oil temperature SSANGYONG KORANDO 2012 Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 468 of 1082

15-31490-00

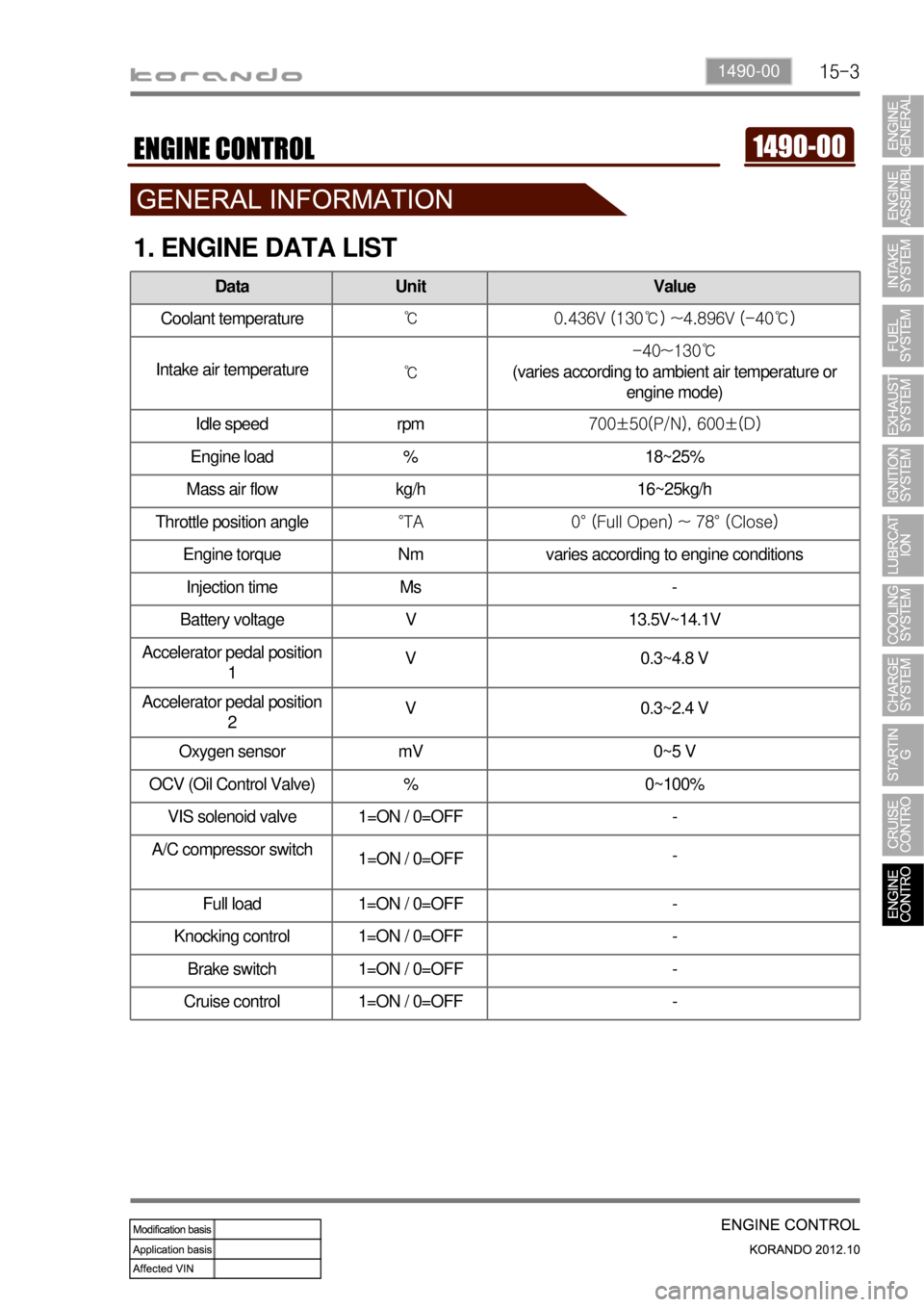

1. ENGINE DATA LIST

Data Unit Value

Coolant temperature℃ 0.436V (130℃) ~4.896V (-40℃)

Intake air temperature

℃-40~130℃

(varies according to ambient air temperature or

engine mode)

Idle speed rpm700±50(P/N), 600±(D)

Engine load % 18~25%

Mass air flow kg/h 16~25kg/h

Throttle position angle°TA 0° (Full Open) ~ 78° (Close)

