transmission SSANGYONG KORANDO 2012 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 661 of 1082

04-278712-03

8) SKM Warning Control

(1) Smart key not found warning (Key out warning)

If no verified smart key is identified as being in the vehicle with IGN ON or ACC ON, the SKM sends the

signal, which identifies that there is no verified key inside the vehicle, to the BCM and instrument cluster

through the BCAN (Smart key not found warning). This warning continues for up to 10 sec. until the

warning condition is deactivated.

The SKM stops the warning immediately after the warning condition is deactivated.

Initial condition:

Operation by driver

<006b009600960099009a006100470063006b009600960099009a004700960097008c00950047008c009f008a008c0097009b0047008b00990090009d008c0099004e009a0047008b00960096009900650047004d00470063007b008800900093008e008800

9b008c004700960097008c0095006502e70047006300680093>l doors closed> &

SKM operation -

-

-

The SKM starts to identify a smart key by using the interior antenna after confirming that all the

doors are closed through CAN communication.

If no smart key is found it sends the signal for [Smart key not found warning].

* No cyclic smart key searching after transmission

If a smart key is found, no operation is performed.

- Smart key not found warning deactivation conditions

If below conditions are met, the SKM sends the signal for [Smart key not found warning]

to deactivate the warning.

:

2.

3. Smart key not found warning with ACC ON ▶

Smart key not found warning with IGN/ENGINE ON ▶

Initial condition:

Operation by driver

<006b009600960099006100470063006b009600960099004700960097008c009500650047004d00470063007b008800900093008e0088009b008c004700960097008c00950065004702e7004700630068009300930047008b009600960099009a0047008a00

930096009a008c008b00650047004d00470063007b00880090>lgate closed>

SKM operation -

-

-

The SKM starts to identify a smart key by using the interior antenna if the [Smart key not found

warning] signal is not output.

a. If no smart key is found it sends the signal for [Smart key not found warning].

b. If a smart key is found, no operation is performed.

The SKM searches for a smart key inside the vehicle at 3 sec. intervals while the [Smart key not

found warning] signal is output.

a. If no smart key is found it sends the signal for [Smart key not found warning].

b. If a smart key is found it sends the signal for [Smart key not found warning

deactivation] signal to deactivate the key out warning. 1.

2.

Page 663 of 1082

04-298712-03

(4) Smart key battery discharge warning (3) Smart key verification fail warning

When the verification is requested for ignition status change or engine starting and no verified smart key

is in the vehicle, the SKM sends the [smart key verification status] signal, which indicates that the

verification has failed, for up to 10 sec. until the verification fail conditions are deactivated.

Verification fail detection and transmission conditions ▶

When the ignition status is changed after a smart key is verified by the START switch ON input, the

SKM sends the verification status for 10 sec. -Normally, the smart key verification warning is one of the smart key fail conditions. -

Ignition status change

(OFF ->ACC) / (OFF ->IGN)/(ACC ->IGN) / (IGN -> engine ON) *

If above conditions are met again, the SKM re-verifies a smart key and sends the verification status for

another 10 sec.

When the ignition status is changed by the transponder verification while the smart key status is sent

through the BCAN, the SKM sends the smart key verification signal and also sends the transponder

verification signal for 10 sec. -

-

If low smart key battery is detected during the verification process for ignition status change or engine

start, the SKM sends the signal for [smart key battery low voltage warning] to the BCM and instrument

cluster through the BCAN for up to 10 sec. until the warning condition is deactivated.

Smart key battery discharge confirmation and deactivation ▶

If the smart key battery low voltage is confirmed, the SKM sends the smart key battery low voltage

warning signal.

If the smart key battery is in normal condition, the SKM sends the smart key battery low voltage

warning deactivation signal.

The smart key is the last used key. -

-

*

(5) Transponder verification fail warning

If a verified smart key is not found by the key verification process, the SKM sends the information that

indicates the key is not verified to the instrument cluster through the BCAN for up to 10 sec. until the

verification fail condition is deactivated.

The SKM sends the transponder verification warning when the verification has failed with the smart key

inserted into the immobilizer holder. -

Transponder verification fail detection and transmission conditions ▶

When the ignition status is changed after the transponder is verified by the START switch ON input,

the SKM sends the transponder verification status for 10 sec. -

Page 664 of 1082

04-30

Ignition status change

(OFF ->ACC) / (OFF ->IGN)/(ACC ->IGN) / (IGN -> engine ON) *

If above conditions are met again, the SKM re-verifies the transponder and sends the verification

status for another 10 sec.

When the ignition status is changed by a smart key verification while the transponder verification is

processed, the SKM sends the signal for [transponder verification fail], and sends the smart key

verification status for 10 sec. -

-

(6) Transmission position warning

When the gear selector lever is in a position other than P or N with IGN ON and engine started, the

SKM sends the [gear position warning] signal to the instrument cluster through the BCAN for up to 10

sec. until the operating conditions are deactivated.

