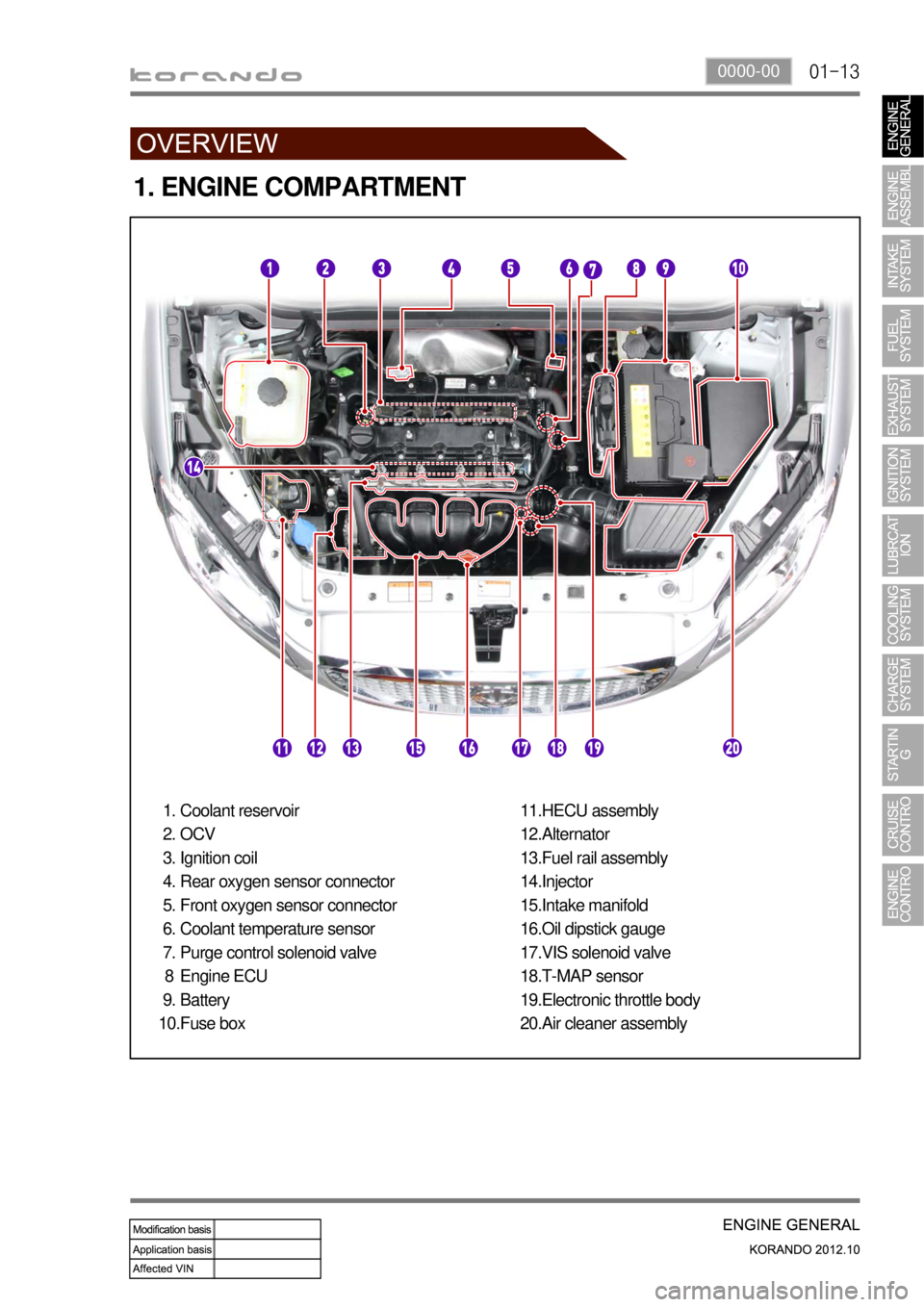

1. ENGINE COMPARTMENT

Coolant reservoir

OCV

Ignition coil

Rear oxygen sensor connector

Front oxygen sensor connector

Coolant temperature sensor

Purge control solenoid valve

Engine ECU

Battery

Fuse box 1.

2.

3.

4.

5.

6.

7.

8

9.