Engine torque Nm varies according to engine conditions

Injection time Ms -

Battery voltage V 13.5V~14.1V

Accelerator pedal position

1V 0.3~4.8 V

Accelerator pedal position

2V 0.3~2.4 V

Oxygen sensor mV 0~5 V

OCV (Oil Control Valve) % 0~100%

VIS solenoid valve 1=ON / 0=OFF -

A/C compressor switch

1=ON / 0=OFF-

Full load 1=ON / 0=OFF -

Knocking control 1=ON / 0=OFF -

Brake switch 1=ON / 0=OFF -

Cruise control 1=ON / 0=OFF -

Page 472 of 1082

15-70000-00

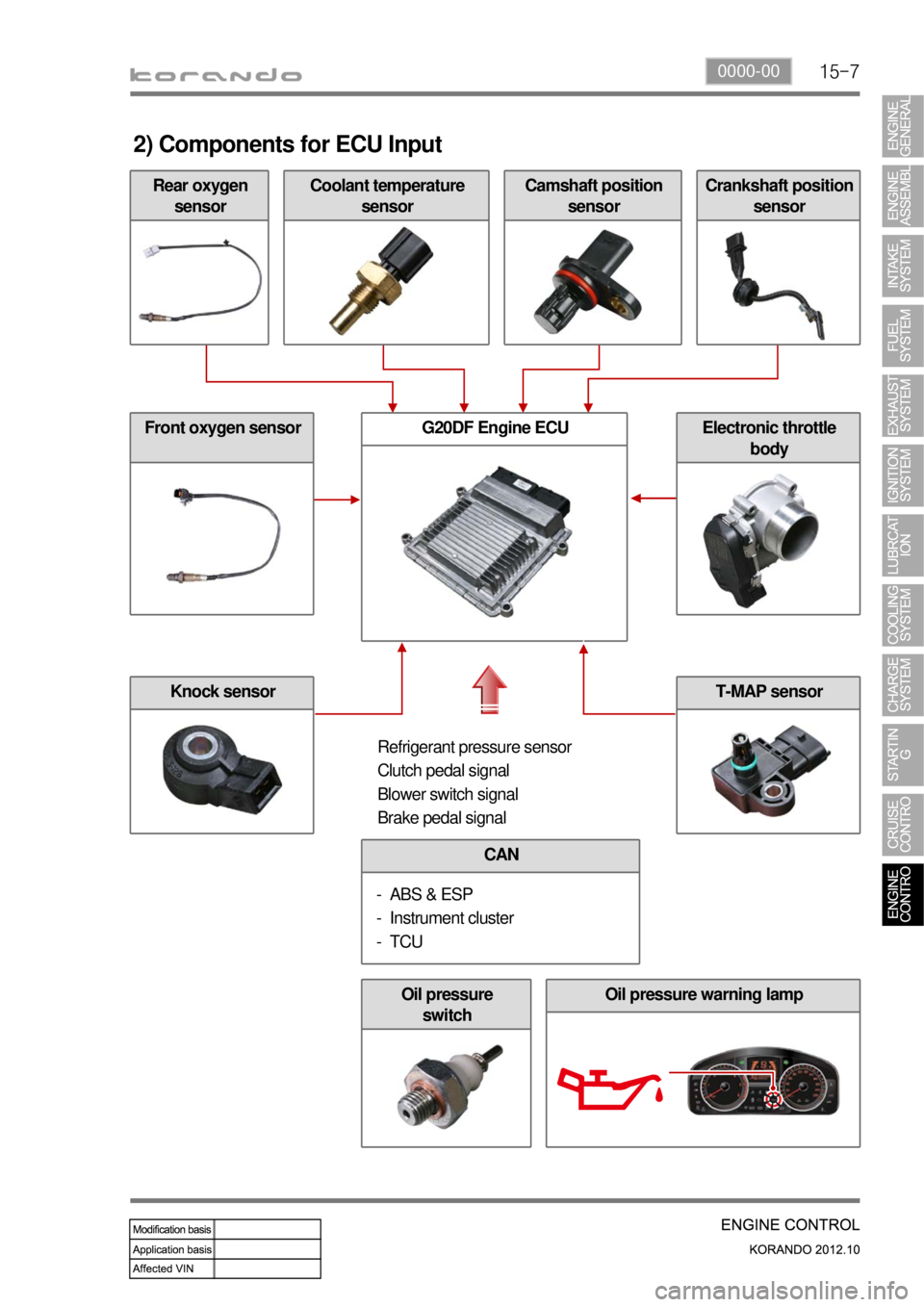

Rear oxygen

sensor

2) Components for ECU Input

Coolant temperature

sensorCamshaft position

sensorCrankshaft position

sensor

Front oxygen sensor

Knock sensor

G20DF Engine ECUElectronic throttle

body

Refrigerant pressure sensor

Clutch pedal signal

Blower switch signal

Brake pedal signal

CAN

ABS & ESP

Instrument cluster

TCU -

-

-

Oil pressure

switchOil pressure warning lamp

T-MAP sensor

Page 474 of 1082

15-91490-00

3. ECU CONTROL

1) Functions

ECU receives and analyzes signals from various sensors and then modifies those signals into

permissible voltage levels and analyzes to control respective actuators.

ECU microprocessor calculates injection period and injection timing proper for engine piston speed and

crankshaft angle based on input data and stored specific map to control the engine power and emission

gas.