Transmission position warning deactivation ▶

When re-attempting to start with IGN1 ON and transmission in P or N -

(7) SKM error alert

The SKM sends the SKM error alert signal to the instrument cluster through the BCAN for up to 10 sec.

when an in ignition status related error or passive entry system error occurs.

SKM error transmission conditions ▶

When any of the following errors is detected and a DTC is set, the SKM sends the error alert signal for

10 sec.

B+ (power) low voltage

B+ (logic) low voltage

ACC ON fail

ACC OFF fail

IGN1 ON fail

IGN1 OFF fail

IGN2 ON fail

IGN2 OFF fail

Short circuit in START switch 1.

2.

3.

4.

5.

6.

7.

8.

9.

The SKM sends the corresponding signal only once for 10 sec. when any of the above errors is detected

with IGN OFF/ON. It sends the signal again when a new error occurs.

Page 665 of 1082

04-318712-03

(8) Brake not working alert

The SKM sends the brake not working alert signal for 10 sec. every time the ignition status is changed

after the 1st cycle (OFF-ACC-IGN-ACC-OFF) while the brake is not operated.

when the brake pedal is depressed, the system is reset and alert deactivation signal is sent.

when the 10 min. timer is terminated -

-

(9) Clutch not working alert

The SKM sends the clutch not working alert signal for 10 sec. every time the ignition status is changed

after the 1st cycle (OFF-ACC-IGN-ACC-OFF)

while the clutch is not operated.

when the clutch pedal is depressed, the system is reset and alert deactivation signal is sent.

when the 10 min. timer is terminated -

-

(10) Smart key slot detection alert

The SKM sends the smart key slot detection alert signal for 10 sec. when a smart key inserted into