10.HECU assembly

Alternator

Fuel rail assembly

Injector

Intake manifold

Oil dipstick gauge

VIS solenoid valve

T-MAP sensor

Electronic throttle body

Air cleaner assembly 11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

Page 338 of 1082

01-14

Engine ECU

2. FUEL SYSTEM

Engine compartment

Purge control solenoid

valveFuel railInjector

Page 340 of 1082

01-16

3. IGNITION SYSTEM

Ignition coilIgnition plugEngine ECU

Knock sensorCamshaft position

sensorCrankshaft position

sensor

Page 342 of 1082

01-18

WCCEngine CHECK

warning lampEngine ECU

Exhaust manifoldPCV valveBlow-by hose

Green

5. EXHAUST SYSTEM

Page 344 of 1082

01-20

Oil pumpOil panOil filter module

6. LUBRICATION SYSTEM

Oil pressure switchOil jetEngine oil gauge

Page 346 of 1082

01-22

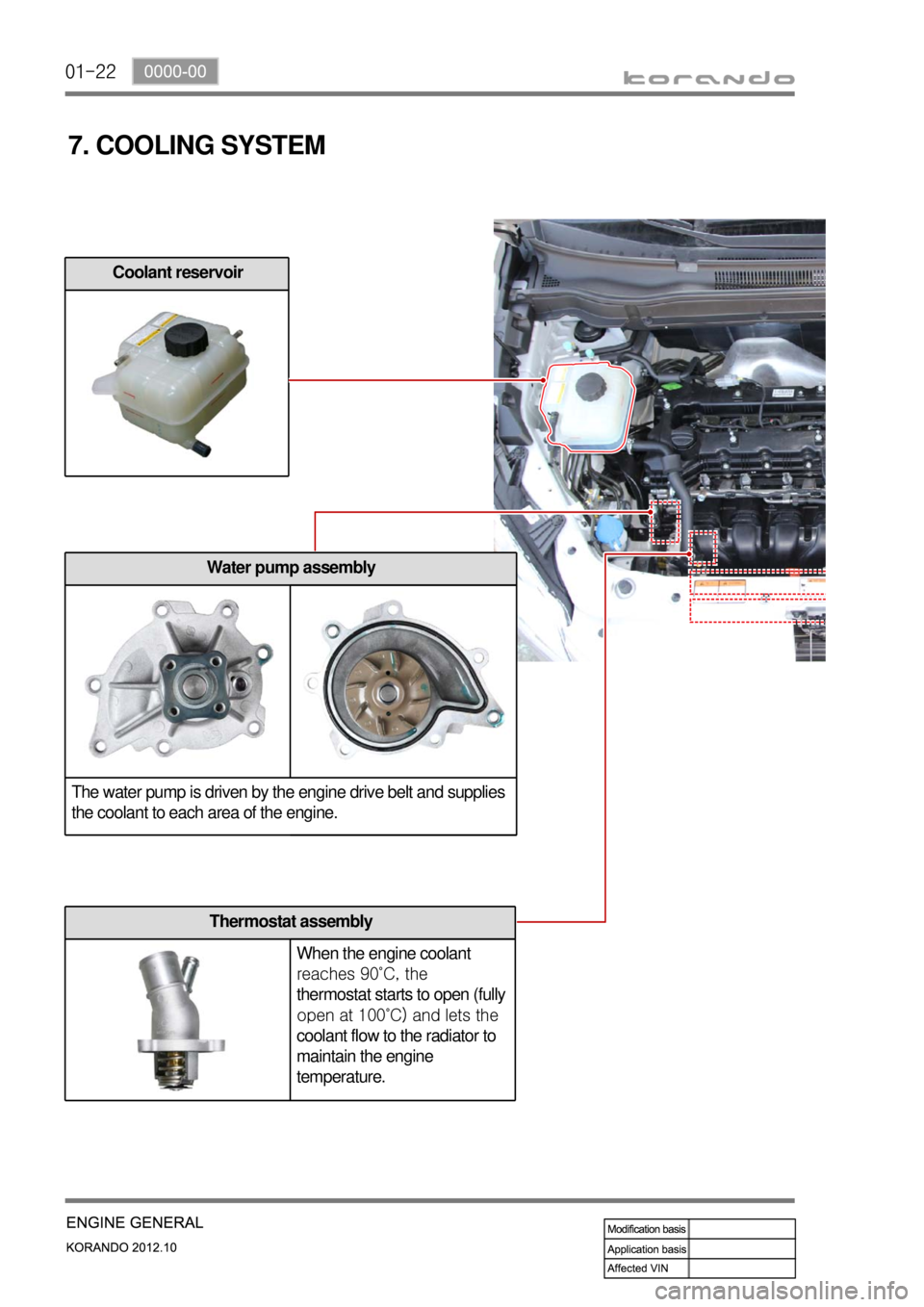

7. COOLING SYSTEM

Coolant reservoir

Water pump assembly

The water pump is driven by the engine drive belt and supplies

the coolant to each area of the engine.