Output signal of the ECU microprocessor activates the injector solenoid valve to control the fuel injection

period and injection timing; so controls various actuators in response to engine changes.

Auxiliary function of ECU has adopted to reduce emission gas, improve fuel economy and enhance

safety, comforts and conveniences. For example, there are autocruise and immobilizer and adopted

CAN communication to exchange data among electrical systems (automatic T/M and brake system) in

the vehicle fluently. And the diagnostic tool can be used to diagnose vehicle status and defectives.

<00760097008c00990088009b00900095008e0047009b008c00940097008c00990088009b009c0099008c0047009900880095008e008c00470096008d0047006c006a007c00470090009a0047009500960099009400880093009300a000470054005b005700

47009b009600470052005f005c00b6006a004700880095008b> protected from factors like oil,

water and electromagnetism and there should be no mechanical shocks.

2) Control Functions

Controls by operating stages:

To make optimum combustion under every operating stage, ECU should calculate proper injection

volume in each stage by considering various factors.

Starting injection volume control:

During initial starting, injecting fuel volume will be calculated by function of temperature and engine

cranking speed. Starting injection continues from when the ignition switch is turned to ignition

position to till the engine reaches to allowable minimum speed.

Driving mode control:

If the vehicle runs normally, fuel injection volume will be calculated by accelerator pedal travel and

engine rpm and the drive map will be used to match the drivers inputs with optimum engine power. -

-

-

Page 478 of 1082

15-130000-00

Coolant temperature

sensor

4) Ignition System Control

(1) Overview

G20DF engine is equipped with the single ignition system. Each spark plug is operated independently

by the ECU and one ignition coil and spark plug are provided for each cylinder.

