oil level SSANGYONG KORANDO 2012 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 474 of 1082

15-91490-00

3. ECU CONTROL

1) Functions

ECU receives and analyzes signals from various sensors and then modifies those signals into

permissible voltage levels and analyzes to control respective actuators.

ECU microprocessor calculates injection period and injection timing proper for engine piston speed and

crankshaft angle based on input data and stored specific map to control the engine power and emission

gas.

Output signal of the ECU microprocessor activates the injector solenoid valve to control the fuel injection

period and injection timing; so controls various actuators in response to engine changes.

Auxiliary function of ECU has adopted to reduce emission gas, improve fuel economy and enhance

safety, comforts and conveniences. For example, there are autocruise and immobilizer and adopted

CAN communication to exchange data among electrical systems (automatic T/M and brake system) in

the vehicle fluently. And the diagnostic tool can be used to diagnose vehicle status and defectives.

<00760097008c00990088009b00900095008e0047009b008c00940097008c00990088009b009c0099008c0047009900880095008e008c00470096008d0047006c006a007c00470090009a0047009500960099009400880093009300a000470054005b005700

47009b009600470052005f005c00b6006a004700880095008b> protected from factors like oil,

water and electromagnetism and there should be no mechanical shocks.

2) Control Functions

Controls by operating stages:

To make optimum combustion under every operating stage, ECU should calculate proper injection

volume in each stage by considering various factors.

Starting injection volume control:

During initial starting, injecting fuel volume will be calculated by function of temperature and engine

cranking speed. Starting injection continues from when the ignition switch is turned to ignition

position to till the engine reaches to allowable minimum speed.

Driving mode control:

If the vehicle runs normally, fuel injection volume will be calculated by accelerator pedal travel and

engine rpm and the drive map will be used to match the drivers inputs with optimum engine power. -