the slot is detected with IGN OFF and the driver's door open. -

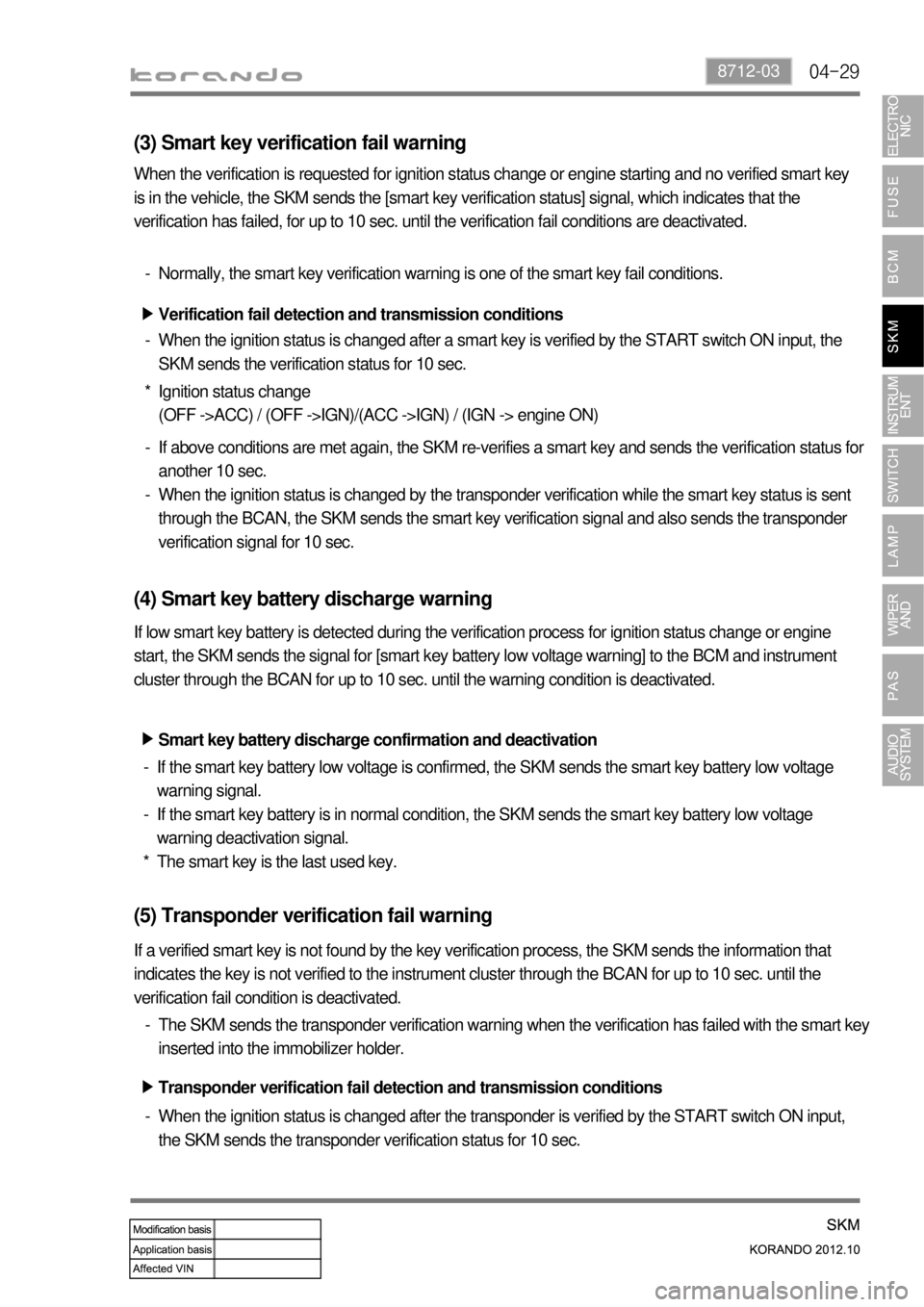

(11) SKM alert priority

1 Smart key out alert EXTERIOR

1

2 Smart key reminder alert EXTERIOR

3 Smart key verification fail alert INTERIOR

2 4 Transponder verification failure alarm INTERIOR

5 Smart key battery low voltage alert INTERIOR

6 Transmission position alert INTERIOR

7 SKM error alert INTERIOR

8 Brake alert INTERIOR

9 Clutch alert INTERIOR

10 Smart key slot reminder alert INTERIOR1

Warning cancellation requirements ▶

Warning cancellation requirements ▶

Warning transmission conditions ▶

Warning cancellation requirements ▶

when the smart key is removed, the alert deactivation signal is sent.