(2) Components

Input Components ▶

Crankshaft position

sensorAccelerator pedal position

sensor

Knock sensorCamshaft position

sensorElectronic

throttle body

Output Components ▶

Page 483 of 1082

15-18

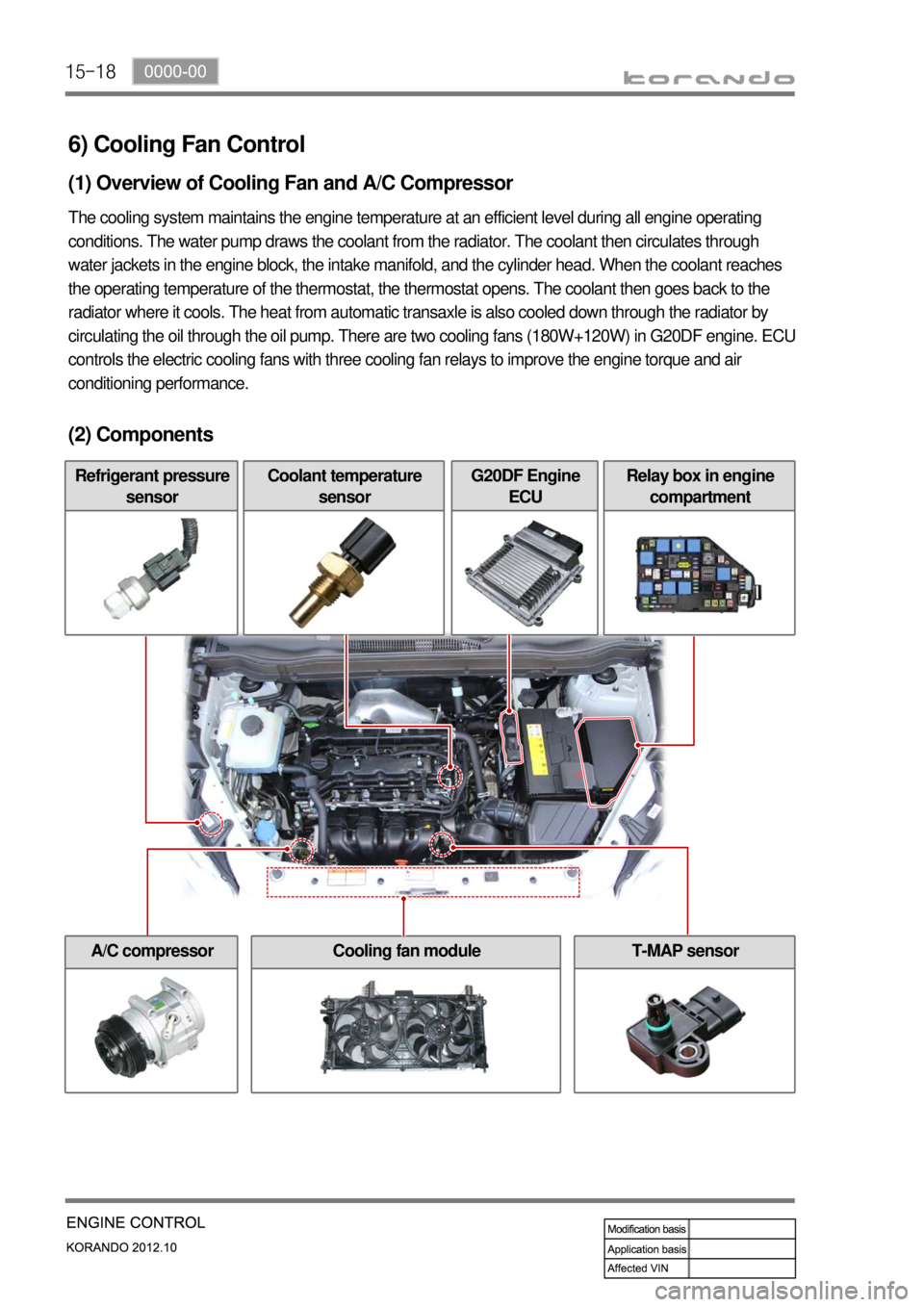

6) Cooling Fan Control

(1) Overview of Cooling Fan and A/C Compressor

The cooling system maintains the engine temperature at an efficient level during all engine operating

conditions. The water pump draws the coolant from the radiator. The coolant then circulates through

water jackets in the engine block, the intake manifold, and the cylinder head. When the coolant reaches

the operating temperature of the thermostat, the thermostat opens. The coolant then goes back to the

radiator where it cools. The heat from automatic transaxle is also cooled down through the radiator by

circulating the oil through the oil pump. There are two cooling fans (180W+120W) in G20DF engine. ECU

controls the electric cooling fans with three cooling fan relays to improve the engine torque and air

conditioning performance.