-

-

Page 483 of 1082

15-18

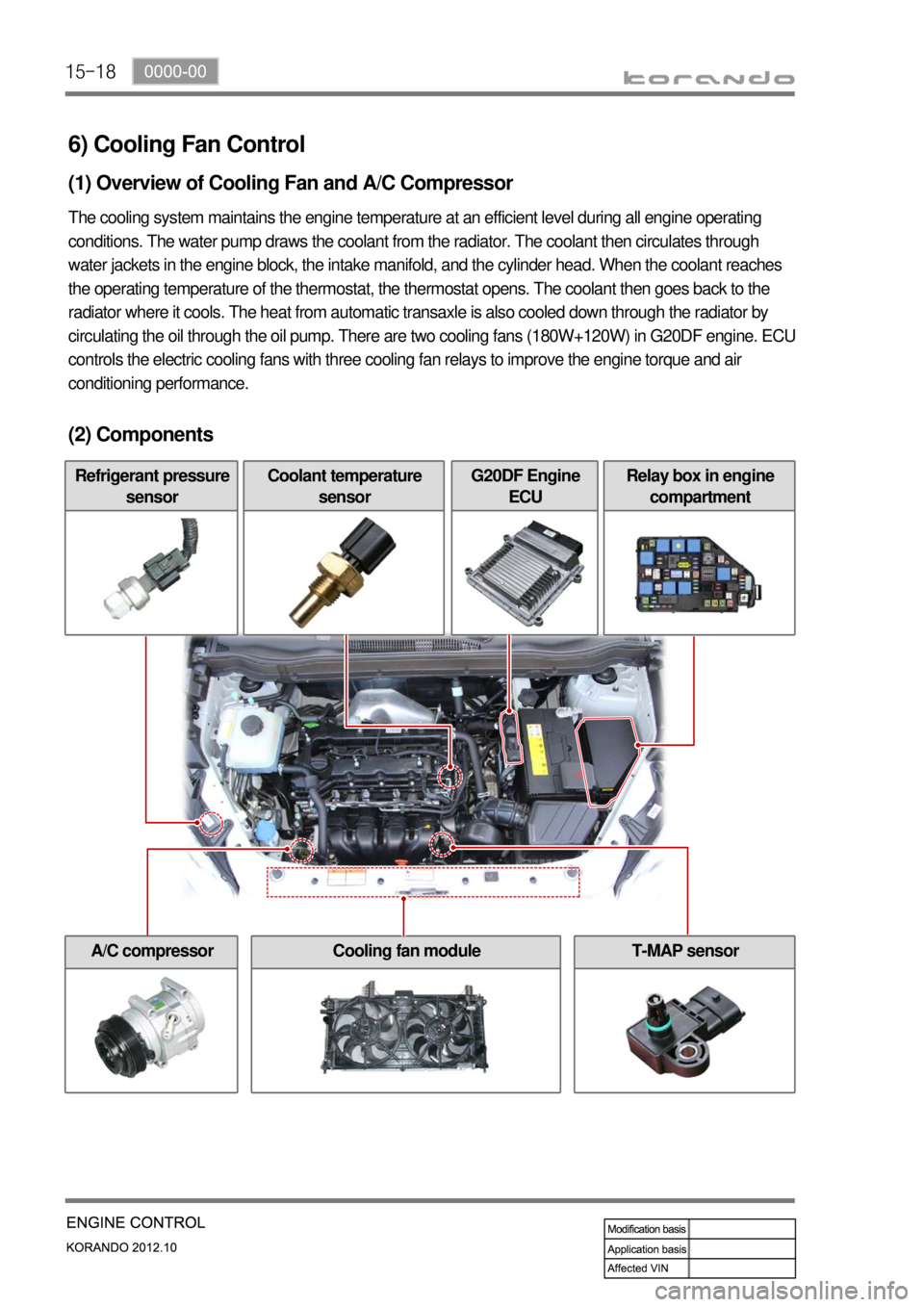

6) Cooling Fan Control

(1) Overview of Cooling Fan and A/C Compressor

The cooling system maintains the engine temperature at an efficient level during all engine operating

conditions. The water pump draws the coolant from the radiator. The coolant then circulates through

water jackets in the engine block, the intake manifold, and the cylinder head. When the coolant reaches

the operating temperature of the thermostat, the thermostat opens. The coolant then goes back to the

radiator where it cools. The heat from automatic transaxle is also cooled down through the radiator by

circulating the oil through the oil pump. There are two cooling fans (180W+120W) in G20DF engine. ECU

controls the electric cooling fans with three cooling fan relays to improve the engine torque and air

conditioning performance.

(2) Components

Refrigerant pressure

sensorCoolant temperature

sensorG20DF Engine

ECURelay box in engine

compartment

A/C compressorCooling fan moduleT-MAP sensor

Page 676 of 1082

05-138010-01

Indicator

(amber)

ESP ▶

ESP OFF indicator ▶

Engine check warning lamp ▶

Indicator

(amber)

Indicator

(amber)

Indicator (red)

Battery charge warning lamp ▶

Indicator (red)

Engine oil level warning lamp ▶This lamp comes on if any sensor or device related to the engine control is

defective.

This lamp comes on when the start switch is ON or when the battery level is

low.

(For EEM, warning lamp is controlled according to CAN signal)

This lamp comes on when the ignition switch is turned to "ON" position,

and then goes off if the engine oil level is normal.

If the engine oil level warning lamp comes on while driving, check the

engine oil level and oil leakage. -

- This indicator comes on when the ESP system is faulty.

This indicator comes on when pressing the ESP OFF switch.

Page 711 of 1082

05-48

Pin No.Message

Operating condition

Domestic Export

Cruise control This message comes on when the ECO cruise mode

is deactivated.

EMSThis message comes on when the engine is faulty.

LampThis message comes on when the tail lamps are ON

with the ignition in the "OFF" or "ACC" position.

SUNROOF

SYSTEMFor the vehicle with SKM, this message comes on

when the sunroof is open with the ignition in the "OFF"

or "ACC" position. For the vehicle without SKM, this

comes on when the sunroof is open with the ignition in

the "OFF" position and the key removed.

Low fuel level This message comes on when the remaining fuel is

insufficient.

ESP checkThis message comes on when the ESP system is

faulty.

ABS check This message comes on when the ABS system is

faulty.

Engine oil level

checkThis message comes on when the engine oil level is

low. Pin No. Message Operating condition

Page 833 of 1082

01-230000-00

3) General Instructions

Before lifting up the vehicle with a lift, correctly support the lifting points.