when the 10 min. timer is terminated -

-

Page 746 of 1082

06-358510-00

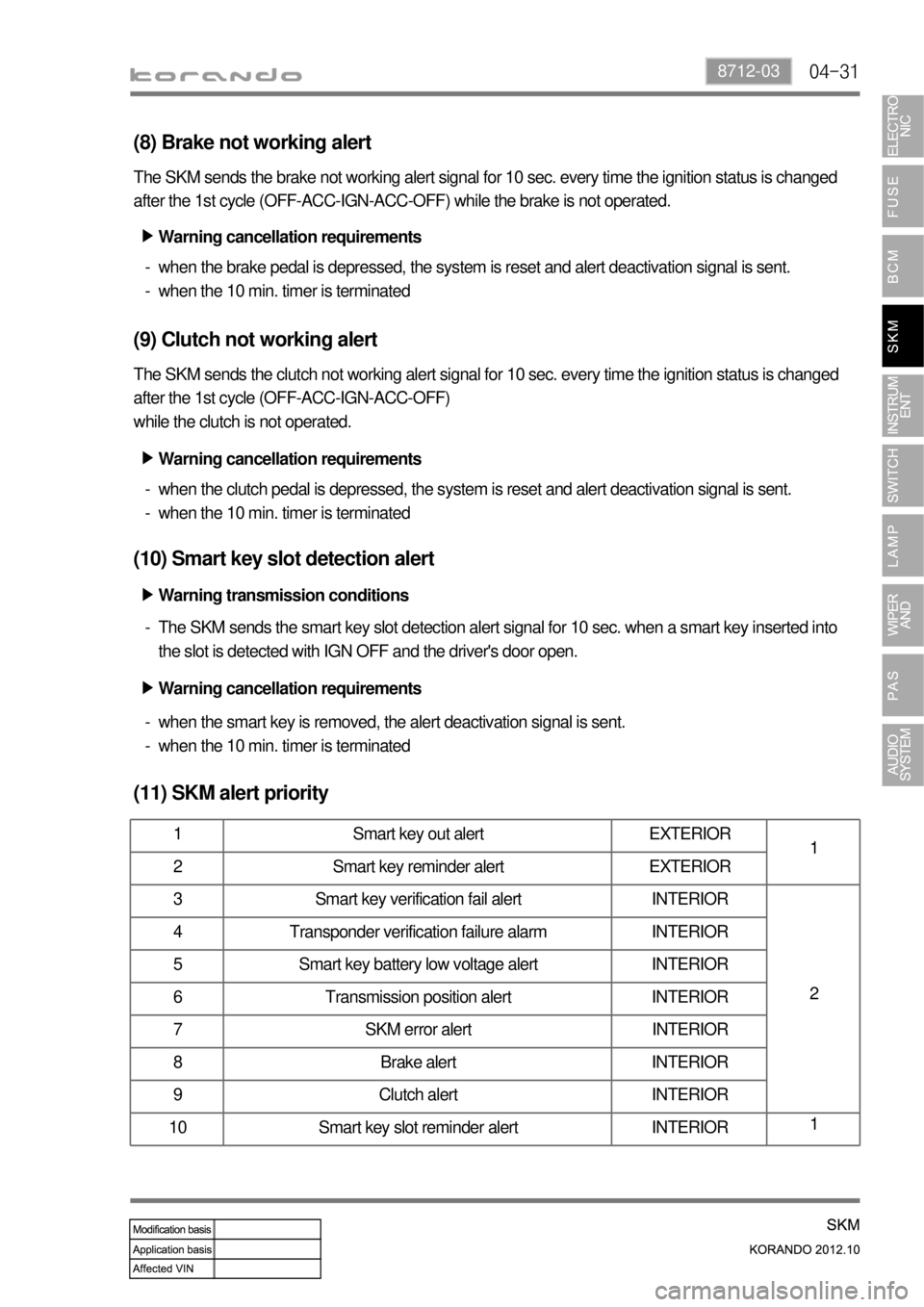

3) Cruise Control Switch

Cruise control switch

The cruise control is an automatic speed control system that maintains a desired driving speed without

using the accelerator pedal. The cruise control switch is fitted to the bottom right section of the steering

wheel. When this switch is operated, the AUTO CRUISE or ECO lamp on the instrument cluster comes

on.

The cruise control switch has a fivefold switch in it. The engine ECU can determine the current driving

condition since the resistance varies depending on the operation of the switch.

The cruise control system is operated at vehicle speed of between 38 km/h and 150 km/h. The manual

transmission is operated in the range of 3rd gear or higher.

This function can be used at the following traffic condition. (It is important to be careful for using this

function)

Cruise control (ON)

Cruise control (OFF)

Cruise control (Acceleration)Cruise control (Deceleration)

Cruise control (Reset)