(2) Components

Refrigerant pressure

sensorCoolant temperature

sensorG20DF Engine

ECURelay box in engine

compartment

A/C compressorCooling fan moduleT-MAP sensor

Page 839 of 1082

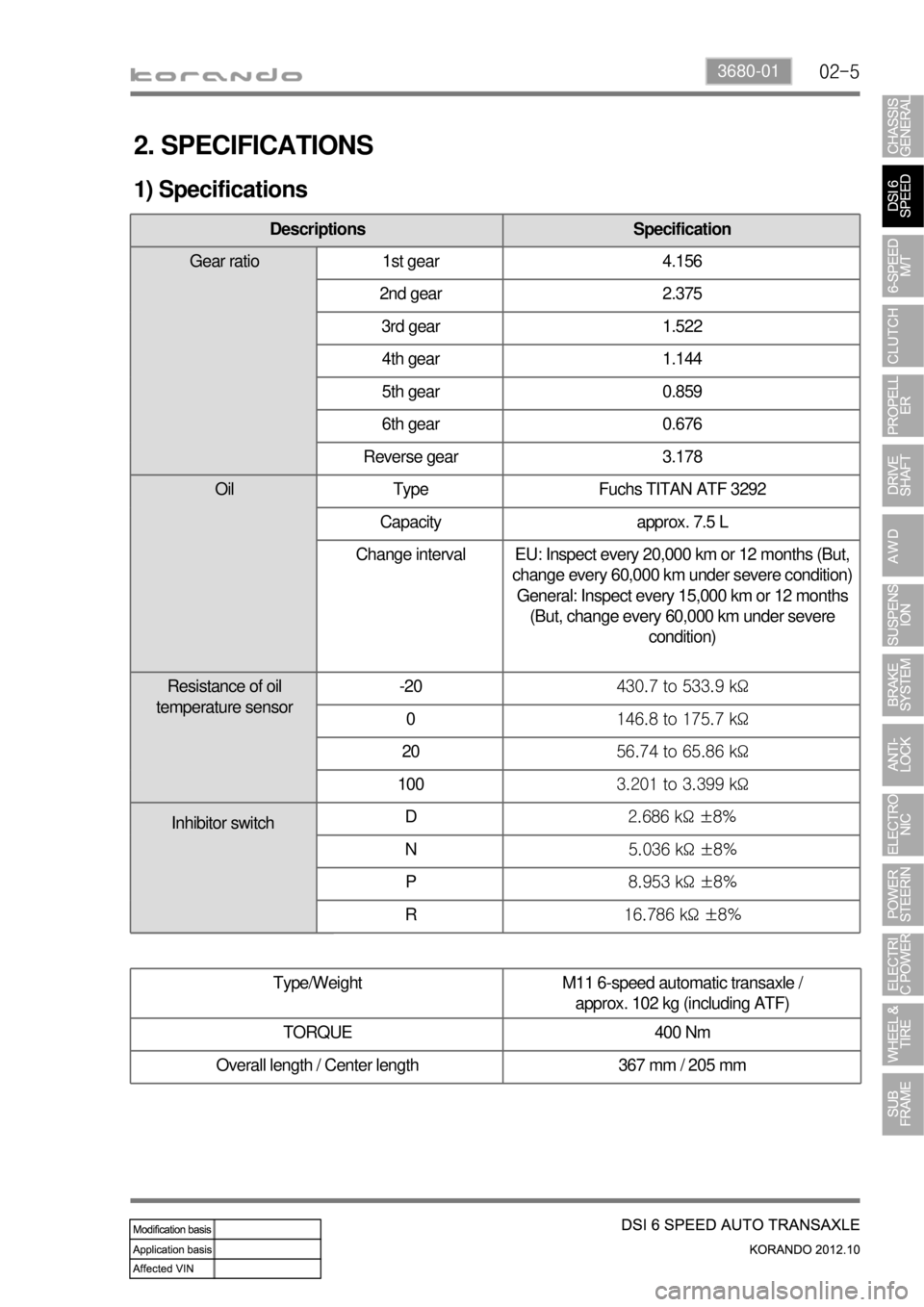

02-53680-01

2. SPECIFICATIONS

1) Specifications

Type/Weight M11 6-speed automatic transaxle /

approx. 102 kg (including ATF)

TORQUE 400 Nm

Overall length / Center length 367 mm / 205 mm

Descriptions Specification

Gear ratio 1st gear 4.156

2nd gear 2.375

3rd gear 1.522

4th gear 1.144

5th gear 0.859

6th gear 0.676

Reverse gear 3.178

Oil Type Fuchs TITAN ATF 3292

Capacity approx. 7.5 L

Change interval EU: Inspect every 20,000 km or 12 months (But,

change every 60,000 km under severe condition)

General: Inspect every 15,000 km or 12 months

(But, change every 60,000 km under severe

condition)