When using a jack, park the vehicle on a level ground and place the wheel chocks under the tires.

Position the jack under the frame and lift up the vehicle and then support with chassis stand before

service work.

Make sure to disconnect the negative (-) cable from the battery to prevent any damage to electric

systems.

If you have to work on vehicle, cover the seats and floor with protection covers to avoid any

damage and contamination.

Brake fluid and anti-freeze can damage the painted surface of body. So carefully handle them

during service work.

To improve the efficiency of service work, use only recommended and specified tools.

Use only Ssangyong genuine spare parts.

Never reuse the cotter pin, gasket, O-ring, oil seal, lock washer and self-locking nut. Replace them

with new ones. If reused, normal functions cannot be maintained.

Store the disassembled parts as a set based on disassembly order and unit.

Pay particular attention not to miss or mix the fasteners.

If necessary, especially for inspection, clean the removed parts completely.

Apply the oil or grease on the running and sliding surfeces before installation. Use the specified

sealant and gasket to prevent leakage if necessary.

Tighten the fasteners to the specified tightening torque.

As a final stage of service work, check if the serviced system is working properly and the problem

has been eliminated clearly. (1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

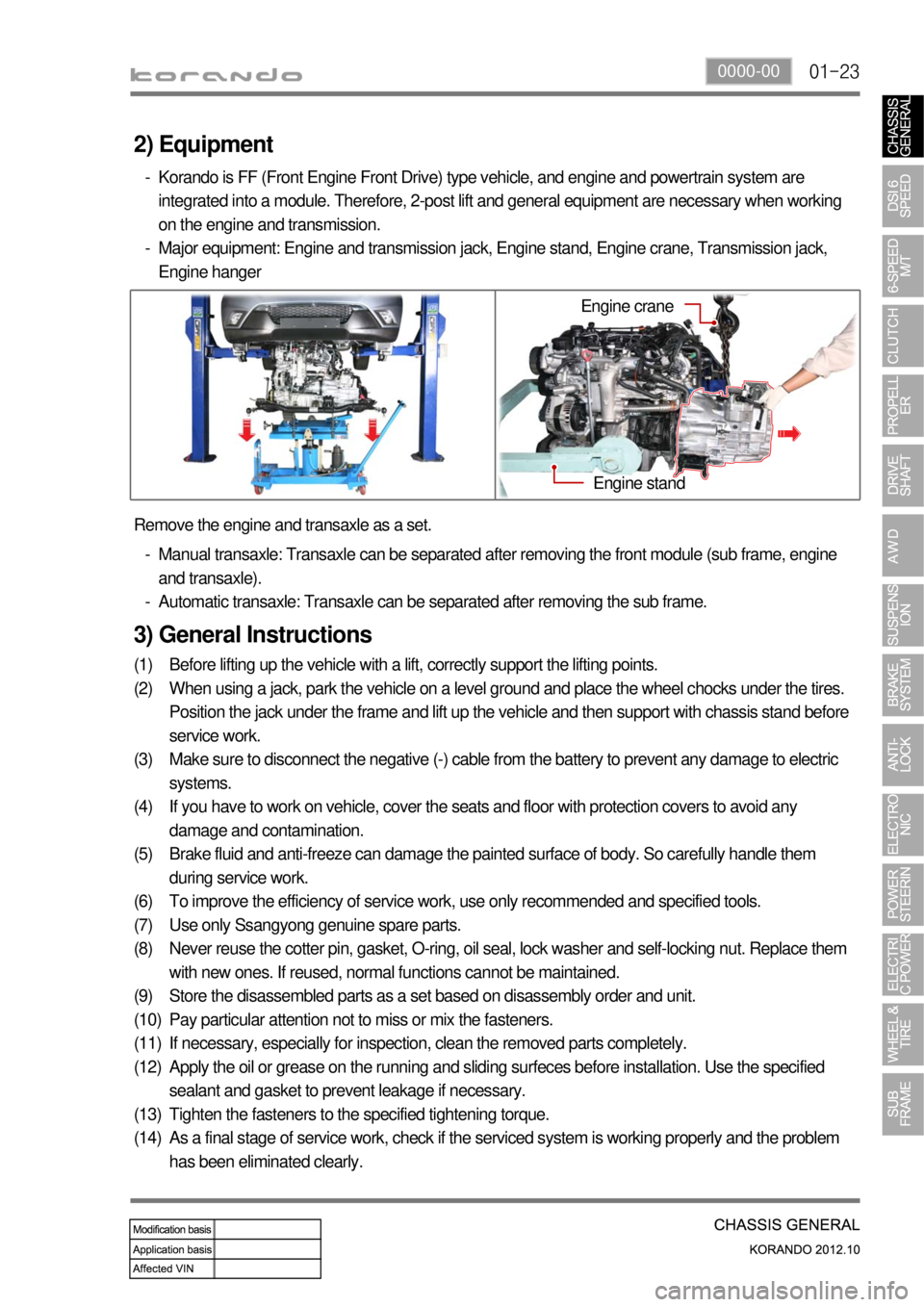

(14) Remove the engine and transaxle as a set.

Manual transaxle: Transaxle can be separated after removing the front module (sub frame, engine

and transaxle).

Automatic transaxle: Transaxle can be separated after removing the sub frame. -

-

2) Equipment

Korando is FF (Front Engine Front Drive) type vehicle, and engine and powertrain system are

integrated into a module. Therefore, 2-post lift and general equipment are necessary when working

on the engine and transmission.

Major equipment: Engine and transmission jack, Engine stand, Engine crane, Transmission jack,

Engine hanger -

-

