ABS SSANGYONG KORANDO 2012 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 795 of 1082

09-38790-00

1. SPECIFICATION

Pin No. Specification Pin No. Specification

Rated voltage

DC 12.0 VInsulating resistance No heat & fire due to current

leak

Operating voltage

DC 9.0 V ~ 16.0 V

Max. permissible

currentUnit: 100 mA or less

Operating

temperature-30℃ ~ +80℃

Sensor: 20 mA or less

Storage temperature

-40℃ ~ +85℃

WeightUnit: 75.7 g±5 g

Maximum humidity

95%Sensor: 38.7 g±5 g

2. CAUTIONS

Sensor Cannot Detect ▶

When the sensor is frozen (operate normally when it's thawed)

When the sensor is covered with foreign materials such as snow or condensation

(if the foreign materials are removed, the sensor operates normally.) -

-

Not defective but improperly working ▶

When the sensing portion is frozen (operates normally after thawed)

When reversing on rough roads, gravel roads, hills, or grass.

When receiving other ultrasonic signals (metal sounds or air braking noises from heavy

commercial vehicles).

When there is heavy rainfall or water drops.

When the sensor is covered with snow. -

-

-

-

-

Certain obstacles that sensors cannot detect ▶

Thin and narrow objects, such as wires, ropes, or chains

Cotton, sponge, clothes, snow that absorb ultrasonic waves. -

-

Weak Sensing Scopes ▶

When the ambient temperature is too high or too low.

When a 1 m or less long small object with a diagmeter of 100 mm or less is detected. -