Resistance of oil

temperature sensor-20430.7 to 533.9 kΩ

0146.8 to 175.7 kΩ

2056.74 to 65.86 kΩ

1003.201 to 3.399 kΩ

D2.686 kΩ ±8%

N5.036 kΩ ±8%

P8.953 kΩ ±8%

R16.786 kΩ ±8%

Inhibitor switch

Page 842 of 1082

02-8

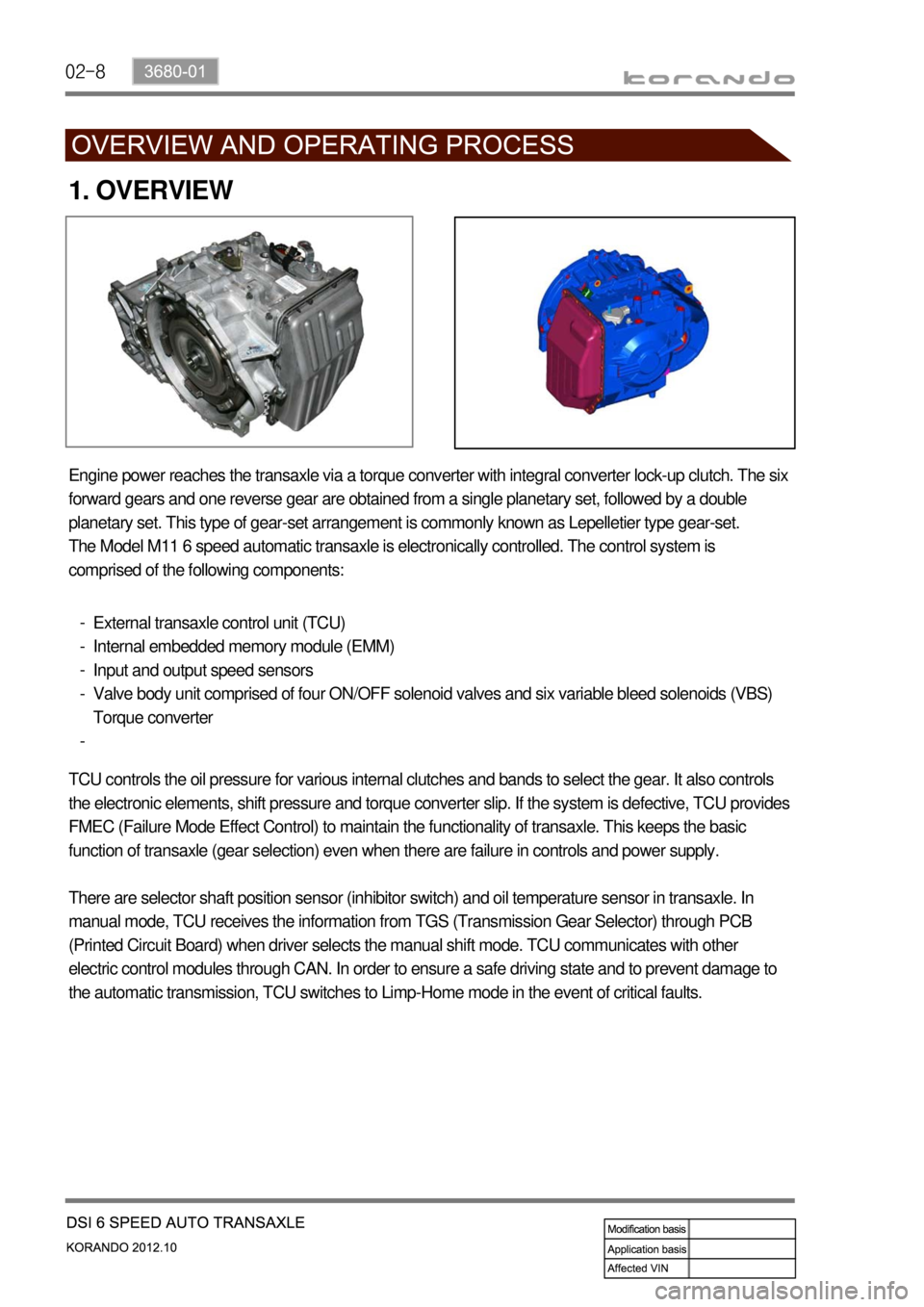

1. OVERVIEW

Engine power reaches the transaxle via a torque converter with integral converter lock-up clutch. The six

forward gears and one reverse gear are obtained from a single planetary set, followed by a double

planetary set. This type of gear-set arrangement is commonly known as Lepelletier type gear-set.

The Model M11 6 speed automatic transaxle is electronically controlled. The control system is

comprised of the following components:

External transaxle control unit (TCU)

Internal embedded memory module (EMM)

Input and output speed sensors

Valve body unit comprised of four ON/OFF solenoid valves and six variable bleed solenoids (VBS)

Torque converter -

-

-

-

-

TCU controls the oil pressure for various internal clutches and bands to select the gear. It also controls

the electronic elements, shift pressure and torque converter slip. If the system is defective, TCU provides

FMEC (Failure Mode Effect Control) to maintain the functionality of transaxle. This keeps the basic

function of transaxle (gear selection) even when there are failure in controls and power supply.

There are selector shaft position sensor (inhibitor switch) and oil temperature sensor in transaxle. In

manual mode, TCU receives the information from TGS (Transmission Gear Selector) through PCB

(Printed Circuit Board) when driver selects the manual shift mode. TCU communicates with other

electric control modules through CAN. In order to ensure a safe driving state and to prevent damage to

the automatic transmission, TCU switches to Limp-Home mode in the event of critical faults.