Engine stand

Engine crane

Page 834 of 1082

01-24

4) Basic Inspection

(1) Horn operation

Listen for the horn sound when pressing the horn pad on the steering wheel. -

(2) Brake operation

Check if there is any abnormal noise, unusually long braking distance, or uneven braking force. If the

brake warning lamp does not go out even after starting the engien or are flashing during driving,

have the brake system checked immediately.

Check the brake pipes and hoses for connection, oil leak, crack or interference after changing the

position of tires. When replacing the tires, check the brake disc for surface condition and wear.

Check the parking brake cable and brake operation. Shorten the checking interval if the parking

brake is used frequently. -

-

-

(3) Exhaust system

Be aware to any changes in sound or smell from the exhaust system. These may be caused by leak or

overheat. Have the exhaust system checked and repaired immediately.

Inspect the exhaust system including catalytic converter. Inspect all the components and body frame

near the exhaust system. -

-

(4) Tires

Unusual vibration of the steering wheel and seats or pulling to one side on the straight and level roads

may indicates the uneven tire inflation pressure or poor wheel balance. -

(5) Steering and suspension system

Inspect the front and rear suspension and the steering system for damage, looseness or missing

parts, signs of wear or lack of lubrication. Inspect the power steering line and the hoses for

connection, leak, crack and chafing. Inspect the drive axle boot and seals for damage, tear or leak.

Replace or repair the system if necessary. -

(6) Engine oil

Check the oil level when the engine is still warm and add the specified engine oil if necessary. -

(7) Coolant

Check the coolant level in the coolant reservoir, coolant conditions (contamination, foreign material),

and hoses for damage and leak. Replace or add the Ssangyong genuine coolant, if needed. -

(8) Engine drive belt

Check all drive belts on the engine for wear, crack and looseness. Retighten or replace the belt, if