-

Page 818 of 1082

01-8

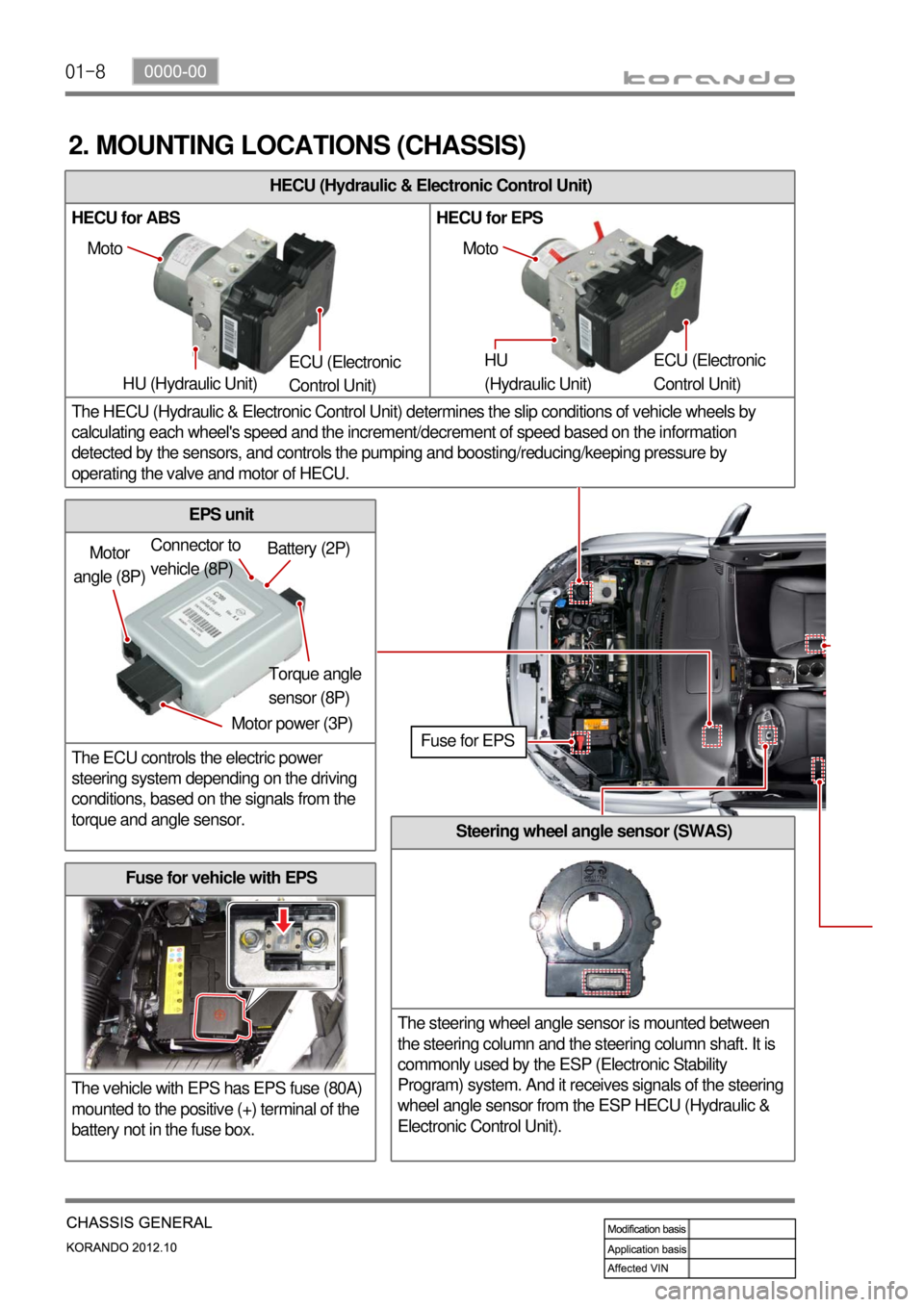

Fuse for vehicle with EPS

The vehicle with EPS has EPS fuse (80A)

mounted to the positive (+) terminal of the

battery not in the fuse box.

EPS unit

The ECU controls the electric power

steering system depending on the driving

conditions, based on the signals from the

torque and angle sensor.

HECU (Hydraulic & Electronic Control Unit)

HECU for ABS HECU for EPS

The HECU (Hydraulic & Electronic Control Unit) determines the slip conditions of vehicle wheels by

calculating each wheel's speed and the increment/decrement of speed based on the information

detected by the sensors, and controls the pumping and boosting/reducing/keeping pressure by

operating the valve and motor of HECU.

2. MOUNTING LOCATIONS (CHASSIS)

Moto

HU (Hydraulic Unit) ECU (Electronic

Control Unit) Moto

HU

(Hydraulic Unit) ECU (Electronic

Control Unit)

Motor

angle (8P)

Motor power (3P)Torque angle

sensor (8P) Battery (2P) Connector to

vehicle (8P)

Fuse for EPS

Steering wheel angle sensor (SWAS)

The steering wheel angle sensor is mounted between

the steering column and the steering column shaft. It is

commonly used by the ESP (Electronic Stability

Program) system. And it receives signals of the steering

wheel angle sensor from the ESP HECU (Hydraulic &

Electronic Control Unit).