Page 819 of 1082

01-90000-00

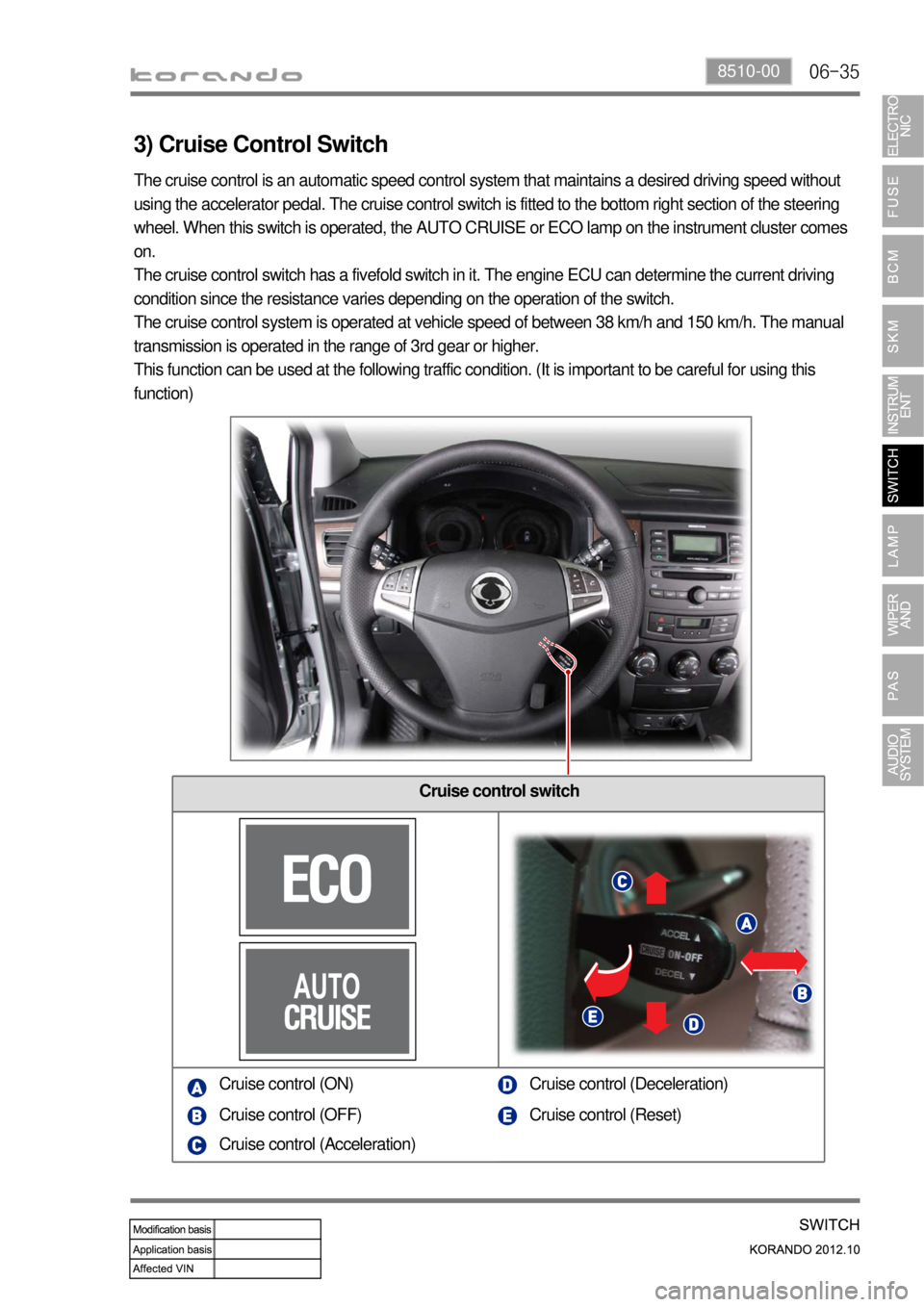

G-sensor(4WD, ABS)

For the vehicle with the ABS, a speed difference

between the wheels is not noticeable as all the

wheels are slipping during abrupt braking.

Therefore, the vehicle needs the speed information

from other sensors other than the wheel speed

sensor. The longitudinal acceleration sensor (G-

sensor) is used for this case. It controls the ABS by

using the signals from the sensor during abrupt

braking and acceleration.

TCU unit

The transmission control unit (TCU) is installed under

the driver seat, and controls the transmission. The

TCU is operated by the ignition power supply and

receives and processes the following information from

the inner sensors through CAN buses.E-coupling unit

The E-coupling unit is a control unit which

determines the magnetic force by

considering CAN signals (wheel speed,

engine torque, pedal opening, ABS/ESP

CAN signals, etc.) from other ECUs.

TGS Lever assembly

The TGS communicates with TCU

(Transmission Control Unit), ECU,

ESP HECU and instrument cluster

to let the driver select the desired

transmission gear and to maintain

the desired driving condition. Also,

the tip switch is installed on the

lever knob and the steering wheel

so that the driver select the gear

manually when the shift lever is in

"M".Sensor cluster

The sensor cluster is linked to

the sensors on the unit board

and CAN interface. And they

are housed in one case and

mounted to the body.