needed. -

Page 926 of 1082

09-6

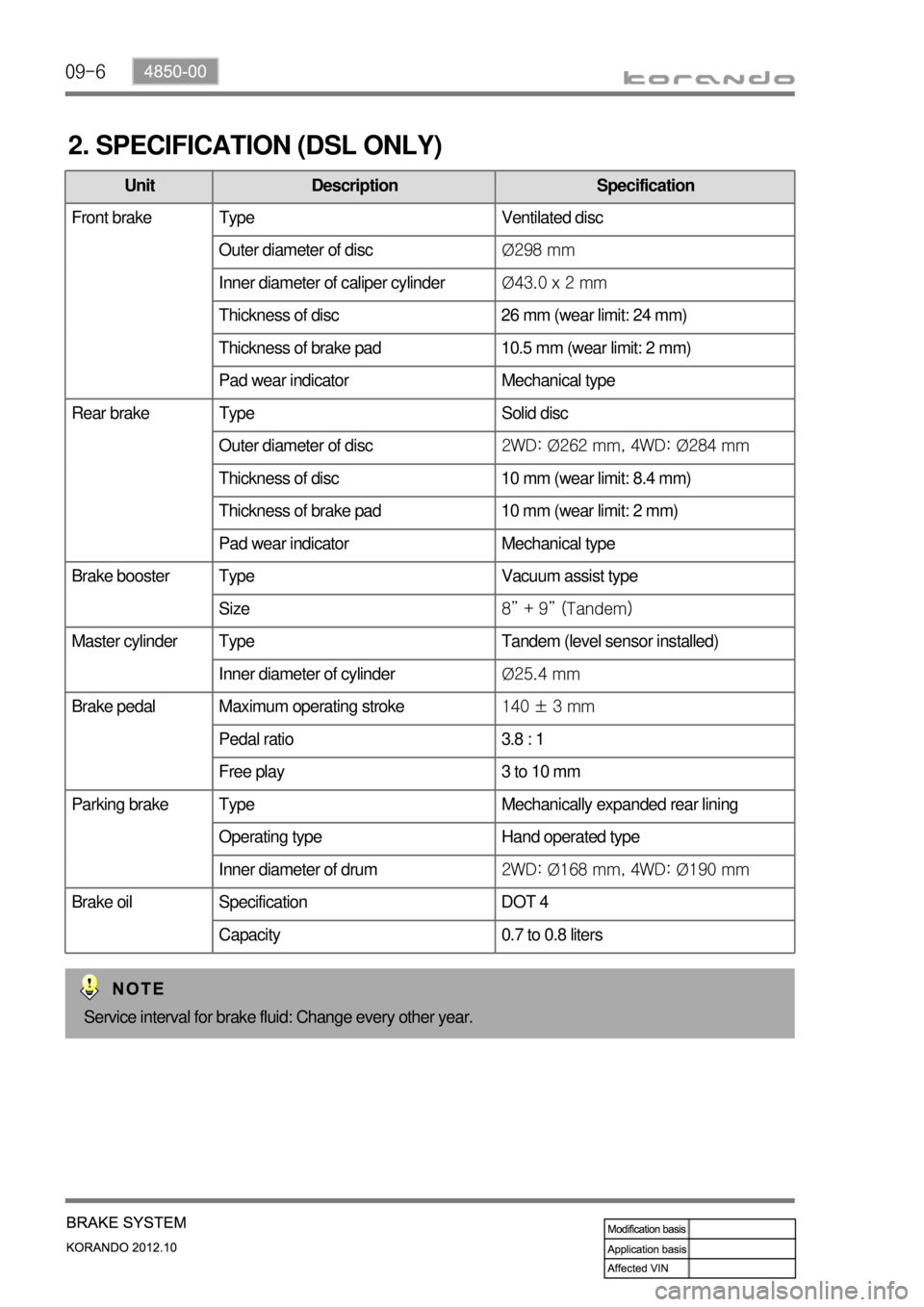

2. SPECIFICATION (DSL ONLY)

Unit Description Specification

Front brake Type Ventilated disc

Outer diameter of discØ298 mm

Inner diameter of caliper cylinderØ43.0 x 2 mm

Thickness of disc 26 mm (wear limit: 24 mm)

Thickness of brake pad 10.5 mm (wear limit: 2 mm)

Pad wear indicator Mechanical type

Rear brake Type Solid disc

Outer diameter of disc2WD: Ø262 mm, 4WD: Ø284 mm

Thickness of disc 10 mm (wear limit: 8.4 mm)

Thickness of brake pad 10 mm (wear limit: 2 mm)

Pad wear indicator Mechanical type

Brake booster Type Vacuum assist type

Size8” + 9” (Tandem)

Master cylinder Type Tandem (level sensor installed)

Inner diameter of cylinderØ25.4 mm

Brake pedal Maximum operating stroke140 ± 3 mm

Pedal ratio 3.8 : 1

Free play 3 to 10 mm

Parking brake Type Mechanically expanded rear lining

Operating type Hand operated type

Inner diameter of drum2WD: Ø168 mm, 4WD: Ø190 mm

Brake oil Specification DOT 4

Capacity 0.7 to 0.8 liters

Service interval for brake fluid: Change every other year.