Page 819 of 1082

01-90000-00

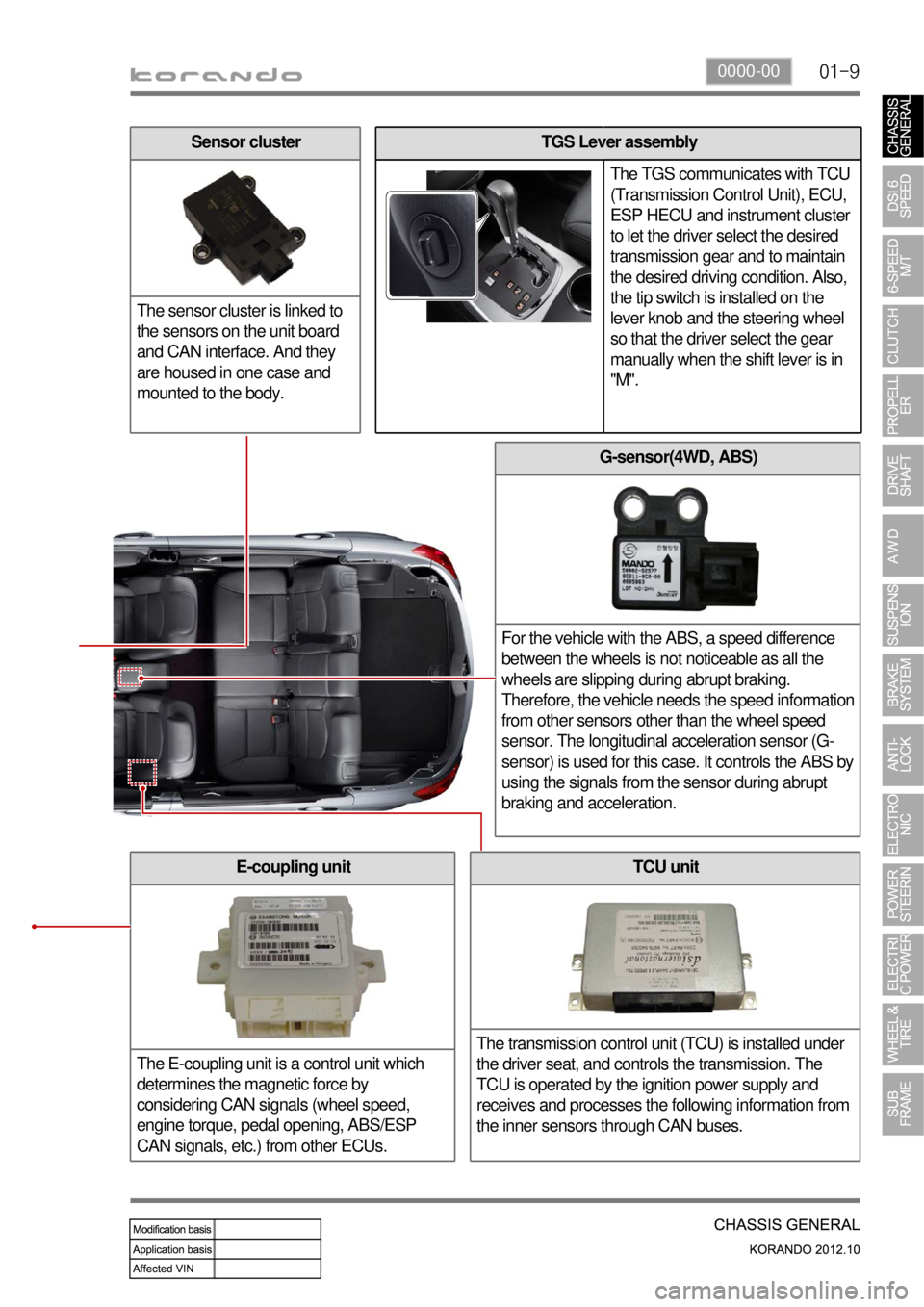

G-sensor(4WD, ABS)

For the vehicle with the ABS, a speed difference

between the wheels is not noticeable as all the

wheels are slipping during abrupt braking.

Therefore, the vehicle needs the speed information

from other sensors other than the wheel speed

sensor. The longitudinal acceleration sensor (G-

sensor) is used for this case. It controls the ABS by

using the signals from the sensor during abrupt

braking and acceleration.

TCU unit

The transmission control unit (TCU) is installed under

the driver seat, and controls the transmission. The

TCU is operated by the ignition power supply and

receives and processes the following information from

the inner sensors through CAN buses.E-coupling unit

The E-coupling unit is a control unit which

determines the magnetic force by

considering CAN signals (wheel speed,

engine torque, pedal opening, ABS/ESP

CAN signals, etc.) from other ECUs.

TGS Lever assembly

The TGS communicates with TCU

(Transmission Control Unit), ECU,

ESP HECU and instrument cluster

to let the driver select the desired

transmission gear and to maintain

the desired driving condition. Also,

the tip switch is installed on the

lever knob and the steering wheel

so that the driver select the gear

manually when the shift lever is in

"M".Sensor cluster

The sensor cluster is linked to

the sensors on the unit board

and CAN interface. And they

are housed in one case and

mounted to the body.