Page 848 of 1082

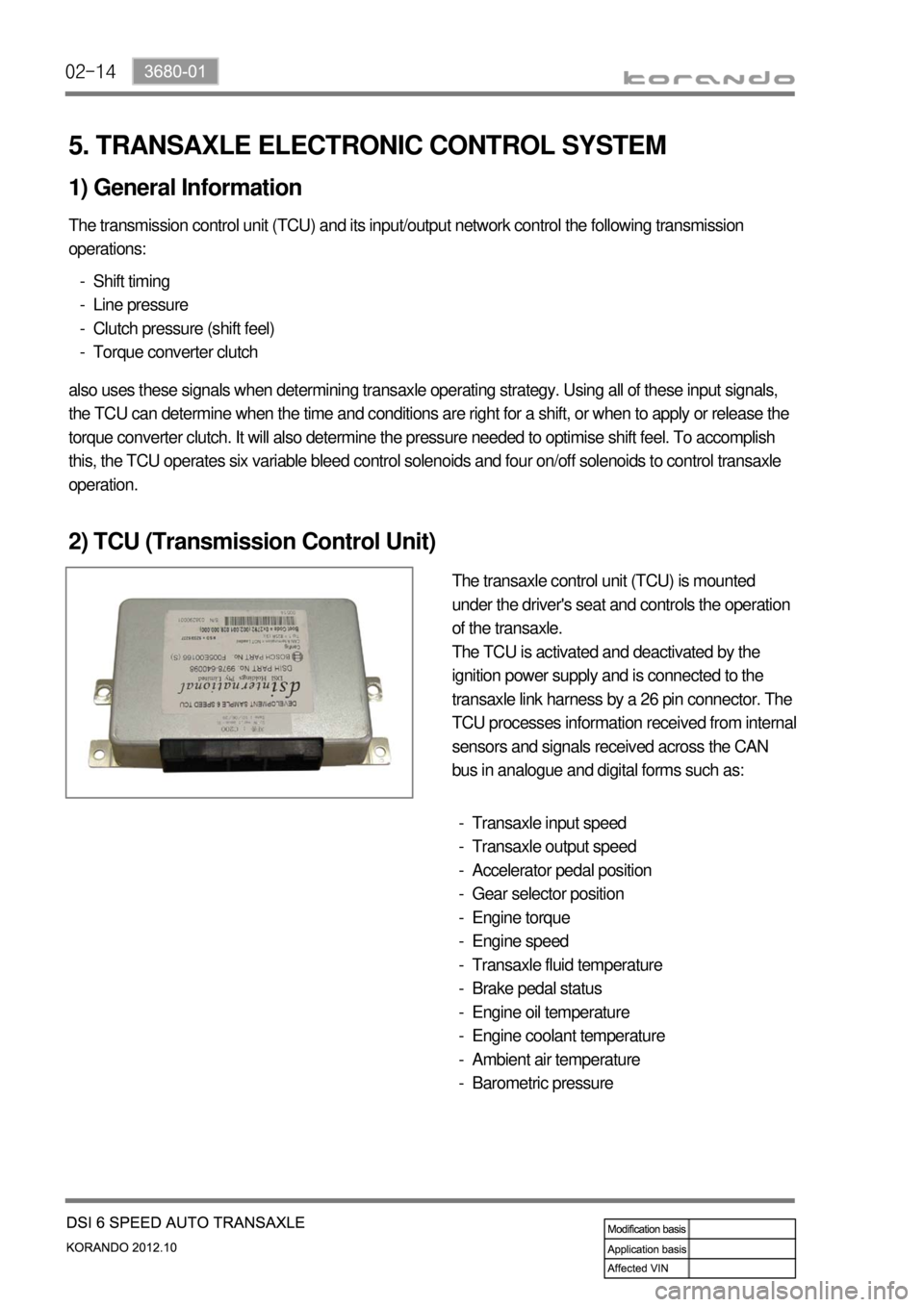

02-14

5. TRANSAXLE ELECTRONIC CONTROL SYSTEM

1) General Information

The transmission control unit (TCU) and its input/output network control the following transmission

operations:

Shift timing

Line pressure

Clutch pressure (shift feel)

Torque converter clutch -

-

-

-

also uses these signals when determining transaxle operating strategy. Using all of these input signals,

the TCU can determine when the time and conditions are right for a shift, or when to apply or release the

torque converter clutch. It will also determine the pressure needed to optimise shift feel. To accomplish

this, the TCU operates six variable bleed control solenoids and four on/off solenoids to control transaxle

operation.

2) TCU (Transmission Control Unit)

The transaxle control unit (TCU) is mounted

under the driver's seat and controls the operation

of the transaxle.

The TCU is activated and deactivated by the

ignition power supply and is connected to the

transaxle link harness by a 26 pin connector. The

TCU processes information received from internal

sensors and signals received across the CAN

bus in analogue and digital forms such as:

Transaxle input speed

Transaxle output speed

Accelerator pedal position

Gear selector position

Engine torque

Engine speed

Transaxle fluid temperature

Brake pedal status

Engine oil temperature

Engine coolant temperature

Ambient air temperature

Barometric pressure -

-

-

-

-

-

-

-

-

-

-

-

Page 866 of 1082

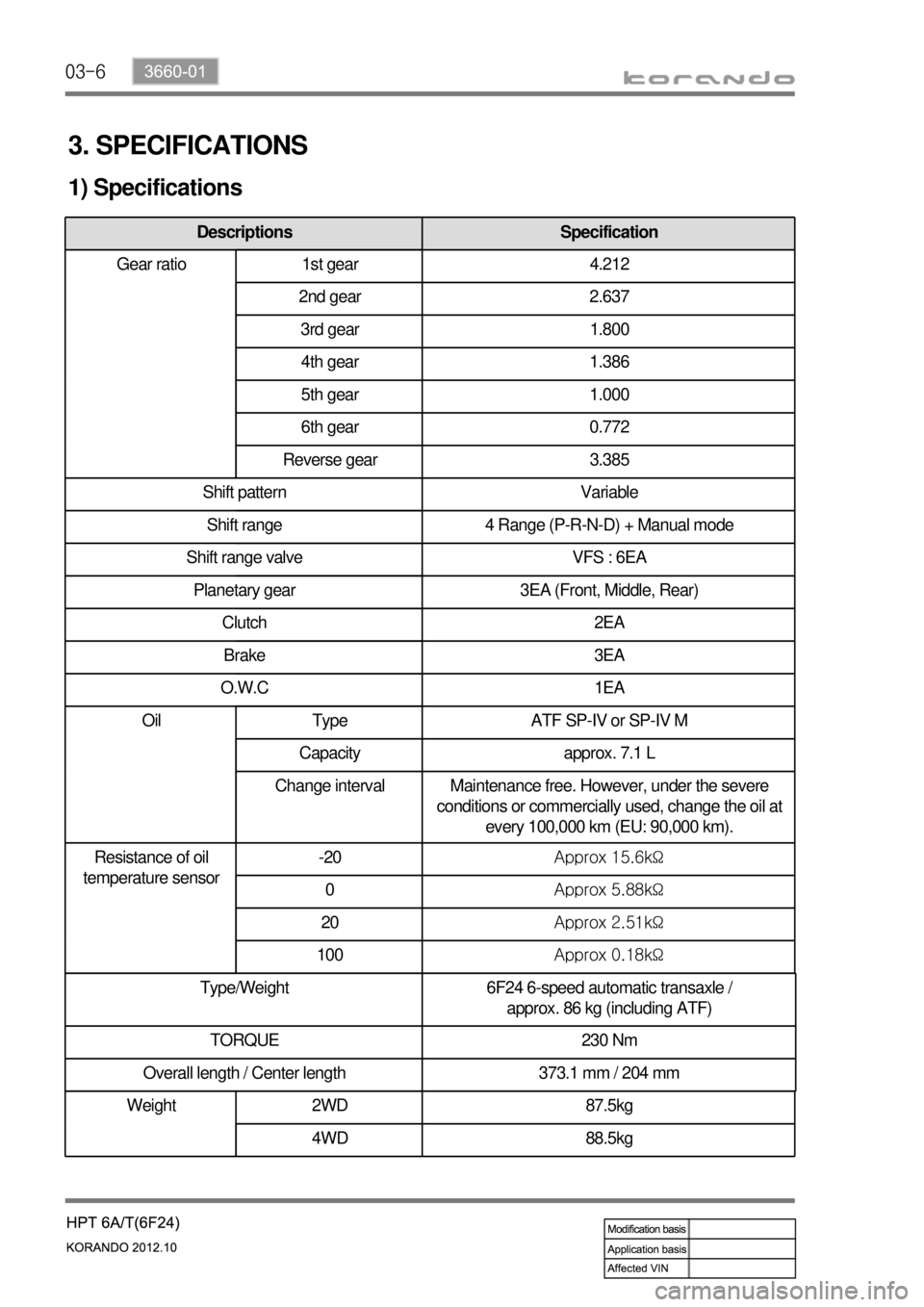

03-6

3. SPECIFICATIONS

1) Specifications

Type/Weight 6F24 6-speed automatic transaxle /

approx. 86 kg (including ATF)

TORQUE 230 Nm

Overall length / Center length 373.1 mm / 204 mm

Descriptions Specification

Gear ratio 1st gear 4.212

2nd gear 2.637

3rd gear 1.800

4th gear 1.386

5th gear 1.000

6th gear 0.772

Reverse gear 3.385

Shift pattern Variable

Shift range 4 Range (P-R-N-D) + Manual mode

Shift range valve VFS : 6EA

Planetary gear 3EA (Front, Middle, Rear)

Clutch 2EA

Brake 3EA

O.W.C 1EA

Oil Type ATF SP-IV or SP-IV M

Capacity approx. 7.1 L

Change interval Maintenance free. However, under the severe

conditions or commercially used, change the oil at

every 100,000 km (EU: 90,000 km).

Resistance of oil

temperature sensor-20Approx 15.6kΩ

0Approx 5.88kΩ

20Approx 2.51kΩ

100Approx 0.18kΩ

Weight 2WD 87.5kg

4WD 88.5kg

Page 868 of 1082

03-8

Automatic transaxle Bolt (engine) 17 mm X 4

14 mm X 1 85.0 ~ 100.0Nm

Bolt (start motor) 14 mm X 2 48.0 ~ 58.8Nm

Bolt (oil pan) 14 mm X 4 56.0 ~ 62.0Nm

Bolt (torque converter) 17 mm X 6 45.0 ~ 52.0Nm

Eye bolt 22 mm X 1 3.0 ~ 5.0Nm

Drain plug 24 mm X 1 34.0 ~ 44.0Nm

Nut (range select lever) 14 mm X 1 17.6 ~ 24.5Nm

Bolt (inhibitor switch) 10 mm X 2 9.8 ~ 11.7Nm

Bolt (oil pan) 10 mm X 19 12.0 ~ 14.0Nm

Bolt (solenoid harness) 10 mm X 6 9.8 ~ 11.7Nm

Bolt (oil temperature sensor) 10 mm X 1 9.8 ~ 11.7Nm

Bolt (input & output sensor) 10 mm X 2 9.8 ~ 11.7Nm

Bolt (detent spring) 12 mm X 1 12.0 ~ 16.0Nm

Bolt (valve body) 10 mm X 8 9.8 ~ 11.7Nm

Bolt (V/B solenoid bracket) H5 mm X 9 9.8 ~ 11.7Nm

Bolt (torque converter housing) 12 mm X 20 28.0 ~ 35.0Nm

Bolt (oil guide A) 10 mm X 3 9.8 ~ 11.7Nm

Bolt (oil guide B) 10 mm X 1 5.0 ~ 7.0Nm

Bolt (oil filter) H5 mm X 2 9.8 ~ 11.7Nm

5. TIGHTENING TORQUE

DescriptionsSize x

NumbersTightening torque

(Nm)

TGS lever Nut 12 mm X 4 17.6 ~ 21.6Nm

Nut (manual control lever) 13 mm X 1 14.0 ~ 20.0Nm

Nut (floor) 12 mm X 1 17.6 ~ 21.6Nm

Nut (dash panel) 12 mm X 2 17.6 ~ 21.6Nm

A/T bracket Bolt (left bracket) 17 mm X 3 88.2 ~ 107.8Nm

Bolt (right bracket) 17 mm X 4 88.2 ~ 107.8Nm

Bolt (upper bracket) 17 mm X 4 88.2 ~ 107.8Nm

TGS lever

TGS cable