Page 820 of 1082

01-10

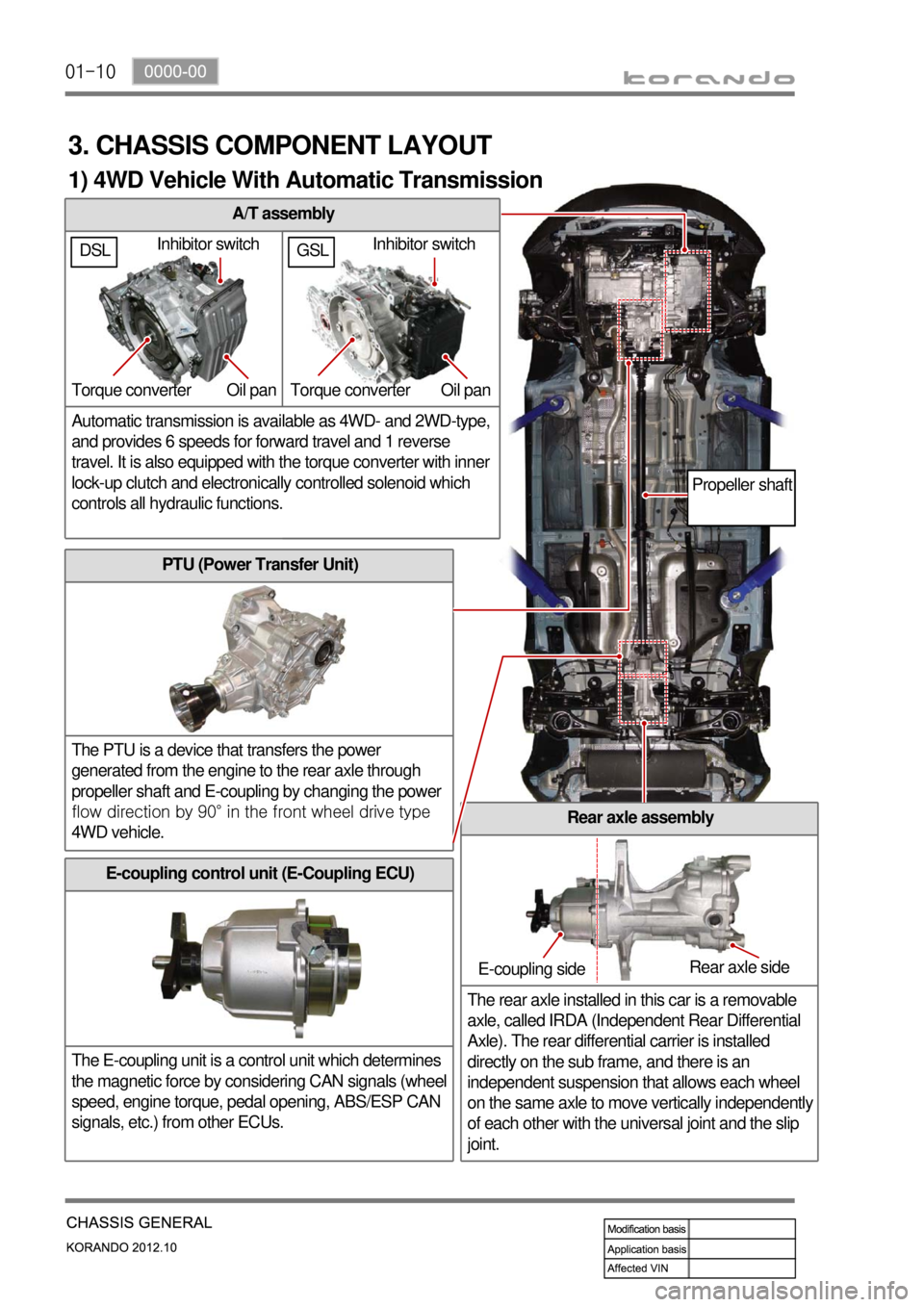

A/T assembly

Automatic transmission is available as 4WD- and 2WD-type,

and provides 6 speeds for forward travel and 1 reverse

travel. It is also equipped with the torque converter with inner

lock-up clutch and electronically controlled solenoid which

controls all hydraulic functions.

3. CHASSIS COMPONENT LAYOUT

PTU (Power Transfer Unit)

The PTU is a device that transfers the power

generated from the engine to the rear axle through

propeller shaft and E-coupling by changing the power

<008d00930096009e0047008b00900099008c008a009b0090009600950047008900a000470060005700b60047009000950047009b008f008c0047008d009900960095009b0047009e008f008c008c00930047008b00990090009d008c0047009b00a0009700

8c0047>

4WD vehicle.

Rear axle assembly

The rear axle installed in this car is a removable

axle, called IRDA (Independent Rear Differential

Axle). The rear differential carrier is installed

directly on the sub frame, and there is an

independent suspension that allows each wheel

on the same axle to move vertically independentl

y

of each other with the universal joint and the slip

joint.

E-coupling control unit (E-Coupling ECU)

The E-coupling unit is a control unit which determines

the magnetic force by considering CAN signals (wheel

speed, engine torque, pedal opening, ABS/ESP CAN

signals, etc.) from other ECUs.