Page 820 of 1082

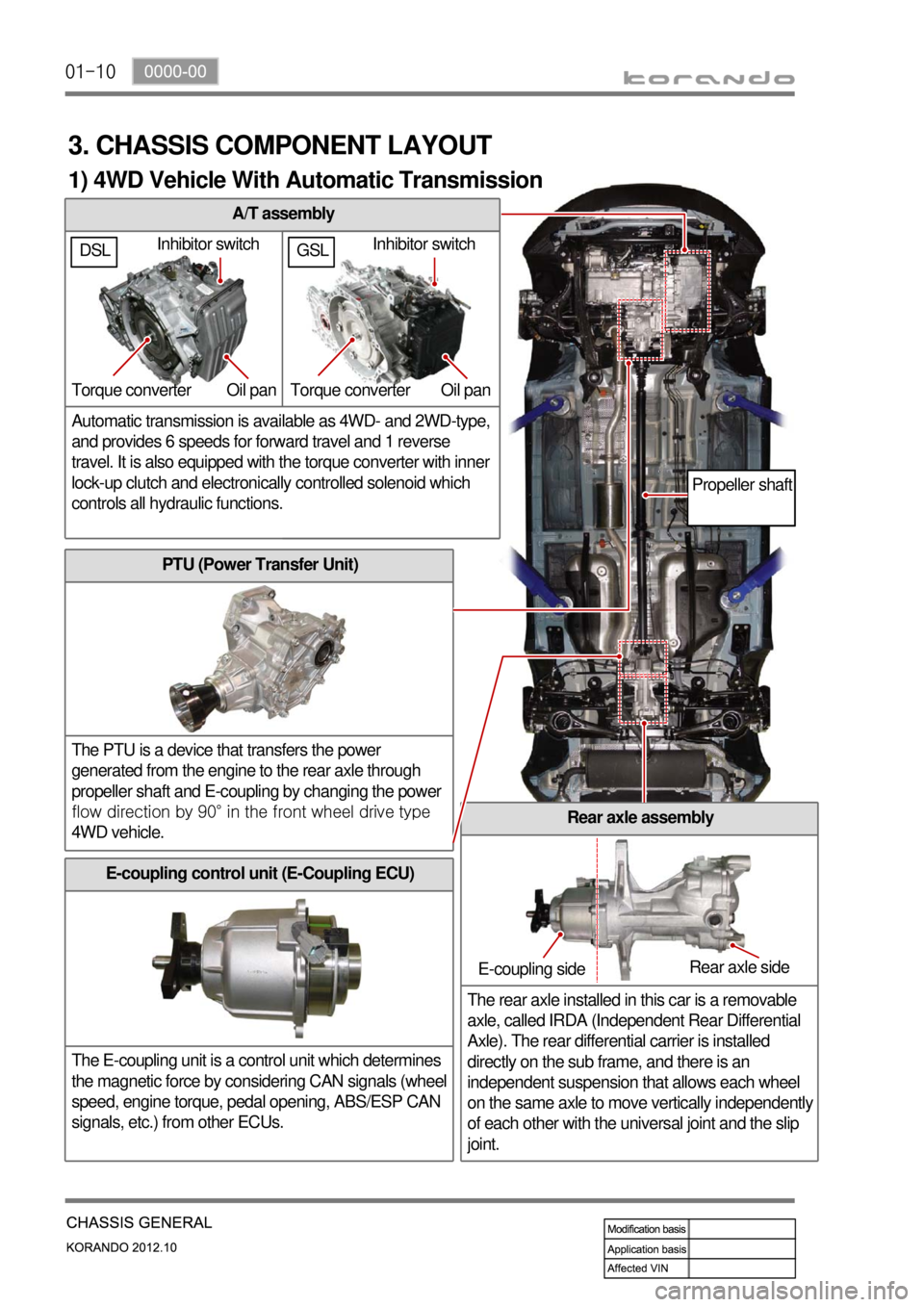

01-10

A/T assembly

Automatic transmission is available as 4WD- and 2WD-type,

and provides 6 speeds for forward travel and 1 reverse

travel. It is also equipped with the torque converter with inner

lock-up clutch and electronically controlled solenoid which

controls all hydraulic functions.

3. CHASSIS COMPONENT LAYOUT

PTU (Power Transfer Unit)

The PTU is a device that transfers the power

generated from the engine to the rear axle through

propeller shaft and E-coupling by changing the power

<008d00930096009e0047008b00900099008c008a009b0090009600950047008900a000470060005700b60047009000950047009b008f008c0047008d009900960095009b0047009e008f008c008c00930047008b00990090009d008c0047009b00a0009700

8c0047>

4WD vehicle.

Rear axle assembly

The rear axle installed in this car is a removable

axle, called IRDA (Independent Rear Differential

Axle). The rear differential carrier is installed

directly on the sub frame, and there is an

independent suspension that allows each wheel

on the same axle to move vertically independentl

y

of each other with the universal joint and the slip

joint.

E-coupling control unit (E-Coupling ECU)

The E-coupling unit is a control unit which determines

the magnetic force by considering CAN signals (wheel

speed, engine torque, pedal opening, ABS/ESP CAN

signals, etc.) from other ECUs.

Inhibitor switch

Torque converter Oil pan

E-coupling sideRear axle side

Propeller shaft

1) 4WD Vehicle With Automatic Transmission

GSLDSLInhibitor switch

Torque converter Oil pan

Page 824 of 1082

01-14

Stabilizer bar assembly

The stabilizer bar assembly is not activated if the left/right

wheels move up/down simultaneously, but if both wheels

move up/down differently it is activated with frame to

minimize the tilting of the body.