Thermostat assembly

When the engine coolant

reaches 90˚C, the

thermostat starts to open (fully

open at 100˚C) and lets the

coolant flow to the radiator to

maintain the engine

temperature.

Page 347 of 1082

01-230000-00

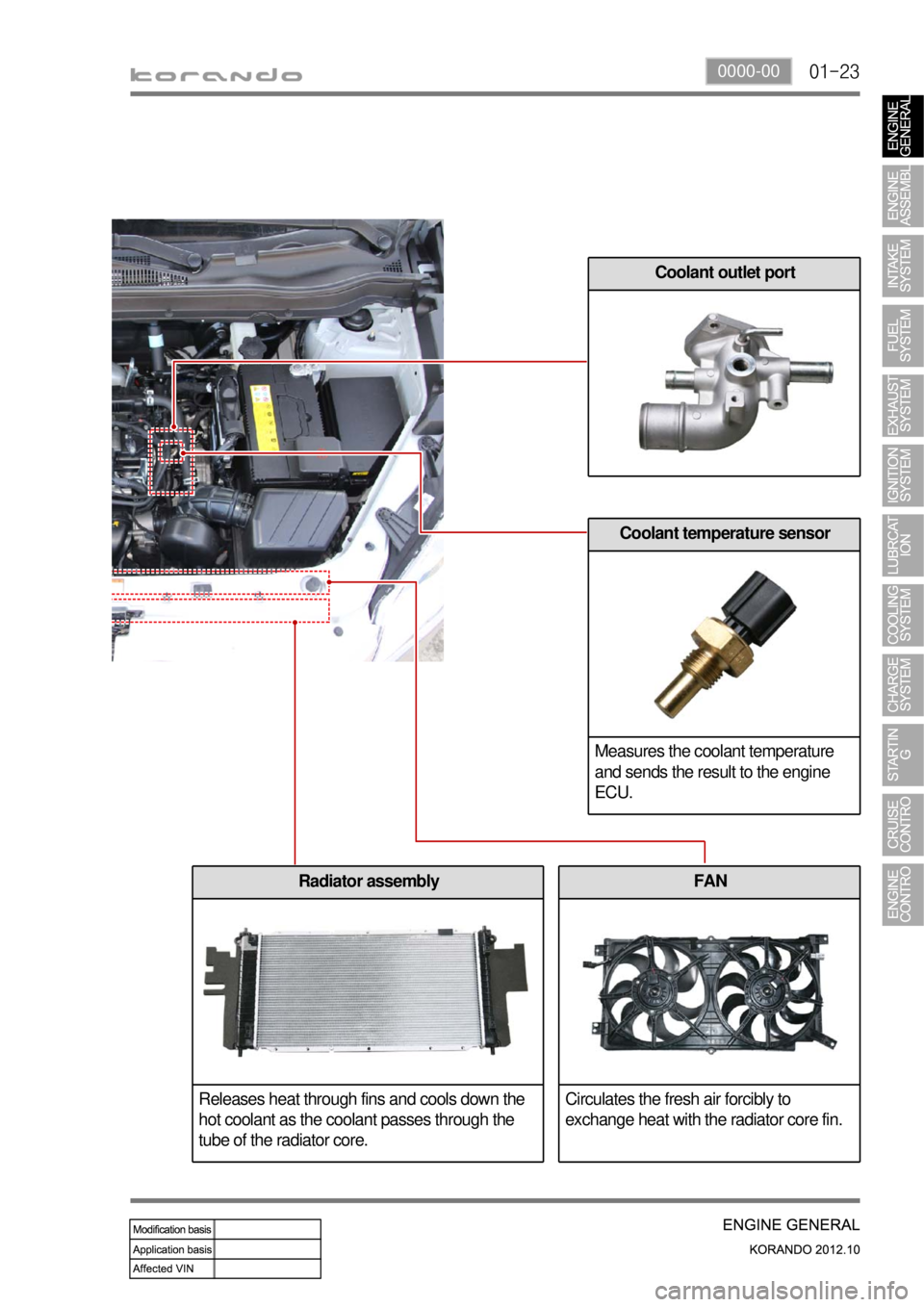

Coolant outlet port

Coolant temperature sensor

Measures the coolant temperature

and sends the result to the engine

ECU.