Inhibitor switch

Torque converter Oil pan

E-coupling sideRear axle side

Propeller shaft

1) 4WD Vehicle With Automatic Transmission

GSLDSLInhibitor switch

Torque converter Oil pan

Page 821 of 1082

01-110000-00

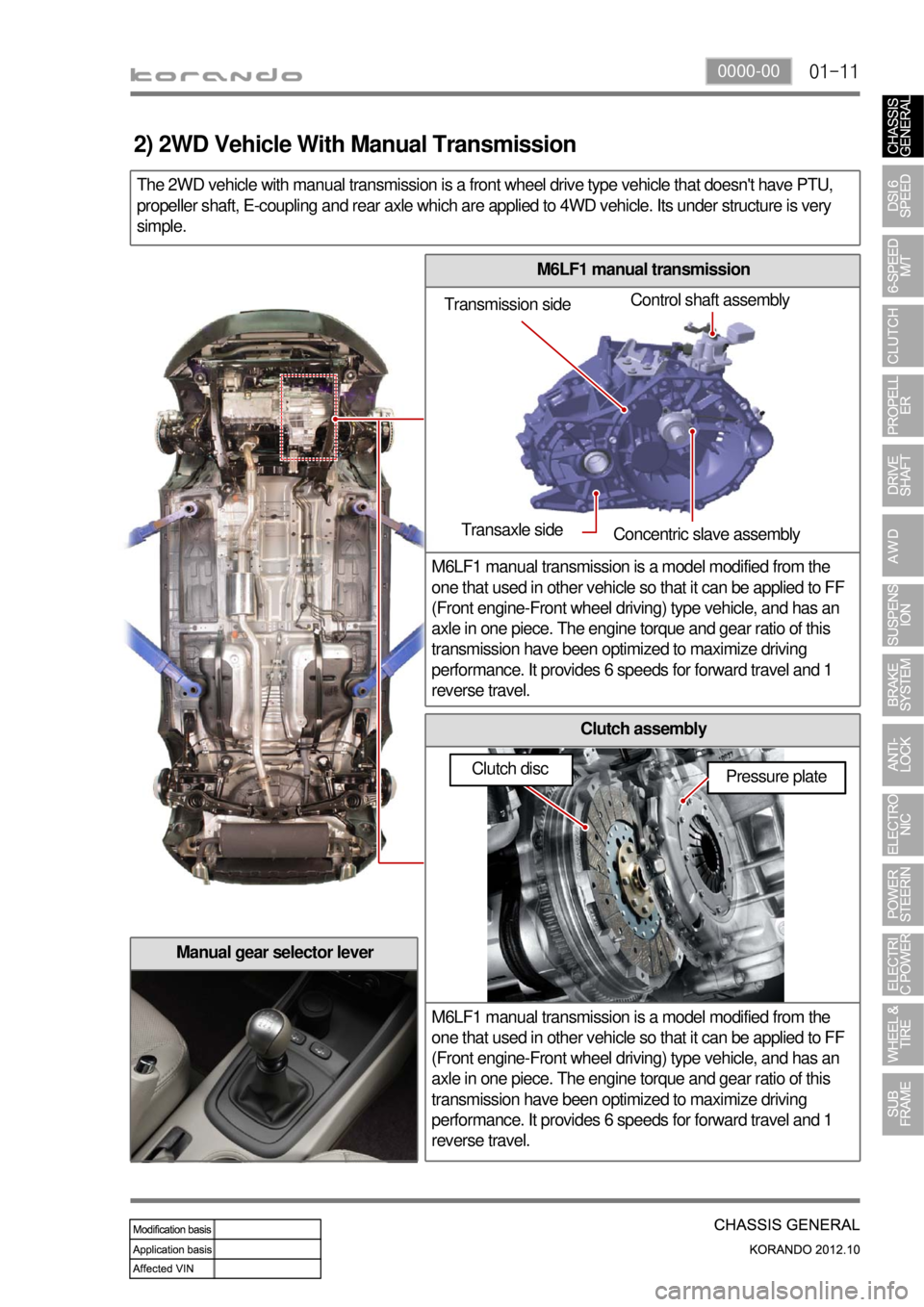

M6LF1 manual transmission

M6LF1 manual transmission is a model modified from the

one that used in other vehicle so that it can be applied to FF

(Front engine-Front wheel driving) type vehicle, and has an

axle in one piece. The engine torque and gear ratio of this

transmission have been optimized to maximize driving

performance. It provides 6 speeds for forward travel and 1

reverse travel.

Clutch assembly

M6LF1 manual transmission is a model modified from the

one that used in other vehicle so that it can be applied to FF

(Front engine-Front wheel driving) type vehicle, and has an

axle in one piece. The engine torque and gear ratio of this

transmission have been optimized to maximize driving

performance. It provides 6 speeds for forward travel and 1

reverse travel.

The 2WD vehicle with manual transmission is a front wheel drive type vehicle that doesn't have PTU,

propeller shaft, E-coupling and rear axle which are applied to 4WD vehicle. Its under structure is very

simple.

Manual gear selector lever

Transmission sideControl shaft assembly

Transaxle side

Concentric slave assembly

Pressure plate

2) 2WD Vehicle With Manual Transmission

Clutch disc

Page 822 of 1082

01-12

Front sub frame with HPS type steering gear box assembly

The front sub frame consists of 4 body bush mountings and 2 transmission

bush mountings which reduce the vibration from the powertrain and road,

and also control the torque. And the frame is equipped with hydraulic

pressure pipe of the HPS type steering gear box.

4. SUB FRAME AND STEERING GEAR BOX LAYOUT

Front sub frame with EPS type steering gear box assembly

This kind of front sub frame system has the same mounting structure with

the frame with HPS. But the EPS type steering gear box has no hydraulic

pressure pipe since it is driven by the electric motor.