5. FRONT SUSPENSION COMPONENT LAYOUT

Front suspension supports the vehicle weight and absorber the vibration from tires. And, in this type of

suspension, the steering linkage tie rod is mounted on the knuckle. The Macpherson Strut suspension

is an independent suspension which has a spring on the strut with a built-in shock absorber. The lower

arm is installed on sub frame and large strut damper is installed on the knuckle to support the tire.

Lower arm assembly

The lower arm assembly connects the frame and

knuckle. It supports the load transferred to the tire

knuckle, relieves the impact from the vehicle and ground

conditions, and ensures driving stability.

Stabilizer bar

Bushing

Clamp

Link

Page 825 of 1082

01-150000-00

Front coil spring assembly

The coil spring is made by winding solid steel rod to form

the coil shape. Its energy absorption rate per weight is

higher than that of the leaf spring and it allows to absorb

small vibration properly resulted in keeping the ride

comforts. Therefore, it's difficult to make an effect on

vibration damping because there is not any friction

between coils.

Coil spring

Shock absorber assembly

Page 826 of 1082

01-16

6. REAR SUSPENSION COMPONENT LAYOUT

Multi-link type suspension is the independent suspension. It provides good ride comfort and drivability

by reducing the coil spring weight. Also, it increases the space for passenger compartment by lowering

the floor.

This type of suspension consists of multiple links such as trailing arm, upper arm, lower arm and track

rod.

Shock absorber assembly

This vehicle uses the gas

shock absorber. This

relieves the vertical

vibrations of vehicle to

provide ride comforts,

prevents the spring break,

enhances drivability, and

extends the life span of

steering components.

Upper arm assembly

Upper arm is installed between knuckle and sub

frame and controls the lateral load and vehicle

height.

Trailing arm assembly

Trailing arm is installed between knuckle and

vehicle body and controls the front and rear load.

Track rod assembly

Track rod is installed between knuckle and rear

sub frame and controls and compensates the

lateral load.

Page 828 of 1082

01-18

A. Indicators on instrument cluster

C. HECU assembly

The HECU assemblies for ABS and ESP have

similar appearance but they have different inner

structure and connector connections from each

other. D. Front brake assembly

The disc brake for 4WD vehicle is the same with

the one for 2WD vehicle.

7. BRAKE SYSTEM AND ESP SYSTEM LAYOUT

B. Master cylinder assembly

Description for master cylinder in this chapter is

based on ABS/ESP equipped vehicle. For CBS,

there is an extra pressure valve mounted to the

master cylinder.

CaliperDisc

Parking brake

warning light

ABS warning lamp

ESP indicator

Page 830 of 1082

01-20

Steering gear box assembly

The steering gear box assembly consists of power cylinder and control valve. The power cylinder has a

cylinder, piston and piston rod. The control valve directs the oil to one end face of the piston to enhance

the steering force. There is a safety check valve which lets the driver steer manually when there is a

malfunction in the hydraulic circuit.

8. STEERING SYSTEM LAYOUT

1) HPS (Hydraulic Power Steering)

The hydraulic pump is a vane

type pump and consists of the

flow control valve and pressure

relief valve.The oil reservoir sends the oil to

the power steering pump and

receives the oil from the power

steering gear.There is a shock absorber which

is folded in the axial direction

when the vehicle is crashed and

a ignition switch assembly on

the column shaft.

The lower shaft minimizes the

torque change using a CV joint

which has constant angular

speed.

Tie rod endSteering cylinderGear box

Tie rod end

Hydraulic pipeColumn shaft

Lower shaft

Steering wheel

assembly

Hydraulic pipe & hose

Page 907 of 1082

05-4

1. OVERVIEW

The propeller shaft is a thin steel pipe which transfers the power from the transmission to the E-coupling,

and has high resistance to torsion and bending.

The propeller shaft has the universal joint (cross axle) mounted on the center of the shaft and splines for

the slip joint on the E-coupling side to accommodate the height and length changes which occur as the

shaft rotates at high speed.

And the rubber bushing for center bearing in the center of the propeller shaft keeps the balance of the

shaft and absorbs its vibration.

Function of propeller shaft ▶

Transmits driving torque.

Accommodates the angle change (universal joint / CV joint).

Accommodates the axial length change (splines for the slip joint). -

-

-

CV joint

Universal yoke and

center bearingUniversal yoke and

rubber coupling