Radiator assembly

Releases heat through fins and cools down the

hot coolant as the coolant passes through the

tube of the radiator core.FAN

Circulates the fresh air forcibly to

exchange heat with the radiator core fin.

Page 348 of 1082

01-24

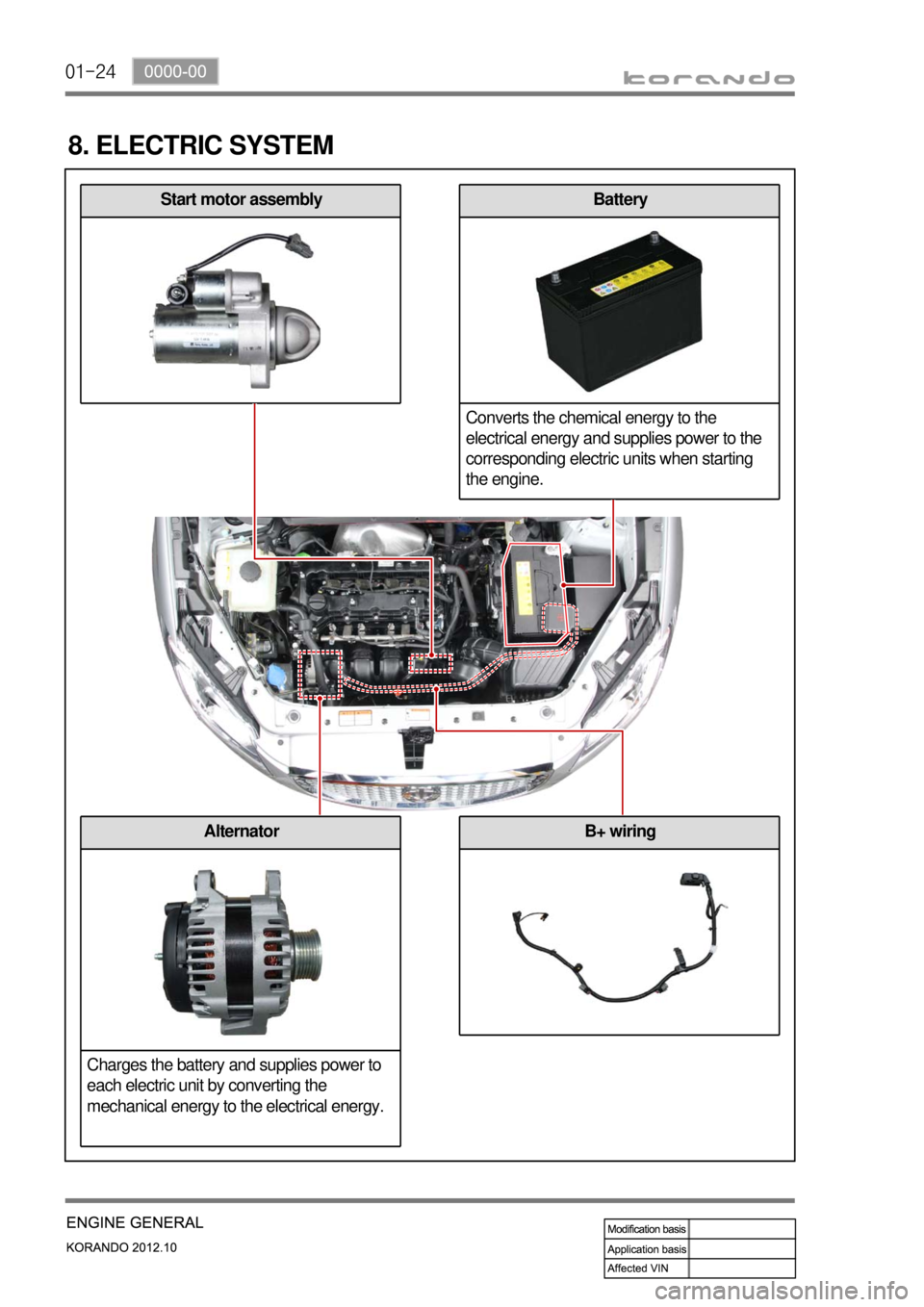

8. ELECTRIC SYSTEM

Start motor assemblyBattery

Converts the chemical energy to the

electrical energy and supplies power to the

corresponding electric units when starting

the engine.