Rear side

Front sideHPS type steering

gear box assembly

Front sub frame

assembly

Rear side

Front side

EPS type steering

gear box assembly

Front sub frame

assembly

Page 833 of 1082

01-230000-00

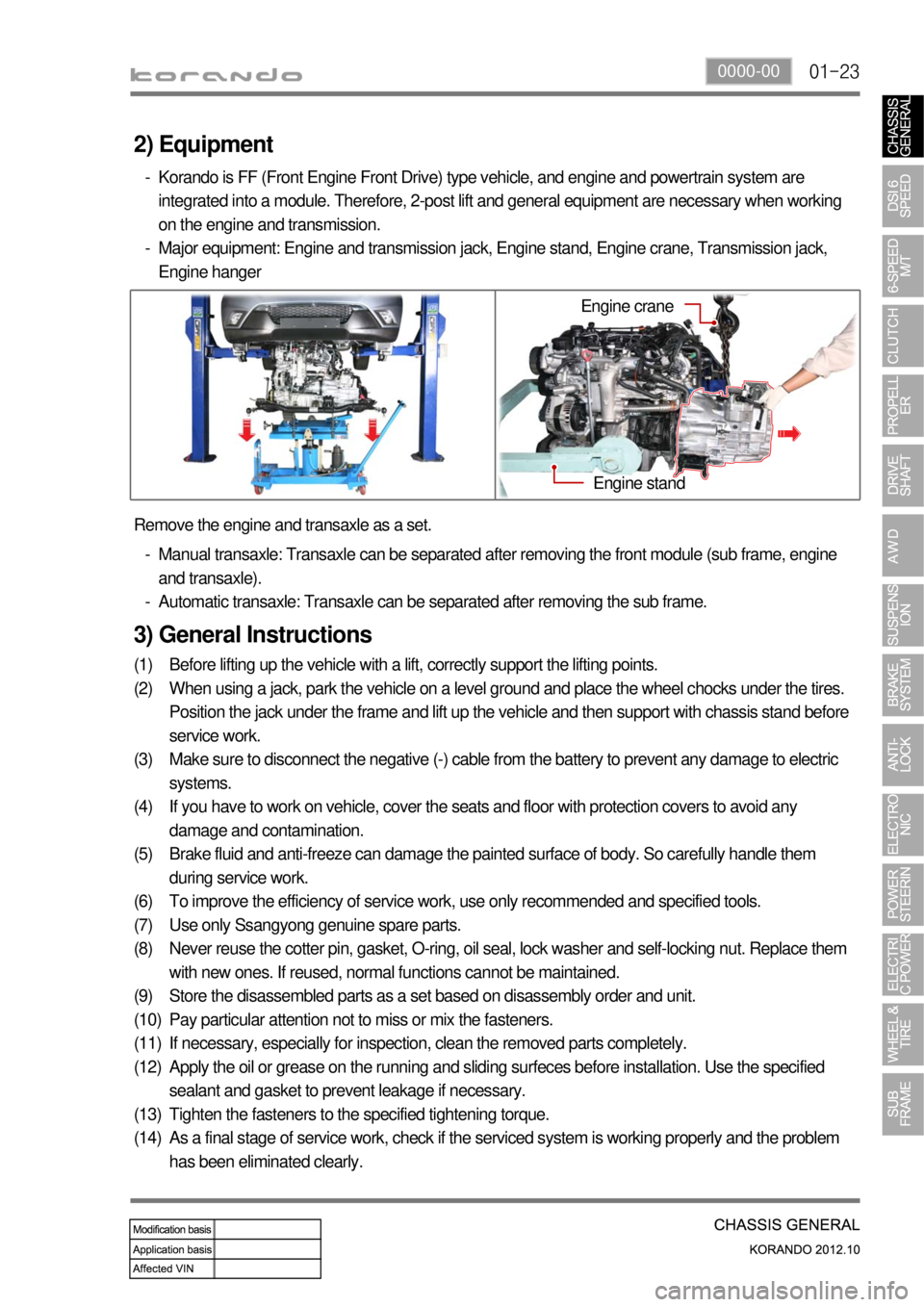

3) General Instructions

Before lifting up the vehicle with a lift, correctly support the lifting points.

When using a jack, park the vehicle on a level ground and place the wheel chocks under the tires.

Position the jack under the frame and lift up the vehicle and then support with chassis stand before

service work.

Make sure to disconnect the negative (-) cable from the battery to prevent any damage to electric

systems.

If you have to work on vehicle, cover the seats and floor with protection covers to avoid any

damage and contamination.

Brake fluid and anti-freeze can damage the painted surface of body. So carefully handle them

during service work.

To improve the efficiency of service work, use only recommended and specified tools.

Use only Ssangyong genuine spare parts.

Never reuse the cotter pin, gasket, O-ring, oil seal, lock washer and self-locking nut. Replace them

with new ones. If reused, normal functions cannot be maintained.

Store the disassembled parts as a set based on disassembly order and unit.

Pay particular attention not to miss or mix the fasteners.

If necessary, especially for inspection, clean the removed parts completely.

Apply the oil or grease on the running and sliding surfeces before installation. Use the specified

sealant and gasket to prevent leakage if necessary.

Tighten the fasteners to the specified tightening torque.

As a final stage of service work, check if the serviced system is working properly and the problem

has been eliminated clearly. (1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14) Remove the engine and transaxle as a set.

Manual transaxle: Transaxle can be separated after removing the front module (sub frame, engine

and transaxle).

Automatic transaxle: Transaxle can be separated after removing the sub frame. -

-

2) Equipment

Korando is FF (Front Engine Front Drive) type vehicle, and engine and powertrain system are

integrated into a module. Therefore, 2-post lift and general equipment are necessary when working

on the engine and transmission.

Major equipment: Engine and transmission jack, Engine stand, Engine crane, Transmission jack,

Engine hanger -

-

Engine stand

Engine crane