B+ wiringAlternator

Charges the battery and supplies power to

each electric unit by converting the

mechanical energy to the electrical energy.

Page 351 of 1082

02-51116-01

Name Size Quantity Tightening torque

Intake manifold lower bracket bolt M8 X 1.25 X 16 425 ± 2.5 Nm

Exhaust manifold nut - 740 ± 5 Nm

Heat protector bolt M6 X 1.0 X 25 710 ± 1 Nm

Oil jet bolt - 410 ± 1 Nm

Oil pump bolt M8 X 1.25 X35 325 ± 2.5 Nm

Oil filter assembly assembly bolt M8 X 1.25 X30 325 ± 2.5 Nm

Oil filter assembly assembly bolt M8 X 1.25 X65 125 ± 2.5 Nm

Water pump bolt M6 X 1.0 X22 110 ± 1 Nm

Belt tensioner upper bolt M8 X 1.25 X30 125 ± 2.5 Nm

Belt tensioner lower bolt M10 X 1.5 X55 182 ± 5 Nm

Water pump pulley bolt M6 X 1.0 X12 410 ± 1 Nm

Thermostat bolt M6 X 1.0 X22 310 ± 1 Nm

Coolant outlet port bolt M6 X 1.0 X22 310 ± 1 Nm

Coolant pipe mounting bolt M6 X 1.0 X14 310 ± 1 Nm

Bypass hose clamp M24 23 ± 0.5 Nm

EPS idler pulley - 125 ± 2.5 Nm

Engine mountinf stud bolt - 250 ± 5.0 Nm

Engine front mounting bolt M10 X 45 360 ± 6.0 Nm

Engine front mounting bolt M10 X 77 160 ± 6.0 Nm

Engine front hanger bracket M8 X 1.25 X 20 225 ± 2.5 Nm

Engine rear hanger bracket M8 X 1.25 X 20 425 ± 2.5 Nm

A/C compressor bolt - 425 ± 2.5 Nm

Alternator bolt M10 445 ± 4.5 Nm

Start motor bolt M10 4 Max. 48Nm

Page 352 of 1082

02-6

3. GUIDELINES ON ENGINE SERVICE

G20DF engine is for FF (Front Engine Front Drive) type vehicle. Therefore, there are some deferent

maintenance and repair works compared to the engine for FR (Front Engine Rear Drive) type vehicle.

For safe and correct works, you must observe the working procedures and instructions in this manual.

And, use the designated tools as follow:

: Power train mounting stand / Engine hanger / Engine stand / Heavy duty engine jack.

Cautions before service works ▶

G20DF engine is FF (Front Engine Front Drive) type engine, and the engine and transmission are

integrated in a same module. Remember that there are many differences compared to

conventional engine in FR (Front Engine Rear Drive) type SUV vehicle.

To remove the engine, use the dedicated equipments such as engine jack, transmission jack,

engine stand and engine crane (1 ton).

To prevent the engine from abruptly starting during service in engine compartment, never allow

anybody to stay in the vehicle.

Make sure to disconnect the negative (-) cable from the battery to prevent any damage to electric

systems.

Make sure to clean the working area and to prepare the necessary tools before service works.

Always place the ignition switch to OFF position if not required. Otherwise, there could be

unexpected damage to electric devices or personal injuries due to short-circuit..

To prevent the foreign material from entering into the fuel injection system, completely seal the

inlets of HP pump, fuel hoses and high pressure pipes.

Do not remove the engine while supporting the oil pan with a jack. -

-

-

-

-

-

-

Lifting up the vehicle ▶

Before lifting up the vehicle with a lift, correctly support the lifting points.

To prevent the vehicle from rolling down, put the chocks under the tires (when using a 4-post lift).

Make sure to support the correct lifting points (when using a 2-post lift). -

-

-